r

-·

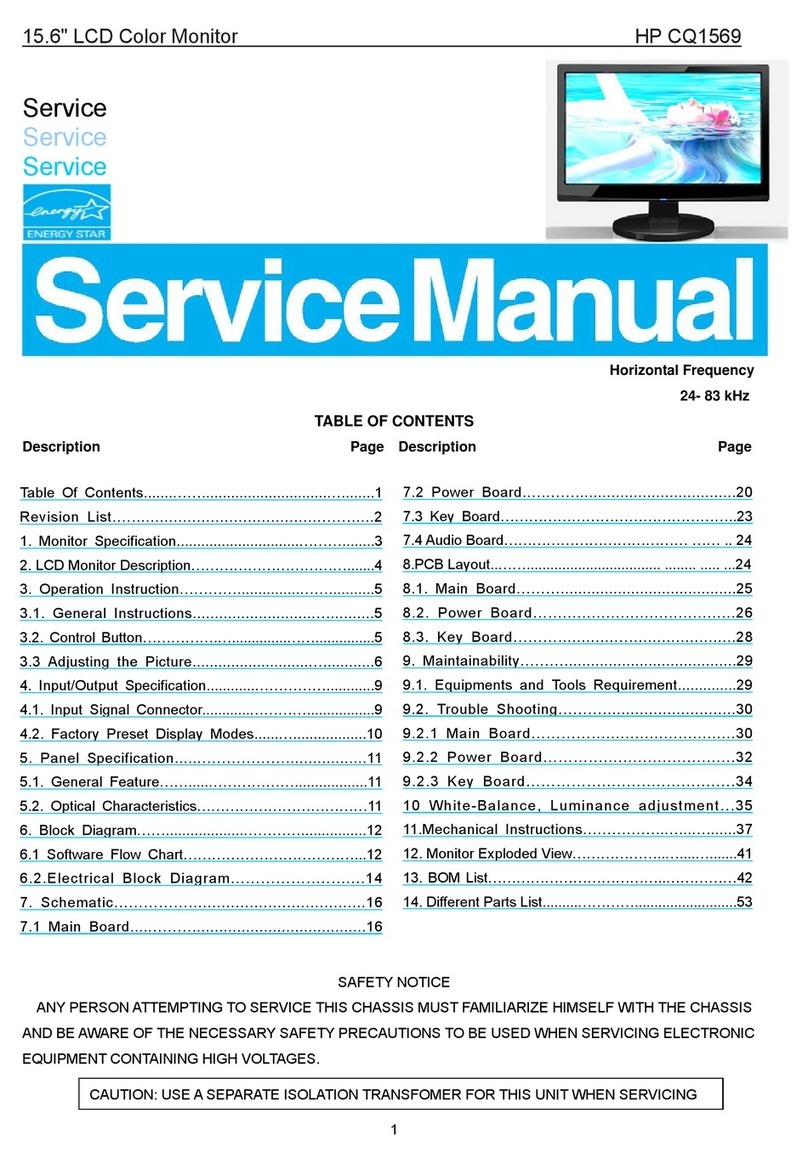

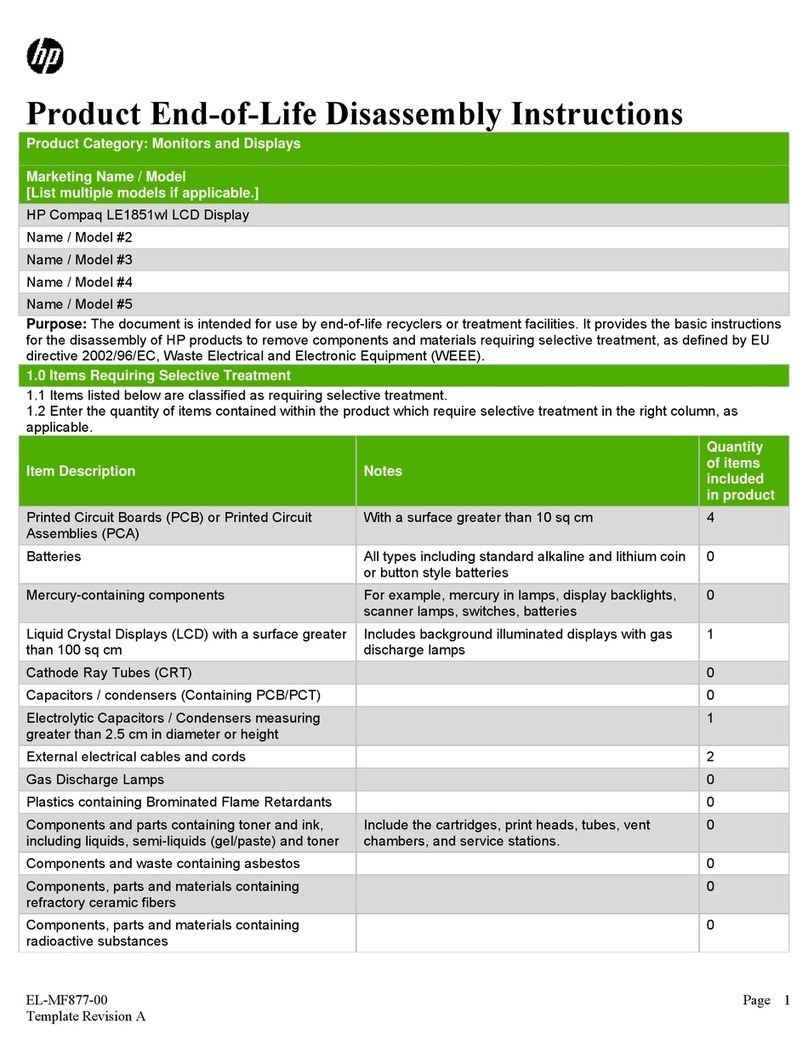

Table

of

Co

ntents

Model 1331A

TABLE

OF

CONTENTS

Section P

age

I

II

III

IV

11

GENERAL

INFORMATION

.....

.

..

....

. 1-1

1-

1.

Introdu

ction . . . . .. . . . .. . . . . .. . . .. 1-1

1-

4.

Description . . . . . . . . . . . . . . . . . . . . . .

1-1

1-10.

Cathode-ray

Tube

................

1-1

1-1

2.

Warranty

....

....

............

...

.

1-1

1-14.

Available

Accessories.

. .

...

.

....

.

1-1

1-16.

Instrument

and

Manu

al

Identifi

cation

. . . . . . . . . . . . . . . . . .

1-1

1-20.

Inquiries.

........

..

...

.

..........

1-3

INSTALLATION.

....

..

...

.

....

..

...

.

...

2-1

2-1.

Introdu

ction

....................

.

2-3

.

Initial

Inspection

...............

.

2-5

.

Preparation

for

Use

..

.

....

.

...

. . .

2-

7.

Rack

Mounting

...........

..

..

.

2-9.

Power

Re

quirements

.......

.

..

.

2-11.

Power

Connections

............

.

2-13.

Instrum

e

nt

Cooling

...........

.

2-17.

Monitored

Inputs

...........

. . .

2-19.

Amplifier

Input

Modifications . .

2-34.

Claims

.

.......

...

..............

. .

2-36.

Repacking

for

Shipm

e

nt

...

.

....

.

OPERATION

...

....

..

...

.

.........

.

....

.

3-1.

Introduction

...

..

.....

.

..

. .

....

. .

3-3.

Controls

and

Connectors

.

.......

.

3-5.

Beam

Find

.

...

................

.

3

-7.

Intensity

.....................

. .

3-9.

Applications

.....

.

.........

.

....

.

3-11.

Preoperational

Adjustments

and

Operator's

Checks .

..

........

. .

3-13.

Operator's

Maintenanc

e

...

.. .. ..

.

3-

15.

Operating

Procedur

es

...........

.

PRINCIPLES

OF

OPERATION

.......

. . .

4-1.

Introdu

ction

....................

.

4-3.

Variable

Persistence

and

Storage

.

4-5.

The

Storage

CRT

.............

.

4-10. Secondary

Emission

Ratio

.

..

. .

4-

12.

Erase

Cycle

...................

.

4-15

.

Variable

Persistence . .

....

.

...

.

4-19

.

Storage

.......

...

.

....

.

.......

.

4-21.

Storage

Precautions

...

.

.......

.

4-23. Block

Diagram

Discussion

.....

.

4-25.

Low Voltage

Power

Supplies . . .

4-27.

High

Voltage Power

Supply

...

.

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-2

2-5

2-5

3-1

3-1

3-1

3-1

3-1

3-2

3-

2

3

-2

3-2

4-1

4-1

4-1

4-1

4-1

4-1

4-2

4-2

4-2

4

-2

4

-2

4-2

Section

Page

v

4-29.

4-31.

4-33.

4-35.

4-37.

4-54.

4-56.

4-64.

4-71.

4-76.

4-78

.

4-82.

X-

and

Y-axis Amplifiers . . . .. . .

4-2

Z-axis Amplifier . . . . . . . . . . . . . . .

4-3

Int

e

nsity

Gat

e . . . . . . .. . . . .. . . . .

4-3

Control

Circuits................

4-3

Pulse

Circuits

..

. . . . . . . . . . . . . . . .

4-3

Detailed

Circuit

Theory

. . . . . . . . . .

4-4

Low

Voltage

Power

Supp

li

es . . .

4-4

High

Voltag

e Power

Supply

. . .

4-5

X-

and

Y-axis Amplifiers

.........

4-5

Z-

axis

Amplifier . . . . . . . . . . . . . . .

4-5

Control

Circuits

. . . . . . . . . . . . . . . .

4-5

Pulse

Circuits.

. . . . . . . . . . . . . . . . .

4-6

PERFORMANCE

CHECKS

AND

ADJUSTMENTS

. . . . . . . . . . . . . . . . . . . . . . 5

-1

5-

1.

Introduction

. . . . . . . . . . . . . . . . . . . . .

5-1

5

-5.

Performance

Check . . . . . . . . . . . . . . 5

-1

5-8. Mode

and

Erase

Checks.

. . . . . . .

5-

2

5-

12.

Deflection

Checks..........

....

5

-2

5-

16.

Phase

Shift

Check

. . . . . . . . . . . . . 5-2

5-2

0.

Common

Mode Rejection

Ratio

(CMRR) Check . . . . . . . . . . . . . . . 5-2

5-2

4.

Bandwidth

Checks

. . . . . . . . . . . . . 5

-3

5-28.

Z-axis Amplifier

Checks.

. . . . . . . 5

-3

5-32.

Erase

Time

Check . . . . . . . . . . . . .

5-4

5-3

6.

Dot

Writing

Time

Check . . . . . . .

5-4

5-40.

Store

Time

Check . . . . . . . . . . 5-5/5-6

5

-44.

Adjustment

....

. .

..

....

.

.....

....

5

-7

5-47. Low

Voltag

e Power

Supply

Adjustments

. . . . . . . . . . . . . . . . . 5-7

5-5

1.

High

Voltage

Power

Supply

Adjustment..

.............

..

. 5-7

5-55. Write Depth

Adjustment

. . . . . . .

5-

7

5;5

9.

Flood

Gun

a

nd

Collimator

Adjustments

. . . . . . . . . . . . . . . . . 5

-8

5-63.

Write

Gun

Intensity

Limit

Adjustment

. . . . . . . . . . . . . . . . . . 5

-8

5-67.

X-

and

Y-axis Amplifier

Gain

Adjustment

...............

.

..

5-8

5-

71.

Phase

Shift

Adjustment

. . . . . . . . 5-8

5

-75.

Writing

Rate

Adjustment

.......

5

-9

5-79. Store

Time

Adjustment..

. .

.....

5

-9

5-83. Z-a

xis

Amplifier Risetime

Adjustment.

. . . . . . . . . . . . . . . . 5-10

5-87.

Calibrating

Modified

Instruments

. . . . . . . . . . . . . . . . . .

5-

10

5-89.

Phase

Shift.

........

.

.........

5-10

5

-91.

Attenuator

Compensation.....

5-10

5-93.

Input

Signal

Amplitudes

. . . . . .

5-11