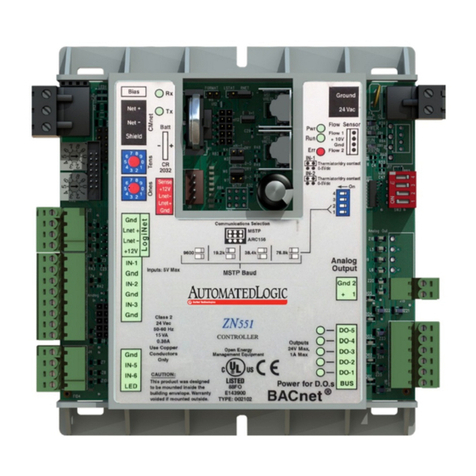

ESD jacks on the OptiX PTN 7900-24

1

ESD Protection

Always wear ESD gloves or an ESD wrist strap prior to contact with the equipment or before handling boards or IC chips

to prevent damage to sensitive components due to electrostatic discharge from the human body. Ensure that the ESD

wrist strap is properly grounded.

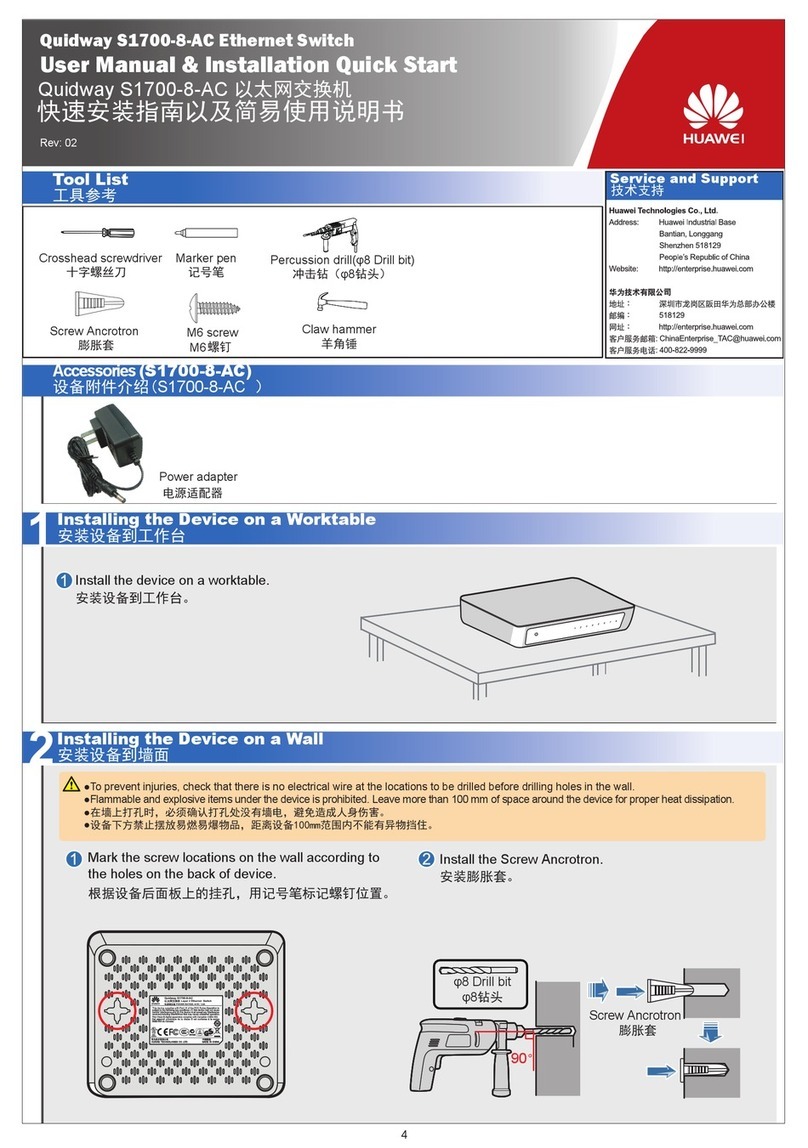

Pre-Installation Check

Ensure that the equipment room, cabinets, power supplies, ground cables, optical cables, and associated devices are

ready for installation. Start the installation according to the engineering design documents after confirming that all

conditions are met.

Bundling Cables

Binding intervals between cable ties or optical fiber binding straps inside the cabinet cannot exceed 250 mm. (Binding

intervals cannot exceed 200 mm for user cables.)

Binding intervals between cable ties for all cables and corrugated pipes outside the cabinet are determined based on the

distance between the two horizontal beams. If the cable trough does not contain any beams, the binding intervals

between cable ties cannot exceed 250 mm.

Safety Information

The equipment is heavy. To prevent human injuries or equipment damage, always use a lifting device to transport or

position the equipment. Use a pallet truck or heavy-duty flat-bed truck to transport the equipment on even ground, and

use a cargo lift to transport the equipment between different floors.

Always wear protective gloves when lifting or transporting a cabinet to prevent hand injuries or damage to the cabinet

surface. Operators must protect themselves first if the cabinet unexpectedly tilts or even turns over during delivery.

This document provides guidelines for quick hardware installation. It describes procedures for onsite installation,

but does not describe pre-delivery assembly.

Installation Precautions