SAFETY RULES

CAUTION RISK OF ELECTRIC SHOCK

This tester has been designed with your safety in mind.

However, no design can completely protect against

incorrect use. Electrical circuits can be dangerous and/or

lethal when lack of caution or poor safety practices are

used.

Do not carry out field measurements on either the power

system grounding, during periods of forecast lightning

activity, in areas that encompass the station being

measured or of the power network connected to the

station being measured. In the event that lightning occurs,

stop all testing and isolate any temporarily installed test

spikes.

Preparations for testing of power system grounding can

leave personnel vulnerable to exposure caused by faults

at or fed from the system under test, transferred potentials

from remote test grounds, and inadvertent line

energisations.

While the probability of the occurrence of one of these

events is low, personnel safety will, nevertheless, be

enhanced by the following:

When working near high tension systems rubber gloves

and safety shoes should be worn.

Work on clean, dry crushed rock or an insulating blanket

or use insulated ladder or insulated lift.

Avoid bare hand to hand contact between the tester and

extended test leads.

INDEX PAGE

SAFETY RULES .................................. 1-2

SAFETY CHECKS ............................... 3

DON'T TOUCH .................................... 3

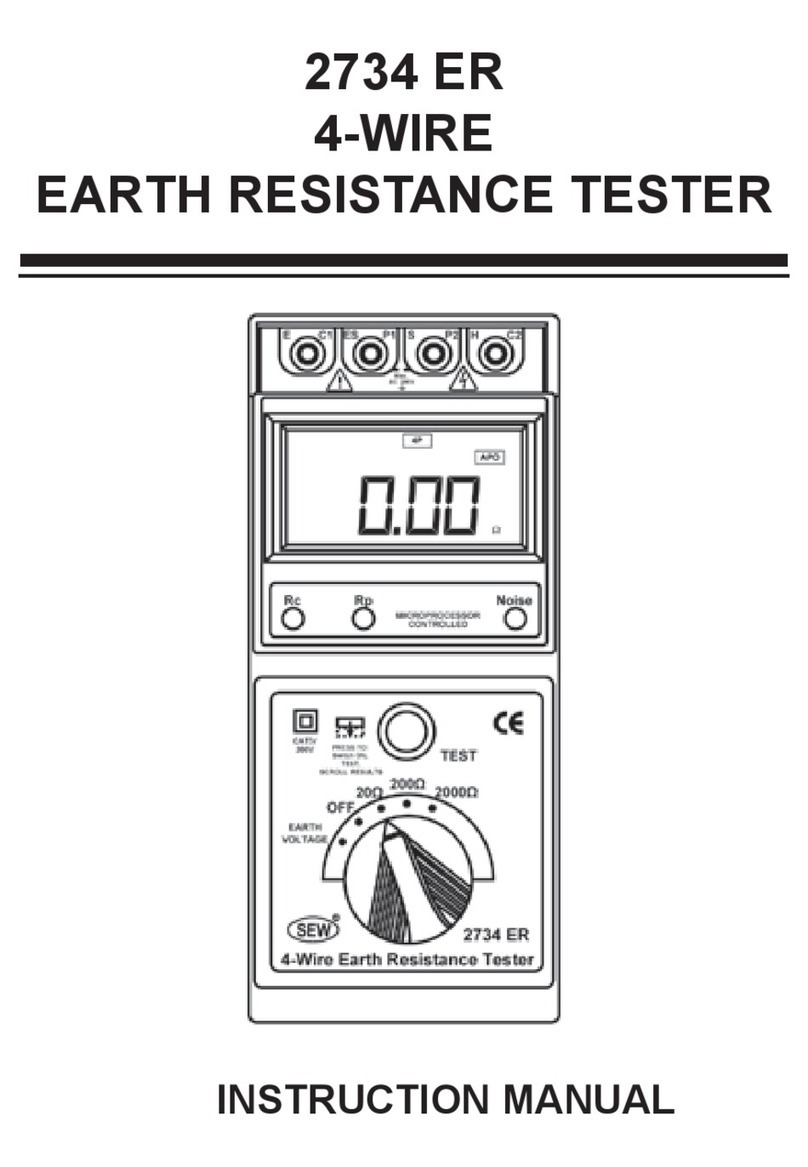

GENERAL DESCRIPTION .................. 4-5

BRIEF PRODUCT DESCRIPTION ...... 6

FEATURES .......................................... 7-8

ACCESSORIES ................................... 8

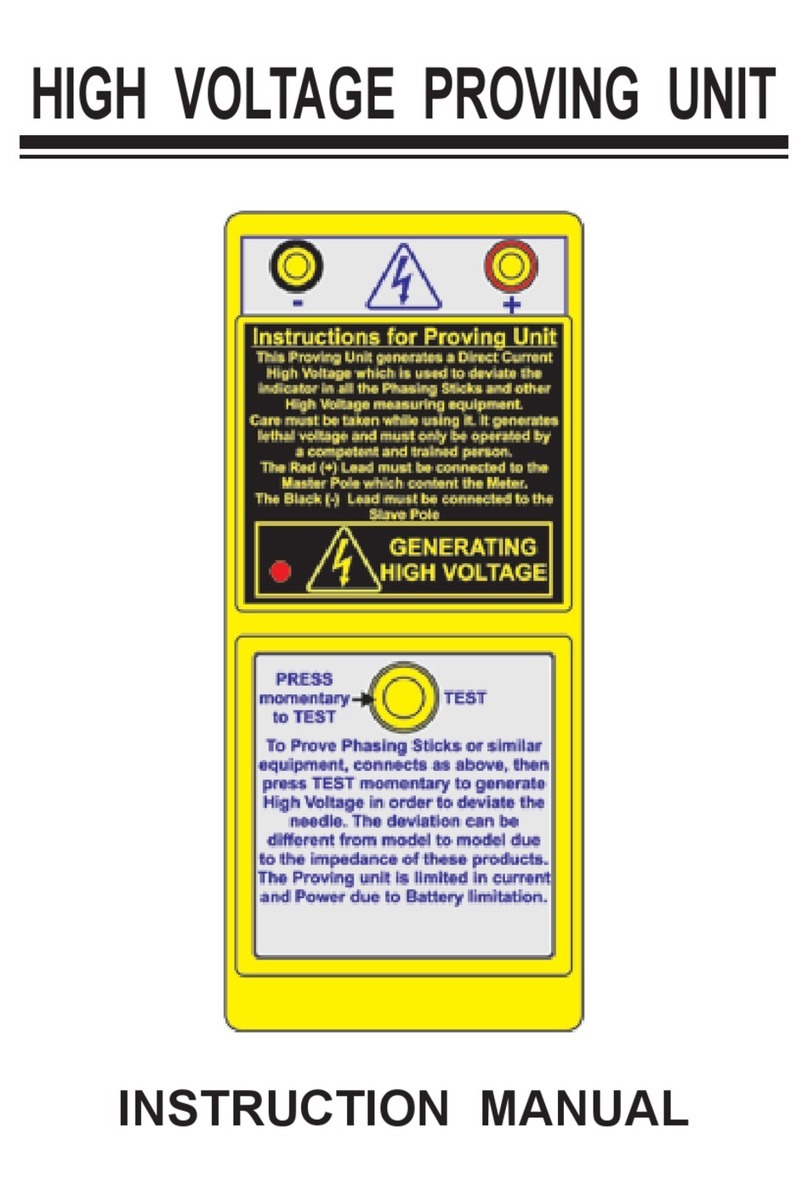

PRE-TESTING PROOFING TEST ....... 8

POST-TESTING PROOFING TEST ..... 9

OPERATING INSTRUCTIONS ............ 10

FACIA LABEL ....................................... 11

SOME APPLICATIONS ........................ 12

PRINCIPLE OF HOW IT WORK-

DISPLAY-RESULTS ............................. 13

FUSE REPLACEMENT ........................ 14

CHANGING TIPS ................................. 14

TAKING CARE OF YOUR DOUBLE

CHECK ................................................. 14

CLEANING ........................................... 14

SPECIFICATIONS ............................... 15

OPTIONS ............................................. 16

LIMITED WARRANTY .......................... 17-18

-1-