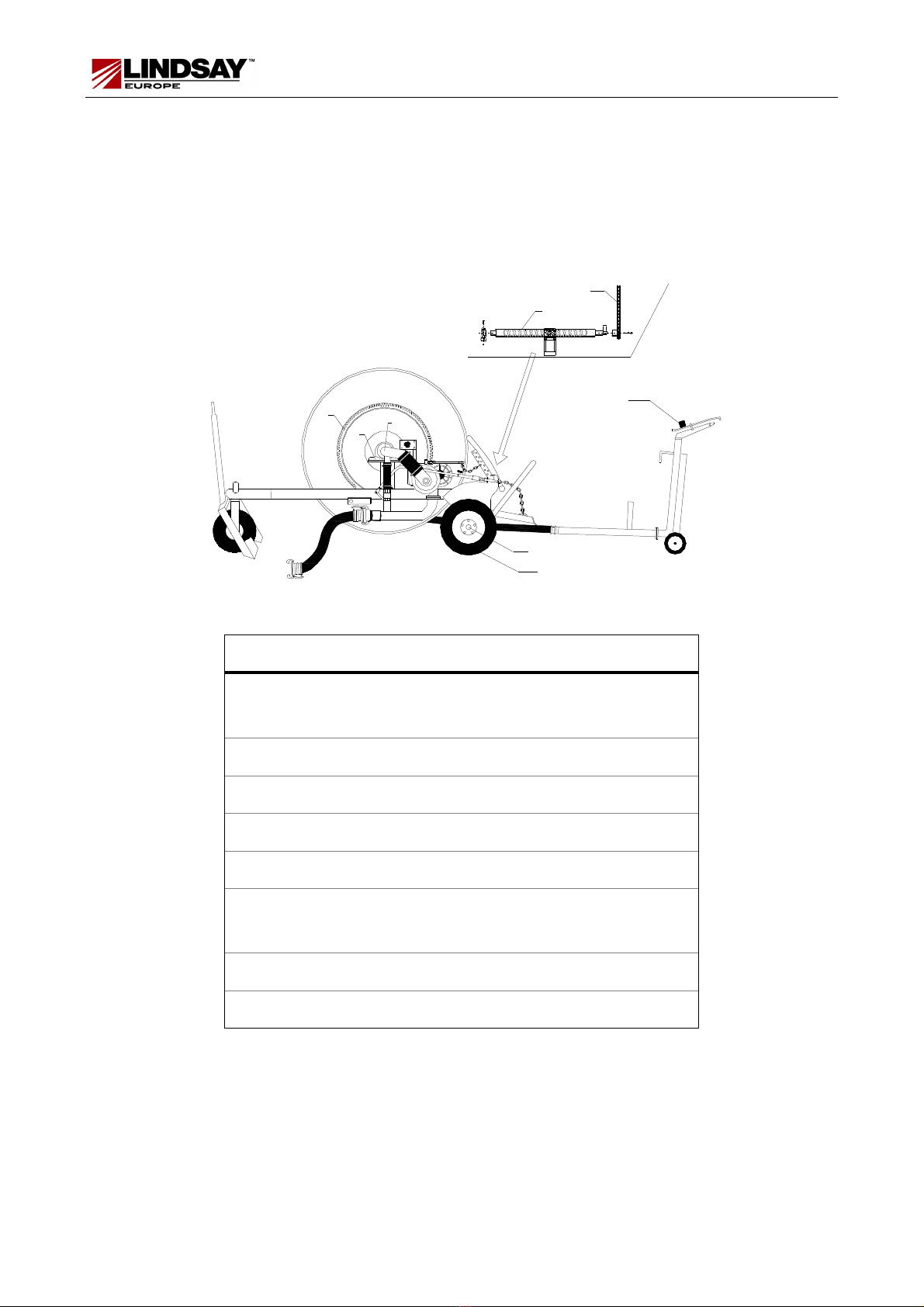

10- IRRIGATION DATA

Ø PE (mm)

(m)

(mm) Water application mm

40 125 3,5

10 15 20 30

endgun

nozzle

(mm)

Endgun

pressure

(bar)

Jet

lenght

(m)

Flow

rate

m3/h

Spacing

(m)

area

(ha)

Speed

m/h

Inlet

pressure

(bar)

Mano

pressure

(bar)

Speed

m/h

Inlet

pressure

(bar)

Mano

pressure

(bar)

Speed

m/h

Inlet

pressure

(bar)

Mano

pressure

(bar)

Speed

m/h

Inlet

pressure

(bar)

Mano

pressure

(bar)

9 2,0 17,5 4,2 28,0 0,35 15 3,3 2,8 10 3,2 2,8 8 3,2 2,8 5 3,1 2,8

9 3,0 19,5 5,2 31,2 0,39 17 4,6 4,1 11 4,6 4,1 8 4,5 4,1 6 4,5 4,1

9 4,0 21,0 6,0 33,6 0,42 18 5,9 5,4 12 5,9 5,4 9 5,8 5,4 6 5,8 5,4

10 2,0 18,0 5,3 28,8 0,36 18 3,7 3,2 12 3,6 3,2 9 3,6 3,2 6 3,5 3,2

10 3,0 20,5 6,4 32,8 0,41 20 5,1 4,6 13 5,0 4,6 10 5,0 4,6 7 5,0 4,6

10 4,0 22,0 7,4 35,2 0,44 21 6,6 6,1 14 6,5 6,1 11 6,5 6,1 7 6,5 6,1

12 2,0 19,0 7,6 30,4 0,38 25 4,7 4,2 17 4,6 4,2 13 4,6 4,2 8 4,6 4,2

12 3,0 21,0 9,3 33,6 0,42 28 6,6 6,1 18 6,6 6,1 14 6,5 6,1 9 6,5 6,1

12 4,0 23,5 10,7 37,6 0,47 28 8,5 8,0 19 8,4 8,0 14 8,4 8,0 9 8,4 8,0

- Hydraulics characteristics correspond to a SIME endgun type SENIOR. A different end gun will give different results.

- Pressure at the hose reel inlet are given for information. They correrspond to a operating conditions regularly encountered but can differ from the real

operating conditions. In particular, type of terrain , field slopes, equipment of turbine may impact hydraulic performances of the whole system.