T

Te

ec

ch

hn

ni

ic

ca

al

l

D

De

es

sc

cr

ri

ip

pt

ti

io

on

n,

,

O

Op

pe

er

ra

at

ti

in

ng

g,

,

M

Ma

ai

in

nt

te

en

na

an

nc

ce

e

a

an

nd

d

R

Re

ep

pa

ai

ir

r

M

Ma

an

nu

ua

al

l

Document No.: 304S/MM

Date of Issue: 08/14

ii

H

H

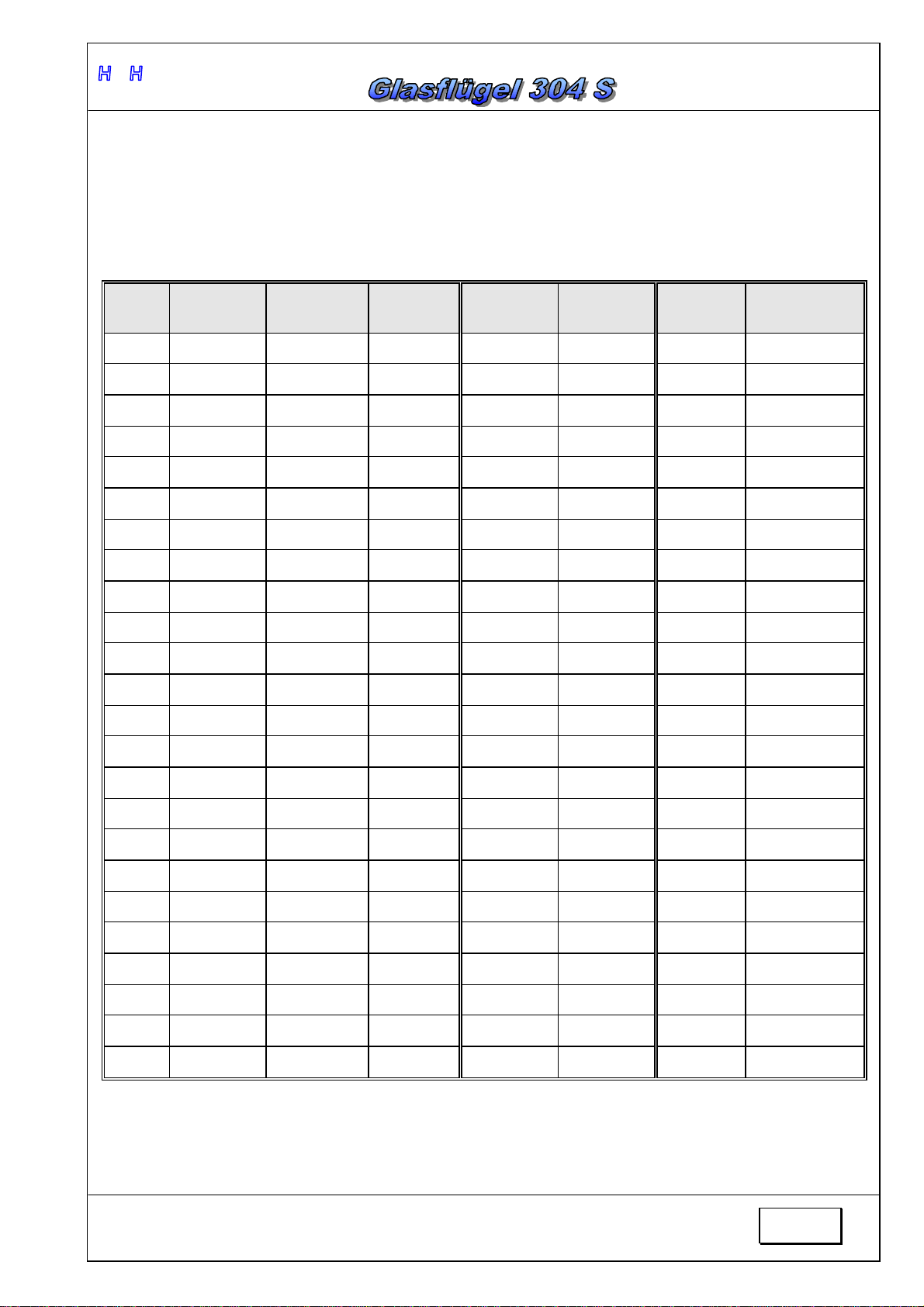

Table of Contents

P

AGE

0.1

L

IST OF

E

FFECTIVE

P

AGES

...........................................................................................................

IV

0.2

R

ECORDOF REVISIONS

.................................................................................................................

V

1.

BASIC TECHNICAL DATA.....................................................................................................1-0

1.1

B

ASIC

T

ECHNICAL DATA

.............................................................................................................1-1

1.2

T

ECHNICAL

D

ESCRIPTION

..........................................................................................................1-2

1.2.1

Fuselage.............................................................................................................................1-2

1.2.2

Wing...................................................................................................................................1-2

1.2.3

Horizontal Tail Unit...............................................................................................................1-2

1.2.4

Vertical Tail Unit...................................................................................................................1-2

1.2.5

Water ballast system............................................................................................................1-2

1.3

S

AILPLANESYSTEMS

.................................................................................................................1-3

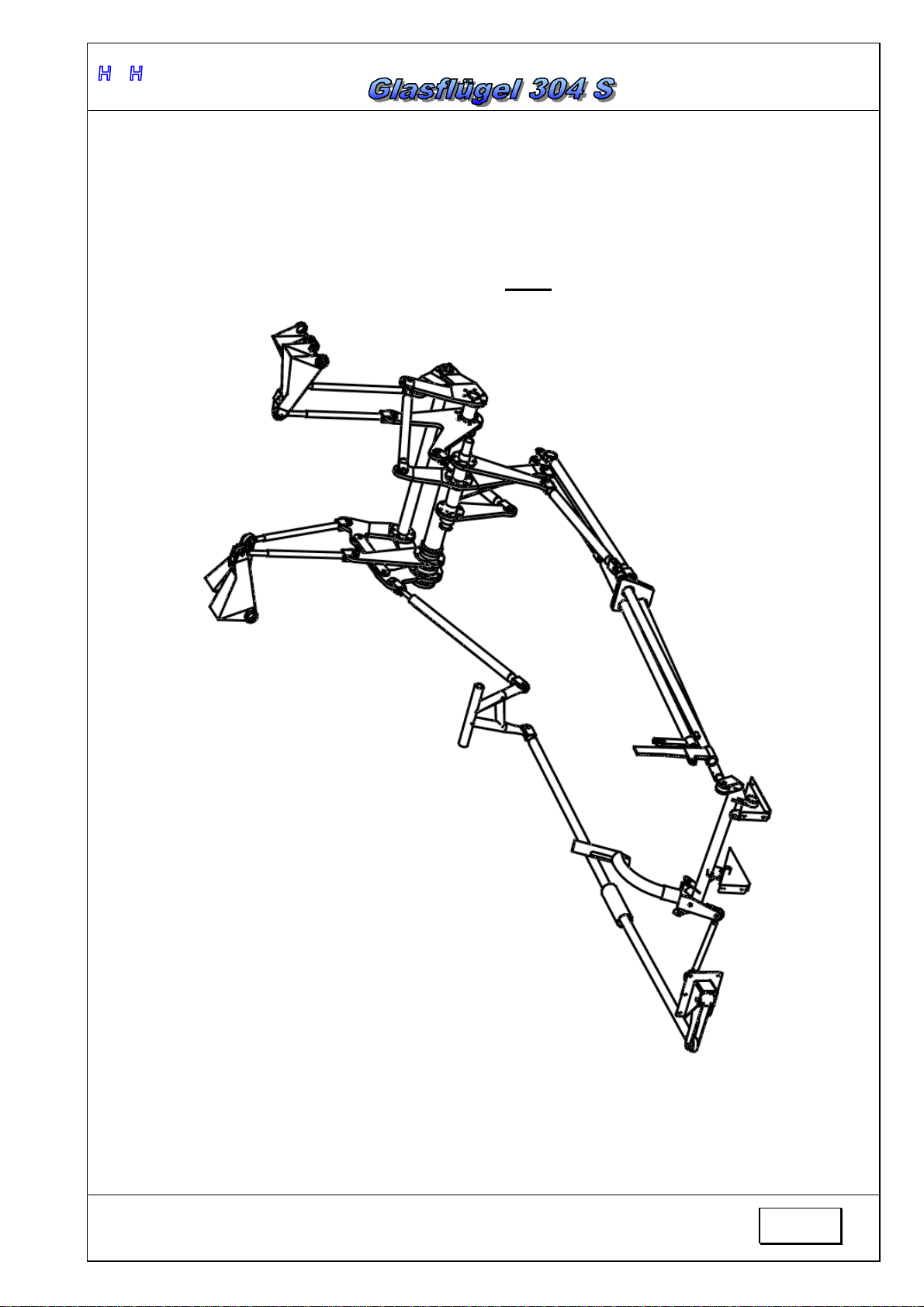

1.3.1

Control systems in the fuselage ............................................................................................1-3

1.3.2

Control systems in the wing..................................................................................................1-4

1.3.3

Rudder control system..........................................................................................................1-5

1.3.4

Main landing gear system.....................................................................................................1-6

1.3.5

Control surface deflections and dimensions ...........................................................................1-7

1.3.6

Electric system ....................................................................................................................1-8

2.

HANGARING, TRANSPORT, RIGGING..................................................................................2-0

2.1.1

Hangaring, Parking, and Ground Handling.............................................................................2-1

2.2

R

IGGING

.................................................................................................................................2-2

2.3

D

E

-

RIGGING

.............................................................................................................................2-3

3.

MAINTENANCE.....................................................................................................................3-0

3.1

M

ANDATORY

M

AINTENANCE

.......................................................................................................3-1

3.2

R

EGULAR

M

AINTENANCE

...........................................................................................................3-2

3.3

S

PECIAL

I

NSPECTION

P

ROCEDURE

..............................................................................................3-4

3.3.1

After hard landing and ground loops......................................................................................3-4

3.4

F

REE

P

LAY IN THE

C

ONTROL

C

IRCUITS

........................................................................................3-5

3.5

F

REE

P

LAY IN

W

ING AND

T

AIL PLANE

A

TTACHMENTS

......................................................................3-6

3.6

P

RIMARY AND SECONDARY STRUCTURES

......................................................................................3-6

3.7

D

AMAGE

.................................................................................................................................3-6

3.8

R

EPAIRS

.................................................................................................................................3-7

3.9

R

EMOVALAND

R

E

-I

NSTALLATION OF

R

ELEASES

.............................................................................3-8

3.10

C

ONTROL

S

URFACE

M

OMENTS

...................................................................................................3-9

3.11

P

LACARDS AND MARKINGS IN THE

C

OCKPIT

.................................................................................3-10

3.12

C

LEANING AND CARE

...............................................................................................................3-11

3.13

L

UBRICATIONSCHEME

.............................................................................................................3-12

3.14

T

IGHTENING

T

ORQUE

M

OMENTS

T

ABLE

.....................................................................................3-13

3.15

S

AFETY

H

ARNESS

..................................................................................................................3-13

3.16

P

ITOT AND

S

TATIC

L

INES AND

I

NSTRUMENT

C

ONNECTIONS

...........................................................3-14

3.17

L

IST OF INSTRUMENTS

.............................................................................................................3-15

3.17.1

Airspeed Indicators.........................................................................................................3-15

3.17.2

Altimeters.......................................................................................................................3-15

3.17.3

Variometers....................................................................................................................3-15

3.17.4

Magnetic Compasses......................................................................................................3-15

3.17.5

Turn and Bank Indicators ................................................................................................3-15

3.17.6

COMM...........................................................................................................................3-16

3.17.7

Transponders.................................................................................................................3-16

3.18

O

XYGENSYSTEM

....................................................................................................................3-17

3.19

S

ERVICE INSTRUCTIONS

..........................................................................................................3-17

3.20

L

IST OF SPECIAL TOOLS

...........................................................................................................3-17

4.

AIRWORTHINESS LIMITATIONS...........................................................................................4-0