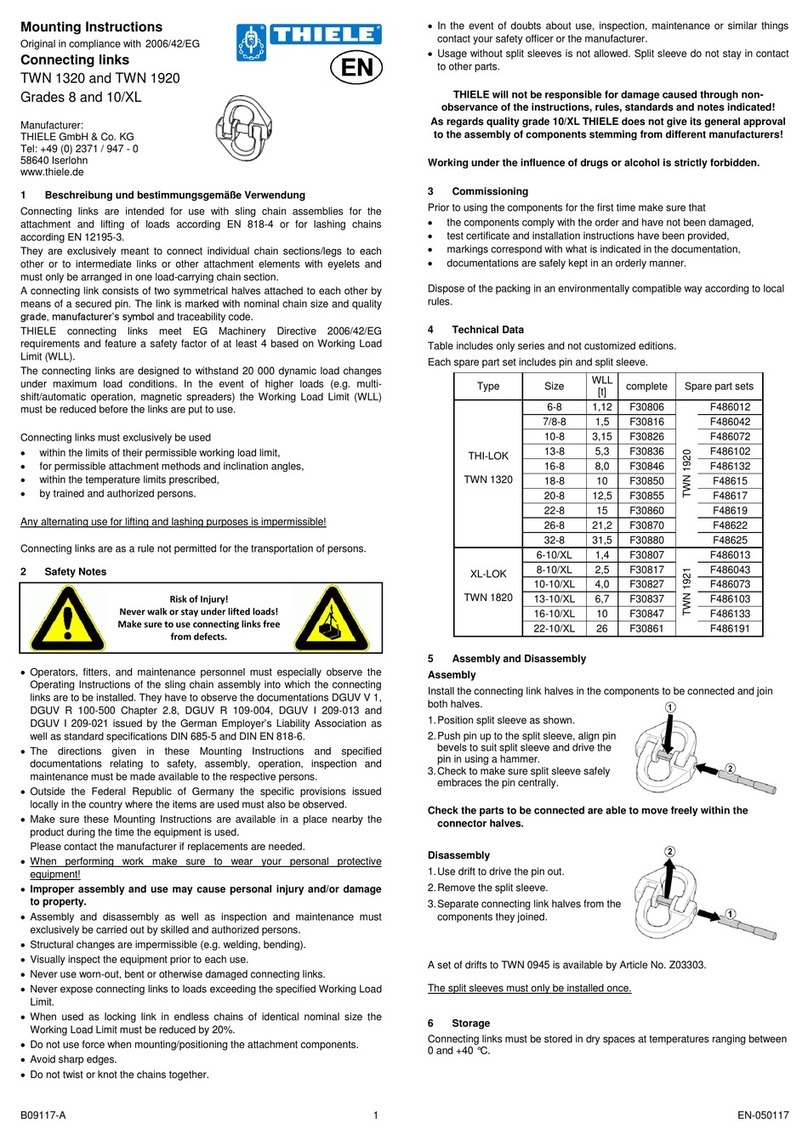

MOUNTING INSTRUCTIONS

OCTA STAR CLEVIS SLING HOOKS

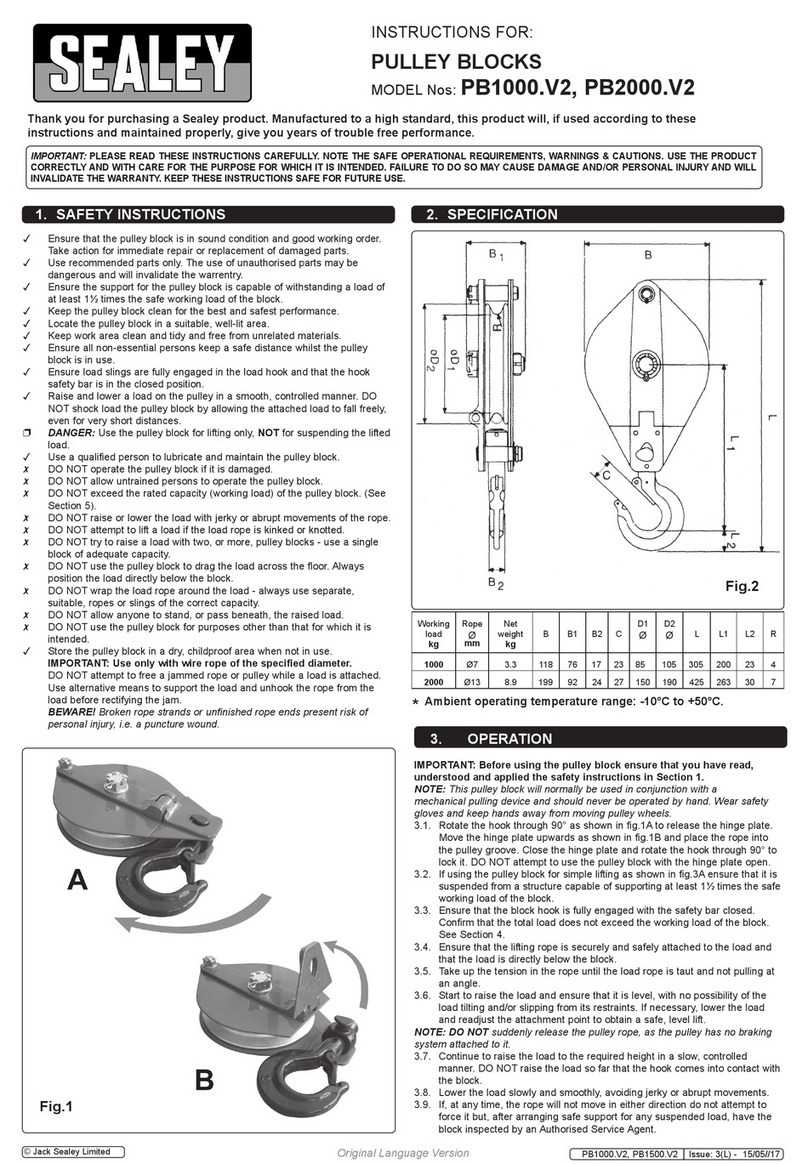

GRADE 80

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de B0 331-A replaces -

© All rights reserved. US 12.2021 1 | 4

The following mounting instructions must always be

followed to avoid the risk of personal injury or property

damage.

Do not use a clevis sling hook before reading these

mounting instructions.

1. ABOUT THIS INSTRUCTION

These mounting instructions describes in particular how

OCTA STAR clevis sling hooks are to be safely used for lifting

purposes.

To comply with these instructions is essential to help avoiding

hazards and increases the reliability and service life of the hooks.

DANGE ! Indicates a hazardous

situation which, if not avoided, will

result in death or serious injury.

WA NING! Indicates a hazardous

situation which, if not avoided, could

result in death or serious injury.

CAUTION! Indicates a hazardous

situation which, if not avoided, could

result in minor or moderate injury.

NOTICE! Is used to address practices

not related to physical injury.

Safety Instructions signs indicate

specific safety-related instructions or

procedures.

DEFINITIONS

Clevis

A U-shaped fitting with pin.

Working Load Limit (WLL)

The maximum load which a hook is designed to support without

shock-loading.

ead ASME B30.10 „Hooks“.

2. BASIC SAFETY REQUIREMENTS

To prevent the risk of injury never walk or stay under lifted

loads!

The working load limit (WLL) must not be exceeded!

Hooks as well as lifting and attachment means to be used

must be free from defects!

Working under the influence of drugs, medications

impairing the sense and/or alcohol is strictly forbidden!

•Operators, fitters and maintenance personnel must in

particular observe the operating instructions of the chain

slings into which the connecting links are to be installed, as

well as standards ASTM A 06/A 06 M (Standard

Specification for Grade 80 and Grade 100 Alloy Steel Chain

Slings for Overhead Lifting), ASTM A 52/A 52 M (Standard

Specification for Forged Grade 80 and Grade 100 Steel Lifting

Components and Welded Attachment Links), ISO 3056 (Non-

calibrated round steel link lifting chain and chain slings; Use

and maintenance), ISO 75 3 (Chain slings assembled by

methods other than welding; Grade T(8)) and ISO 1837

Lifting hooks - Nomenclature.

•The specific safety and operating regulations and standards

issued locally in the country where the items are used must

be observed.

•During operation work, wear your personal protective

equipment!

•The directions given in these mounting instructions and

specified documentations relating to safety, assembly,

operation, inspection, and maintenance must be made

available to persons operating and using the hooks.

•These mounting instructions must be available in a place

near the product during the time the equipment is used.

Please contact the manufacturer if replacements are

needed. Also see chapter 11.

•Improper assembly and use may cause personal injury

and/or damage to property.

•Assembly and removal as well as inspection and

maintenance must exclusively be carried out by skilled,

qualified, trained and authorized persons only.

•Structural changes are impermissible (e.g. welding, bending).

•Operators must carry out a visual inspection and, if

necessary, a functional test of the safety equipment before

each use.

•Never use worn-out, bent or damaged hooks.

•Only lift loads that do not exceed the working load limit of

the corresponding chain sling.

•Never expose hooks to loads exceeding the specified

working load limit.