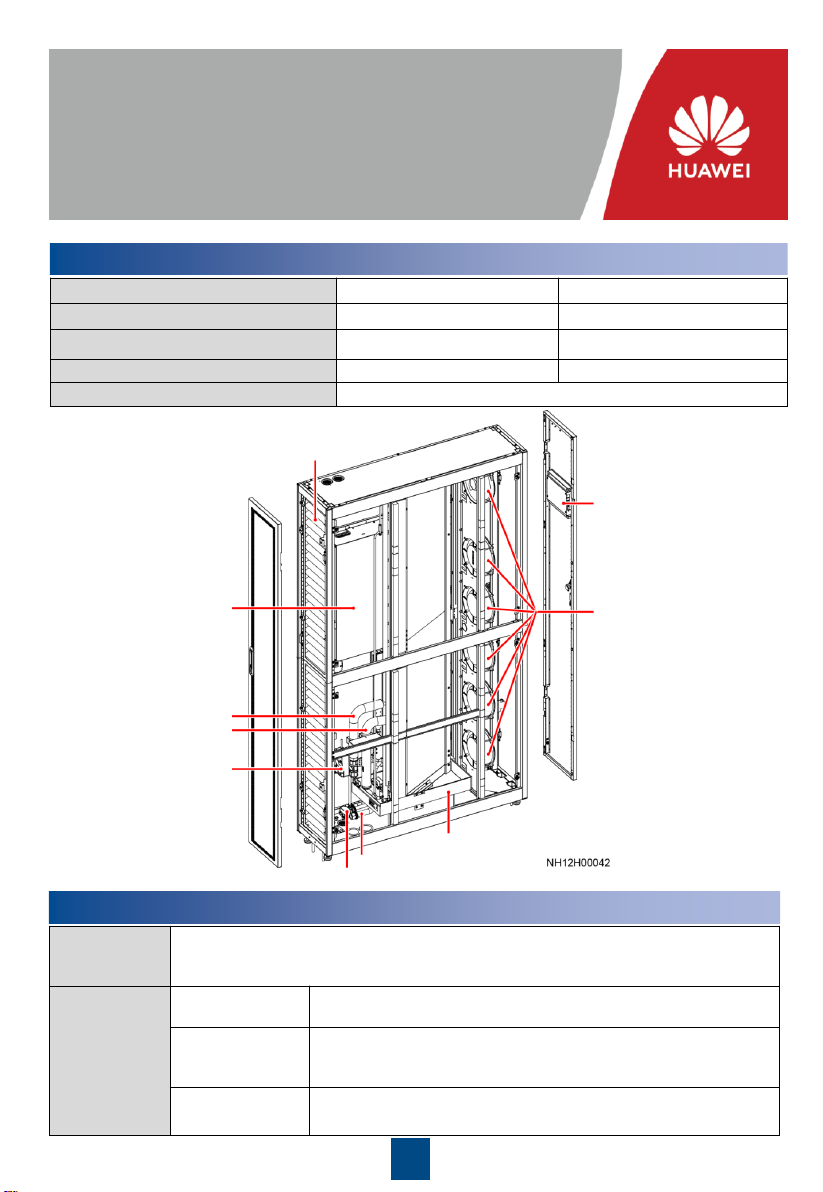

Preparing an Indoor Unit Base

2.1

1. Shock absorption bars (EPDM rubber, 5 mm

thick) need to be installed between the

ground and the base.

2. The base should be at least 250 mm in height.

3. You are advised to use angle steel, square

steel or channel steel. Width of 50 mm and

thickness of 3 mm to 5 mm is recommended.

4. When the width of angle steel is more than 50

mm, it is interfering with the cable routing

holes. Cut out the part on the angle steel to

avoid interfering. If the width is less than or

equal to 50 mm, skip this step.

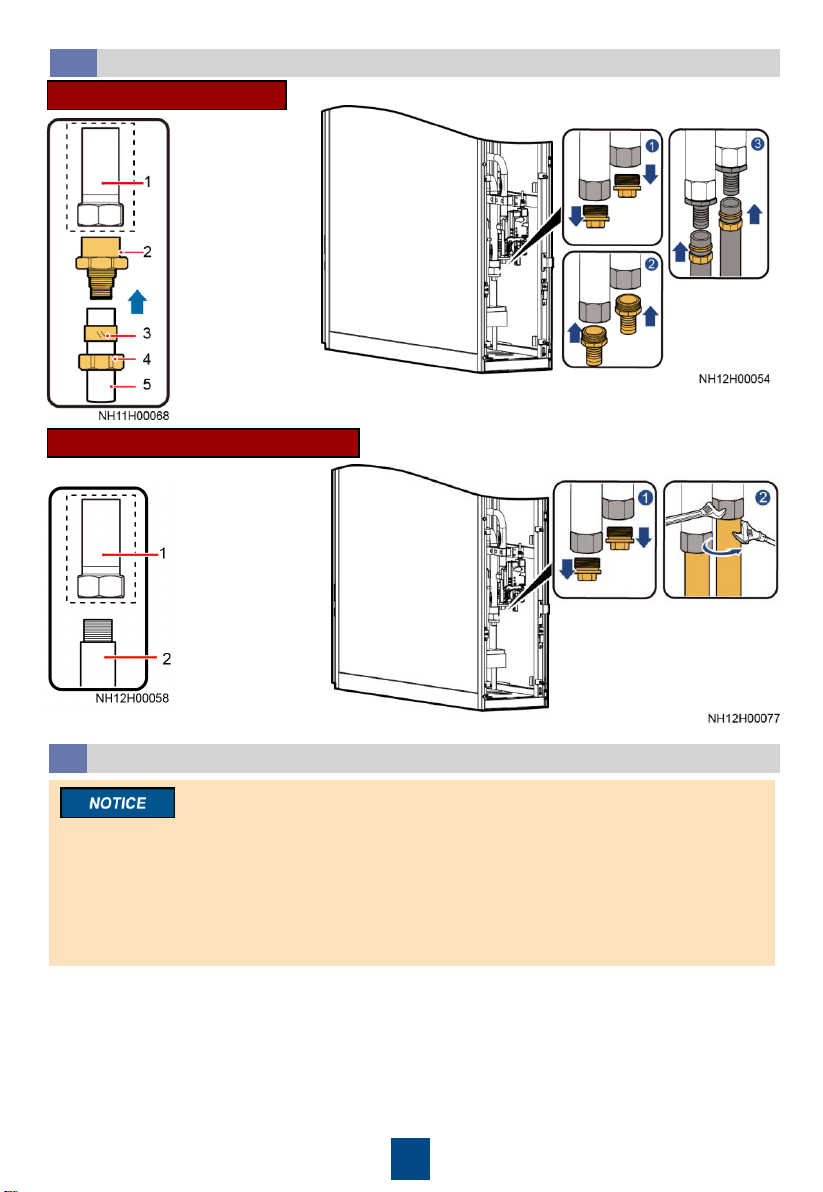

3Installing the Equipment

1. Read the related user manual or instructions before installing the NetCol5000-C.

2. The unit in this document is a fully configured NetCol5000-C. If some components are not

configured, skip the corresponding steps.

3. You are recommended to use tools that are fully insulated when installing devices.

4. Only engineers from the manufacturer or engineers certified by the agent are allowed to install,

commission, and maintain smart cooling products. Otherwise, personal injuries and device

damage may be caused, which is beyond the smart cooling product warranty range.

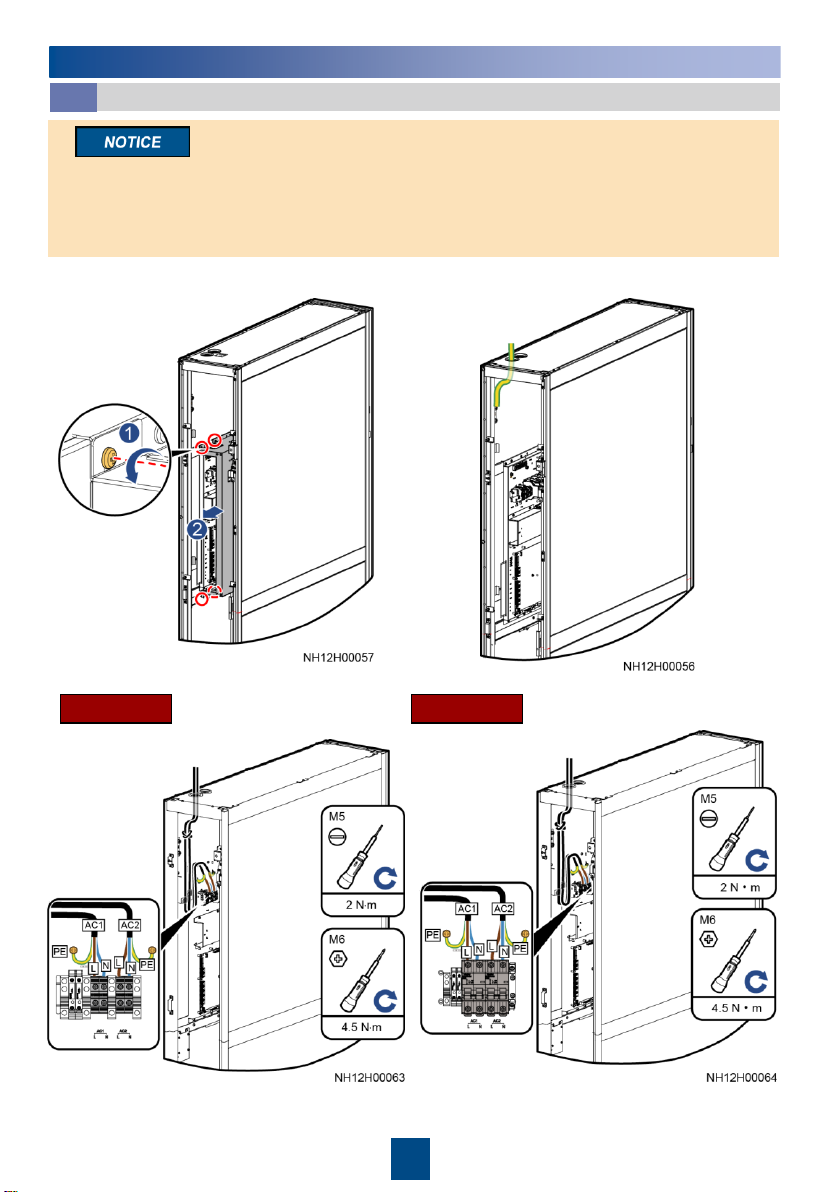

(1) Power cable hole, Φ 43mm

(2) Signal cable hole, Φ 43mm

Front door

(Top view of the top plate)

(Side view)

(Front view)

(Top view)

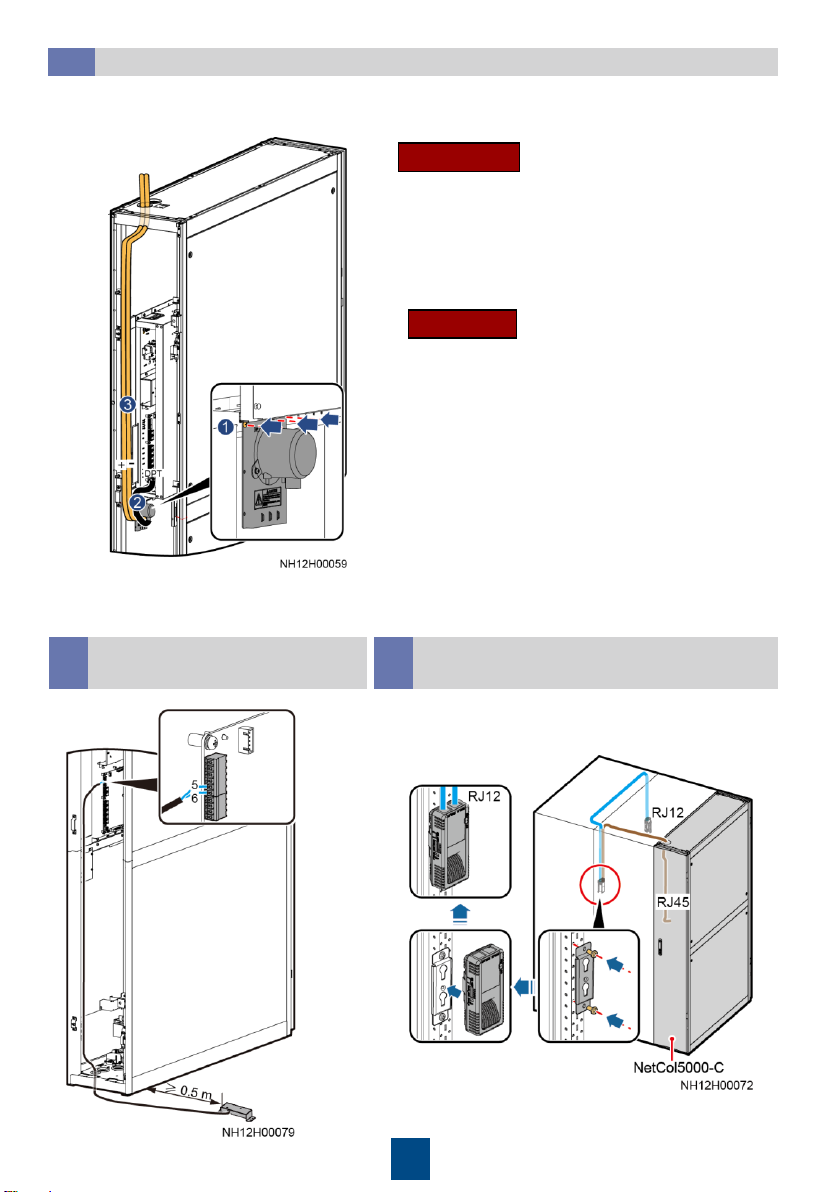

Making Holes on the Floor

2.2 Front door

(Top view of the bottom plate)

(1) Drainpipe hole, Φ 43 mm

(2) Humidifier water inlet pipe hole,

Φ 43 mm

(3) Ground cable hole , Φ 28 mm

(4) Chilled water outlet pipe hole,

Φ 54 mm

(5) Chilled water inlet pipe hole, Φ

54 mm

2