For advice on the safety and suitability of this equipment

contact your local HSS Lift & Shift Depot.

There is a serious risk of personal injury if you do

not follow all instructions laid down in this guide.

This equipment is designed to be used by an able

bodied, competent adult who has read and

understood these instructions. Anyone with either a

temporary or permanent disability should seek expert

advice before using it.

Keep children, animals and bystanders away from

the work area. Cordon off a NO GO area using

cones and either barriers or tape, available for hire

from your local HSS Lift & Shift Depot.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Wear practical, protective clothing,

gloves, footwear and a protective

hard hat. Avoid loose garments and jewellery that could

catch in moving parts, tie back long hair.

Prevent hook overcrowding, with a ‘Bow’

shackle. Join lifting equipment with a ‘D’

shackle. Protect sharp edges to prevent load damage.

Use this equipment for vertical lifts only and

use on a level area able to take the combined

weight of the load and the equipment.

May be used at any angle for lifting, dragging

or pulling. Anchor to a safe, secure point able

to take the load force applied. Allow for contact

friction if dragging.

Ensure the load is balanced, stable and that

personnel stand clear of the raised load.

Use this type of equipment only on structures that

are able to bear its weight and its load.

Make sure you know how to operate this

equipment safely and are aware of its limitations

before you use it.

It is both the hirer’s and the operator’s responsibility

to perform a risk assessment before using this

equipment. You are also responsible for the safety of any

person in the work area.

Make sure that anyone in the immediate work area

is warned of what you are doing.

SAFETY WARNING

This equipment MUST NOT be used to carry or

lift personnel.

GENERAL SAFETY Do not shock load this equipment.

Never leave the equipment loaded or unattended.

Make sure the landing area is unobstructed and

able to accept the load in size and weight.

Never exceed the equipment’s safe working load,

see chart.

Always switch OFF and unplug the machine

before making adjustments to it.

Never carry or pull the equipment by its power

supply cable.

Check the condition of the equipment before use.

If it shows signs of damage or excessive wear, return it to

your local HSS Lift & Shift Depot.

HSS Electric Hoists must be provided with a

suitable 110V generated supply, or powered from

the mains via a suitable 110V transformer (minimum

3kVA tool rating).

If the equipment fails, or if its power supply cable or plug

becomes damaged, return it. Never try to repair it yourself.

Keep cables out of harm’s way, and clear of the work area.

Extension leads should be avoided, however, if

you have no alternative ensure it is fully unwound

and loosely coiled, away from the equipment.

ELECTRICAL SAFETY

Never run leads through water, over sharp edges or

where they could trip someone.

Using electrical equipment in very damp or wet

conditions can be dangerous.

To reduce the risk of electric shock, always

use a suitable RCD (Residual Current-Operated

Device) available from your local HSS Lift & Shift Depot.

Ensure the power socket is switched OFF before

plugging into the power supply.

Most HSS pneumatic hoists require a 125 cfm

compressor to run them. The air connections used

are the claw type quick action couplings.

If the tool fails, or if its hose or coupling gets

damaged, return it. Never try to repair it yourself.

Keep the air hose/s out of harm’s way, keep it clear

of moving parts. Never run them through water, over

sharp edges or where they could trip someone.

Never carry or pull the equipment by its air hose.

Never allow compressed air to travel down an air

hose which is not connected to an air tool or

securely anchored, this may cause personal injury.

Ensure the air supply is turned OFF before

connecting or disconnecting it from the air hose.

Isolate it from the air supply before making

any adjustments.

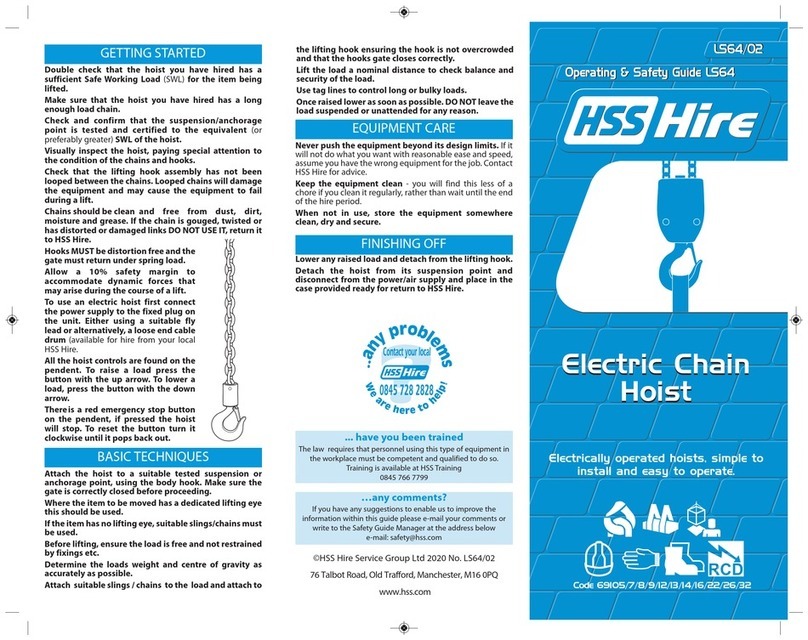

Double check that the hoist you have hired has a

sufficient Safe Working Load (SWL) for the item

being lifted.

Make sure that the hoist you have hired has a long

enough load chain.

Check and confirm that the suspension/anchorage

point is tested and certified to the equivalent (or

preferably greater) SWL of the hoist.

Visually inspect the hoist, paying special attention

to the condition of the chains and hooks.

Check that the lifting hook assembly has not been

looped between the chains. Looped chains will

damage the equipment and may cause the

equipment to fail during a lift.

Chains should be clean and free from dust,

dirt, moisture and grease. If the chain is gouged,

twisted or has distorted or damaged links DO

NOT USE IT, return it to your local HSS Lift &

Shift Depot.

Hooks MUST be distortion free and the gate must

return under spring load.

GETTING STARTED

AIR SAFETY

Comm SWL Height of

Code (kg) Lift (m)

Pneumatic Model

68931 1,000 10

68932 1,000 20

68961 6,000 10

68962 6,000 20

Comm SWL Height of

Code (ton) Lift (m)

Electric Model

69104 0.5 6

69105 0.5 9

69107 0.5 12

69108 0.5 15

69109 0.5 25

69111 1.0 6

69112 1.0 9

69113 1.0 12

69114 1.0 15

69116 1.0 25

69121 2.0 6

69122 2.0 12

69126 2.0 25

69132 3.0 15