Contence

1.0 Warranty............................................................................................................................................ 3

1.1 Out of Warranty Service.................................................................................................................... 4

1.2 Repair Facilities and Parts ................................................................................................................. 4

1.3 Safety Information............................................................................................................................. 4

1.4 Use Proper Input Plug........................................................................................................................ 4

1.5 Make Proper Connections................................................................................................................. 4

1.6 Observe All Terminal Ratings ............................................................................................................ 4

1.8 Avoid Exposed Circuitry..................................................................................................................... 4

1.9 Do Not Operate with Suspected Failures .......................................................................................... 4

1.10 Orient the Equipment Properly....................................................................................................... 4

1.11 Place Product in Proper Environment ............................................................................................. 5

1.12 Observe all Warning Labels on Product .......................................................................................... 5

1.13 Caution Notice................................................................................................................................. 5

1.14 Compliance...................................................................................................................................... 5

1.15 Copyright ......................................................................................................................................... 5

1.16 Trademarks...................................................................................................................................... 5

2.0 Introduction....................................................................................................................................... 6

2.1 Preliminary notes on the pump system ............................................................................................ 6

2.2 Range of application and safety precautions .................................................................................... 7

2.3 Residual risks ..................................................................................................................................... 7

2.4 List of items supplied......................................................................................................................... 8

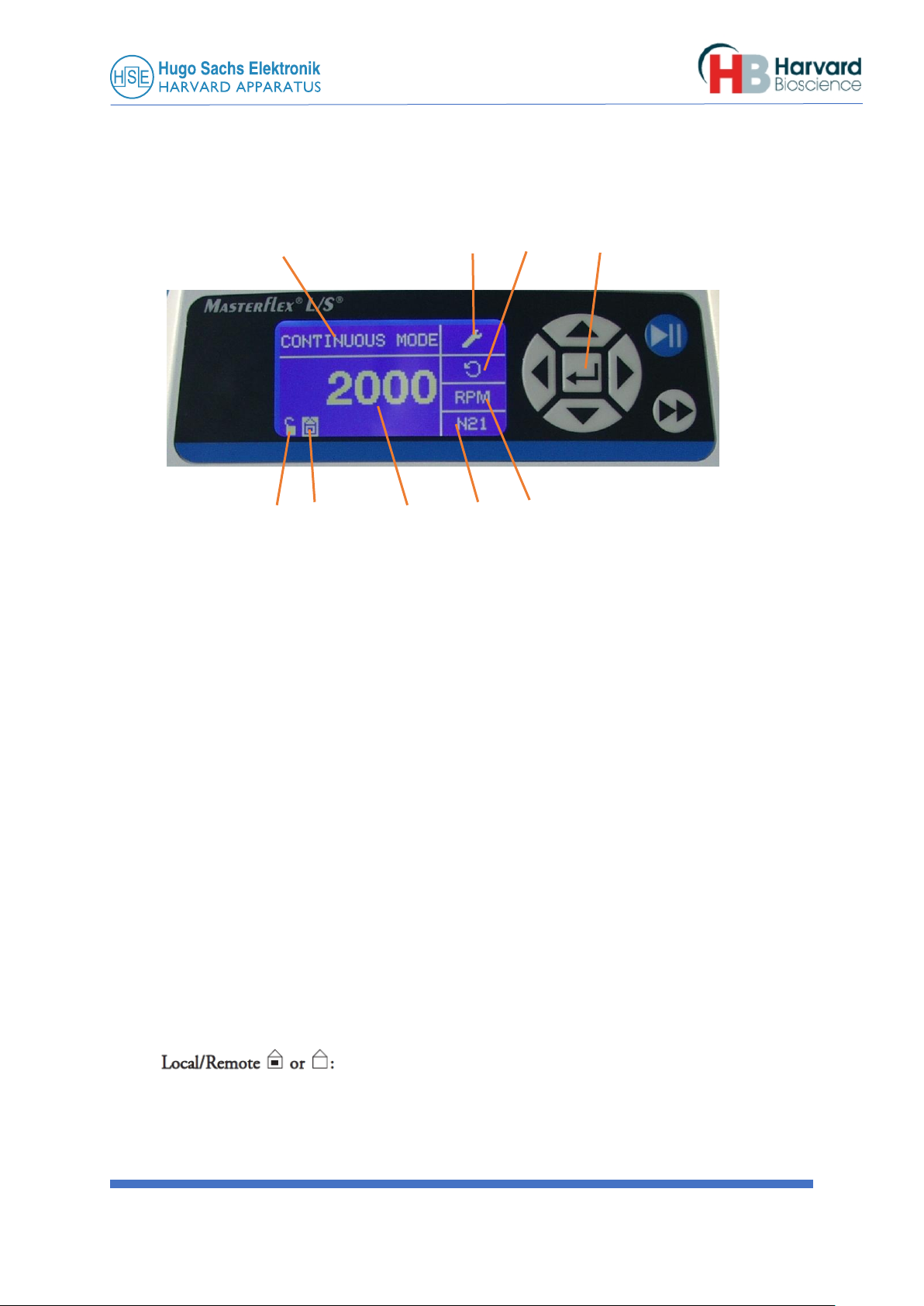

3.0 Operating panel................................................................................................................................. 8

3.1 Starting up Overview....................................................................................................................... 10

3.3 Filling Pump Head bubble free ........................................................................................................ 14

4.0 Application example: Controlling the Centrifugal Pump by PLUGSYS SCP module i.o. to perform a

constant pressure perfusion ................................................................................................................. 16

5.0 Analog interface connector............................................................................................................. 17

6.0 Centrifugal pump head.................................................................................................................... 17

6.1 Output characteristic of an AP40 pump head................................................................................. 18

6.2 Fitting and removing the AP40 pump head .................................................................................... 19

7.0 Operating notes............................................................................................................................... 22

8.0 Maintenance and cleaning .............................................................................................................. 23