Door panels and

header not shown

for clarity

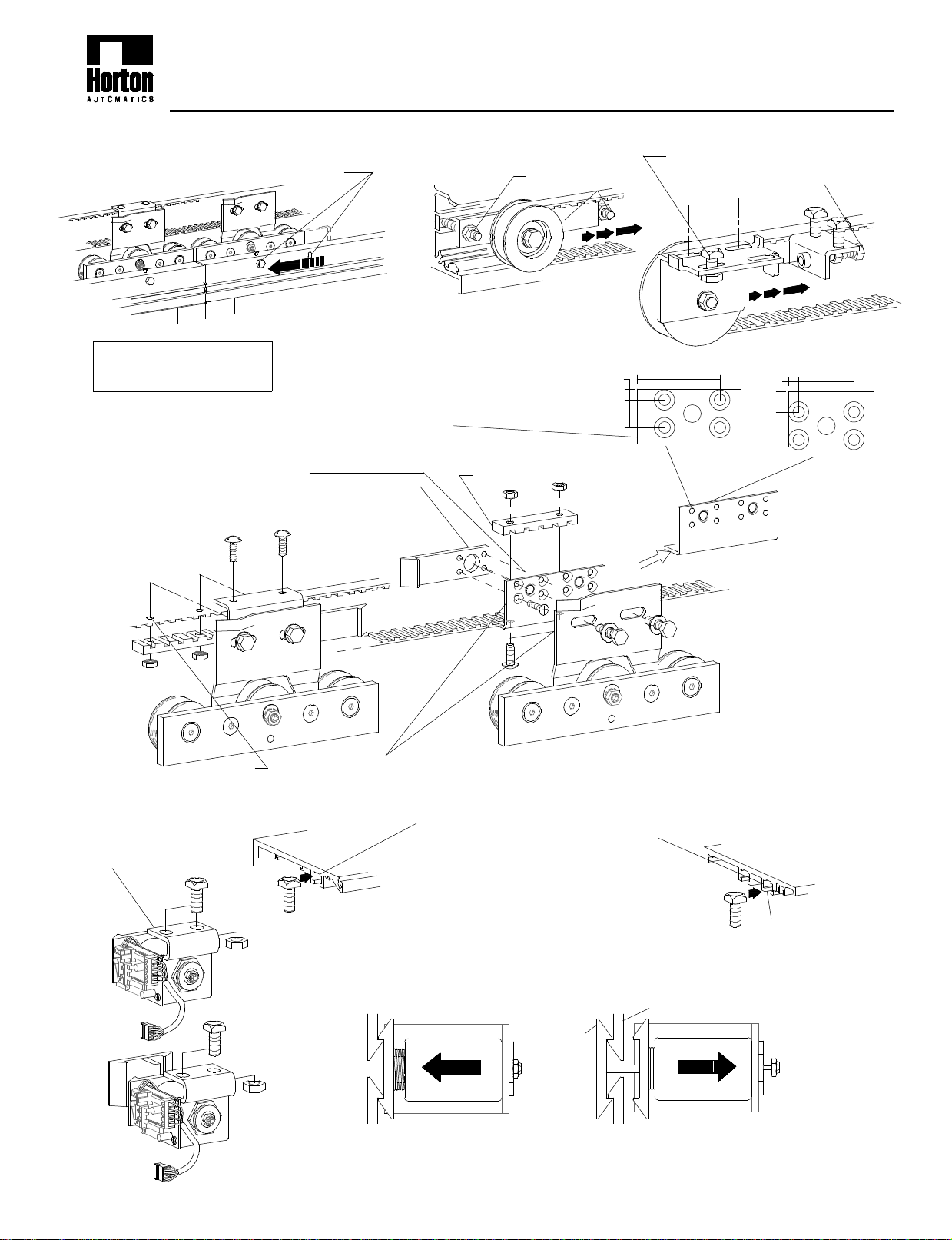

Re-position the close monitor switch. Re-tighten the belt.

Slide 2 square head bolts into the "T"

slot in the top of the header.

Place the bolts in the center of the header.

Access is gained through relief holes

cut in the "T" slot.

(additional relief holes may be cut if required)

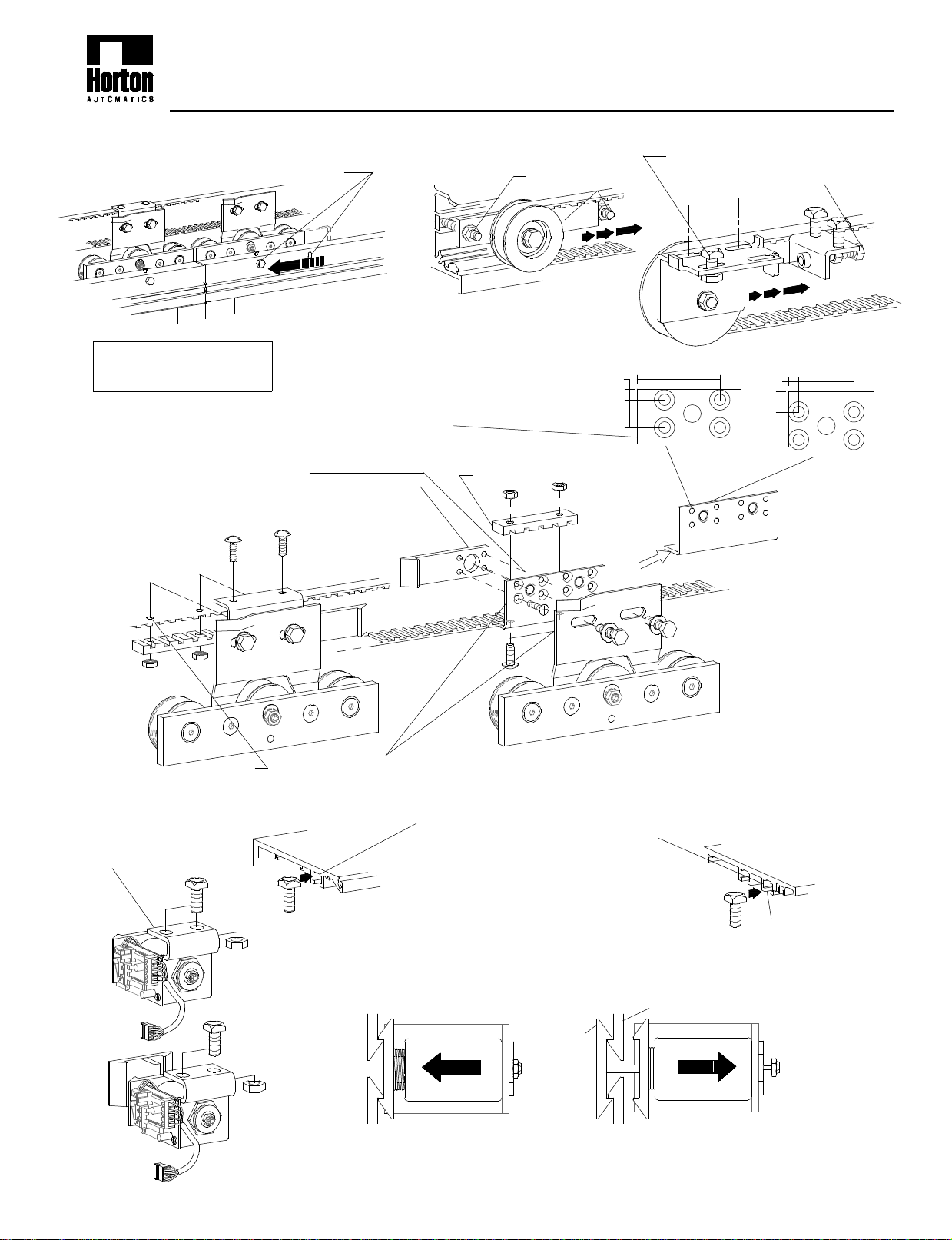

•Place the Autolock at the centerline of the header and mount

with 5/16" nuts and washers (do not tighten).

•Place the door in the fully closed position - the lock should

contact the keepers with out binding.Tighten the 5/16"(2003) or 3/8"(2001) nuts.

Install the brackets to the wheel

carriages as shown

7th Step

Fail secure

top view locked

SOLENOIDSOLENOID

5th Step

Fail

safe

2003

Fail

secure

2003

See page 4 for

Autolock setup

9th Step

Re-connect the belt through

the existing holes.

6th Step

2003 lock is shown

2001 lock is similar

8th Step

2003

Keepers

top view locked

SOLENOID

Fail safe

Lock hooks

L

C

2.205d

2001

First slot

Autolock Installation for 2001 & 2003 Bipart units

BELT DRIVE SUPPLEMENTAL INSTRUCTIONS

2nd Step

Loosen the belt.

Remove the belt connections

3rd Step

NOTE: If necessary the existing bracket

may be drilled and countersunk for #10

screws as shown.

CAUTION:

Disconnect power before

starting this procedure.

•Remove the old belt brackets

•Install the keepers on the new belt brackets

with countersunk holes using 4 #10 FHMS

4th Step

If the wheel carriages are located at the 9 1/2" position

they must be moved to the 4 7/16" position

1st Step

1-800-531-3111

1/2"

13/64" 1"

1/2"

2003 2001

3/16" 1"

3/8"

1/2"

2001

Loosen bolts (on the pully bracket)

and remove belt tension by backing

off the idler pully lock.

Loosen bolts and

slide idler

2003

S200

10/99