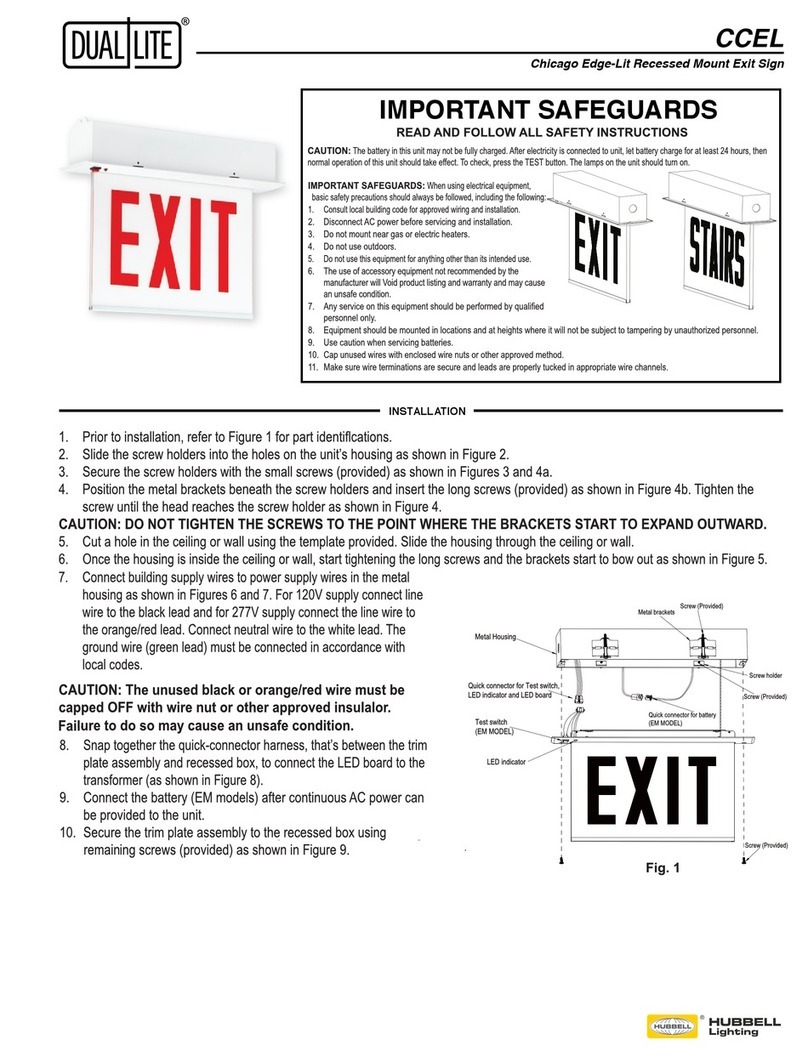

INSTALLATION

SURFACE MOUNT INSTALLATIONS

1. Remove retainer screw from right side of the sign. Remove side panel and mounting canopy, set aside.

2. Remove retainer screw from the front cover of the unit. Remove the front cover and set aside.

3. Remove 7/8” DIA KO mounting hole located at the top portion of back plate. Use bushings provided to protect

wires from metal edge. Install mounting pan and cable tie to back plate. Secure wires using cable tie. Feed wires

through 7/8” DIA KO bushing.

4. Adhering to National, State and Local codes, make wiring connection. For 120V, use black and white wires and

for 277V, use red/orange and white wires. WARNING: Properly insulate the unused leads with wire nuts (provided)

or other approved methods.

5. Push wire connections into the J-box.

6. Mount sign equipment securely in place on the wall. Two additional “Key Hole” mounting holes are located at the

top of the unit housing in addition to the j-box mounting holes. These two additional mounting slot holes must be

used. Additional chain support may be required by local codes.

7. Carefully replace the glass into the sign frame channel and replace end panel and retainer screw.

8. Connect battery in unit by connecting the Red (+) lead from the PC board assembly to the positive (+) board

assembly to the negative (-) battery terminal. terminal on the battery and the Black (-) lead from PC CAUTION:

Observe polarity. Failure to connect the battery properly will result in equipment failure and an unsafe condition.

NOTE: Emergency lights will NOT come ON at this time.

9. Replace and secure the front cover.

10. Energize the sign xture with AC supply. The charge indicator lights will illuminate.

11. Adjust and focus the lighting heads as required.

CEILING OR LEFT-SIDE END MOUNT

Note: Cannot be right-side end mounted

1. Remove retainer screw from right side of the sign. Remove side panel and mounting canopy, set aside.

2. Remove retainer screw from the front cover of the unit. Remove the front cover and set aside.

3. Remove both 7/8” DIA KO mounting hole located on the frame. For ceiling mount, knock out mounting holes will

be located on top of the frame. For left-side wall mount, knock out mounting holes will be located on the side of

the frame.

4. Thread 7/8” nuts (2 required, provided by others) onto 7/8” pipe nipples (2 required, provided by others). Slide

pipe nipples through canopy holes.

5. Place screws (provided) in holes on the canopy.

6. Route wires through knockouts in Unit frame (ceiling mount) or in EXIT frame (side mount), pipe nuts and metal

mounting plate.

7. Adhering to National, State and Local codes, make wiring connection. For 120V, use black and white wires and

for 277V, use red/orange and white wires. WARNING: Properly insulate the unused leads with the wire nuts

(provided) or other approved methods.

8. Push wire connections into the J-box. Secure mounting plate to J-box (hardware not included).

9. Secure the canopy to the steel mounting plate with screws installed in step 5.

10. Place pipe nipples through the mounting holes of the frame until the canopy is touching the frame. Thread a

second nut (provided by others) onto each of the pipe nipples on the inside of the housing and lock the canopy

into place. Once canopy is locked into position there will not be any side-to-side movement on the canopy.

11. Carefully replace the glass into the sign frame channel and replace end panel and retainer screw.

12. Connect battery in unit by connecting the Red (+) lead from the PC board assembly to the positive (+) terminal

on the battery and the Black (-) lead from PC board assembly to the negative (-) battery terminal. CAUTION:

Observe polarity. Failure to connect the battery properly will result in equipment failure and an unsafe condition.

NOTE: Emergency lights will NOT come ON at this time.

13. Replace and secure the front cover.

14. Energize the sign xture with AC supply. The charge indicator lights will illuminate.

15. Adjust and focus the lighting heads as required.

GENERAL:

This sign may be shipped with an extra face plate and Red lens to make the sign double face. Replace the back plate

with the extra face plate and lens at the start of the installation process, if the application calls for a double face sign.