MODERN AG PRODUCTS CHOPPERRR User manual

C

h

oppe

rrr - 1

O

perator

’

s Manual

YOU'RE ALWAYS AHEAD...WITH A MODERN BEHIND.

CHOPPERRR

32%2;%($802177;

)$;

www.modernusa.com

Go Galvanized!

FALL 2011

SPRING 2017

2 CHOPPER

SAFETY SECTION

3CHOPPER

The SAFETY ALERT SYMBOL indicates

that there is a potential hazard to personal safe-

ty involved and extra safety precautions must be

taken. When you see this symbol on your ma-

FKLQH RU LQ WKLV PDQXDO EH DOHUW DQG FDUHIXOO\

read the message that follows it.

DANGER ,QGLFDWHV DQ LPPLQHQWO\ KD]DUGRXV

VLWXDWLRQ ZKLFK LI QRW DYRLGHG ZLOO UHVXOW LQ

death or serious injury. This signal word is lim-

ited to the most extreme situations.

WARNING ,QGLFDWHV D SRWHQWLDOO\ KD]DUGRXV

VLWXDWLRQ ZKLFK LI QRW DYRLGHG FRXOG UHVXOW LQ

death or serious injury.

CAUTION,QGLFDWHVDSRWHQWLDOO\KD]DUGRXVVLW-

XDWLRQZKLFKLIQRWDYRLGHGPD\UHVXOWLQPLQRU

or moderate injury. It may also be used to alert

against unsafe practices.

Driveline shields and gearbox shields should be

used and maintained in good working condi-

tion.

Do not mount or dismount the spreader while

the tractor id moving. Mount and dismount the

tractor only when it is completely stopped.

Do not turn sharp enough to get sever “knock-

ing” of the driveline which will cause accelerated

wear and breakage of drive train components

and possible injury from the separated driveline

sections.

Never allow riders on either tractor or spreader.

)DOOLQJFDQEHIDWDO

Never allow children to operate or ride on the

tractor or spreader.

Never work under the spreader unless it is

securely supported or blocked up. A sudden

or inadvertent fall by any of these components

could cause serious injury or death.

%HIRUH OHDYLQJ WKH WUDFWRU VHDW DOZD\V HQJDJH

the brake and or set the tractor transmission in

SDUNLQJJHDU'LVHQJDJHWKH372VWRSWKHHQ-

JLQH UHPRYH WKH NH\ DQG ZDLW IRU DOO PRYLQJ

parts to stop. Place the tractor shift lever into a

low range or parking gear to prevent the tractor

from rolling. Never mount or dismount a mov-

ing tractor. Operate the tractor controls from the

tractor seat only.

The rotating parts of this machine continue to

rotate even after the PTO has been turned off.

7KH RSHUDWRU VKRXOG UHPDLQ LQ KLV VHDW IRU

VHFRQGVDIWHUWKH EUDNHKDVEHHQVHW WKH372

GLVHQJDJHGWKHWUDFWRU WXUQHGRII DQG DOOHYL-

dence of rotation has ceased. “Wait a minute...

Save a life!”

5HPRYHK\GUDXOLFSUHVVXUHGLVHQJDJHWKH372

and turn off engine prior to doing any mainte-

nance.

Inspect the entire machine periodically. Look

IRUORRVHIDVWHQHUVZRUQRUEURNHQSDUWV0DNH

sure all pins have cotter pins and washers. Seri-

ous injury may occur from not maintaining this

machine in good working order.

!

OPERATION

WARNING

DANGER

DANGER

SAFETY SECTION

4 CHOPPER

Never operate the tractor and spreader until

you have read and completely understood this

PDQXDOWKHWUDFWRURSHUDWRU·VPDQXDODQGHDFK

of the Safety Messages found on the decals on

the tractor and spreader.

Always maintain the safety decals in good

readable condition. If the decal become dam-

DJHG RU XQUHDGDEOH RUGHU UHSODFHPHQW GHFDOV

immediately.

It may be necessary to shorten PTO shaft before

RSHUDWLRQWRSUHYHQWGDPDJHWRJHDUER[VKDIW

or operator.

PROLONGED EXPOSURE TO LOUD NOISE MAY

CAUSE PERMANENT HEARING LOSS.

Tractors with or without spreaders attached can

RIWHQ EH QRLV\ HQRXJK WR FDXVH SHUPDQHQW

partial hearing loss. We recommend that you

wear hearing protection on a full time basis if

WKHQRLVHLQWKHRSHUDWRU·VSRVLWLRQH[FHHGV

GE1RLVHRYHUGERQDORQJWHUPEDVLVFDQ

cause severe hearing loss. Noise over 90 db ad-

jacent to the operator over a long-term basis

PD\FDXVHSHUPDQHQWWRWDOKHDULQJORVV1RWH

hearing loss from loud noise is cumulative over

a lifetime without hope of natural recovery.

HYDRAULIC SYSTEM WARNINGS

ALWAYS release the pressure on the hydraulic

system of the CHOPPERRR prior to

removing the attachment from the skid steer

loader or working on any part of the

hydraulic system. Hydraulic hoses and compo-

nents operate under extreme pressure and

KHDW$VPDOOVWUHDPRIÁXLGIURPDSLQKROHOHDN

in a hydraulic hose can penetrate the

skin and/or cause burns. Whenever hydraulic

ÁXLGLVLQMHFWHGLQWRWKHERG\VHHN

medical attention at once to reduce chances of

a dangerous infection. ALWAYS wash

skin with soap and water after contact with hy-

GUDXOLFÁXLGDVLWLVDQLUULWDQWWRVNLQDQG

eyes.

CHOPPERRR rotary cutters have been designed

to reduce the likelihood of hydraulic

system leakage. Each and every hydraulic sys-

tem is checked prior to shipment.

+RZHYHU RYHU WLPHDQ\K\GUDXOLFV\VWHP PD\

GHYHORSÁXLGOHDNV9HU\VPDOOOHDNV

PD\SURGXFHKLJKSUHVVXUHGLVFKDUJHÁRZVFD-

pable of causing injury should skin come

in contact with such discharge.

/HDNLQJ ÁXLG FDQ PDNH WKH GHFN DQG JURXQG

VXUIDFHVYHU\VOLSSHU\FDXVLQJGLIÀFXOW\LQ

using tools and also increasing the possibility of

slips and falls. ALWAYS wipe away

DOO ÁXLG WKDW PD\ KDYH OHDNHG GXULQJ PDLQWH-

nance.

1(9(5RSHUDWHD&+233(555URWDU\FXWWHURQD

´KLJKÁRZµVNLGVWHHUORDGHUXQOHVV

WKHFXWWHULVHTXLSSHGZLWKD´KLJKÁRZµPRWRU

Motor failure can occur if such use is

performed. CHOPPERRR is NOT RESPONSIBLE

for damage incurred to the

K\GUDXOLFPRWRUGXHWR´KLJKÁRZµXVDJH3OHDVH

refer to the front cover of the manual

IRUWKHPD[LPXPDOORZDEOHÁRZIRU\RXU&+23-

PERRR rotary cutter.

WARNING

WARNING

WARNING

WARNING

CAUTION

SAFETY SECTION

5CHOPPER

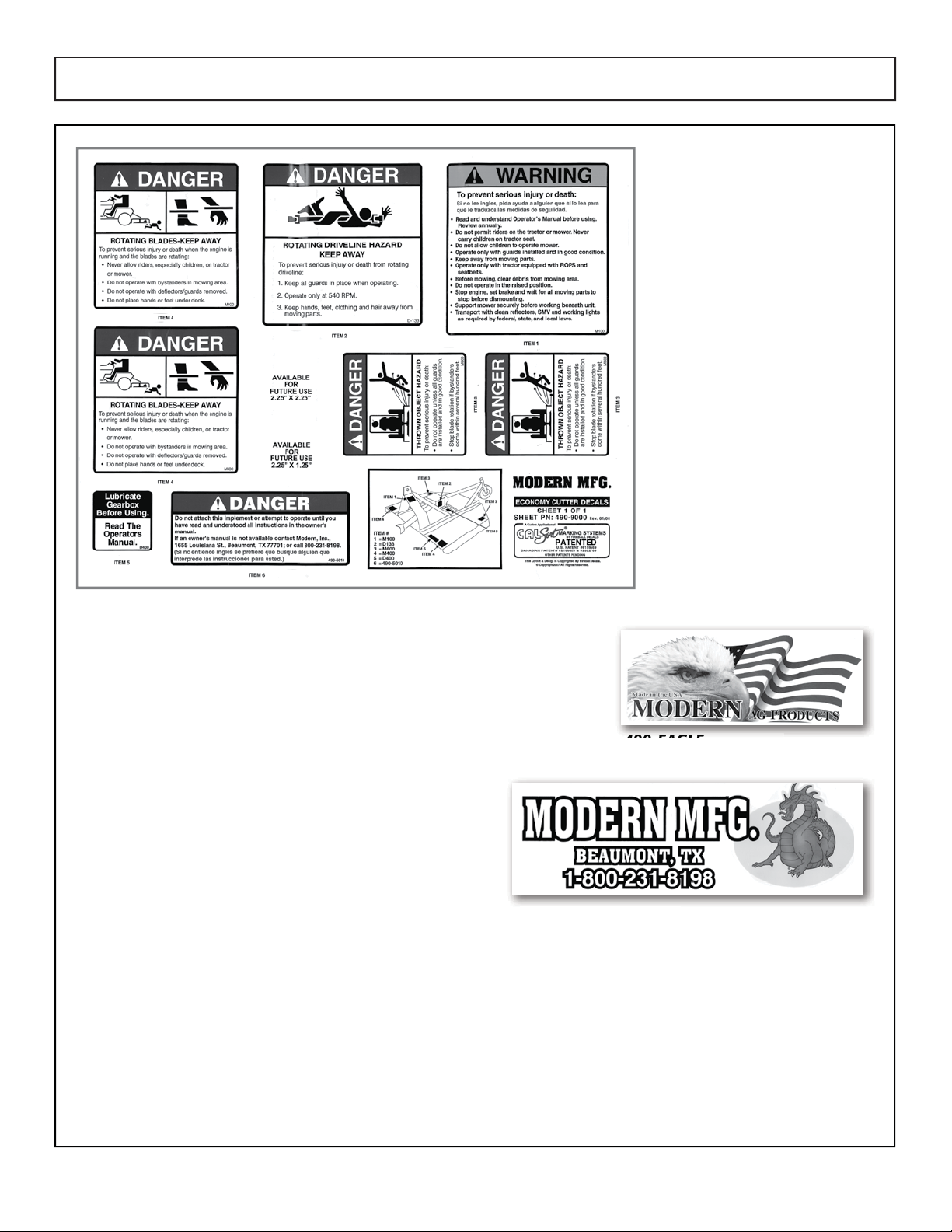

490-9000 Decal Sheet contains:

:DUQLQJ7R3UHYHQW,QMXU\

5RWDWLQJ%ODGHV.HHS$ZD\

(1) Rotating Driveline Hazard

'DQJHU5HDG2SHUDWRU0DQXDO

(1) Thrown Object Hazard

(1) Lubricate Gearbox

490-EAGLE

49

49

0

0

EA

EA

GL

GL

E

E

490-1031

SAFETY SECTION

6 CHOPPER

OPERATING INSTRUCTIONS

7CHOPPER

OPERATING INSTRUCTIONS

ATTACHMENT OF MACHINE

The installation of your CHOPPERRR rotary cut-

ter is the same for any other powered attach-

PHQWIRU\RXUVNLGVWHHUORDGHU

1. Pull up to the rotary cutter and connect it to

your skid steer loader.

6HFXUHWKHORFNGRZQOHYHURUOHYHUV

&RQQHFWWKHK\GUDXOLFKRVHVIURPWKHURWDU\

cutter to your machine. The hoses provided

DUH HTXLSSHG ZLWK TXLFNGLVFRQQHFW ÀWWLQJV

(both male and female) for ease of use.

CUTTING OPERATION

7KH&+233(555URWDU\FXWWHULVFDSDEOHRIDQG

LQIDFWLQWHQGHGWREHXWLOL]HGIRUPXOFKLQJWUHHV

and other vegetation of varying heights and

GLDPHWHUVRIXSWRµ²µ$VDVDIHW\IHDWXUH

ZKHQ FXWWLQJ ODUJH GLDPHWHU YHJHWDWLRQ WKH

CHOPPERRR rotary cutter is equipped with a hy-

draulic motor cushion valve for shut down of the

blade system. This feature lessens the chance of

GDPDJLQJWKHFXWWHU·VK\GUDXOLFV\VWHPRUEODGH

system when cutting larger diameter vegetation.

'LUHFWLRQVIRUXVHDUHDVIROORZV

CUTTING GROUND LEVEL

VEGETATION

Raise the rear of the CHOPPERRR rotary cut-

WHU DSSUR[LPDWHO\ µ ² µ DERYH JURXQG OHYHO

The deck of the rotary cutter should be sloping

downward and away from the operator. This is

the optimum position for cutting materials that

are close to the ground.

Please note: If the operator can see the blade

system in operation, the back of the rotary

cutter is raised TOO HIGH!

CUTTING ABOVE GROUND LEVEL

VEGETATION

Raise the front deck of the CHOPPERRR rotary

FXWWHU XS DSSUR[LPDWHO\ · ² · DERYH JURXQG

level. Do not lift the rear portion of the deck.

.HHSLWDSSUR[LPDWHO\µ²µDERYHJURXQGOHY-

el. Slowly drive into the vegetation and use the

hydraulic tilt (roll) the bend or push the vegeta-

tion over. As you bend the vegetation over and

GULYHLQWRLWWKHEODGHVZLOOFXWLWLQWR7KHYHJH-

tation can now be mulched by rotating the front

of the rotary cutter and driving forward several

feet. Then roll the back of the cutter down and

back-drag atop the vegetation.

OPERATING INSTRUCTIONS

8 CHOPPER

REPAIR AND MAINTENANCE

INSTRUCTIONS

9CHOPPER

PRE-MAINTENANCE & REPAIR STEPS

Prior to performing any repair or maintenance

ZRUNRQ\RXU&+233(555PDNHVXUHWKDWWKH

IROORZLQJVWHSVDUH$/:$<6IROORZHG

9LVXDOO\YHULI\WKDWWKHORFNGRZQSLQVDUHIXOO\

engaged through the quick attach.

5HOHDVH WKH SUHVVXUH RQ WKH URWDU\ FXWWHU·V

hydraulic hoses.

7XUQWKHVNLGVWHHUORDGHUHQJLQHRII

'LVFRQQHFWWKHK\GUDXOLFKRVHVWKDWFRQQHFW

to the skid steer loader.

BLADE REMOVAL

)ROORZ DOO VWHSV LQ WKH ´3UH0DLQWHQDQFH

Repair Steps” at the top of this page.

6/2:/< URWDWH WKH EODGH FDUULHU XQWLO WKH

blade-attaching nut is aligned in the access

hole.

)URP WKH WRS RI WKH GHFN LQVHUW D VRFNHW

through the access hole onto the blade nut.

Remove the nut and insure that the blade

drops to the ground. Repeat the process for

the remaining blades.

$IWHU WKH QXWV KDYH EHHQ UHPRYHG DQG WKH

EODGHV KDYH GURSSHG EDFN XS WKH VNLG

steer loader and CHOPPERRR to retrieve the

blades.

$IWHU UHWULHYLQJ WKH EODGHV ORZHU WKH

CHOPPERRR back to the ground and shut the

skid steer loader engine down.

,QVSHFW WKH EODGHV IRU GDPDJH DQG GHWHU-

mine if the blades need to be sharpened or

replaced.

Safety Note: When sharpening or replacing the cut-

ting blades, all blades must be either sharpened or

replaced to ensure proper blade balancing. NEVER

mix sharpened blades with new blades.

BLADE INSTALLATION

)ROORZ DOO VWHSV LQ WKH ´3UH0DLQWHQDQFH

5HSDLU6WHSVµDWWKHWRSRIWKLVSDJH

7LOWWKHIURQWRIWKH&+233(555XS

6HFXUHO\SRVLWLRQDµ[µSRVWRUHTXLYDOHQW

VWUHQJWKVWUXWXQGHUWKHIURQWRIWKH&+23-

PERRR and SLOWLY rotate the blade carrier

until the blade-attaching nut is aligned in the

DFFHVVKROH,QOLHXRIXVLQJDµ[µSRVWRU

RWKHU VWUXW WKH URWDU\ FXWWHU FDQ EH OHDQHG

against the trunk of a large tree and allowed

to stay in such position until the blade holder

LV UHPRYHG ,I WKH ODWWHU PHWKRG LV FKRVHQ

remember to scotch or chock the skid steer

ORDGHU·VWLUHVZLWKDEULFNORJRURWKHUDSSUR-

priate strength item.

,QVHUW WKH EROW XS WKURXJK WKH KROH LQ WKH

blade and the blade holder. Insert the lock-

washer and nut through the access hole and

hand-tighten.

8VH WKH VRFNHW WR ÀQLVK WLJKWHQLQJ WKH QXW

through the access hole that is located on top

of the deck. The nut should be tightened with

DWRUTXHZUHQFKWRIWOEV

&DUHIXOO\UHPRYHWKHµ[µRURWKHUVWUXWDQG

lower the CHOPPERRR to the ground.

!

!

REPAIR AND MAINTENANCE INSTRUCTIONS

10 CHOPPER

BLADE HOLDER REMOVAL

)ROORZ DOO VWHSV LQ WKH ´3UH0DLQWHQDQFH

5HSDLU6WHSVµsee page 5

7LOW WKH &+233(555 GHFN DW D QHDU YHUWLFDO

DQJOH &DUHIXOO\ DQG VHFXUHO\ SRVLWLRQ D µ [

µ SRVW RU HTXLYDOHQW VWUHQJWK VWUXW XQGHU

the rear portion of the CHOPPERRR deck. In

OLHXRIXVLQJDµ[µSRVWRURWKHUVWUXWWKH

IURQWSRUWLRQ RI WKH URWDU\ FXWWHU·VGHFN FDQ

be leaned against the trunk of a large tree

and allowed to stay in such position until the

blade holder is removed. If the latter method

LVFKRVHQ UHPHPEHUWRVFRWFKRUFKRFNWKH

VNLG VWHHU ORDGHU·V WLUHV ZLWK D EULFN ORJ RU

other appropriate strength item.

5HPRYH WKH FRWWHU SLQ DQG FDVWOH QXW WKDW

secures the blade holder to the gearbox. Be

FDUHIXOLQSHUIRUPLQJWKLVVWHSDVLWLVSRVVLEOH

that the blade holder will fall and cause bodily

damage.

5HVWDUW WKH VNLG VWHHU ORDGHU·V HQJLQH DQG

VORZO\EXWÀUPO\VWULNHLIUHTXLUHGWKHERWWRP

SRUWLRQ RI WKH URWDU\ FXWWHU·V GHFN RQ WKH

ground. Repeatedly strike the rotary cutter on

the ground until the blade holder falls off.

BLADE HOLDER INSTALLATION

)ROORZ DOO VWHSV LQ WKH ´3UH0DLQWHQDQFH

Repair Steps”. see page 5

5HSRVLWLRQWKH&+233(555LQDQHDUYHUWLFDO

position. Position the strut back under the rear

SRUWLRQRIWKHGHFNRUOHDQWKHIURQWSRUWLRQ

of the deck back against the tree.

&DUHIXOO\ SODFH WKH EODGH KROGHU EDFN LQWR

SRVLWLRQRQWKHVKDIWRIWKHJHDUER[PDNLQJ

sure that the splines in the shaft match up to the

grooves on the shaft. Be careful in performing

this step as it is possible that the blade holder

can fall and cause bodily damage.

6FUHZWKHFDVWOHQXWEDFNRQWRWKHVKDIWDQG

place the cotter pin back into the hole on the

shaft. Remember to bend at least one of the

prongs on the cotter pin.

HYDRAULIC HOSE REMOVAL

)ROORZ DOO VWHSV LQ WKH ´3UH0DLQWHQDQFH

Repair Steps”. see page 5

0DUN RU RWKHUZLVH GRFXPHQW WKH SURSHU

location of each hose. The hoses can be

LGHQWLÀHGE\HLWKHUKDYLQJDPDOHRUDIHPDOH

quick-disconnect coupling.

8VLQJ D FUHVFHQW ZUHQFK ORRVHQ WKH KRVH

connectors at the motor.

HYDRAULIC HOSE INSTALLATION

)ROORZ DOO VWHSV LQ WKH ´3UH0DLQWHQDQFH

Repair Steps”. see page 5

,GHQWLI\WKHSURSHUORFDWLRQIRUHDFKKRVHRQ

the hydraulic motor.

+DQGWLJKWHQ HDFK KRVH FRQQHFWRU 3HUIRUP

ÀQDOWLJKWHQLQJZLWKDFUHVFHQWZUHQFK

1RWH'2127XVH7HÁRQWDSHRUDQ\RWKHUWKUHDG

bonding material when installing the hoses into

the hydraulic motor.

QUICK-DISCONNECT COUPLING

REMOVAL

)ROORZ DOO VWHSV LQ WKH ´3UH0DLQWHQDQFH

5HSDLU6WHSVµsee page 5

8VLQJ PDVNLQJ WDSH ODEHO HDFK KRVH ZLWK D

mark indicating which coupling was on it.

8VH WZR FUHVFHQW ZUHQFKHV WR UHPRYH WKH

quick-disconnect couplings. One will be used

on the hose end and the other will be used on

the coupling.

REPAIR AND MAINTENANCE INSTRUCTIONS

11CHOPPER

REPAIR AND MAINTENANCE INSTRUCTIONS

see page 9

12 CHOPPER

7

KL

VSDJH

L

QWHQW

L

RQD

OO

\

O

H

I

W

EO

DQ

N

13CHOPPER

ASSEMBLY/PARTS SECTION

ASSEMBLY/PARTS SECTION

14 CHOPPER

&GGFDUJWF'FCSVBSZ4LJE4UFFSDVUUFSTXJMMCFCVJMUVTJOH

5IJTDIBOHFXJMMGPMMPXBMMDVUUFSHPJOHGPXBSE

CFHJOOJOHXJUITFSJBMOVNCFS

15CHOPPER

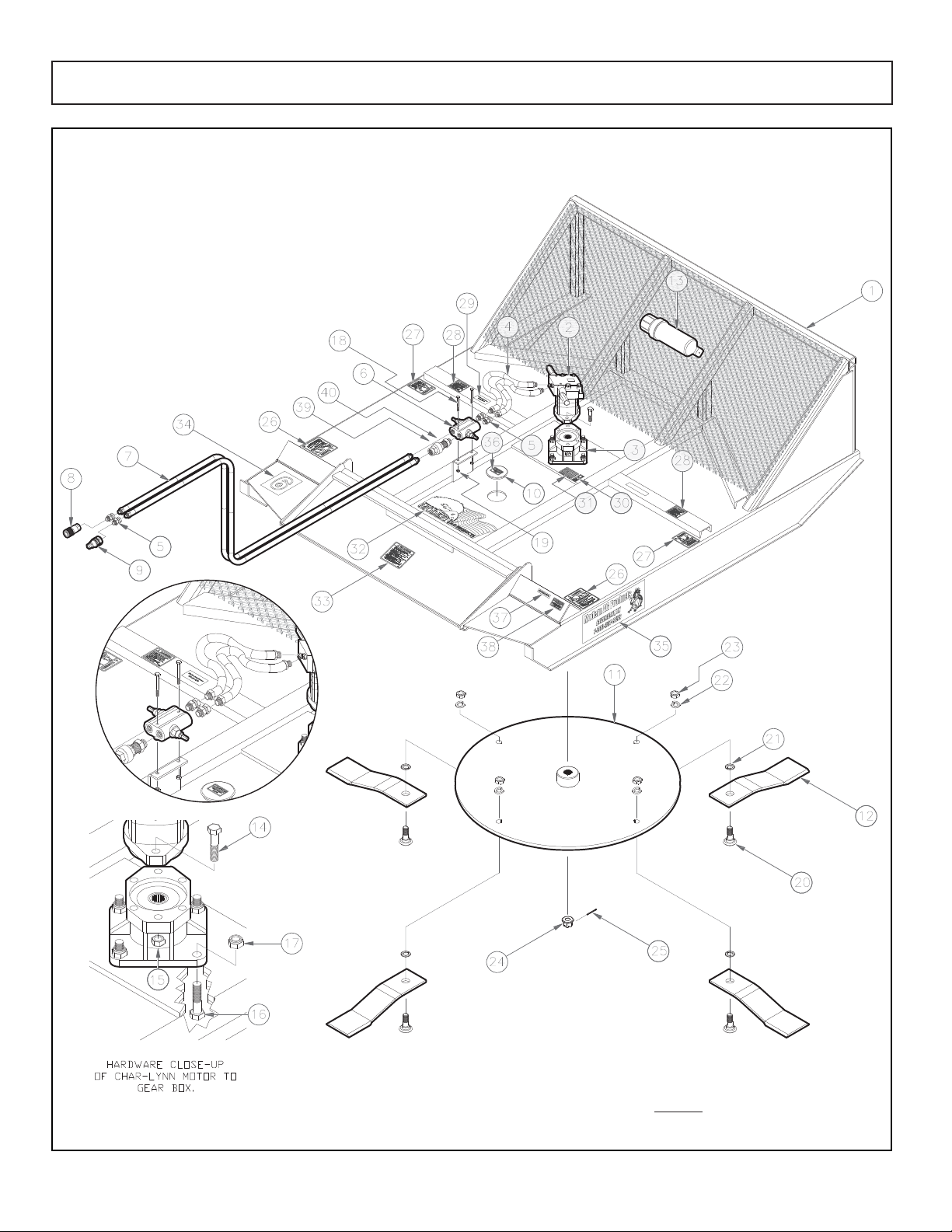

6’ Skid Steer Mower (Chopper) Parts List

Item Part Number Description Qty

1..............401-6SKIDSTEER .......6’ SKID STEER BODY ................................................1

2..............104-3654-006...........CHAR-LYNN MOTOR...............................................1

3..............401-0179..................GEAR BOX, MDH-40................................................1

4..............415-0160..................16” HOSE, 3/4” MPT X 7/8” ORB 14........................2

5..............50-118......................ST SWIVEL ADAPTER, 3/4MPT : 3/4FPT...................4

6..............262-1161..................CUSHION VALVE DRV-2HH.....................................1

7..............415-0096..................96” HOSE, 3/4MPT X 3/4MPT...................................2

8..............227-5053..................COUPLER, 1/2 FM PIPE 1/2-14NPSF........................1

9..............227-5054..................NIPPLE, 1/2 FM PIPE 1/2-14NPSF.............................1

10............116-1656..................MOWER DECK PLUG...............................................1

11............115-8019..................STUMP JUMPER, SKID STEER 41”..............................1

12............401-0156..................BLADE.......................................................................4

13............412-9099..................MANUAL HOLDER....................................................1

14............412-2007..................BOLT, 9/16”-12 X 2-1/2” GR8..................................2

15............412-2006..................TOP LOCK NUT, 9/16”-12........................................2

16............412-0023-02.............TAP BOLT, 5/8” X 2” GR5.........................................4

17............412-5284..................HEX NUT, 5/8-11 NC NYLOCK.................................4

18............400-0018..................BOLT, 5/16” X 3” UNC GR8.....................................2

19............620-5........................HEX NUT, 5/16” ........................................................2

20............125-907....................BLADE BOLT, 1-1/8” BB70........................................4

21............830-1018NH.............WASHER W/ KEYWAY..............................................4

22............900-8771..................LOCK WASHER, 1-1/8”............................................4

23............125-925....................JAM NUT, 1-1/8” GR8..............................................4

24............MDH40-120050........NUT, HEX SLOTTED, 1-14UNS ...................................1

25............501-0940..................COTTER PIN..............................................................1

*26..........M400........................DECAL, DANGER ROTATING BLADES....................2

*27..........M600........................DECAL, DANGER THROWN OBJECTS....................2

28............490-5010..................DECAL, DANGER DO NOT OPERATE.....................1

29............490-2003..................DECAL, MODERN ATTACHMENTS..........................1

30............490-FEMA.................DECAL, FEMA MEMBER...........................................1

31............490-1023..................DECAL, US FLAG......................................................1

32............490-EAGLE...............DECAL, EAGLE MADE IN AMERICA.......................1

*33..........M100........................DECAL, TO PREVENT SERIOUS INJURY ...................1

34............490-1105..................DECAL, “6”...............................................................1

*35..........490-1031..................DECAL, MODERN AG PRODUCTS .........................2

36............490-1024..................DECAL, CAUTION KEEP HANDS CLEAR.................1

*37............................................DECAL, MODERN MFG...........................................1

38............490-GALVCOAT......DECAL, CAUTION GALVANIZED COATING ..........2

(*) .......... 490-9000..................DECAL SHEET (CONTAINS ITEMS #26,#27,#33,#35 & #37)

ITEMS IN THIS SHEET ARE SOLD AS A SET ONLY. SEE PAGE 5.

ASSEMBLY/PARTS SECTION

3.................&KHFN9DOYH&9 ..........

.................+H[1LSSOH ..........

16 CHOPPER

ASSEMBLY/PARTS SECTION

17CHOPPER

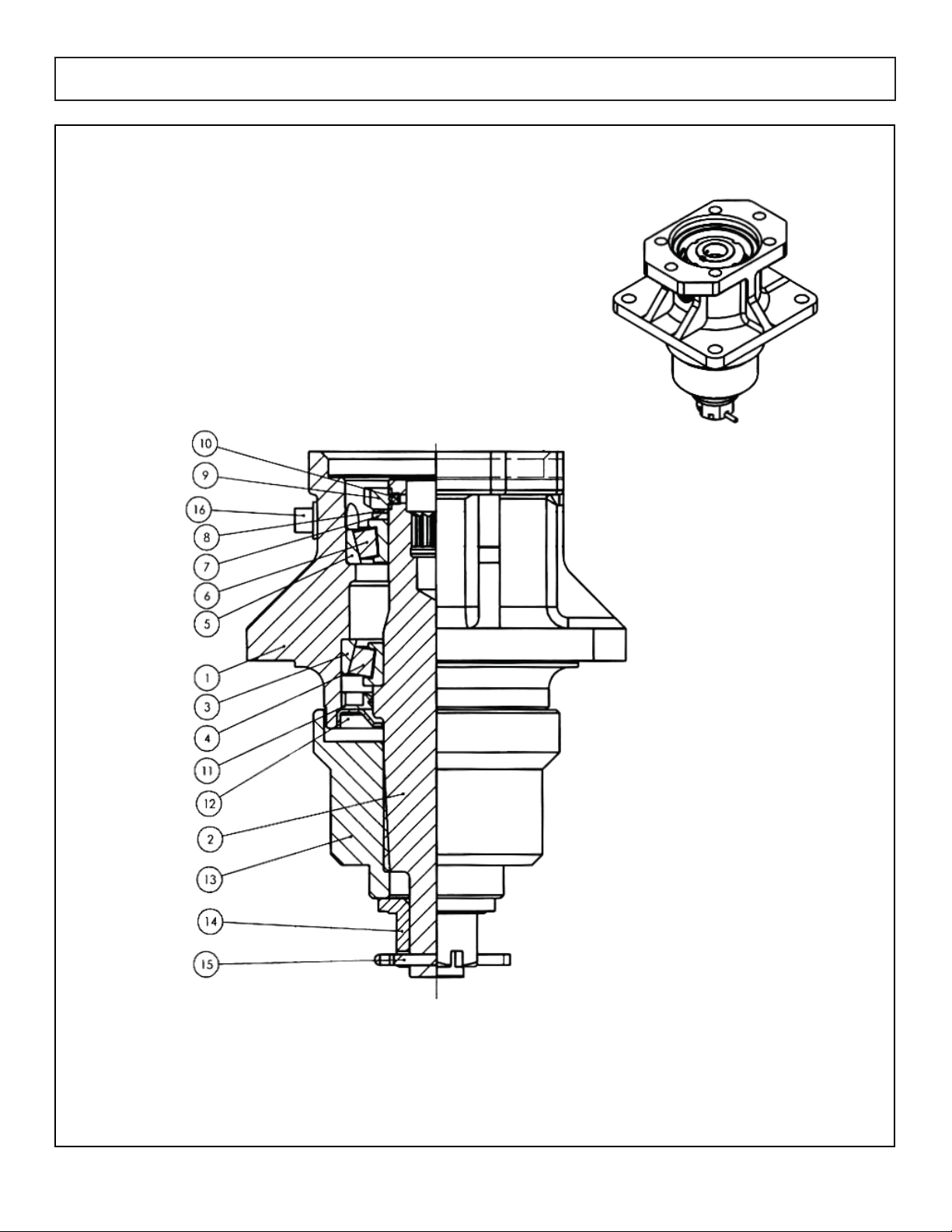

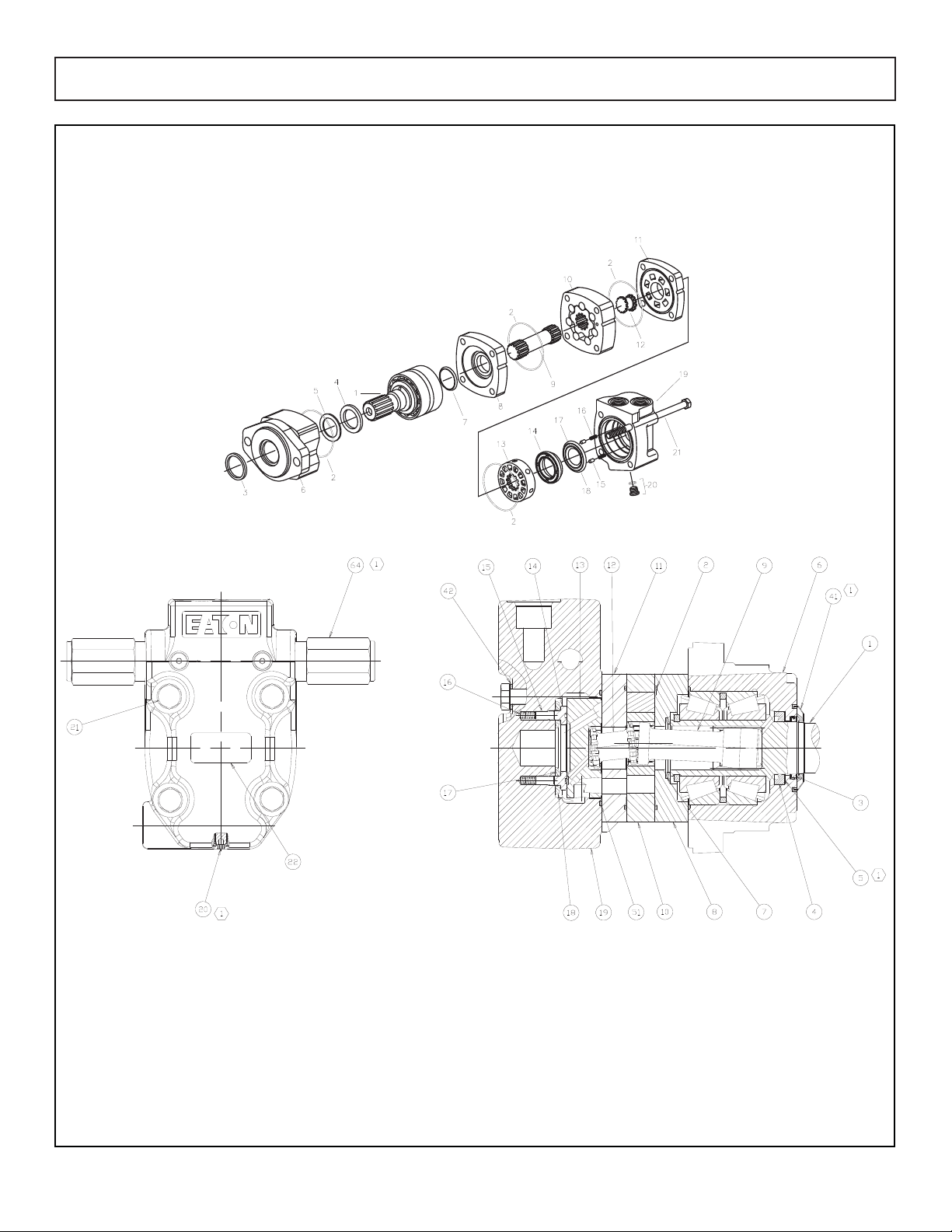

401-0179 Gearbox MDH-40 Parts List

Item Part Number Description Qty

1................................................HOUSING, MDH-40 .................................................1

2..............MDH40-040778........SHAFT-13Z INPUT SPLINE-11.....................................1

3..............MDH40-050200........BEARING, CUP 30210Y............................................1

4..............MDH40-050201........BEARING, CONE 30210X.........................................1

5..............MDH40-050239........BEARING, CUP 30209Y............................................1

6..............MDH40-050240........BEARING, CONE 30209X.........................................1

7..............MDH40-090464........WASHER WITH TANG...............................................1

8..............MDH40-130099........LOCK WASHER, M45...............................................1

9..............MDH40-120136........LOCKNUT, M45 X 1.5 BEARING ..............................1

10............MDH40-110304........SET SCREW, M5........................................................2

11............MDH40-060183........LIP SEAL-OUTPUT......................................................1

12............MDH40-240567........SEAL PROTECTOR....................................................1

13............MDH40-210034........BLADE HUB 15T ........................................................1

14............MDH40-120050........NUT, HEX SLOTTED, 1-14UNS ...................................1

15............MDH40-100001........COTTER PIN 5MM X 50MM......................................1

16............MDH40-140023........PLUG, PIPE SQUARE HEAD, 3/8”-18NPT.................2

ASSEMBLY/PARTS SECTION

(Reference only not included W/GB)

18 CHOPPER

ASSEMBLY/PARTS SECTION

19CHOPPER

104-3654-006 Char-Lynn Motor Parts List

Item Part Number Description Qty

1..............21618-007................SHAFT SUB-ASSEMBLY .............................................1

2 .............4999136-001............SEAL..........................................................................4

3..............9121-001..................SEAL, SHAFT EXCLUSION.........................................1

4..............9057-009..................SEAL, SHAFT..............................................................1

5..............7382-000..................BACK-UP RING.........................................................1

6..............21578-001................HOUSING, BEARING................................................1

7..............9050-000..................SEAL, SHAFT FACE ...................................................1

8..............22102-000................PLATE, WEAR............................................................1

9 .............21371-010................DRIVE........................................................................1

10............21625-002................GEROLER SUB-ASSEMBLY........................................1

11............22134-000................PLATE, VALVE...........................................................1

12............8433-000..................DRIVE, VALVE ..........................................................1

13 ...........21466-000................VALVE.......................................................................1

14............8915-000..................PLATE, BALANCING.................................................1

15............14351-000................PIN ............................................................................2

16............7383-000..................SPRING.....................................................................2

17............9049-001..................SEAL, INNER FACE ...................................................1

18............9135-002..................SEAL, OUTER FACE ..................................................1

19............4994646-007............HOUSING, VALVE S/A.............................................1

20............9072-003..................PLUG SUB-ASSEMBLY...............................................1

21............14384-006................SCREW, CAP............................................................4

22............9029-007..................PLATE, NAME ...........................................................1

42............16048-184................WASHER ...................................................................4

51............250002-039..............SEAL..........................................................................1

64............02-199293................RELIEF VALVE S/A....................................................2

16096-610................PLUG, SHIPPING (NOT SHOWN).............................1

ASSEMBLY/PARTS SECTION

20 CHOPPER

LIMITED WARRANTY

POLICY & REGISTRATION

Table of contents

Other MODERN AG PRODUCTS Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions