1

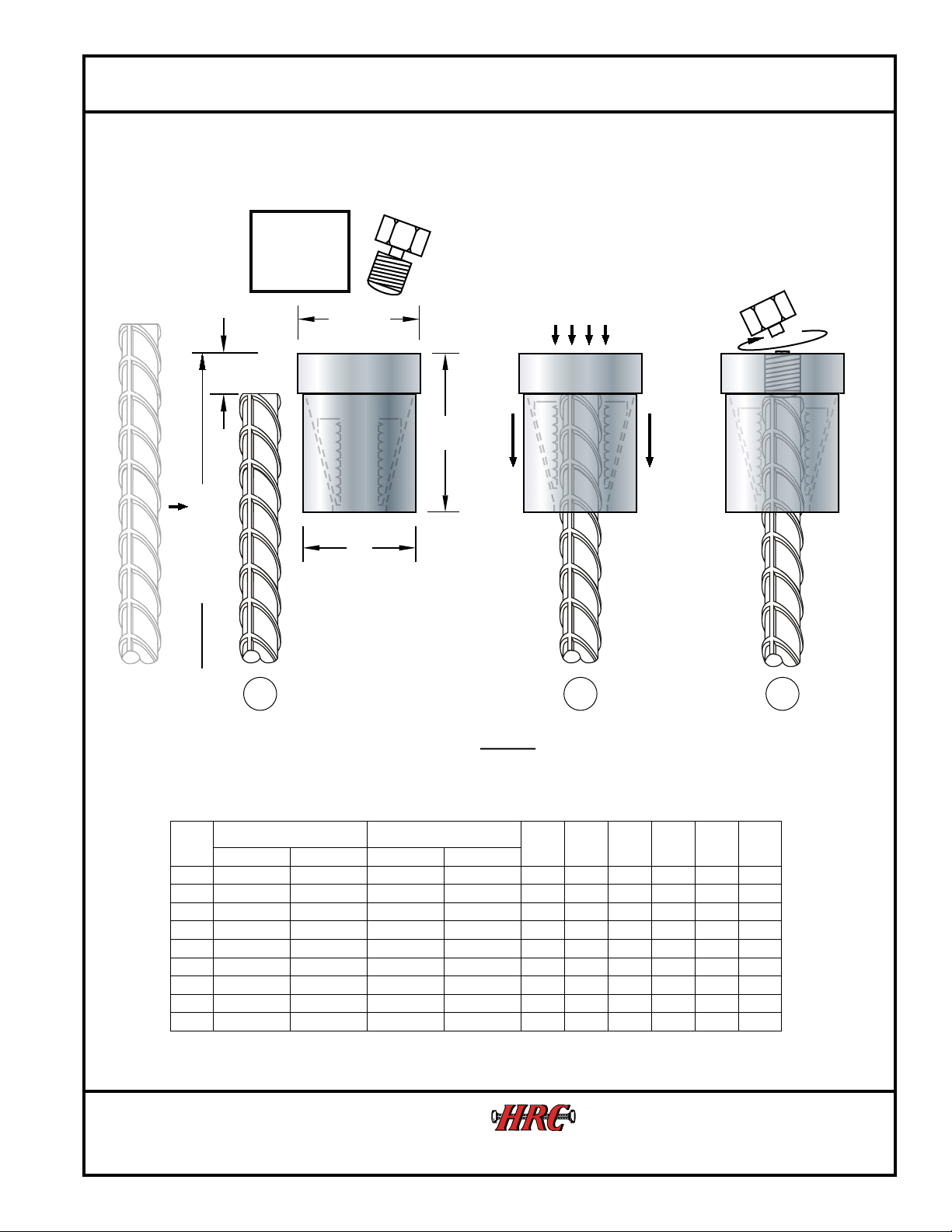

D1[in] D2[in] DL[in] L[in] X[in]

1.5

1.75

2.08

2.375

2.625

3.0

3.5

4.0

5.25

1.75

1.875

2.25

2.5

2.75

3.25

3.625

4.0

5.25

2.0

2.5

2.875

3.25

3.625

4.0

4.5

5.5

7.25

2.0

2.313

2.75

3.125

3.375

3.5

4.0

5.0

6.5

0.5

0.5

0.625

0.625

0.75

0.875

1.0

1.07

1.07

Bolt

Socket

Size

¾ in

¾ in

¾ in

1 in

1 in

1 ¼ in

1 ½ in

1 ½ in

1 ½ in

min yield[lbs]

18,600

26,400

36,000

47,400

60,000

76,200

93,600

135,000

240,000

min tensile*[lbs]

24,800

35,200

48,000

63,200

80,000

101,600

124,800

180,000

320,000

min yield[lbs]

24,800

35,200

48,000

63,200

80,000

101,600

124,800

180,000

320,000

min tensile*[lbs]

31,000

44,000

60,000

79,000

100,000

127,000

156,000

225,000

400,000

#5

#6

#7

#8

#9

#10

#11

#14

#18

A706/A615* Grade 60 A615/A706* Grade 80

Bar

Size

All data subject to change without notice. Patent No.: US 9,091,064 B1

* The lower min tensile strength of the 2 specs shown (A706).

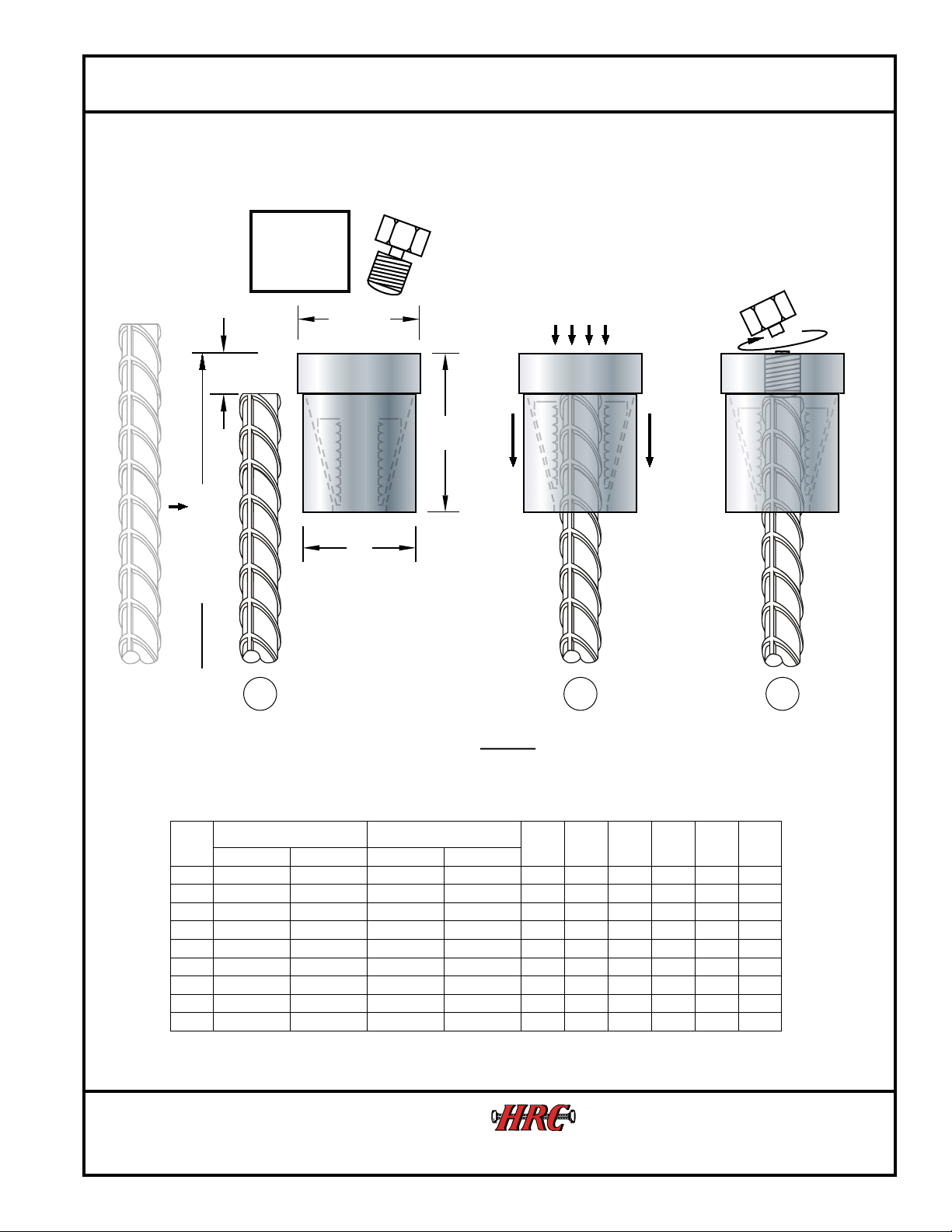

Cut bar to desired elevation -X”

Clean debris and concrete off

bar end. Grind down burrs and

imperfections if necessary.

Push HRC 670 onto bar,

without bolt, until it bottoms

out. Verify bar end is up

against bolt hole. Hammer

down if necessary.

R e - i n s e rt b o lt a n d

torque until bolt head

breaks off.**

No Special Equipment Needed

X

Finished Length

L

D1

d

D2or DL

2 3

**Although the bolt torque secures the HRC 670 from longitudinal movement in tension and compression, it may be possible to rotate the device around the bar axis.

Remove

Bolt

Before

Installation

Rebar fixed in concrete or manually fixed to prevent rotation

HEADED REINFORCEMENT CORP.

1-800-HRC-6775

11200 Condor Ave., Fountain Valley, CA. 92708, USA

®

Installation Procedure HRC 670

(Approx.)

/HRC Work/670 Installation procedure.cvx Rev. 08/2018

SAFETY FIRST! In all cases, follow jobsite safety plans and consider your own personal safety. Make sure you

are wearing PPE, and are securely positioned so that you will not slip or fall during installation.

* See reverse side for California Proposition 65 warning.