For advice on the safety and suitability of this equipment

contact your local HSS Hire Shop.

There is a serious risk of personal injury if you do

not follow all instructions laid down in this guide.

This equipment should be used by an able bodied,

competent adult who has read and understood these

instructions. Anyone with either a temporary or permanent

disability, should seek expert advice before using it.

Keep children, animals and bystanders away from

the work area.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Safety goggles MUST be worn by everyone in

the work area.

Some materials when cut contain substances

which, when inhaled, can be harmful to

health. A suitable mask must be worn when using this

equipment. Respiratory protective equipment is available

for hire, contact your local HSS Hire Shop for details.

This equipment generates potentially harmful

noise levels. To comply with health and safety at

work regulations, ear defenders must be worn by

everyone in the vicinity.

Wear practical, protective clothing, gloves and

footwear. Avoid loose garments and jewellery that

could catch in moving parts, tie back long hair.

Ensure the work area is well lit and ventilated, if in

doubt, ask about lighting and ventilation equipment at

your local HSS Hire Shop.

If working above ground level, work from a stable,

purpose-made platform. For prolonged, heavy work

an access tower or something similar is a must.

Do not work near flammable gases or liquids, petrol

or paint thinner fumes for example. Keep combustible

materials at a safe distance - at least 5m.

Make sure you know how to switch this machine

OFF before you switch it ON in case you get

into difficulty.

Always switch OFF the equipment before making

adjustments to it. Having switched OFF, always wait

for moving parts to come to rest.

Exhaust Danger

Never operate petrol engines in a

confined space.

The exhaust contains gases that can kill.

GENERAL SAFETY Check that you have removed all spanners before

restarting. Never leave it running and unattended.

Check the condition of the equipment before use.

If it shows signs of damage or excessive wear, return it to

your local HSS Hire Shop.

Ensure the guard is correctly fitted and secure

before starting work.

COSHH information sheets are available from your local

HSS Hire Shop.

HSS offer a choice of either diamond wheels

or abrasive wheels. Diamond wheels are

available to hire, with a wear charge for the

amount of diamond used, alternatively it may be

purchased outright.

Abrasive wheels are available on a sale or return

basis, contact your local HSS Hire Shop for advice.

Begin by fitting the appropriate 350mm wheel.

Immobilize the rear flange plate by inserting a

locking pin into the hole in the drive belt housing.

Now, unscrew the flange-retaining bolt, remove

the front flange plate and seat the new wheel

onto the rear flange plate.

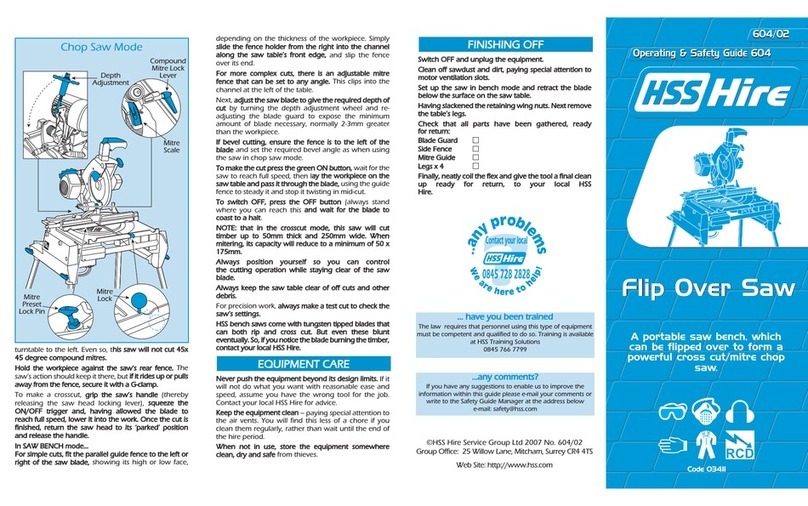

GETTING STARTED

Fuel Safety

NEVER refuel while the engine is hot or running.

NEVER smoke or allow naked lights into the

area while refuelling.

ALWAYS mop up fuel spillages as quickly as possible.

Change your clothes if you spill fuel on yourself.

ALWAYS store fuel in an approved container, in

a cool, safe place away from the work area.

Never mix petrol/oil in the machine’s fuel tank.

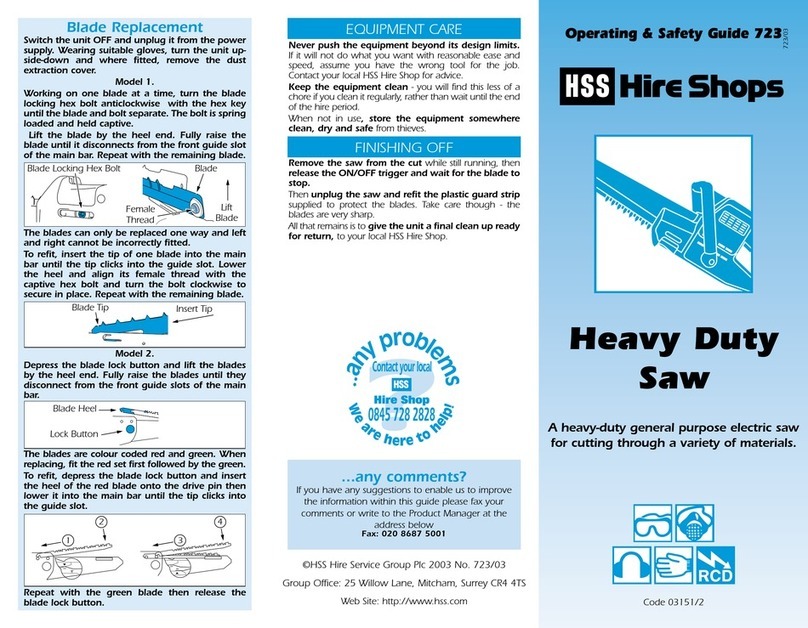

Refit the front flange plate and screw the flange-

retaining bolt back into place, tightening this up

using the spanner provided. DO NOT OVER-TIGHTEN.

Double check that both flange plates are secure,

the wheel is central and spins freely.

To start the motor...

Mix 5 Litre of unleaded petrol with 1 bottle of HSS

2-Stroke oil in a suitable container, and fill the fuel

tank. Each tank-full gives about 30 minutes use. Never

add the oil and petrol to the tank unmixed.

Slide the ON/OFF switch to the ON position and, if

starting from cold, set the choke. Pull the blue choke

lever fully out and push in the decompression

valve. Now, squeeze the throttle and press the

trigger lock button to hold the throttle open.

Pull the starter handle a few times until the motor

‘coughs’, then push in the blue choke lever, push in

the decompression valve and pull the starter

handle once more. The motor should fire.