4.4 LUBRICATION

Use motor oil or grease to lubricate all moveable parts.

5. GUIDE TO SAFETY OPERATION

For safe operation of the Hand Pallet Truck, please read all warning signs and instructions

here and on the pallet truck prior to use.

5.1 Do not operate the pallet truck unless you are familiar with it and have been trained or

authorized to do so.

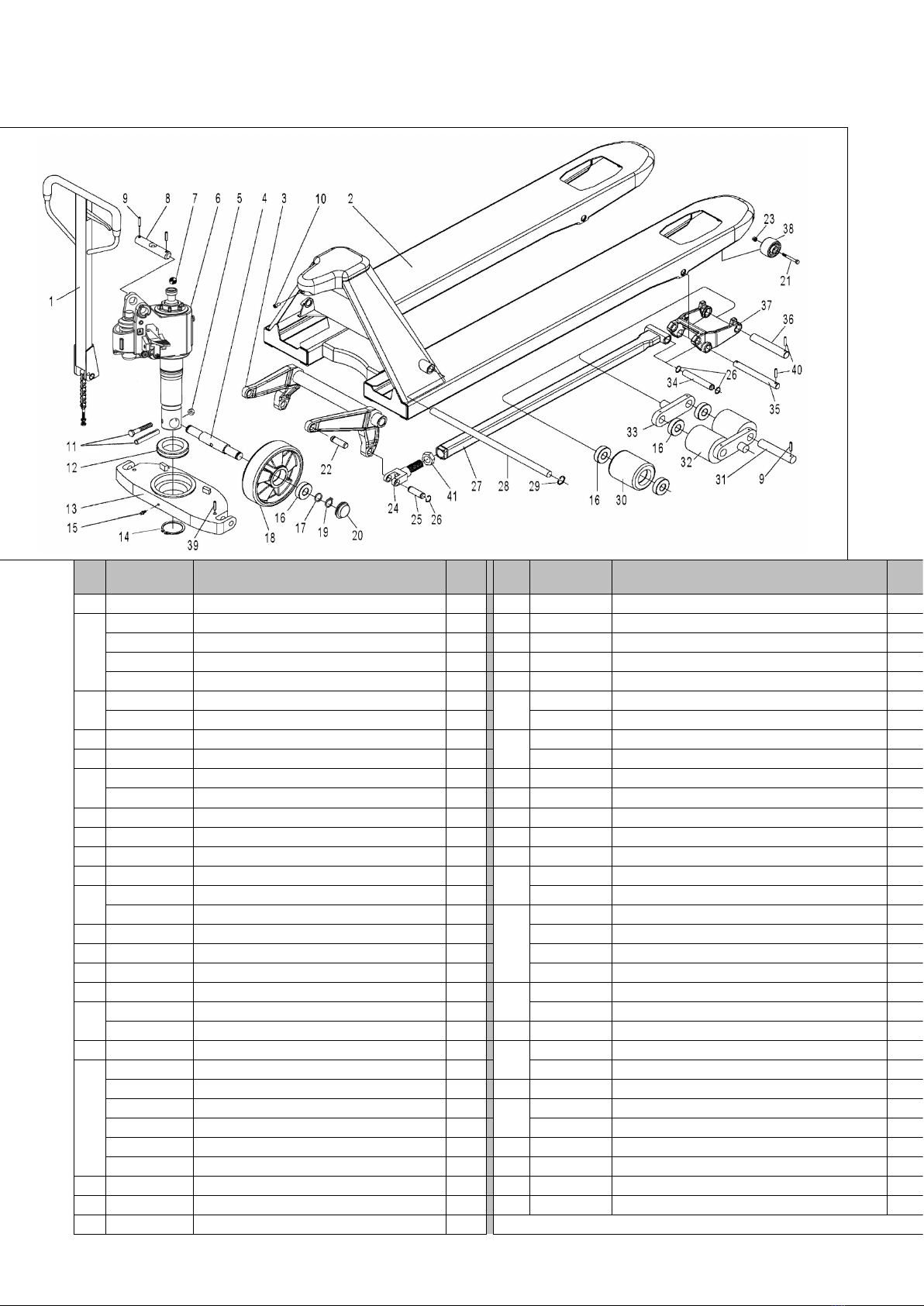

5.2 Do not operate the truck unless you have been trained and authorized. Give special attention to

the wheels, the handle assembly, the forks, and the lower control.

5.3 Do not use the truck on sloping or uneven ground.

5.4 Never place any part of your body in the lifting mechanism or under the forks or load. Do not

carry passengers.

5.5 We advise that operators should wear gloves and safety shoes.

5.6 Do not handle unstable or loosely stacked loads.

5.7 Do not overload the truck.

5.8 Always place loads centrally across the forks and not at the end of the forks (See Fig. 2).

5.9 The capacity of the truck assumes an evenly distributed load with the centre of the load being

at the halfway point of the length of the forks.

5.10 Make sure that length of the forks matches the length of the pallet.

5.11 Lower the forks to lowest height when the truck is not being used.

5.12 In other specific conditions the operators should take extra care in operating the truck.

6. TROUBLES SHOOTING

The forks can

not reach the

max. height.

- The hydraulic oil is insufficient.- Top up the oil reservoir.

The forks can

not be lifted up.

-No hydraulic oil.

- The oil has impurities.

- The nut is too high or the screw is too

close, keep the pumping valve open.

- Air within the hydraulic oil.

- Fill with hydraulic oil.

- Change the oil.

- Adjust the nut or the

screw .(see item 3.4)

-Remove the air.(see item 4.2)

The forks

can not

be lowered.

- The piston rod or pump body is

deformed resulting from partial loading

slanting to one side or over-loading.

- The fork was kept in the high position

for long time with piston rod exposed

causing corrosion and jamming of the

rod in position.

- The adjusting nut or the screw is not

in the correct position.

- Replace the piston rod or

pump body.

- Keeping the fork in the

lowest position if not using,

and pay attention to lubricate

the rod.

- Adjust the nut or the

screw.(see item 3.3)

- Sealing parts worn or damaged.

- Some part cracked or worn .

- Replace with the new one.

- Replace with the new one.