Jefferson Professional Tools & Equipment JEFPOWH250 User manual

User Manual

v.1.1

JEFPOWH250

250KG

POWER HOIST

2www.jeffersontools.com

USER GUIDE v1.1

JEFPOWH250

250kg POWER HOIST

Please read and ensure that you understand all of the

operating instructions, safety precautions and warnings

in this user guide before operating or maintaining this

equipment. Keep a copy of this user guide with the

equipment for future reference.

An accident can often be avoided by recognizing a

potentially hazardous situation before it occurs, and by

observing appropriate safety procedures. Never use this

equipment or modify it for any other use other than that

which it has been designed to perform.

Contact Jefferson Tools for all information relating to the

repair and maintenance of this equipment. Contact a

qualied electrician for advice on any issues relating to

electrical safety in your working environment.

EQUIPMENT OVERVIEW

• Compact, general purpose electric power hoist

• Fitted with a powerful 540W Motor

• Ideal for all manner of lifting work

• Strong Ø3mm x 12M twist-free cable

• 125kg (Single) or 250kg (Double) lifting capacity

• Easy to install & supplied with xing clamps for tting the hoist

on square box section beams

• Includes remote control for convenient operation

• Approved and tested to EU and UK Lifting Gear Regulations

SPECIFICATIONS

Model Number: JEFPOWH250

Load Capacity: 125kg • 250kg

Lifting Height: 12M • 6M

Lifting Speed: 10M / Min • 5M / Min

Cable Diameter / Length: Ø3mm x 12M

Voltage ~ Frequency: 230V ~ 50Hz

Input Power: 540W

Ingress Protection: IP54

Insulation Class: B

Weight: 11kg

USER GUIDE v1.1

JEFPOWH250

250kg POWER HOIST

EQUIPMENT IDENTIFICATION

The key parts and features of the power hoist are indicated in Fig.1

and identied in the table below:

1Fixing Clamps

2540W Motor

3Power Cable

4BS1363/A 13 Amp

UK 3-Pin Plug

5Remote Control Handle

6Lift-Lower Control Switch

7 Emergency Stop Button

8a Lifting Hook

8b Hook Safety Bar

9Cable Block

10 Ø3mm x 12M Cable

11 Limit Frame

12 Cable Roll

EQUIPMENT SAFETY

The following safety guidelines will help to ensure safe use of this

equipment:

• This hoist should only be operated by competent and trained

individuals who have read this user guide and who have a thorough

knowledge of the safe operation of the equipment.

• The hoist should be installed in a dry work location free from frost

and low temperatures and explosive materials.

• Ensure adequate lighting and maintain a clean debris-free work area.

• Do not leave the hoist connected to the mains supply when not in

use and keep children away from the work area at all times.

• Never attempt to exceed the rated lifting capacity indicated on the

hoist's specication plate and in this user guide.

• If the equipment is unable to hoist a load, do not continue pressing

the hoisting button: this means that the load exceeds the machine's

maximum capacity.

• Do not use two or more electric hoists to lift one item.

• Do not lift heavy items aslant; do not use the electric hoist to drag

items along the ground.

• Do not attempt to lift or pull xed or stationary items.

• Never stand under a hoisted loads.

• Never wrap the hoist cable around the load.

• Never allow a raised and supported load to fall and thus shock load

the mounting, hoist, cable and hook.

• Do not attempt to lift angled loads or to drag loads with the hoist.

• The centre of gravity of the load must always be directly below the

hoist.

• Do not attempt to carry out maintenance on the hoist while it is

running or while it is connected to the power supply.

• For indoor use only! Do not use outdoors or in stormy weather

conditions where power-outages are a risk.

• Never operate the hoist if you are tired, under the inuence of

medication, drugs or alcohol. Never use the hoist to lift another

person. Never use the hoist to lift dangerous materials.

1

2

3

45

6

7

8a

9

10

11

12

8b

Fig.1 Identification

3

www.jeffersontools.com

USER GUIDE v1.1

JEFPOWH250

250kg POWER HOIST

Fitting the hoist on square

box section with mounting

brackets

Single Cable

Max: 125kg Double Cable

Max: 250kg

Fig.3 Installation

ELECTRICAL SAFETY

Ensure that you check the equipment thoroughly to ensure it is safe

and t for purpose before each use. It is important that you inspect

all plugs, sockets, power cables and electrical ttings for wear and

damage and repair or replace any defective components. The risk of

electric shock can be minimised by the correct use of the appropriate

electrical safety devices. We recommend that you t a Residual

Current Circuit Breaker (RCCB) in the main distribution board and

that a Residual Current Device (RCD) is used when operating this

equipment.

The Electricity at Work Act 1989 includes legislation that places legal

implications on employers to ensure the safety of electrical devices in the

workplace. The regulations dictate that all portable equipment must be

inspected regularly and tested to ensure that it is safe for use. 'Portable

equipment' means any electrical item that can be moved and this is often

referred to as Portable Appliance Testing (PAT). PAT testing should be

carried out regularly on this equipment by trained, authorised personnel, as

required by the legislation.

The Health and Safety at Work Act 1974 states that it is the responsibility

of the owner of electrical appliances to ensure that both the equipment and

working environments are maintained to ensure safe operation at all times.

Check that all equipment power cables are secure, correctly insulated,

free from damage, and protected against short circuit and overload before

connecting to the power supply. Do not use worn or damaged cables,

plugs, sockets or other ttings.

This equipment is supplied with

a BS1363/A UK 13 Amp 3-Pin

plug. Ensure that the power supply

matches the voltage requirements

specied on the equipment and

that the plug is wired correctly

and tted with the correct fuse. If

the electrical fuse blows, ensure

it is replaced by an identical type

of fuse with the same rating. (See

Fig.2)

Ensure the power cable is kept away from heat, oil and sharp edges. We

recommend that the equipment is connected directly to the power supply

without the use of extension leads as the resulting voltage drop can reduce

motor performance.

Always disconnect the equipment from the power source before servicing,

inspecting, maintaining, cleaning, replacing or checking any parts.

INSTALLATION

The hoist is tted with a specially designed bracket system that allows it to

be tted to a suitaby sized square box section beams as shown in (Fig.3

below).

The hoist can be congured with a single or double cable setup depending

on the weight of load you need to lift.

USER GUIDE v1.1

JEFPOWH250

250kg POWER HOIST

OPERATION GUIDE

BEFORE LIFTING:

Before beginning to operate the machine, ensure that the steel

cable is correctly wound on the spool and the pitch is equal to

the cable diameter. Leave at least 3 complete windings of cable

on the hoist, to avoid damage to the cable xing. (See Fig.4).

Fig.4 Correct Cable Spool Winding

Press the lift button before loading to eliminate any slack in the

steel rope, before lifting the load. Avoid winding over 15m of

cable on the hoist.

IMPORTANT: In an emergency press the emergency

stop button to halt the hoist. To release the emergency

stop button, turn it clockwise.

LIFTING:

1. Ensure that the load to be lifted is directly

below the hoist and that any lifting straps,

ropes or chains being used are capable of

supporting the weight.

2. With mains power switched on, operate

the Lift-Lower Control Switch to bring the

hook to load height. Press the lower half of

the control switch to lower hook and upper

half to raise hook. Release the control switch

to stop hoist.

3. Attach the lifting hook to the load, ensur-

ing that safety bar is fully closed.

4. Use the control switch to raise or lower

the load to the required height.

DOUBLE LINE LIFTING:

To carry out a double line lift, rst hook the single line hook in the hoist

aperture. Then take the double line pulley and hook, remove the ‘R’

pin, shaft and washers and undo nyloc nuts and remove the small

bolts. Place the pulley on the cable loop between the hoist drum and

single line hook. Replace hook and ret shaft, washers and ‘R’ pin,

then ret small bolts and tighten the nyloc nuts on them.

Ensure that pulley is free to rotate. Proceed with the lifting procedure

outlined above.

IMPORTANT: In order to prevent the motor/gearbox

from overheating, the hoist should not be operated

for longer than four minutes at any one time. Any

period of use should be followed by a similar period

with the hoist at rest.

Do not wind loose cable onto the drum - ensure that

cable is always under tension.

Cable Grip

Neutral

Wire

(Blue)

Live

Wire

(Brown)

Earth Wire

(Yellow

& Green) 13 Amp

Fuse

Fig.2 Plug Wiring

Fig.5 Controls

Emergency

Stop

Lift-Lower

Control

Switch

4www.jeffersontools.com

USER GUIDE v1.1

JEFPOWH250

250kg POWER HOIST

5

www.jeffersontools.com

USER GUIDE v1.1

JEFPOWH250

250kg POWER HOIST

1Wrap Angle Back 34 Bearing 67 Wheel axle

2Handle 35 Front cover 68 Hook washer

3Wrap Angle Front 36 Sealed paper pad 69 Pulley hook

4Cover 37 Bearing 70 Pulley

5Water Joint 38 First gear 71 Pulley splint

6Power Switch 39 Flat key 72 Prevailing torque type

7Guard 40 Gear shaft 73 Prevailing torque type

8Back Panel 41 Second gear 74 Three-prong plug

9Fan 42 Bearing 75 Limit shaft

10 Wrap Angle 1 43 Gear case 76 U-waterproof cover

11 Bottom Panel 44 Socket head cap screw 77 Plastic closing ring

12 Front Panel 45 Bearing 78 Limit switch

13 Current Adjuster 46 Elastic collar 79 Holding xture

14 Current Meter 47 Flat key 80 Junction box cover

15 O.C Light 48 Socket head cap screw 81 Terminal

16 Adjuster 49 Rope shaft 82 Junction box base

17 Plastic Front Panel 50 Limit frame 83 Upper limit spring

18 Quick Connector 51 Rope inner washer 84 Cable conductor

19 Main Control Board 52 Wire rope 85 Plastic coated wire ropes

20 Relay 53 Rope roll 86 Socket

21 IGBT 54 Wedge 87 Lanyard plate

22 Inverter Radiator 55 Rope external washer 88 Emergency stop switch

23 Capacitor 56 Bearing 89 Rise and down switch

24 Rectier Bridge Radiator 57 Straight pin 90 Upper lid of the handle

25 Rectier Bridge 58 Driving gear 91 Handle seal

26 Fixed Terminal 59 Aluminum pipe 92 Adjusting locknut

27 Radiator 60 Block 93 The switch block base

28 Diode 61 Rope thimble 94 Urgent stop switch

29 Drive Transformer 62 Hook 95 Holding xture

30 Mosfet 63 Crossed slot round bolt 96 Crossed slot round bolt

31 Transformer 64 Plastic limit piece 97 Lower lid of the handle

32 CBB Capacitor 65 Hexagon bolt 98 Capacitor

33 Power Board 66 Hexagon bolt

MAINTENANCE

The hoist should be thoroughly checked over at regular intervals to ensure that it is undamaged and that it is functioning correctly.

Isolate from the power supply and inspect the following for any signs of damage, wear or looseness, as appropriate:

a) Lifting cable

b) Electrical cables/connections

c) Control switch

d) Mounting brackets/bolts

e) Support structure

Rectify any faults that are found, before using the hoist again. Reconnect to power supply and check for correct operation of the control switch

and the maximum lift cut-out switch - the hoist should stop when the counterweight lifts the cut-out arm.

Contact Jefferson Tools for all information relating to the repair and maintenance of this equipment. Use only approved replacement parts.

Damage caused by misuse of the hoist, poor maintenance or use of unauthorised parts will void the warranty offered with this product.

PARTS LIST & DIAGRAM

6www.jeffersontools.com

USER GUIDE v1.1

JEFPOWH250

250kg POWER HOIST

ENVIRONMENTAL PROTECTION

Recycle any packaging and unwanted materials instead of disposing of them as waste. All tools, accessories and packaging

should be sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable, reaches the end of its working life and requires disposal, drain off any uids

(if applicable) into approved containers and dispose of the product and the uids according to local regulations.

WEEE Waste Electrical and Electronic Equipment Statement

Information on Disposal for Users of Waste Electrical & Electronic Equipment

This symbol on the product(s) and / or accompanying documents means that used electrical and electronic products should not

be mixed with general household waste. For proper treatment, recovery and recycling, please take this product(s) to designated

collection points where it will be accepted free of charge.

For private households:

Dispose of this product at the end of its working life and in compliance with the EU Directive on Waste Electrical and Electronic Equipment

(WEEE). Contact your local solid waste authority for recycling information for this equipment. Disposing of this product correctly will help

save valuable resources and prevent any potential negative effects on human health and the environment, which could otherwise arise from

inappropriate waste handling. Please contact your local authority for further details of your nearest designated collection point. Penalties may be

applicable for incorrect disposal of this waste, in accordance with you national legislation.

For business users in the European Union:

If you wish to discard electrical and electronic equipment, please contact your dealer or supplier for further information.

Information on Disposal in other Countries outside the European Union:

This symbol is only valid in the European Union. If you wish to discard this product please contact your local authorities or dealer

and ask for the correct method of disposal.

RoHS (2014/35/EU - Restriction of Hazardous Substances)

Based on randomly-sampled examination of the evaluated product, the results of Lead, Cadmium, Hexavalent chromium,

Polybrominated biphenyls (PBB), Polybrominated diphenyl ethers (PBDE) in tested samples comply with the limits as set by RoHS

Directive 2011/65/EU ANNEX II; recasting 2002/95/EC.

WARRANTY

Jefferson Professional Tools & Equipment, warrants its customers that its products will be free of defects in workmanship or material. Jefferson

shall, upon suitable notication, correct any defects, by repair or replacement, of any parts or components of this product that are determined by

Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration, abnormal operations, improper care, service

or repair. Unless otherwise stated, the guarantee is 12 months from purchase date, proof of which is required for any claim.

Full details of how you can register and activate your warranty as well as instructions on how to make a warranty claim are available on our

website: https://jeffersontools.com/warranty-repairs.

For any further information relating to Jefferson warranty cover please call +44 (0)1244 646 048 (UK) or +353 (0)1473 0300 (ROI).

RoHS

7

www.jeffersontools.com

USER GUIDE v1.1

JEFPOWH250

250kg POWER HOIST

EU DECLARATION OF CONFORMITY

We, Jefferson Professional Tools & Equipment, as the authorised UK representative of the manufacturer, declare that this equipment

conforms to the requirements of the following:

EN ISO 12100:2010 - Safety of machinery — General principles for design — Risk assessment and risk reduction

EN 14492-2 - Cranes – Power driven winches and hoists Part 2: Power driven hoists

2014/30/EU EMC Directive

2006/42/EC Machinery Directive

2011/65/EU RoHS Directive

Notified Testing Body: TÜV Rheinland (China) Ltd.

Equipment Category: Electric Rope Hoist

Product Code / Description: JEFPOWH250 • 250kg Power Hoist (230V)

Signed By:

Date: 22.02.2023

Name and address of manufacturer or

authorised representative:

Jefferson Professional Tools & Equipment

24 Lisgorgan Lane, Upperlands, BT46 5TE,

Tel: +44 (0)1244 646 048 (UK)

+353 (0)1473 0300 (ROI)

Email: [email protected]

UKCA DECLARATION OF CONFORMITY

We, Jefferson Professional Tools & Equipment, as the authorised UK representative of the manufacturer, declare that this equipment conforms

to the requirements of the following:

BS EN 55014-1:2017

BS EN 55014-2:1997+A2

BS EN 55014-2:2015

BS EN 61000-3-2:2014

BS EN IEC 61000-3-2:2019

BS EN 61000-3-3:2013

BS EN 61000-3-3:2013+Al

Notified Testing Body: TÜV Rheinland (China) Ltd.

Equipment Category: Electric Rope Hoist

Product Code / Description: JEFPOWH250 • 250kg Power Hoist (230V)

Signed By:

Date:

22.02.2023

Name and address of manufacturer or

authorised representative:

Jefferson Professional Tools & Equipment

24 Lisgorgan Lane, Upperlands, BT46 5TE,

Tel: +44 (0)1244 646 048 (UK)

+353 (0)1473 0300 (ROI)

Email: [email protected]

Jefferson Professional Tools & Equipment

24 Lisgorgan Lane,

Upperlands,

BT46 5TE

Tel: +44 (0)1244 646 048 (UK) / +353 (0)1473 0300 (ROI)

Email: [email protected]

www.jeffersontools.com

IMPORTANT! SAFETY FIRST!

Before attempting to use this product please read

all the safety precautions and operating instructions

outlined in this manual to reduce the risk of fire,

electric shock or personal injury.

Table of contents

Popular Chain Hoist manuals by other brands

Power Climber Wind

Power Climber Wind PC1 Series operating instructions

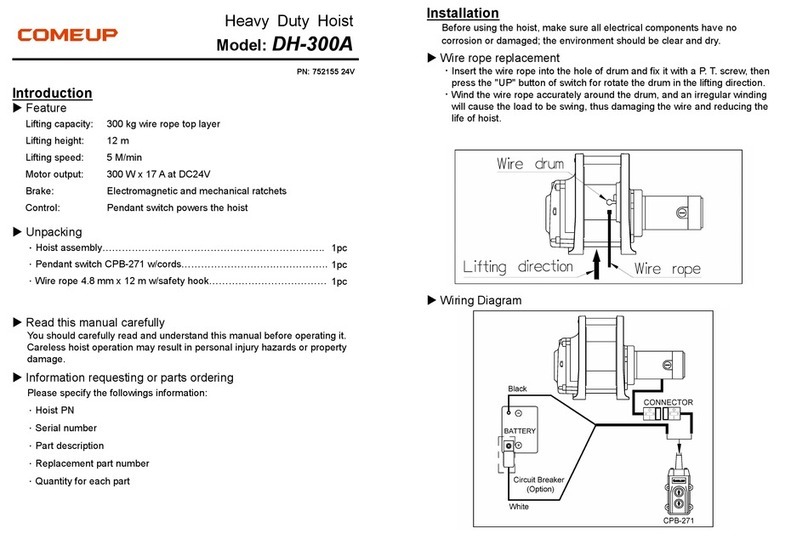

Comeup

Comeup DH-300A quick start guide

Haklift

Haklift SKTH50018V manual

Comeup

Comeup GTD-650 manual

Elephant

Elephant YII-25 YA-50 Instruction manual and safety instructions

Coffing Hoists

Coffing Hoists Concert Series Operating, Maintenance & Parts Manual