2

1. Important notes

1.1 Intended use ........................................................................................................................................................................3

1.2 Explanation of the symbols ................................................................................................................................................3

1.2.1 Warnings ..........................................................................................................................................................................3

1.2.2 Symbols............................................................................................................................................................................3

2. Technical information

2.1 Installation location in the wall housing/control panel......................................................................................................4

2.1.1 Modbus TCP dimensional drawing ....................................................................................................................................4

2.1.2 Modbus RS485 dimensional drawing.................................................................................................................................4

2.2 Connections of the gateway................................................................................................................................................4

2.2.1 Back .................................................................................................................................................................................4

2.3 Technical data for the TopTronic®E Modbus interface......................................................................................................5

2.3.1 Connections on the underside...........................................................................................................................................5

2.3.2 CAN pin assignment on RJ45............................................................................................................................................5

3. Installing and connecting the gateway

3.1 Installing the gateway in the wall housing or control panel..............................................................................................6

3.2 Installing the gateway in the heat generator......................................................................................................................6

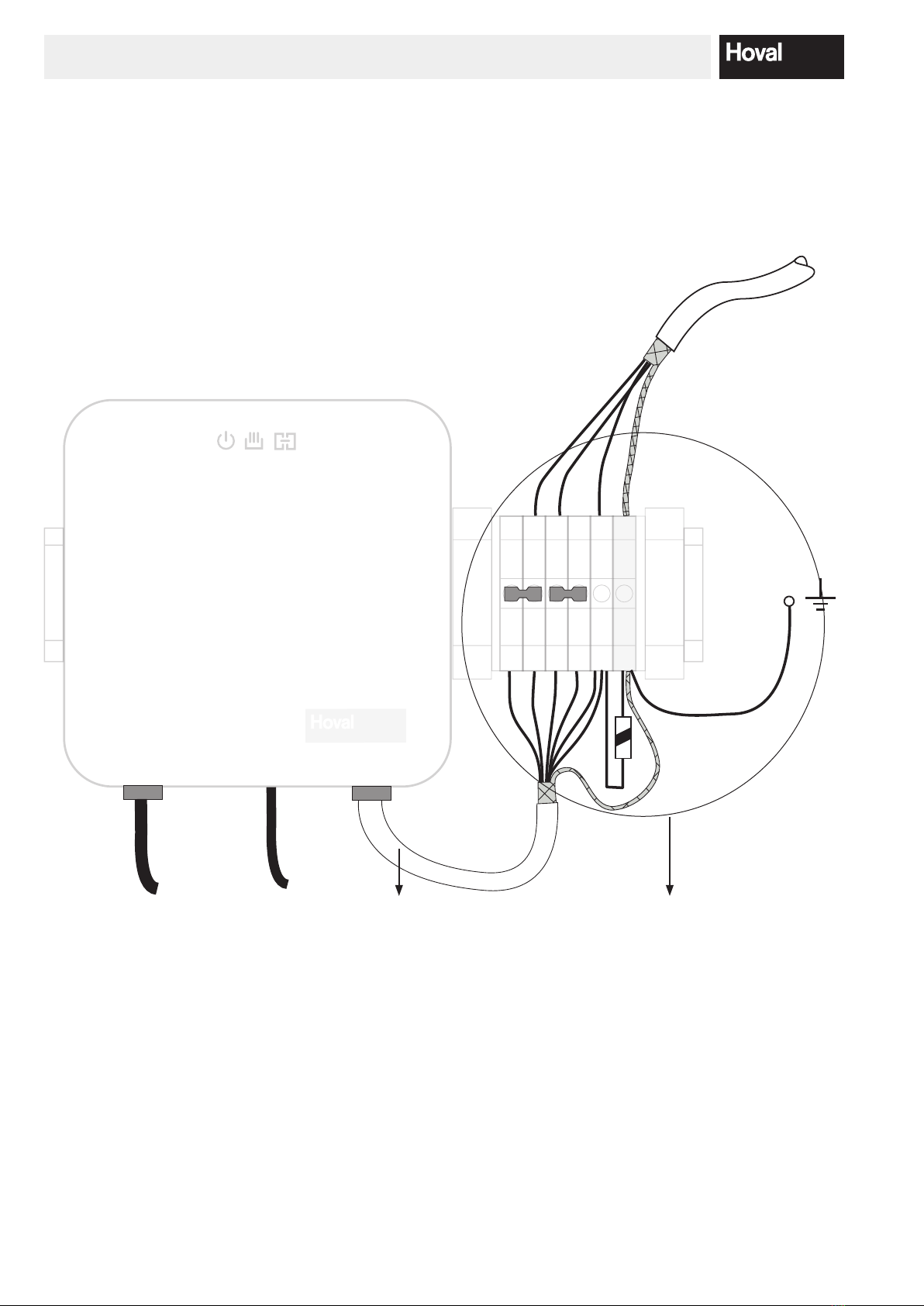

3.3 Connection for the heat generator (WEZ / CAN bus) .........................................................................................................7

3.4 Connection for the Modbus TCP.........................................................................................................................................8

3.5 Connection for the Modbus RS485 .....................................................................................................................................9

3.6 LED lights on the gateway ................................................................................................................................................10

4. Commissioning the TopTronic®E Gateway module Modbus

4.1 Connecting the Modbus TCP/RS485 (RTU) to the gateway ............................................................................................11

5. General Modbus information

6. Data point list

6.1 Important columns ............................................................................................................................................................13

6.2 Module addresses .............................................................................................................................................................14

6.3 Special data points............................................................................................................................................................14

6.3.1 Four-byte data points ......................................................................................................................................................14

6.3.2 Active errors ...................................................................................................................................................................15

6.3.3 LIST data types...............................................................................................................................................................15

6.4 Essential data points.........................................................................................................................................................16

6.4.1 The following lists contain a selection of important data points. TTE-WEZ.......................................................................16

6.4.2 TTE-HK/WW ...................................................................................................................................................................18

6.4.3 TTE-PS...........................................................................................................................................................................20

6.4.4 SOL ................................................................................................................................................................................20

6.4.5 TTE-FW..........................................................................................................................................................................21

6.4.6 TTE-MWA .......................................................................................................................................................................22

4 214 514 / 02

TABLE OF CONTENTS