10

Before cleaning the attachment with water or steam jets (high-pressure cleaners) or other cleaning

agents, cover or tape all openings and electrical components which –for safety and operational

reasons –must be protected against ingress of water, steam or cleaning agents (if applicable).

After cleaning, if applicable, examine all fuel, lubricant and hydraulic oil lines for leaks, loose

connections, scuffing marks and damage. Any defects found must be rectified without delay.

Always retighten any screwed connections that have been unscrewed during maintenance and

repairs.

Any safety devices removed for setting-up, maintenance or repair purposes must be refitted and

checked immediately upon completion of the maintenance and repair work and prior to operation.

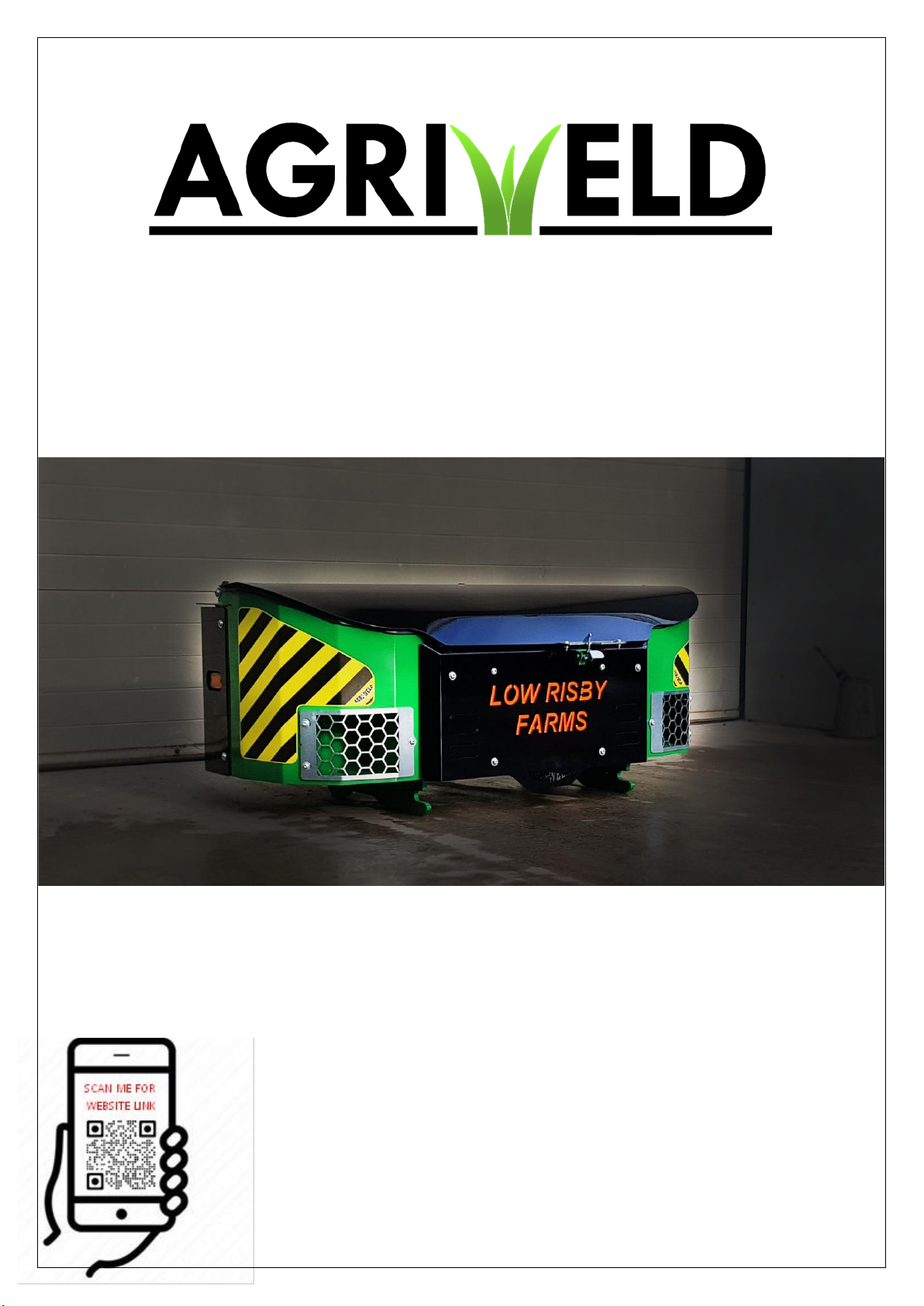

There are no operational parts associated with your transport box although please follow the

checks below regularly to ensure that any noticeable damage or faults are noticed.

•Before use, always check round the transport box to ensure no damage has occurred and

that the attachment appears safe to use.

•Keep the transport box clean at all times to enable users to perform easy visual check for

damage/faults.

Acquiring spare parts

Please quote the details on the type plate(s) as well as the machine’s serial no. on every order for

spare parts or accessories, or enquiries of a technical nature.

The use of spare parts supplied by others shall only be permitted after consultation with the

manufacturer. Original spare parts and accessories authorised by the manufacturer ensure safe and

reliable operation. The use of other parts may invalidate the liability of the manufacturer for any

consequences arising from such use.

Disposing of replaced parts

The following points should be observed before replacing or disposing of parts.

-Replaced parts, which still function, should be cleaned and stored in an orderly manner.

-Machine parts, which cannot be repaired should only be disposed of at appropriate

collecting points or be collected by a scrap metal dealer.

-So-called “valuable” materials should be disposed of in a proper way, i.e. plastics, rubber,

scrap metal, etc. should be recycled.

-Collect and dispose of old oil in accordance with the current regulations.

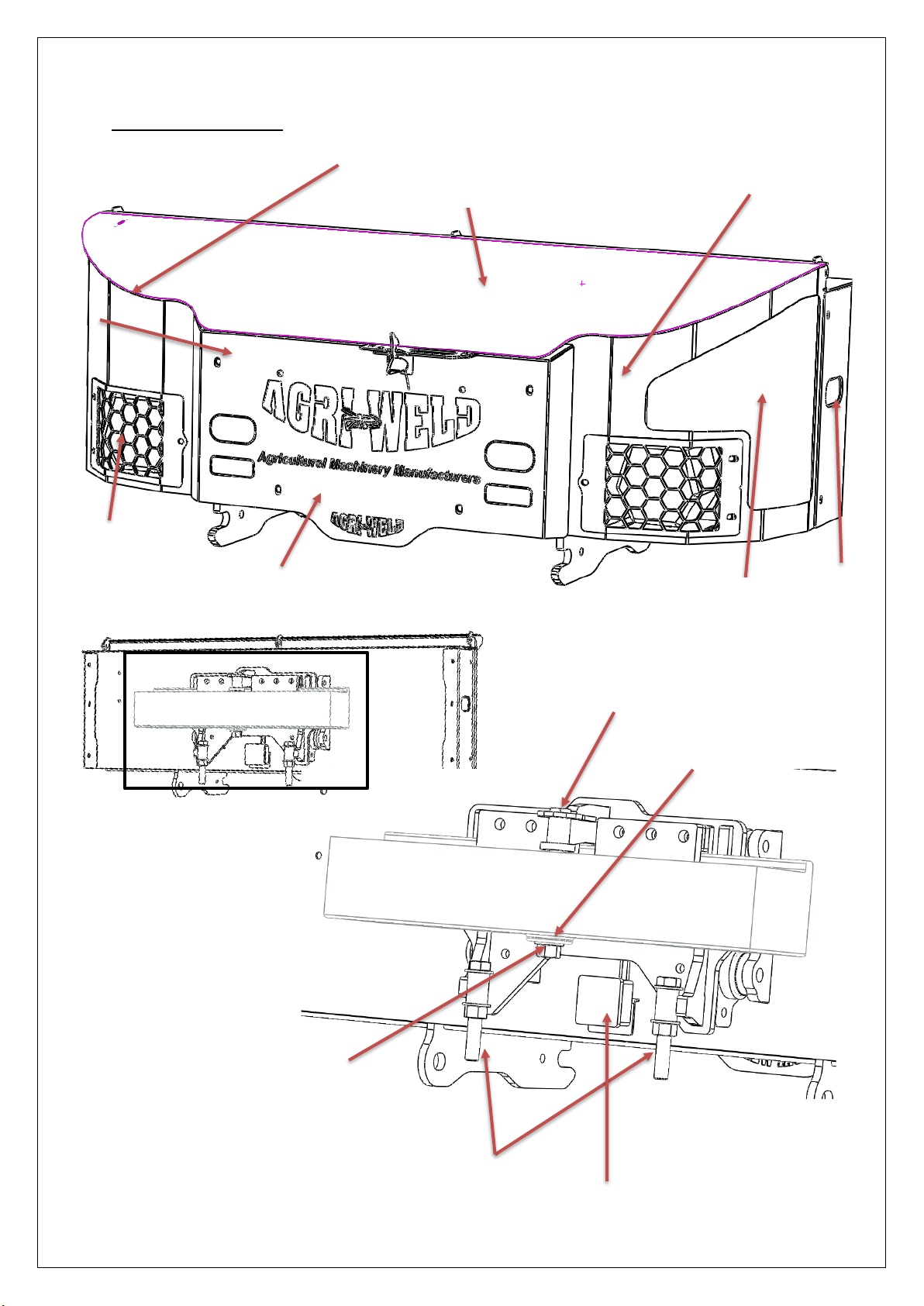

CONNECTING LEDS

The transport boxes are fitted with amber side marker lights as standard, however, it is not supplied

with the relevant 12-24V electrical plug which can vary, to suit the connection to your tractor.

Please check that your LEDs are working correctly before use in the dark and especially when in use

on public roads. Please note that you are responsible for ensuring the LEDs are in full working order

before each use and this should form part of your routine maintenance checks.