Model 300 - 5

d/b/a Hydraulic Power Systems • Phone: (816) 221- 4774 • hydraulicpowersystems.com

1.1 Warranty

GeoQuip Power Systems, LLC hereby warrants that the Model 300 is free from defects in material and workmanship attributable

to GeoQuip Power Systems, LLC under normal use and service for a period of ninety (90) days from date of delivery of such

machine.

THE EXCLUSIVE REMEDY OF THE BUYER UNDER THIS WARRANTY is the repair or replacement, without charge, of any

defective part or parts of this machine as long as buyer noties GeoQuip Power Systems, LLC by registered mail of such defect

within seventy-ve (75) days from the date of delivery of this machine.

Any part or parts claimed to be defective must be shipped to the GeoQuip Power Systems, LLC factory at 1203 Ozark, N. Kansas

City, Missouri 64116, transportation prepaid. The GeoQuip Power Systems, LLC acceptance of any part so shipped shall not be

deemed an admission that the part is defective, and if GeoQuip Power Systems, LLC nds that any part returned is not defective,

such part shall be re-shipped to the Buyer at Buyer’s expense.

THE BUYER’S SOLE AND EXCLUSIVE REMEDY AGAINST GeoQuip Power Systems, LLC UNDER THIS WARRANTY shall be for

the REPAIR OR REPLACEMENT of defective parts as provided above. THE BUYER AGREES THAT NO OTHER REMEDY, INCLUDING,

BUT NOT LIMITED TO, INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR LOST PROFITS, LOST SALES, INJURY TO PERSONS OR

PROPERTY OR OTHER INCIDENTAL OR CONSEQUENTIAL LOSS SHALL BE AVAILABLE TO THE BUYER.

THE SOLE PURPOSE OF THE STIPULATED EXCLUSIVE REMEDY shall be to provide the Buyer with free repair or replacement

of defective parts in the manner provided herein. This EXCLUSIVE REMEDY shall not be deemed to fail of its essential purpose so

long as GeoQuip Power Systems, LLC is willing and able to repair or replace defective parts in the prescribed manner. THE BUYER

SHALL NOT BE REQUIRED TO DELIVER A DEFECTIVE PART TO GeoQuip Power Systems, LLC IF:

(1)The part was destroyed as a result of its defect in any party covered in the warranty.

AND

(2)GeoQuip Power Systems, LLC is reasonably satised that the part was defective at the time of sale.

If both of these conditions are met, GeoQuip Power Systems, LLC shall replace the part in the same manner provided herein as if

the Buyer had delivered it to GeoQuip Power Systems, LLC at its factory.

THIS WARRANTY SHALL NOT APPLY to any machinery which has suered abuse, misuse, neglect or accident or to any

machinery which has been altered so as to aect its ability or reliability, (except where such alteration has been accomplished with

the prior written consent of GeoQuip Power Systems, LLC) or which has been repaired in any way by the Buyer without the prior

written consent of GeoQuip Power Systems, LLC or which has been negligently installed by the Buyer.

WARNING: THIS PRODUCT IS NOT TO BE USED IN ANY FASHION DIFFERENT FROM THAT WHICH BUYER HAS ADVISED

SELLER SHALL BE ITS INTENDED USE. NO WARRANTY CONVEYED HEREIN SHALL APPLY TO A USE OTHER THAN THAT WHICH

BUYER HAS INDICATED TO SELLER AT THE TIME OF PURCHASE.

SELLER DOES NOT WARRANT PRODUCTS MANUFACTURED BY OTHER MANUFACTURERS WHICH MAY BE USED IN THE

ASSEMBLY OF THE TOTAL PRODUCT SOLD BY SELLER, BUYER’S SOLE REMEDY AS TO PRODUCTS MANUFACTURED BY

OTHERS SHALL BE PURSUED WITH SUCH OTHER COMPONENT PRODUCT MANUFACTURERS.

THE BUYER EXPRESSLY UNDERSTANDS THAT GeoQuip Power Systems, LLC HAS MADE NO EXPRESSED OR IMPLIED

WARRANTIES, INCLUDING, BUT NOT LIMITED TO, IMPLIED OR EXPRESSED WARRANTIES FOR MERCHANTABILITY OR FITNESS,

OTHER THAN THE EXPRESSED WARRANTY SET FORTH ABOVE. THE SELLER, HEREBY, DISCLAIMS ALL OTHER EXPRESSED

WARRANTIES, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, AND ALL OTHER

IMPLIED WARRANTIES.

Any oral statements made by any person about the machine described in the Agreement DO NOT CONSTITUTE WARRANTIES

and are not part of this Agreement. The entire Agreement between the parties hereto is embodied in this writing. This writing

constitutes the nal expression of the parties’ Agreement, and it is a COMPLETE AND EXCLUSIVE STATEMENT of the terms of that

Agreement. All oral or written agreements between the parties made prior to the execution of this Agreement are hereby merged

herein. This Agreement SHALL NOT BE MODIFIED OR ALTERED in any way other than by writing, signed by the parties to the

Agreement, their successors or authorized agents, and this Agreement SHALL NOT BE VARIED, SUPPLEMENTED, QUALIFIED,

EXPLAINED, OR INTERPRETED BY ANY PRIOR COURSE OR DEALING BETWEEN THE PARTIES OR BY ANY USAGE OF TRADE.

GeoQuip Power Systems, LLC

1203 Ozark

North Kansas City, Missouri 64116

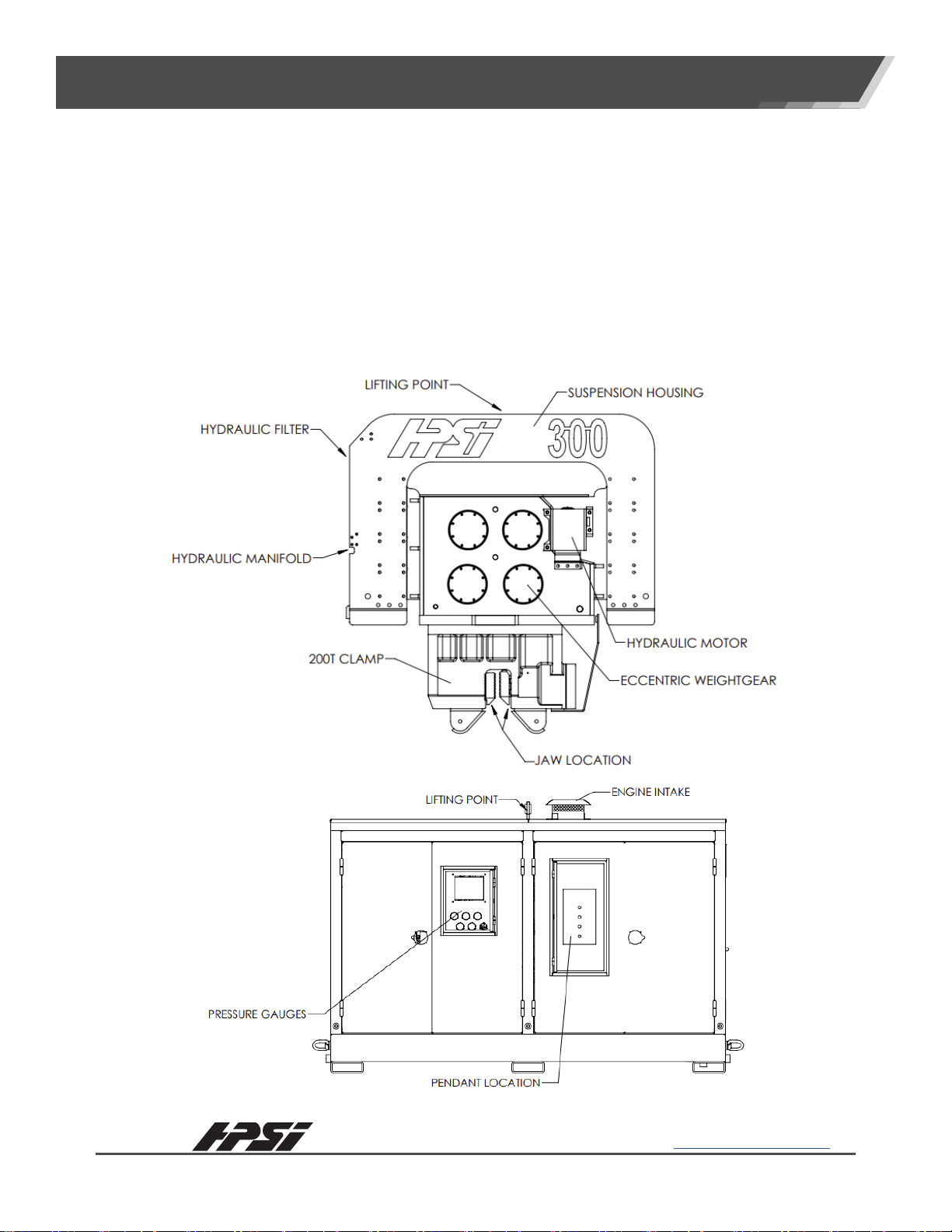

GENERAL INFORMATION