For advice on the safety and suitability of this equipment

contact your local HSS Safe and Sure Depot.

There is a serious risk of personal injury if you do not

follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all

necessary risk assessments have been completed

prior to the use of this equipment.

This equipment should only be used by an operator

who has been deemed competent to do so by

his/her employer.

This equipment may be used in a workplace

subject to a permit to work. It is the hirer’s

responsibility to ensure that the equipment’s

technical specification meets the requirements of

any such permit to work prior to starting work. For

further technical information contact your local

HSS Safe and Sure Depot.

This equipment should be used by an able bodied,

competent adult who has read and understood these

instructions. Anyone with either a temporary or permanent

disability, should seek expert advice before using it.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Keep children, animals and bystanders away from

the work area.

Wear sensible, reasonably protective clothing and

footwear plus any safety wear appropriate to the

work in progress.

Check the condition of the equipment before use.

If it shows signs of damage or excessive wear,

return it to your local HSS Safe and Sure Depot.

Never leave the equipment switched ON and

unattended.

Always switch OFF and disconnect the equipment from

its power source before making any alterations or

adjustments to it.

Lights get hot. Always leave them to cool before touching

them and never remove or interfere with any safety

guards fitted.

Never position the lights near overhead power

lines or similar hazards.

The HSS Tank and Compact Link Lights are only

available in 110V (fitted with a safety push and twist

16A round yellow plug) and must be provided with a

suitable 110V generated supply, or be powered

from the mains via a suitable 110V transformer.

The plug and socket fitted to this equipment are

the safety push and twist type, no other type of

connection can be used. If in doubt contact your local

HSS Safe and Sure Depot.

ELECTRICAL SAFETY

GENERAL SAFETY Extension leads fitted with the correct plug and

socket, should be fully unwound and loosely

coiled, away from the work area. Never run them

through water, over sharp edges or where they

could trip someone.

Keep the equipment dry. Using electrical equipment

in very damp or wet conditions can be dangerous.

To reduce the risk of electric shock, always use

a suitable RCD (Residual Current-Operated Device)

available from your local HSS Safe and Sure Depot.

If using a transformer to provide power, ensure

that the total power load is less than 75% of the

units power rating.

The lights can be linked to create a continuous

run, the chart below will help you set up the

maximum amount.

If the equipment fails, or if its plug or lead gets

damaged, return it. Never try to repair it yourself.

Never carry or pull the equipment by its power

supply cable.

Ensure the power socket is switched OFF before

plugging into the power supply.

Position the lights with care, somewhere they won’t

be knocked over and where they won’t dazzle people,

this can be as dangerous as darkness.

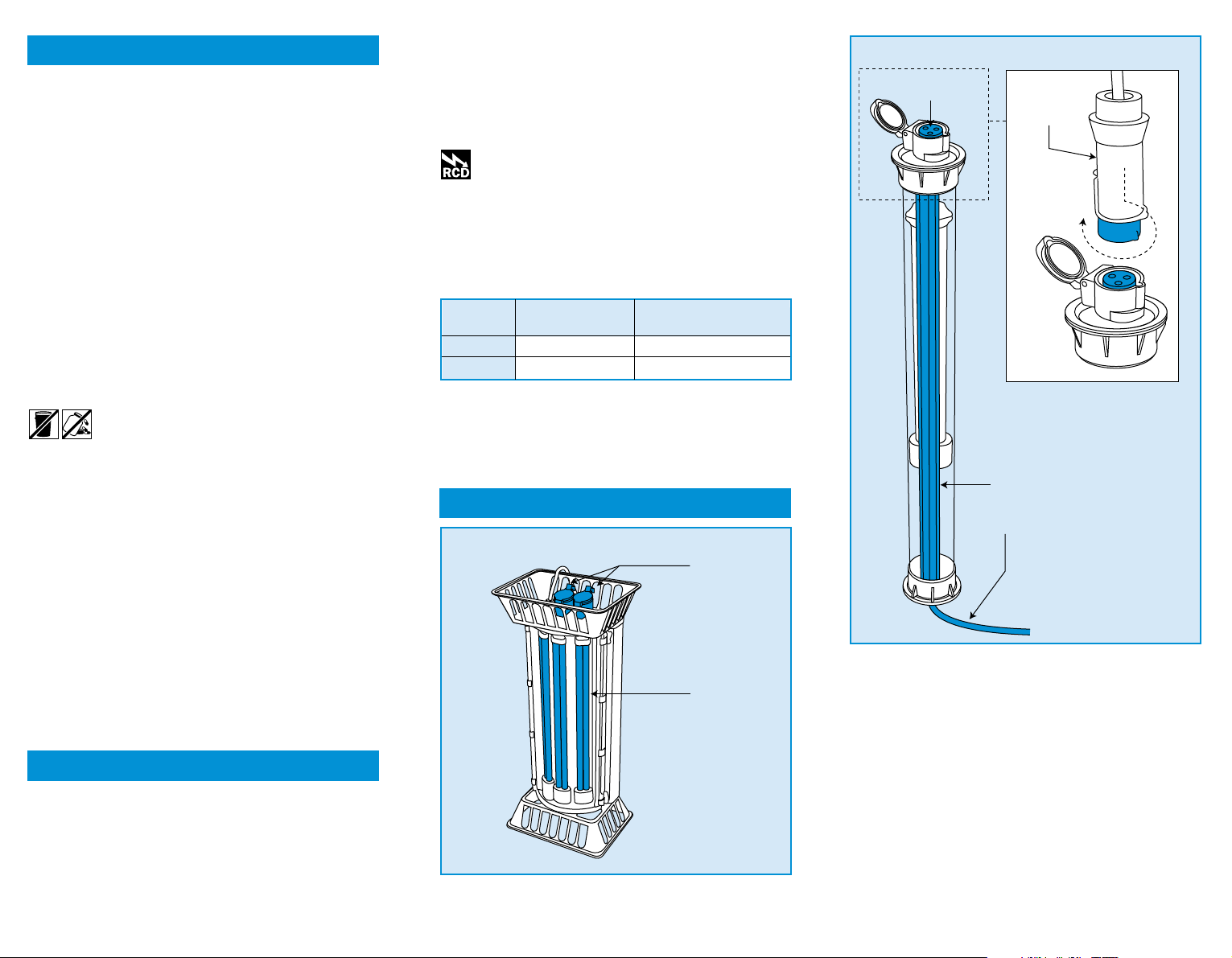

GETTING STARTED

Position each light before connecting plugs to sockets.

The compact model can be stood upright or lain

on the ground.

The tank model can be either lain on the ground

or suspended by its hanging strap.

Now, starting with the light furthest from the

power supply connect each unit to the next.

To make the connection, lift and hold the cover to the

power take-off socket (PTO). Insert the plug into the

PTO ensuring the lug lines up with the slot (see

illustration).

Push the plug fully home, then turn clockwise

approximately a quarter turn, ensuring the socket lid

catches onto the plug.

Coil excess lead neatly but loosely, close to the power

source and away from the work area where people

can’t trip over it.