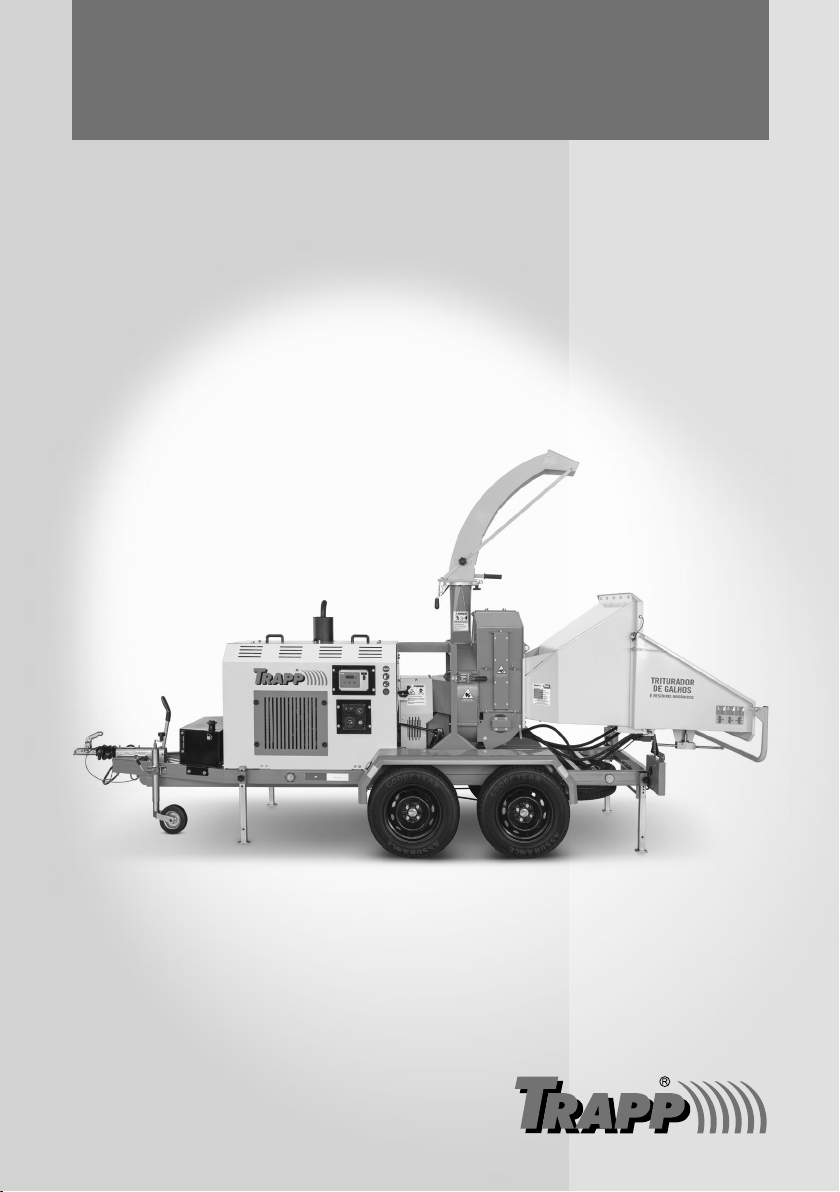

TRAPP TR 1500 User manual

TR 1500

TR 2000

Organic Residue

Shredder

Organic Residue

Shredder

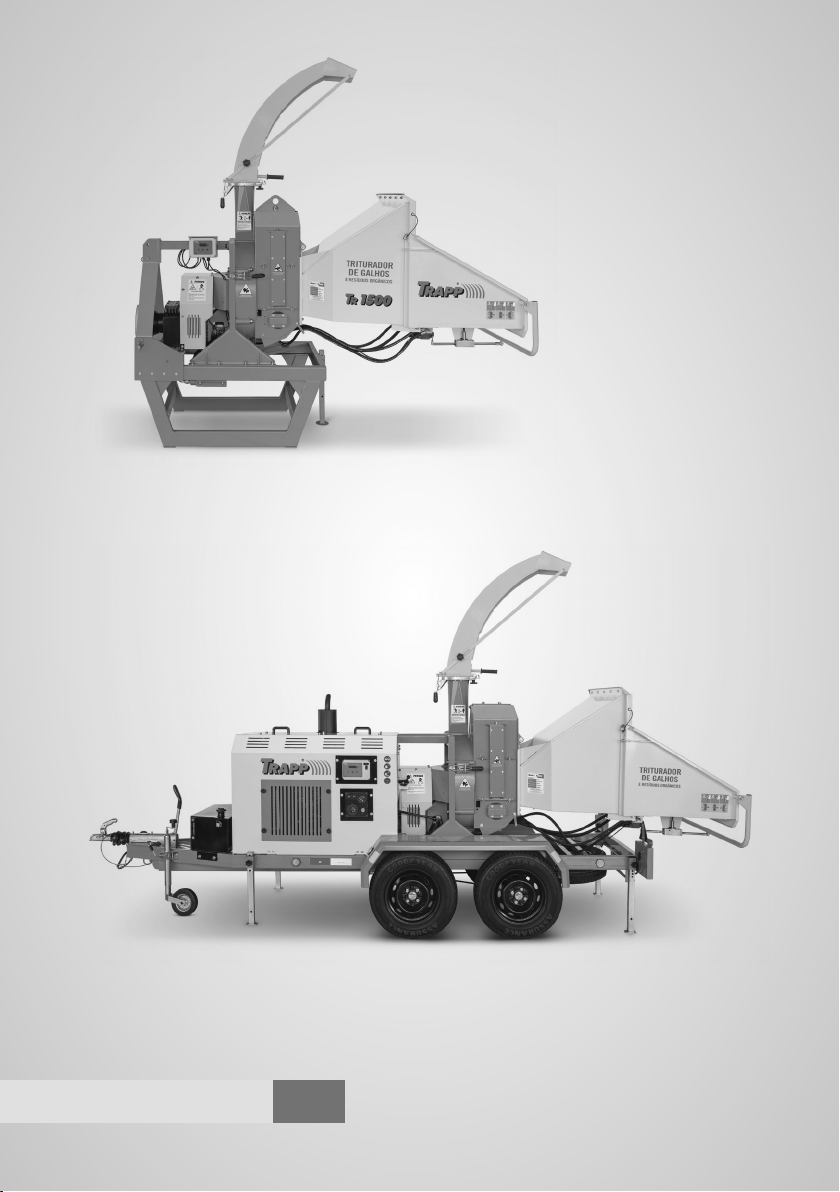

Models

TR 1500

TR 2000

Instructions Manual

TRP 1500

TRP 2000

TRP 1500

TRP 2000

3English

ENGLISH

3

www.trapp.com.br

Congratulations!

You have just acquired a quality product developed with the highest TRAPP

technology. This product will provide quickness and efciency on the jobs, with

savings and complete safety. For this, some precautions are necessary. The critical

safety measures contained in this Instructions Manual do not cover all possible

situations that may occur. The operator must understand that common sense,

attention, and precautions are not factors that can be incorporated into the product;

they must be supplied by the people that operate it and perform its due maintenance.

Important Recommendations

Caution!

Read all the instructions contained

in this manual before operating the

equipment, always observing the

safety indications and following the

instructions to prevent accidents and/

or injuries.

Read and keep these instructions.

1 - Work area

Do not operate the equipment near an

explosive atmosphere, nor wherever there are

flammable liquids, gases, and/or suspended

dust. The electrical installation of the equipment

produces sparks that may ignite flammable

liquids, gases, or suspended dust.

Keep children and spectators distant. When

the equipment is in use, all persons, especially

children, must remain at a safe distance from

the work area. The operator/user is

responsible for possible accidents that may

occur.

2 - Electrical safety

Do not expose the equipment to rain or

moisture. Install the equipment in a dry

location and protected from inclement

weather. Water inside the equipment may

damage the engine’s electrical circuits,

besides increasing the risk of electric shock

and cause the oxidation of the machine’s

structure.

3 - Personal safety

Caution!

Whenever you perform any cleaning

or maintenance operation, rst assure

that the equipment is turned off and the

blades are stationary, because the blades

continue in motion for some instants

after the equipment is shut down.

Most accidents occur while the

operator is using the machine or

during its maintenance, and are

caused by the lack of attention to the

basic safety precautions. Therefore,

it is necessary to be aware of the

potential risks of an action, paying

attention to your own actions and

their effects.

ENGLISH

4

www.trapp.com.br

Do not hold or lean yourself on the machine

during its transport; keep away at a safe

distance.

Keep alert. Remain aware of what is

happening and use common sense when you

are operating. Do not operate the equipment

when you are tired, distracted, or under the

influence of drugs, alcoholic beverages, or

medication. A moment of inattention may

result in serious injury risk.

Use safety gear such as gloves, goggles,

respiratory mask, and hearing protector,

according to the operation performed. Observe

the labels on the machine indicating the type for

safety gear required to use the shredder and

check, on page 6 of this manual, what each label

represents.

Dress appropriately. Do not wear loose clothing

or jewelry, because it may get caught on moving

parts of the equipment. If you have long hair,

keep it tied up during the job.

Prevent accidental operation.

Assure that the equipment is

disconnected from the power plug

of the tractor or, if started by a

diesel engine, turn off the key at the

starting dashboard and remove the

battery cable before performing any

maintenance on the shredder.

At no time insert any part of your

body inside the machine’s cutting

system to avoid personal damages.

Remove any object before turning on the

equipment. A tool or any other object stuck

on the moving parts of the equipment may

result in injuries.

4 - Use and precautions

Caution!

Check often if all the bolts are well

attached, especially those on the

knives and counter-knife. Always keep

the measure of the knife and counter-

knife regulated to ensure proper

performance of the shredder.

Support the machine on the ground and

lower the stabilization shoes of the machine

before turning on the shredder.

To perform the job safely, position the

machine at a site that is flat and suitable, free

from obstacles that may cause the operator to

trip upon introducing the material in the

shredder.

Do not force the equipment. Use it correctly

and for the applications described in this

manual, thus obtaining better performance

and safety in your job. Follow the indications

of use and applications on page 6 of this

manual to achieve better performance of the

shredder.

Do not use the equipment if

the “NO STRESS” system is not

operating. The equipment cannot

be controlled if this is damaged.

In this case, it must be repaired

immediately.

ENGLISH

5

www.trapp.com.br

Disconnect the battery cable,

remove the fuses, or disconnect the

power plug before performing any

adjustments or changing cutting

blades and accessories. Before

accessing the cutting system, wait

for the complete stop of the disk to

open the machine body and have

access to the shredder’s cutting

system. Such preventive measures

reduce the risk of accidental

operation of the equipment.

Carefully observe the way of introducing

the materials into the shredder; irregular

materials may hit the operator when pulled

by the feeder roll. Insert the material in the

input funnel and, when the feeding roll pulls

it, step away from the shredder.

Do not allow unacquainted persons to use

the equipment. The equipment may become

dangerous at the hands of users unacquainted

with its operation.

Check the site where you intend to release

the shredded material and regulate the

material outlet nozzle before turning on the

shredder. It is recommended that the nozzle

work in parallel to the disk so to avoid

clogging on the exit of material.

Do not use the shredder in sites that are moist

and poorly illuminated.

As soon as the disk reaches the ideal rotation,

start the feeding rolls through the drive bar

located in the feeding funnel and insert the

material you wish to shred.

Before introducing the material you wish to

shred, check the information in this manual

to see the indicated work rotation.

Be acquainted with all the triggering

commands of the shredder to know how to

act in a possible emergency stop.

Conserve your equipment. Check often if the

moving parts are fixed, if any component is

damaged or any other condition that may

affect its proper functioning. If there is a

problem, make the repair before using the

equipment. Many accidents are caused by a

lack of adequate maintenance.

Keep the cutting disk clean and with the

cutting blades clean and sharp, with the

knife and counter-knife measurement

between 3 and 4 mm.

Keep the feeding rolls clean after using the

shredder and remove the leftover material

from the protection of the smooth roll. The

accumulation of material on the feeding

rolls hampers the operation of the hydraulic

engines that trigger the feeding rolls. Keep

the machine on for a few minutes after

finishing the job; this helps in the cleaning of

the shredder.

The cutting blade keeps moving after the

equipment is shut off. Therefore, be aware

of this when performing any maintenance

or cleaning.

Never use a pressurized water jet to clean the

machine, so to not damage the electrical

components. Also do not use chemical

cleaning products, avoiding the corrosion of

the material; only use neutral detergent and

moist cloth or compressed air.

Use the equipment and accessories

according to the instructions contained in

this manual, taking into account the work

conditions and the service to be performed.

The use of the equipment for operations not

included in this manual may result in

hazardous situations.

Turn the shredder off immediately if the

nozzle is clogged, if the cutting disk is locked,

or if you notice excessive vibration of the

machine. With the machine turned off and

the disk stopped, assess the situation and

unblock the outlet nozzle or the disk and

resume the work. If the problem persists,

contact a TRAPP Assistant.

ENGLISH

6

www.trapp.com.br

Do not shred material that is not indicated for

this shredder; this results in loss of equipment

warranty. Besides these products, for any

other type of material that is not specified in

the manual, the factory must be consulted

before shredding it.

In TR 2000, watch out for the output of the

exhaust during the machine’s operation; it

produces wind and toxic smoke, and may

also cause burns due to the working

temperature.

Do not transit around the machine while it is

operating, especially in the direction in which

the outlet nozzle is releasing the material.

The material released by the nozzle may

cause serious physical damages to the

operator.

Repairs to the equipment must only be

performed by qualied professionals

and with original TRAPP parts. Always

use the services of the Authorized

TRAPP Technical Assistants. TRAPP

does not take responsibility for possible

accidents or damages that occurred due

to the use of non-original parts.

Note: Some materials contain resin, in which case the

cleaning of the machine must be performed more

often during the job to avoid the clogging of the

shredder. The recommendation is not to shred this

material when it is green since this reduces the

amount of resin.

Uses and Applications

TRAPP shredders were developed with an

efficient cutting system. The electronically-

monitored cutting disk model, cutting blades,

feeding rolls, and feeding control allow a

wide variety of materials to be shredded, with

this being a differential among other shredder

models. The list of materials that may be

shredded is presented next:

Wood trunks1) from tree pruning with

diameters up to 20 cm;

Branches with leaves and bushes;

Leaves2) and trunks of palm trees and coconut

trees;

Bamboo2);

Food-derived organic material2);

Wooden pallets and construction wood

without nails or cement residues.

Notes: 1) Wood that is very dry and of hard quality

must be fed with greater caution not to

lock or damage the cutting system.

2) These materials require some precautions

upon feeding to avoid clogging the outlet

nozzle and accumulating material in the

cutting system. Moist material may cause

clogging, while very dry material may

accumulate in the cutting system, which

needs to be cleaned more often.

Materials such as glass, metal, plastic, paper,

cardboard, styrofoam, and cement or clay

artifacts cannot be shredded. For any unspecified

materials of vegetable origin, TRAPP must be

contacted to assess the application before

shredding; damages caused by the use of non-

recommended materials lead to loss of

warranty.

Through the various types of materials that may

be shredded in TRAPP shredders, it is possible

to achieve an excellent composting result for

the enrichment of soil nutrients, cover material

for soil, use in seedbeds of gardens and

vegetable gardens, or as fuel for boilers.

Important: Certify that the result

obtained from the shredded material is

appropriate for use in composting, soil

coverage, or boiler fuel.

ENGLISH

7

www.trapp.com.br

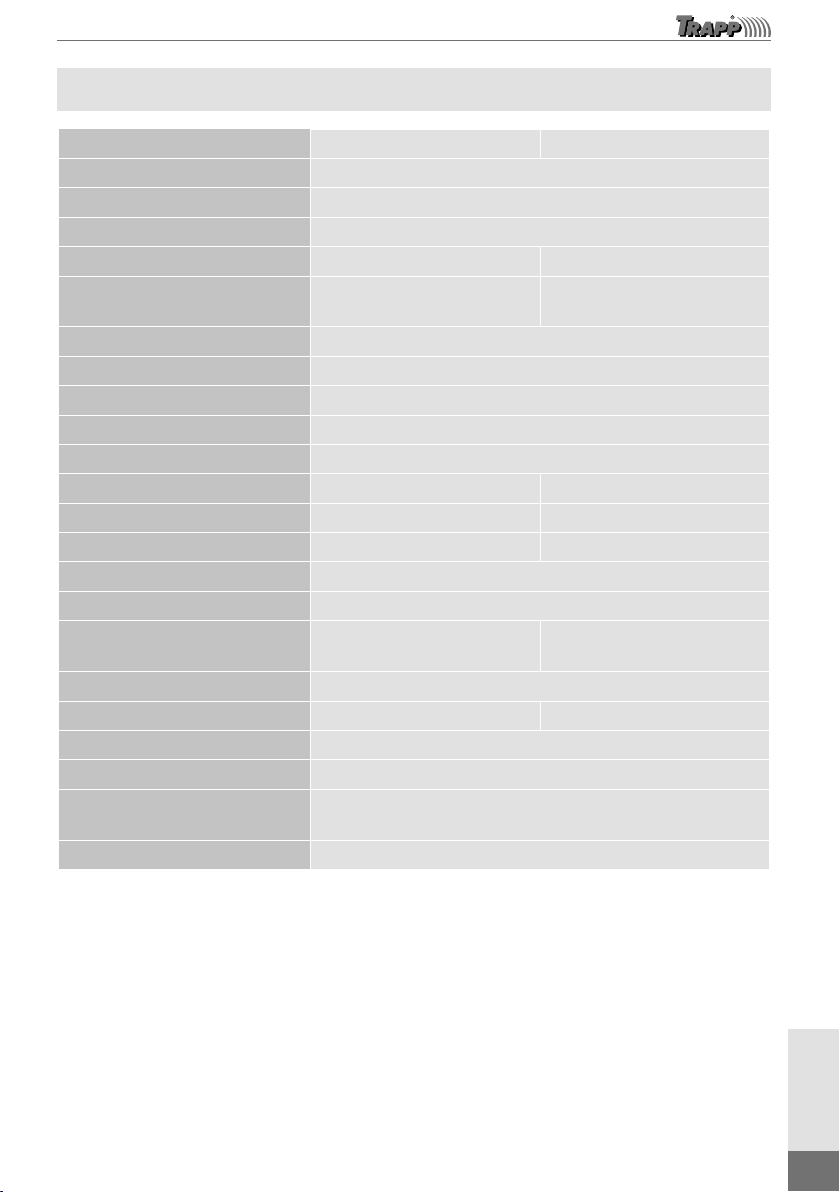

Technical Characteristics

Model TR 1500 TR 2000

Upper hydraulic engine 622 Nm

Lower hydraulic engine 311 Nm

Disk rotation Rotation 1,600-1,150 (rpm) Maximum/Minimum

Minimum power 65 HP (tractor) 54 cv/40 kW (engine)

Minimum power for power

take-off 50 HP (with 540 rpm) Not applicable

Hydraulic system pressure 160 bar of work and a maximum of 170 bar

No Stress system Powered by 12 V - with a 10 A fuse

Activation Manual/mechanical with 3 stages

Disk diameter Ø680 mm

Number of knives 3 pieces

Total length 2,800 mm 4,850 mm

Total width 1,350 mm 1,550 mm

Total height with the nozzle 2,900 mm 2,900 mm

Cutting capacity Ø180 mm hard and dry wood, Ø200 mm green wood

Productivity 2 to 18 m3

Transmission type B-belt B39 (box/disk)

A36 (disk/pump)

V-belt BSX 35 (box/disk)

A36 (disk/pump)

Counter-knife adjustment 4 mm ±1 mm

Shredder weight 940 kg 1,450 kg

Oil in the hydraulic tank 18 liters (ISO VG68)

Oil in the gearbox 4 liters (W140)

Oil in the diesel engine

crankcase 5.5 liters with oil lter SAE 15W40

Noise 89 db(A)

ENGLISH

8

www.trapp.com.br

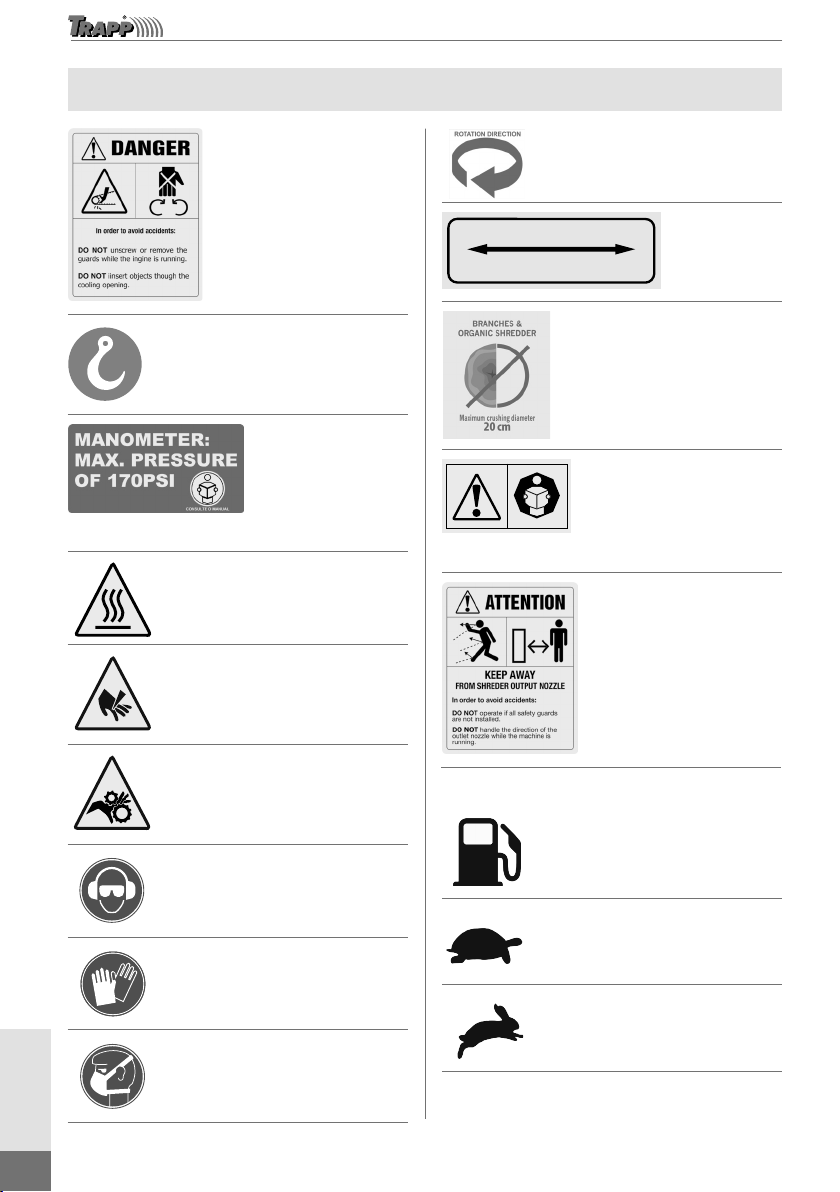

Safety Stickers

Danger of hand injuries:

Do not open or remove

the safety protections

while the machine is

operating.

Lifting point of the machine.

Manometer: maximum pressure of 170 PSI.

Superfície quente

Hot surface.

Lâminas de corte,

não introduza as mãos

Cutting blades, do not insert

hands.

Cuidado rolos de alimentação

com facas, não introduza

nenhuma parte do corpo.

Caution: feeding rolls with

knives, do not insert any body

part.

Utilizar óculos de proteção

e protetor auricular adequados

Use proper protection goggles

and hearing protector.

Utilizar luvas de

proteção adequadas

Use proper protection gloves.

Utilizar máscara de

proteção adequadas

Use proper protection mask.

Rotation direction.

Desembrear

Embreagem / Embrague / Clutch

Embrear

Embragar

Engage

Desembragar

Disengage

Clutch.

Maximum shreddable

diameter.

Caution:

Carefully read all the

instructions and safety

norms before using the

machine.

Keep away:

To avoid severe or fatal

injuries, only trigger the

shredder if there are no

people or animals close

to the machine.

Only for TR 2000

Combustível

Fuel.

Lento

Slow.

Fast.

ENGLISH

9

www.trapp.com.br

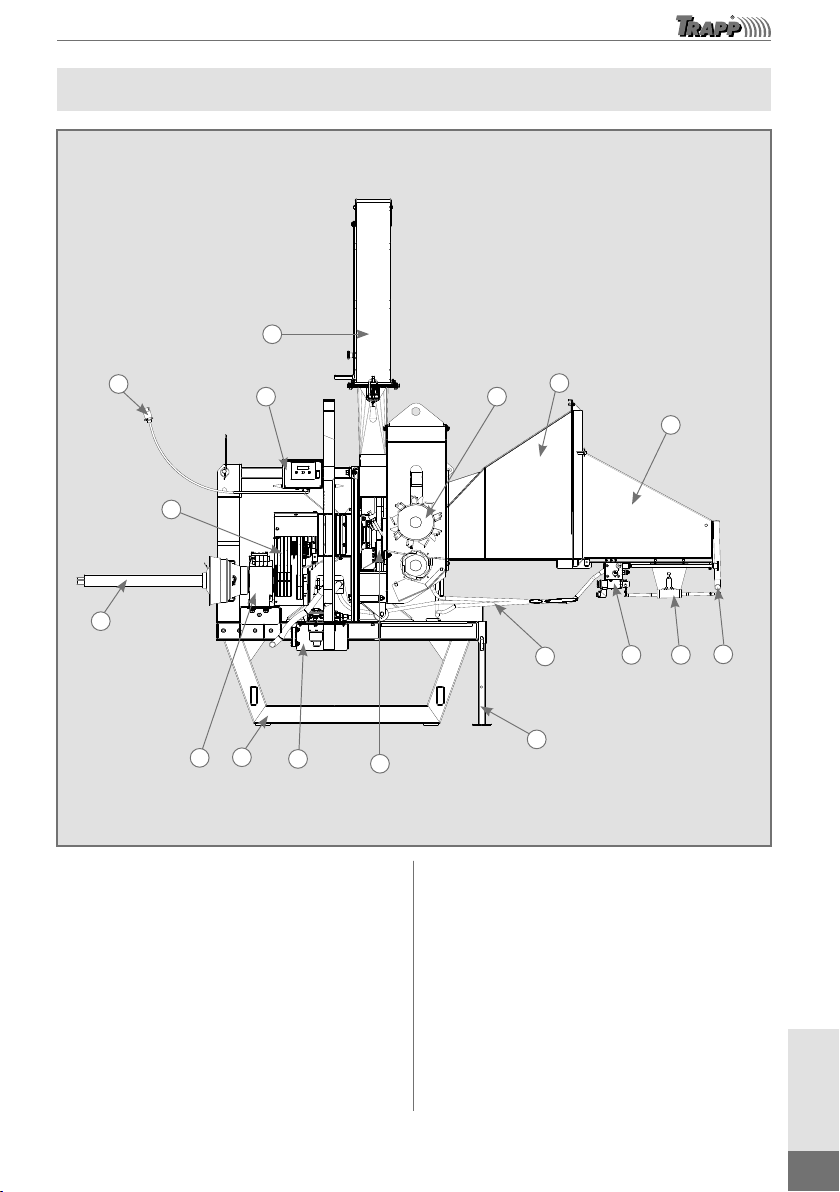

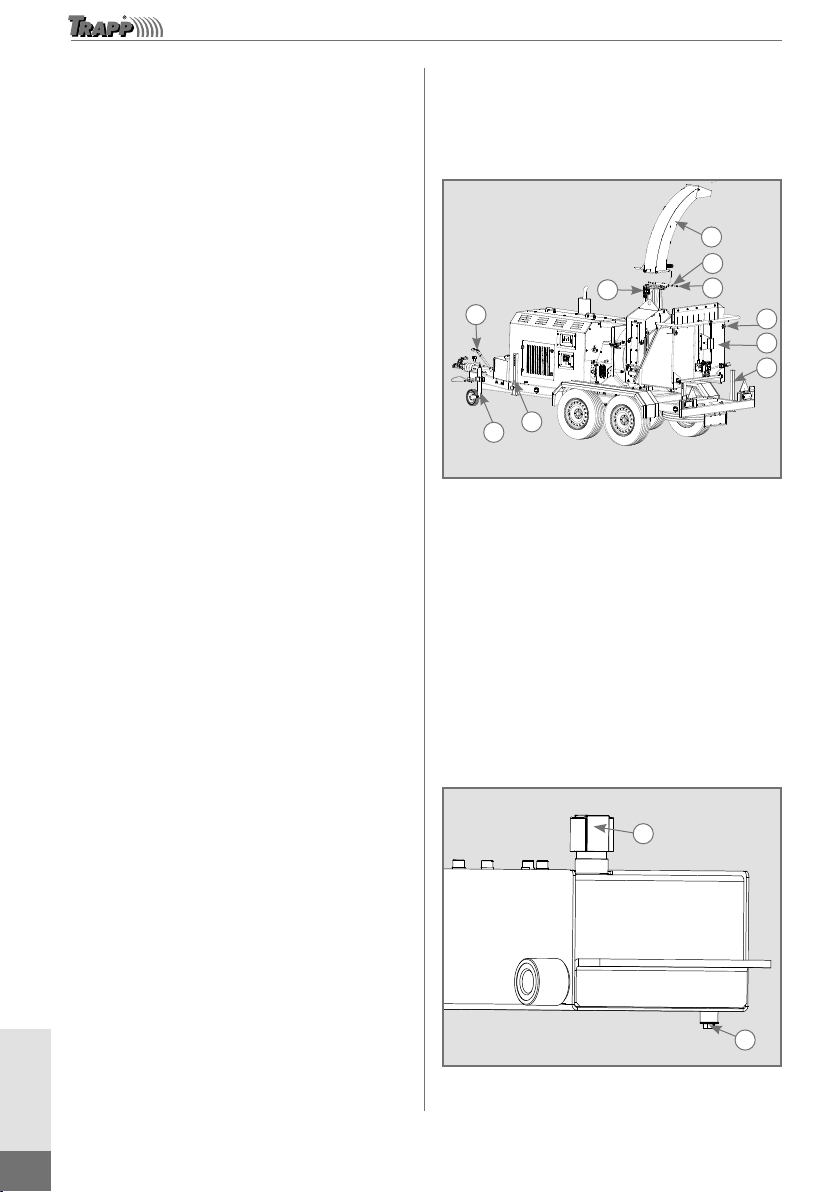

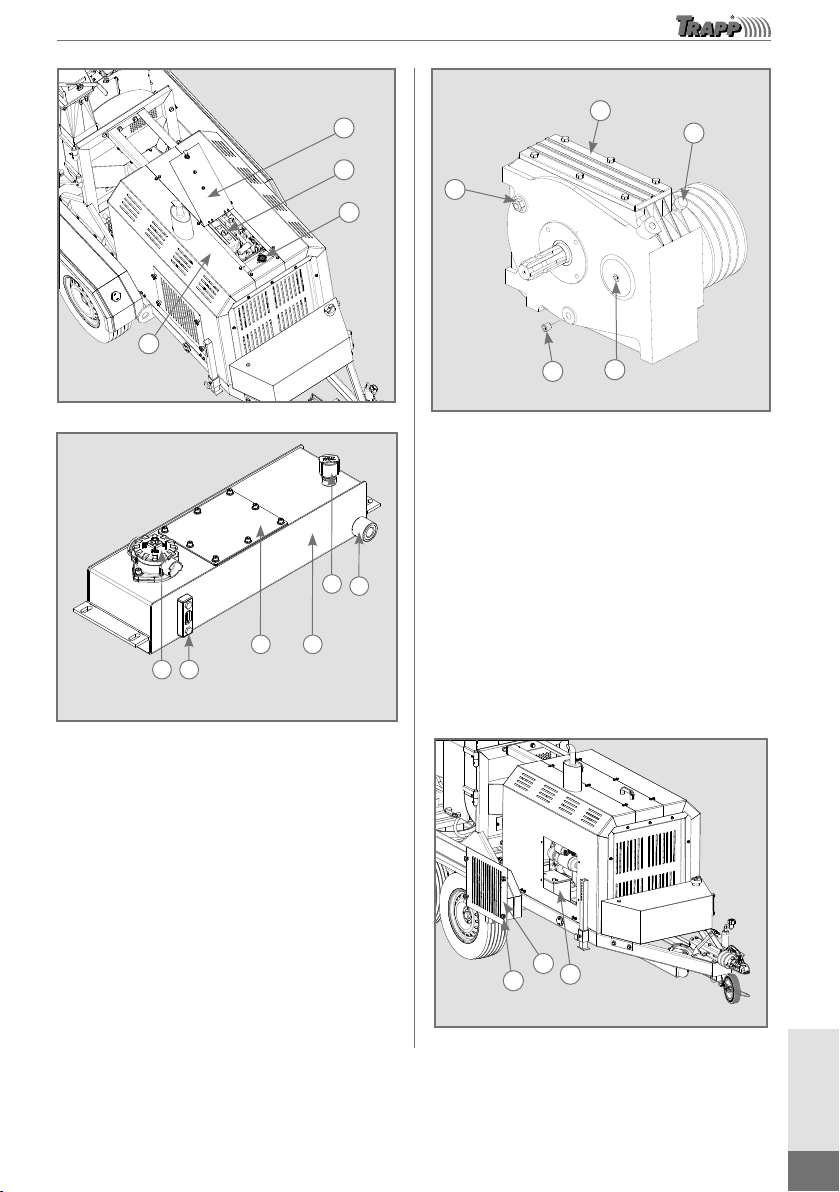

Main Components - TR 1500

11

15

16

7

5

91

10

17

14 13 12 4

86

2

3

Image merely illustrative

1. Machine base.

2. Feeding funnel lid.

3. Feeding funnel.

4. Drive bar of the feeding rolls.

5. Feeding rolls.

6. Cutting disk.

7. Set of pulleys and belts for operation.

8. Hydraulic tank.

9. Gearbox.

10. Cardan shaft.

11. Outlet nozzle.

12. Drive block of the feeding rolls.

13. Hydraulic block.

14. Hydraulic system hoses.

15. Control panel of the “NO STRESS” system.

16. Electrical outlet: 12 V.

17. Stabilizing shoe.

ENGLISH

10

www.trapp.com.br

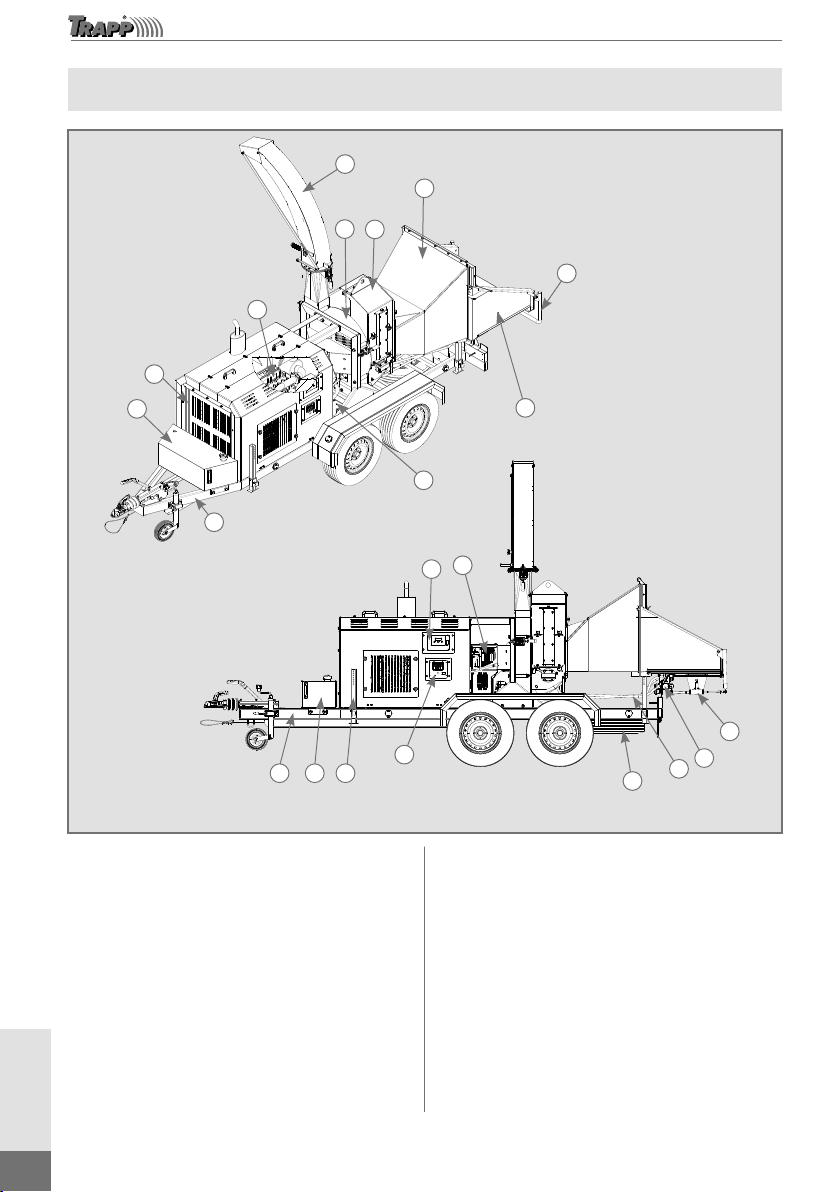

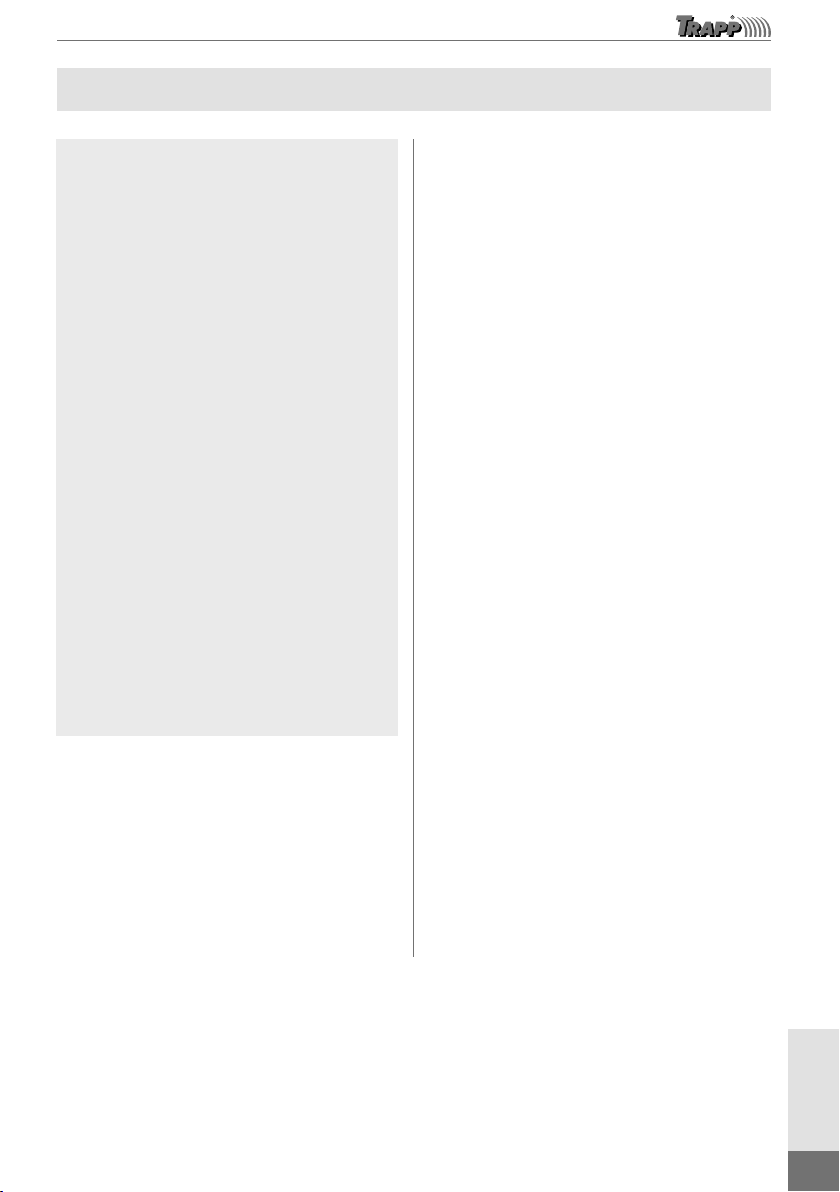

Main Components – TR 2000

6

3

2

10

1

9

8

13

4

5

7

11

1 9 17

16 15

14

12

Image merely illustrative

18

19

1. Tow.

2. Feeding funnel lid.

3. Feeding funnel.

4. Machine body where the feeding rolls are

located.

5. Machine body where the cutting disk is

located.

6. Outlet nozzle.

7. Set of pulleys and belts.

8. 54 hp engine

9. Diesel fuel tank.

10. Hydraulic tank. Control panel of the “NO

STRESS” system.

11. On/off panel and indicators of the diesel

engine.

12. Drive bar of the feeding rolls.

13. Drive block of the feeding rolls.

14. Hydraulic block.

15. Hydraulic system hoses.

16. Spare tire.

17. Stabilizing shoe.

18. Battery (located inside the fairing).

ENGLISH

11

www.trapp.com.br

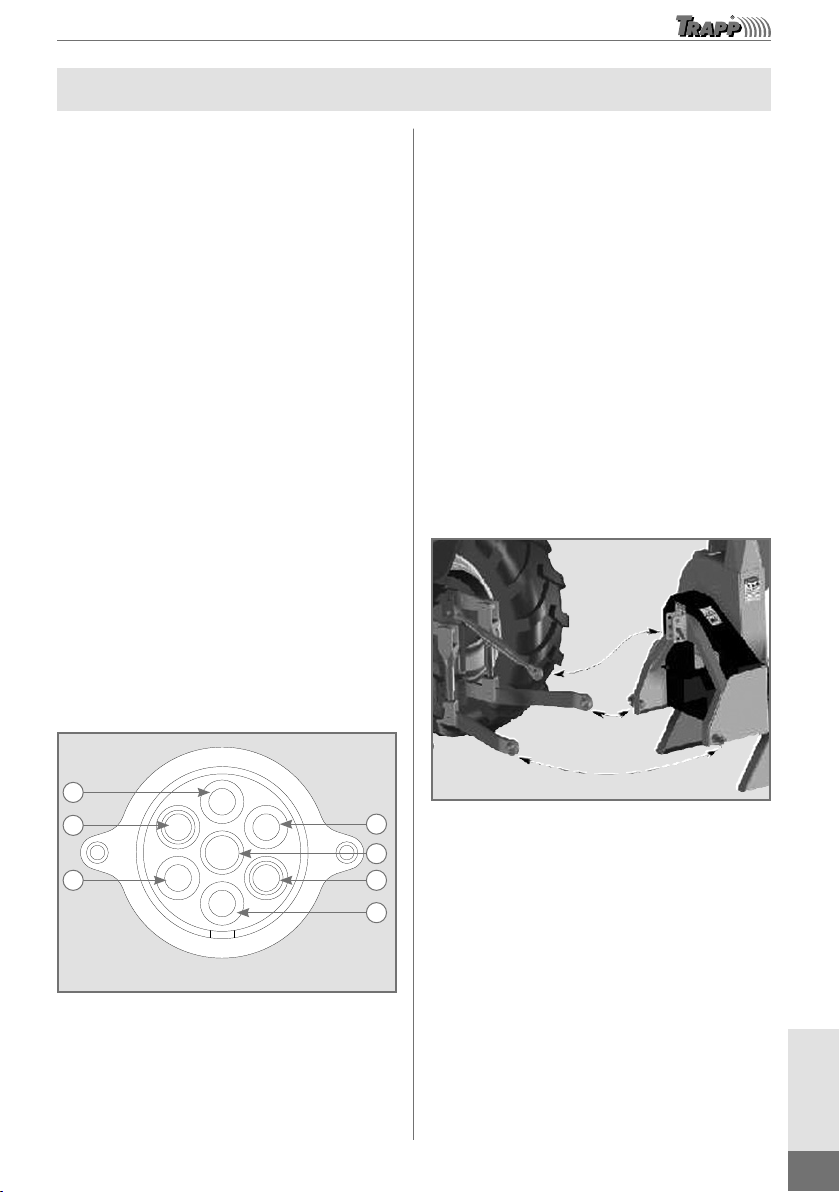

Initial Assembly and Operation Instructions

TR 1500

1. Positive.

2. Negative.

TR 200D

1. Tail light.

2. Break.

3. Left blinker.

4. Reverse light.

5. Ground.

6. Right blinker.

7. Auxiliary.

After concluding the connection of the

electrical part, check if all the functions are

correct and, then, complete the remaining

procedures for using the shredder.

1

2

3

4

13

Image merely illustrative

Figure 2

Before connecting the equipment to the

tractor, position both on flat terrain, keeping

observers and children at a distance.

Slowly approximate the shredder to the

hydraulic arms; first, connect the lower arms,

then hook it up to the upper point. The

shredder is equipped with fixing pins for

Category-II tractors.

Certify the fixation of the pins with the

corresponding safety lock; then, suspend the

shredder and lock it, lifting the stabilizing

shoe of the base of the shredder, indicated on

page 9 of this manual.

Carefully read the instructions and seek to

familiarize yourself with the controls and

proper use of the equipment.

Remember that the operator or user is

responsible for any accident or damage

involving third parties or their properties.

After removing the shredder from the

packaging, perform the assembly of the

unassembled parts to give start to the use of

the equipment.

TR 1500

For using the TR 1500, check the 12 V

electrical outlet connection with the tractor

battery, for the correct connection scheme, as

per Figure 1.

Check the oil in the gearbox and that in the

hydraulic tank. Consult the table on page 7 of

this manual. The TR 1500 shredder was

designed to be attached to a tractor equipped

with a 3-point hydraulic arm with universal

coupling, as shown in Figure 2.

Note: The warranty does not cover the burning of

electronic components, lamps, or fuses due to

incorrect installation. In doubt, contact a

professional qualified for the job.

1

2

3

4

7

6

5

Image merely illustrative

Figure 1

Note: This indication is the connection of the outlet of

the tractor or automobile.

ENGLISH

12

www.trapp.com.br

Position and lock the hydraulic arms of the

tractor with the anti-vibration lock current or

tensioners, after hitching the shredder at the

three points of the tractor. The tractor needs

to have the fixing locks to transport the

machine safely; the warranty does not cover

machine falling due to incorrect fixation.

After attaching the shredder to the tractor,

slowly lift the lifting arms with the tractor’s

hydraulic system and observe if the weight of

the machine will suspend the front wheels of

the tractor; if necessary, mount the ballasts on

the front of the tractor to balance the weight.

Cardan shaft: the Cardan shaft is a

fundamental component in the transmission

of force from the tractor to the shredder; it

must meet the mounting specifications so not

to damage the shredder during the operation

and cause excessive vibration. For the TR

1500, a 6-ridge Cardan shaft is recommended.

Assembly of the Cardan Shaft

Observe the indication of load capacity upon

suspending the TR 1500 on the hydraulic

system of the tractor; check the weight of the

machine on page 7 and consult the tractor

manufacturer.

To obtain a proper assembly between the

tractor’s power take-off and the machine, the

Cardan shaft must have a superposition of at

least 1/3 of its length to meet the safety norms.

The recommendation for the working

inclination of the Cardan shaft is of at least

15°; adjust the inclination angle by regulating

the tractor’s hydraulic system. If the tractor

model allows and the angle is compatible,

keep the TR 1500 supported on the ground

during the job to achieve better access to the

feeding funnel. If the height of the machine

gets uncomfortable to feed the funnel due to

the inclination, position the tractor in terrain

with elevations to facilitate the access to the

feeding funnel and maintain the equipment

supported on the ground.

Note: When suspending the TR 1500

with the tractor’s hydraulic system,

check the maximum inclination allowed

of the Cardan shaft assembled on the

machine and the power take-off of the

tractor.

Exceeding the inclination may damage

the equipment and produce excessive

vibration on the operating shredder.

To perform maneuvers with TR 1500

assembled onto the tractor, disconnect

the Cardan shaft from the machine.

Upon positioning the machine on the

ideal working site, mount the Cardan

shaft again and check its inclination,

adjusting if necessary.

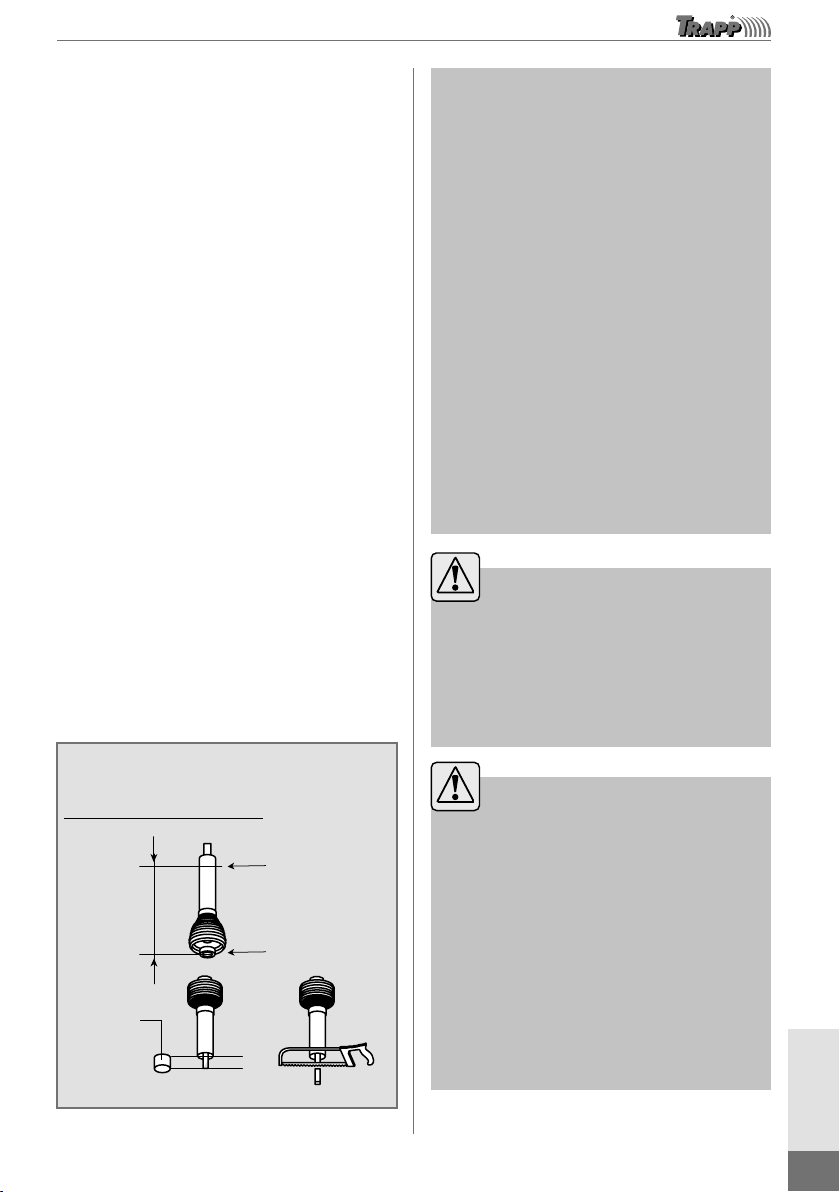

To assemble the Cardan shaft, remove it from the

package and separate the male from the female.

To obtain the measure to cut the Cardan shaft,

mount the machine at the 3 points of the tractor,

align the axes of the power take-off of the tractor

and of the machine, and check the distance bet-

ween the ends of the axes.

The measure found between the axes of the

power take-off must be divided by 1.3. The

value of this division will indicate

measurement A; mark the Cardan shaft with

measurement A and cut the surplus, as shown

in Figure 3. At the marked position, cut the

excess of the male and female Cardan with a

saw bow with a 24-tooth steel-cutting blade

or with a cutting disk, using protective gear.

After concluding the complete cut, mark the

plastic protection of the male and female

Cardan and remove 3 centimeters of the

plastic protection only, cutting with a saw,

leaving the Cardan shaft with the tip exposed,

as indicated in Figure 3.

After performing the cutting procedure,

remove the burr from the cut pieces, discard

the cut material, and mount the Cardan shaft

on the machine. If necessary, release the

machine that is attached to the tractor so you

will have room to assemble the Cardan shaft.

Fit the male and female parts of the Cardan

shaft and mount the female side on the axis of

the power take-off of the TR 1500, then fit the

male Cardan shaft on the axis of the power

ENGLISH

13

www.trapp.com.br

take-off of the tractor until you hear a click,

showing that it is in the correct fitting position

on both sides.

After the assembly and adjustment of the

protection chains, move the inclination of the

tractor’s hydraulic system and check if there is

slack between the male and female Cardan,

positioning the machine at the recommended

tilt of at most 15°.

Fix the retention chains of the protection. The

ideal functioning condition is obtained with the

chain positioned radially relative to the

transmission. Regulate the length of the chains to

allow the articulation of the transmission in any

condition of work, transport, and maneuver.

Certify that the chains do not wrap around the

transmission due to excessive size. Before

starting the job, check the rotation of the power

take-off; it must not exceed 540 rpm. Check also

the inclination and if the machine is supported

on the ground to avoid damages to the shredder

and cause the warranty loss.

Observe, as the machine moves, if the male

and female Cardan shafts get close enough to

the point of touching; if this occurs, turn off the

power take-off immediately. Dismantle the

male and female Cardan shafts and perform the

cutting again so to leave slack of at least 1 to 2

centimeters between the ends of the Cardan

shaft to initiate the functioning of the shredder

following the operating instructions.

Image merely illustrative

Cut out

3 cm of

the plastic

protection

Measure A

The measure of the cut.

Dividing the measurement found between axes by 1.3 will

supply the measure to cut the Cardan shaft.

Measure from the

extremity of the

cardan shaft

Cutting line

The measure between Cardan shafts

1.3 = Measure A

Figure 3

Note: The cut pieces of the massive

and tubular parts of the Cardan must

have the same length.

Do not stop the rotation of the power

take-off of the tractor suddenly unless

for safety purposes. The abrupt

stop may damage the transmission

system of the equipment.

Do not use the chains to transport

or support the Cardan transmission.

It is not recommended to work

with the male and female Cardan

shafts without slack since this may

damage the power take-off axes of

the tractor and shredder. To perform

maneuvers, remove one of the parts

of the cardan shaft.

Caution!

These operations must only be

performed on appropriate terrain

and only after having stopped the

tractor, turned off the power take-

off, and pulled the parking brake.

Caution!

If necessary, lift the machine from

the ground. However, for the safety

of all, put it over support, avoiding

any accident that may be caused by

a possible sudden fall.

Before removing the shredder from

the 3-point hitch of the tractor,

position the stabilizer shoe of the

base as indicated on page 9 of this

manual.

ENGLISH

14

www.trapp.com.br

TR 2000

The TR 2000 shredder was designed to be

triggered by a diesel engine and with a utility

trailer homologated by the Department of

Transportation (Detran) to transport the

equipment in urban roads, according to each

city’s legislation.

Before hooking up the utility trailer with the

TR 2000 to any automobile, check the

indication of load capacity of the automobile’s

support and compare if it is compatible with

the weight of the machine. Before connecting

the trailer to an automobile, position both on

flat terrain, keeping observers and children

away. Before turning on the 12 V outlet of the

carriage to an automobile, check the electrical

outlet connection and the wiring scheme;

consult Figure 1 on page 11 for the correct

wiring scheme. Damages caused by incorrect

connections are not covered by warranty.

After hooking up the utility trailer to the

automobile and securing the safety cables

and chains, suspend the support wheel (1) by

turning the upper gauntlet; to lift the entire

set, release the side gauntlet and lift at most

for transport, then secure it again. Then,

suspend the stabilizer shoes (2) and retighten

its screws; release the stationary brake (3) as

indicated in Figure 4 and test the brake light

and blinkers.

Before transporting the equipment, close the

material input funnel lid (4) using the lock (5)

to secure it, and remove the material outlet

nozzle (6) by loosening the screws (7),

washers (8), and the lock (9) as indicated in

Figure 4; check if the protections and

accessories of the TR 2000 are well fixed.

After transporting the TR 2000 at the worksite,

place it on a flat position and, if you wish to

work with the utility trailer disconnected

from the automobile, adjust the support

wheel and the stabilizer shoes leaving the

machine aligned, then trigger the stationary

brake and disengage the trailer from the

automobile.

Assemble the material outlet nozzle and

direct it towards the desired position; check

if, with the transport of the machine, all its

parts are well fixed before operating the

shredder.

Image merely illustrative

2

1

3

2

4

5

7

9

8

6

Figure 4

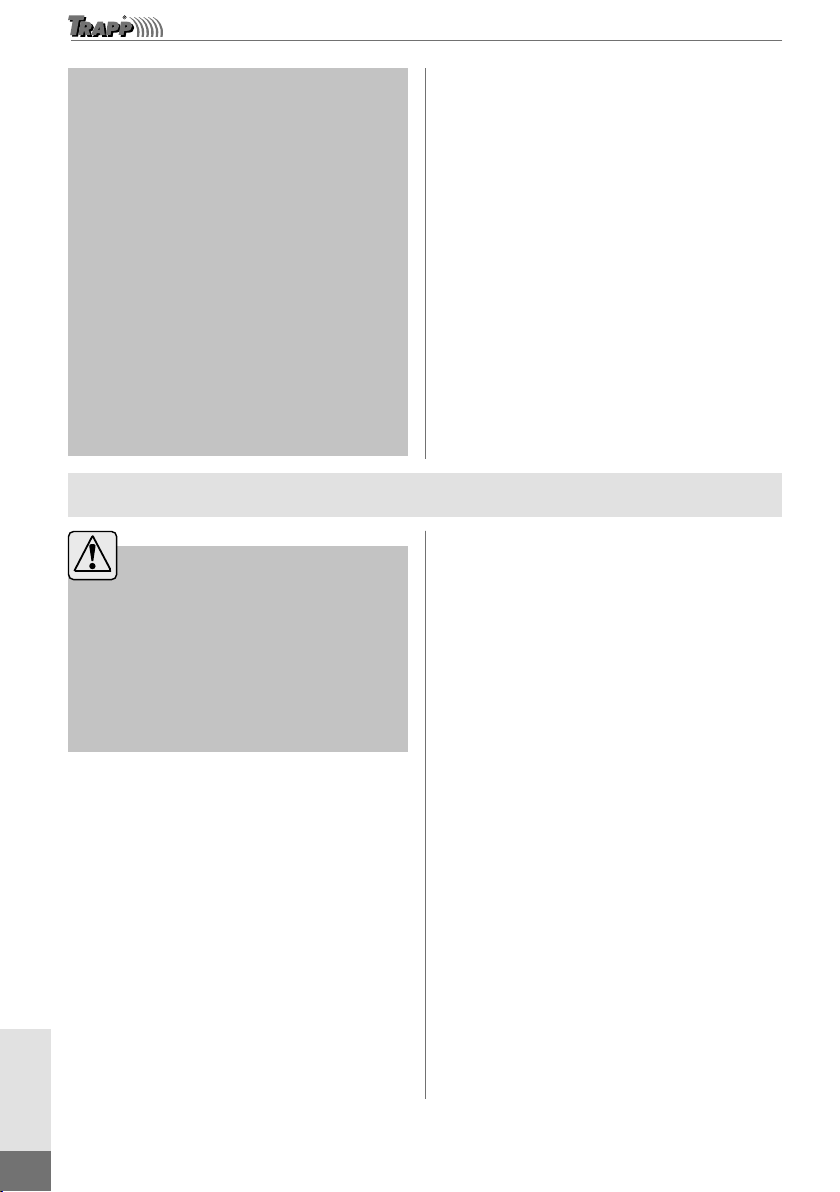

Hydraulic Reservoir Oil Change

To change the hydraulic reservoir oil, remove

the oil input lid (1), position a container with

capacity to support the amount of oil in the

reservoir below the drain plug with the drain

screw (2), remove the drain screw (2) located on

the lower part of the tank and wait for all the oil

to drain. After all the oil has been drained, fix the

drain screw again (2) and complete with 18

liters of VG68 oil; check the level and then

close the oil input lid (1).

Image merely illustrative 2

1

ENGLISH

15

www.trapp.com.br

Operation Instructions

Operator requisites:

Every operator that uses the equipment

must be competent and necessarily

meet the following characteristics:

O Physical: Have good eyesight,

coordination, and capacity to perform

all the necessary functions for using

the machine.

O Mental: Have the capacity of

understanding and applying the safety

norms and precautions established

in this instruction manual. The user

must be alert for their own safety and

that of other persons, as well as to

avoid damage to the equipment.

O Training: The user must have read,

studied, and understood this manual,

graphics, and schemes. They must

be qualied and trained for use or

maintenance of the equipment,

signing the back of the manual after

becoming acquainted with all the

instructions of operation and safety of

the machine.

Checklist

Before putting the shredder into operation,

one must check:

O The use of adequate apparel and footwear,

as well as safety gear such as protective

goggles, respiratory mask, hearing

protector, and gloves.

O If there is nothing locking the cutting disk.

O If there are no tools or objects inside or on

top of the equipment, especially inside the

feeding funnel.

O If the rotation direction is correct.

O If there are no people or objects near the

pulleys and belts or around the machine.

Spectators must be at a radius of 30 m

away from the machine.

O If the Cardan shaft is duly fitted both on

the shredder as the tractor’s power take-off

(TR 1500).

O If the hydraulic hoses are all duly fixed

and with no leakages.

O If the outlet nozzle is duly fixed and

directed towards a safe location.

O If the hydraulic tank and gearbox are duly

filled up with the indicated amount of oil

(TR 1500).

O If the hydraulic tank, fuel tank, radiator,

and diesel engine crankcase are filled up

with the amounts of fluid indicated in the

manual (TR 2000).

O Only shred woods and plants in the

dimensions of the machine’s capacity.

O Certify that there is enough fuel in the

tractor and in the fuel tank of TR 2000 to

avoid a forced stop. Only fuel TR 2000

with standard Diesel.

O Only use the shredder in safe conditions

and ventilated and well-lit places.

ENGLISH

16

www.trapp.com.br

Note: After checking the items above

and with the equipment being duly

prepared for the job, start the engine

(connecting the tractor to TR 1500 or

turning on the diesel engine for TR

2000). Wait until the maximum rotation

is reached, then wait approximately 5

minutes for the hydraulic oil to reach

the working temperature. Never start

or leave running a diesel or gasoline

combustion engine in closed or

unventilated environments. The gas

expelled by the exhaust contains

carbon monoxide, an odorless and

lethal gas.

O Avoid exposing the shredder to a location

with much sun intensity to not heat the

machine in some parts which already

reach high temperatures. To protect your

hands, use gloves, and protect other body

parts to prevent burns.

O Avoid inadequate work postures or effort

during the use of the shredder, following

the use instructions of the shredder.

8. .

Shredder Utilization

Caution!

Read all the instructions contained

in this manual before operating the

equipment, always observing the

safety indications and following the

instructions to prevent accidents and/

or injuries.

Check if all the fluids of the shredder, as per

the model table on page 7, have been

supplied and are in accordance with the

following specifications:

TR 1500

O The oil in the transmission box;

O The oil in the hydraulic tank.

TR 2000

O The oil in the hydraulic tank;

O The oil in the engine crankcase;

O The water in the engine’s radiator;

O The diesel in the fuel tank.

For the instructions for filling the diesel

engine fluids, open the upper protection (1)

of the cowl (2) that gives access to the radiator

lid (3) and the crankcase oil lid (4); add water

to the radiator, if necessary, and oil to the

crankcase, following the recommendations

in the engine manual; then, close the upper

protection again and certify that you have

closed the radiator and oil input lids, see

Figure 5.

To insert oil in the hydraulic tank (1) in TR

2000 and TR 1500, proceed as follows:

O Remove the oil input lid (6) and, with the

aid of a funnel, supply 18 liters of VG68

oil. Check the oil level through the

viewfinder (5) and, after filling up, check if

there are leaks at the hose outlet (4). If you

need to clean, open the lid (2) by

loosening the screws, noting that, after

opening the lid, it must be glued with

gasket glue to avoid leakages. On the

return filter (3), there is a saturation

indicator that turns red when it must be

changed, as per figure 6; for changing,

consult a TRAPP assistant.

ENGLISH

17

www.trapp.com.br

Image merely

illustrative

4

2

1

3

Figure 5

4

6

12

3 5

Image merely illustrative

Figure 6

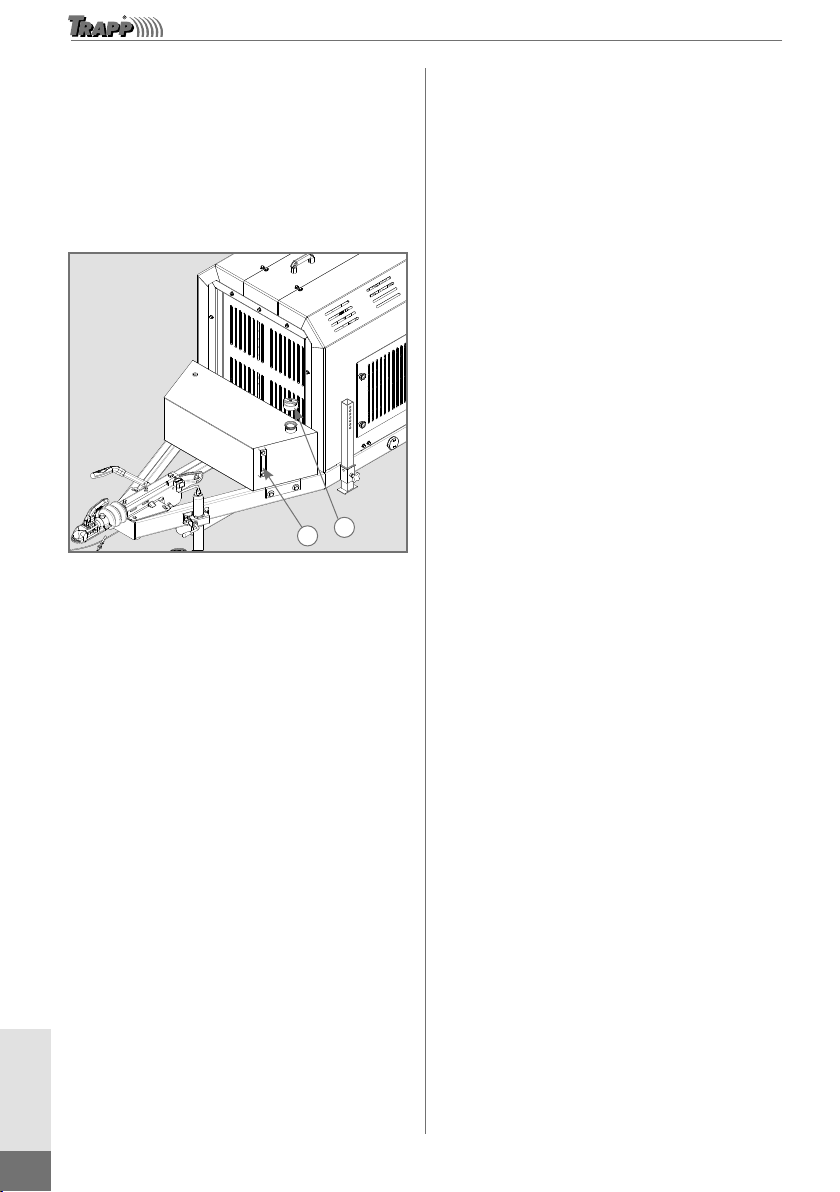

In TR 1500, to insert oil in the gearbox,

proceed as follows:

O Open the lid (4) and add 4 liters of W140

oil, checking the level through the

viewfinder (1). If maintenance or cleaning

is necessary, open the lid (4) and, if you

need to remove the oil, open the drain

plug (3). The screw (5) may be removed

when necessary for maintenance; the

gearbox has a pressure relief valve (2), as

per Figure 7.

Image merely illustrative

35

2

4

1

Figure 7

Note:

The radiator of the TR 2000 is supplied with

water; just check the water level and complete, if

necessary.

For TR 2000, to connect the battery (1),

proceed as follows:

O Open the lid (2) for accessing the engine,

loosening the fixing knobs (3) and connect

the negative and positive cables at their

respective places. After fixing the cables,

certify that the battery is well set, assemble

the lid (2) again using the knobs (3), which

must be quite tight, as per Figure 8.

Image merely illustrative

3

21

Figure 8

ENGLISH

18

www.trapp.com.br

For TR 2000, to supply the fuel tank, proceed

as follows:

O Open the lid (1) using the key and check

the amount through the viewfinder (2), as

per Figure 9. Fuel only with standard

diesel. After fueling, close the lid and check

if there is no fuel leak or spillage before

starting the engine. Capacity: 45 liters.

Image merely

illustrative

21

Figure 9

For TR 1500, the electrical part of the

machine is fed by the tractor’s battery. In this

case, after checking the connection between

the cables, connect the plug of the “NO

STRESS” panel to the power outlet of the

tractor, 12 V tension.

For TR 2000, the diesel engine has a manual

pump to eject fuel and requires “bleeding the

diesel” when turning on for the first time. For

this, consult the engine’s manual.

In TR 2000, as soon as the engine runs, let it

warm up for about 5 minutes, turn on the

“NO STRESS” panel, then engage the clutch

to tension the disk belt. As soon as it is

tensioned, accelerate the engine until the

panel indicates the rotation of 1,500 rpm.

For TR 1500, as soon as the tractor is turned

on, engage its power take-off at low rotation.

As soon as the Cardan shaft begins rotating,

turn on the “NO STRESS” panel and

accelerate the tractor until reaching the

rotation of 1,450 rpm on the machine’s panel

or 540 rpm on the tractor.

When the equipment is in use, all persons,

especially children, must remain at a safe

distance from the work area. The operator/

user is responsible for possible accidents that

may occur.

Never let anyone touch the machine while it

is being used or transported.

When using the equipment, only one person

must give instructions and perform signals

related to the movement of the load.

Tips for good operation

The opening of the input funnel next to the

feeding roll is of 20 cm; if the material to be

shredded exceeds this measure, it may lock

the material input. Woods with irregular

measures must be selected and have their

size adjusted before being inserted into the

feeding funnel.

Organic materials derived from food leftovers

must be inserted into the machine

accompanied by branches and leaves to

facilitate the shredding and the entry into the

feeding roll.

Do not hold the introduced material after the

feeding roll pulls it. When the material begins

being pulled, back away from the feeding

funnel since irregular woods or branches

might produce unexpected movements

striking the operator and causing severe

accidents.

Do not introduce material with over 2 m of

length into the feeding funnel, since it may

damage the shredder or cause physical

damages to the operator. If necessary, cut the

material into parts before inserting it into the

feeding funnel.

Material with length lower than 40 cm must

be inserted into the feeding roll right after

more lengthy material to ease the entry of the

material into the feeding roll.

ENGLISH

19

www.trapp.com.br

Materials with diameters above 15 cm must

be inserted in the feeding roll right after

materials with smaller diameters that are

already being shredded to facilitate the

opening of the feeding roll. If necessary, the

feeding roll’s input opening may be adjusted

to aid the entry of materials with varying

measures.

To achieve proper operation of the cutting

system and not lock the cutting disk or clog

the material outlet nozzle, regulate the speed

of the feeding rolls by adjusting the knob (1)

in the input funnel, monitoring the system

pressure with the manometer (2) as per Figure

10, and proceed with the following

recommendations:

O Assess and separate the material to be

shredded. Set aside materials with

diameters over 16 cm, which require a

differentiated adjustment to obtain better

shredder performance and avoid constant

stops due to clogging or locked disk. For

this purpose, turn the knob to the negative

sign (-) to reduce the feeding roll speed;

O Materials with diameters smaller than 16

cm and with more leaves may be shredded

with a higher feeding speed, thus

achieving better productivity. For this

purpose, turn the knob to the positive sign

(+) to increase the feeding roll speed;

O Fibrous materials such as palm and

coconut tree leaves, as well as eucalypts

bark, tend to accumulate easily on the

disk, so mix them with drier woods, and

this will help the self-cleaning of the

cutting set;

O Change the programming of the “NO

STRESS” panel to shred wood with

diameters over 16 cm; regulate the

stopping rotation to 1,250 rpm, as per the

programming instruction in this manual;

O Woods with diameters smaller than 16 cm

may be shredded with the regulation of

the rotation on the panel at 1,150 rpm, as

when it left the factory.

Image merely illustrative

2

1

Figure 10

Image merely illustrative

Figure 11

The knob located at the entry of the feeding

funnel has the function of altering the rotation

of the feeding rolls.

To obtain a reference and be able to regulate

the rotation of the feeding rolls, observe the

pressure indication on the manometer

positioned on the outside of the funnel.

When the pressure on the manometer

indicates 170 psi, this means that the rotation

of the feeding rolls is already at the smallest

rotation possible; this adjustment applies to

wood with diameters larger than 16 cm.

ENGLISH

20

www.trapp.com.br

When the pressure indicates 50 psi, the

rotation of the feeding rolls is at the ideal

rotation for wood or branches with leaves

with diameters smaller than 16 cm and other

materials.

The panel with the “NO STRESS” system

monitors the worked hours and the rotation

of the cutting disk, and releases or blocks the

rotation of the feeding rolls; the feeding rolls

do not run if the panel is not on.

The panel has quite sensitive buttons for

programming; the programming of the

rotation may be changed to ensure the

control on the feeding of the material to the

disk, ensure the safety of the cutting set, and

improve the efficiency of the shredder for

various applications.

Assess the type of material to be shredded;

some materials need to be shredded

separately, and others may be mixed for

better performance;

Wood with diameters below or above 16 cm

must be shredded with differentiated

programming. For this, proceed as follows:

1. Simultaneously press the 3 keys

(F ▼▲), try multiple times until the panel

shows the programmed rotations of 1,650

(maximum) and 1,150 (minimum);

2. When the light starts blinking, keep pressing

the F key and release the two other keys

(▼▲) the panel will show the programmed

rotation; never alter the rotation without

consulting the manual;

3. Adjust the first rotation (minimum) to 1,250

rpm by pressing the keys (▼▲) of the panel

to increase or decrease the numbering; this

programming is for wood with diameters

above 16 cm. Do the same for wood with

diameters below 16 cm, programming the

rotation to 1,150 rpm. When finished, release

the F key;

4. To change the information on the panel

display and show the hours worked, press

the F key. Observe Figure 11, which shows

the panel and the programming buttons;

The maximum rotation of 1,600 rpm must

not be changed; in case you have difficulty

performing the programming, contact a

TRAPP Assistant.

Remove foreign bodies such as pieces of

metal, glass, or rocks before turning the

machine on.

Turn on the shredder and wait for it to reach

the maximum rotation to insert materials to

be shredded.

Assess the pressure of the hydraulic system

through the manometer located at the feeding

funnel. The pressure indicated when the rolls

are running must not exceed 170 psi; if the

pressure exceeds this value and the roll is not

turning, consult the closest TRAPP Technical

Assistance.

In case the shredder has been idle

for a long time, some adjustments

may be necessary to the hydraulic

system or the diesel engine, such as

the bleeding of the injector nozzles;

if necessary, consult the closest

TRAPP Technical Assistance.

TRAPP does not take responsibility for

occurrences and damages caused by the lack

of compliance with the instructions contained

in this manual.

After defining the programming of the ideal

work rotation, move the drive bar of the

feeding rolls, located at the feeding funnel, to

test the three stages: advance, still, and retreat,

as per Figure 12.

This manual suits for next models

1

Table of contents

Other TRAPP Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions