5

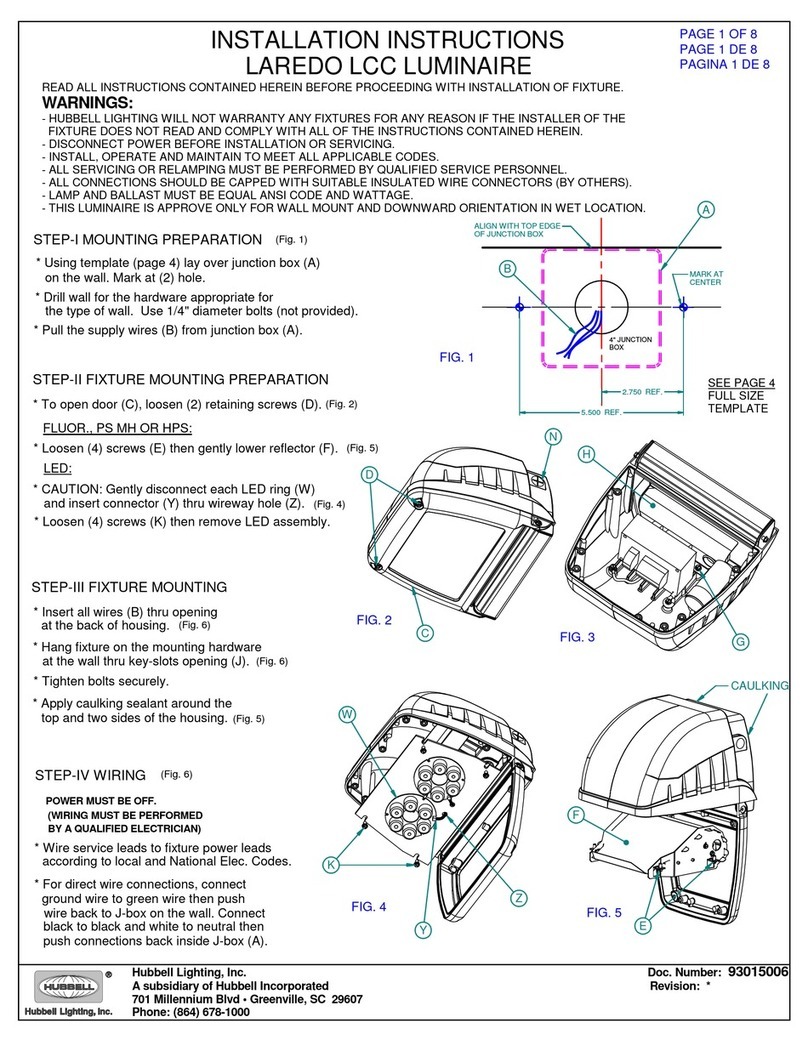

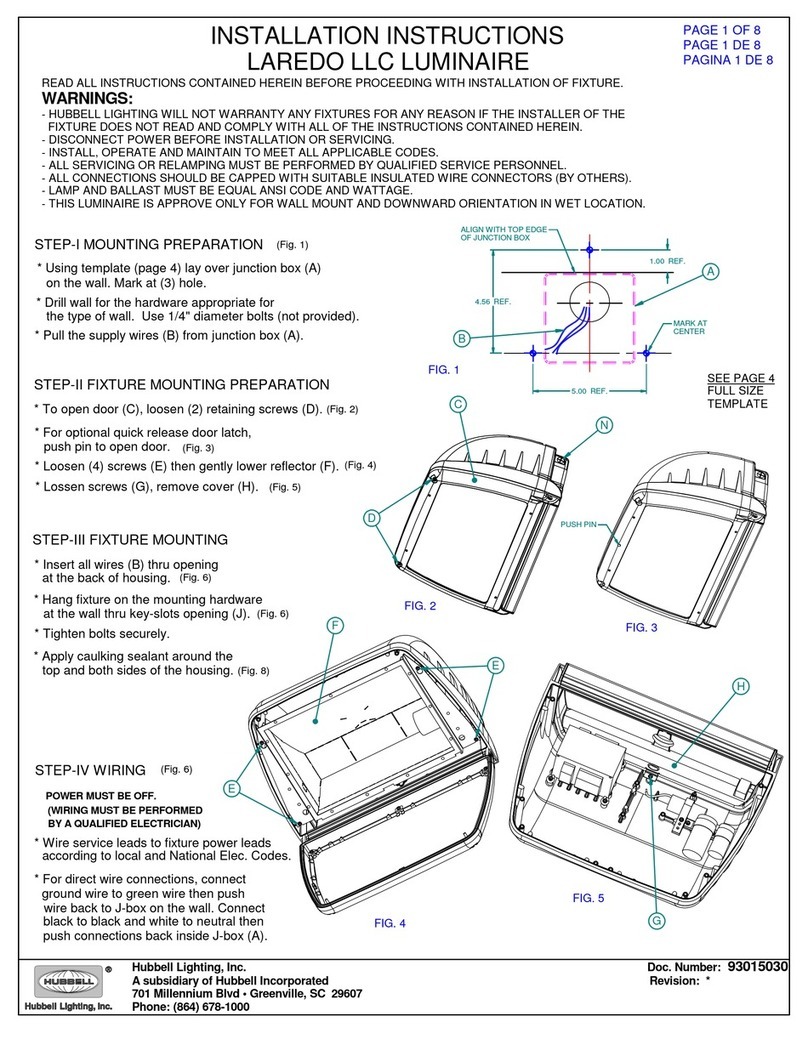

INSTALLATION INSTRUCTIONS

UTB2

INSTALLATION INSTRUCTIONS

Hubbell Lighting, Inc. Doc. No. 93097040

A subsidiary of Hubbell Incorporated Revision P0

701 Millennium Drive • Greenville, SC 29607 Page 5 Phone (864) 678-1000

FIGUR

E 5A

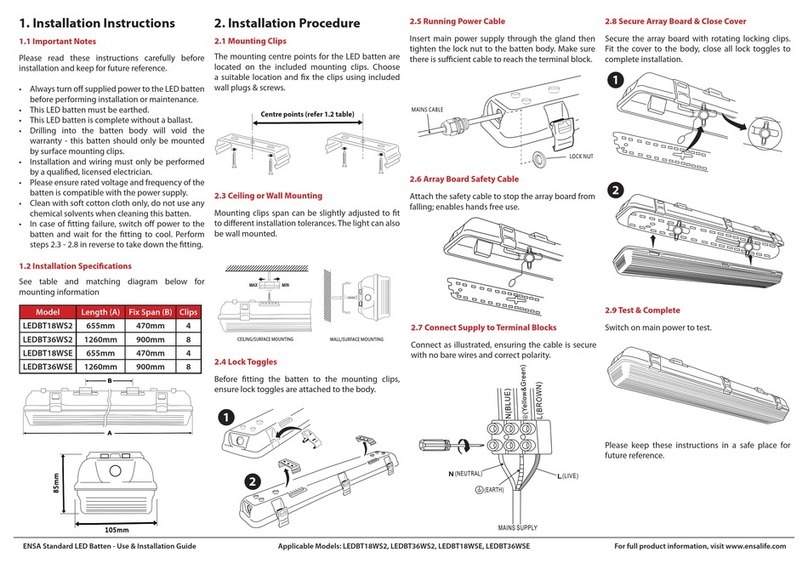

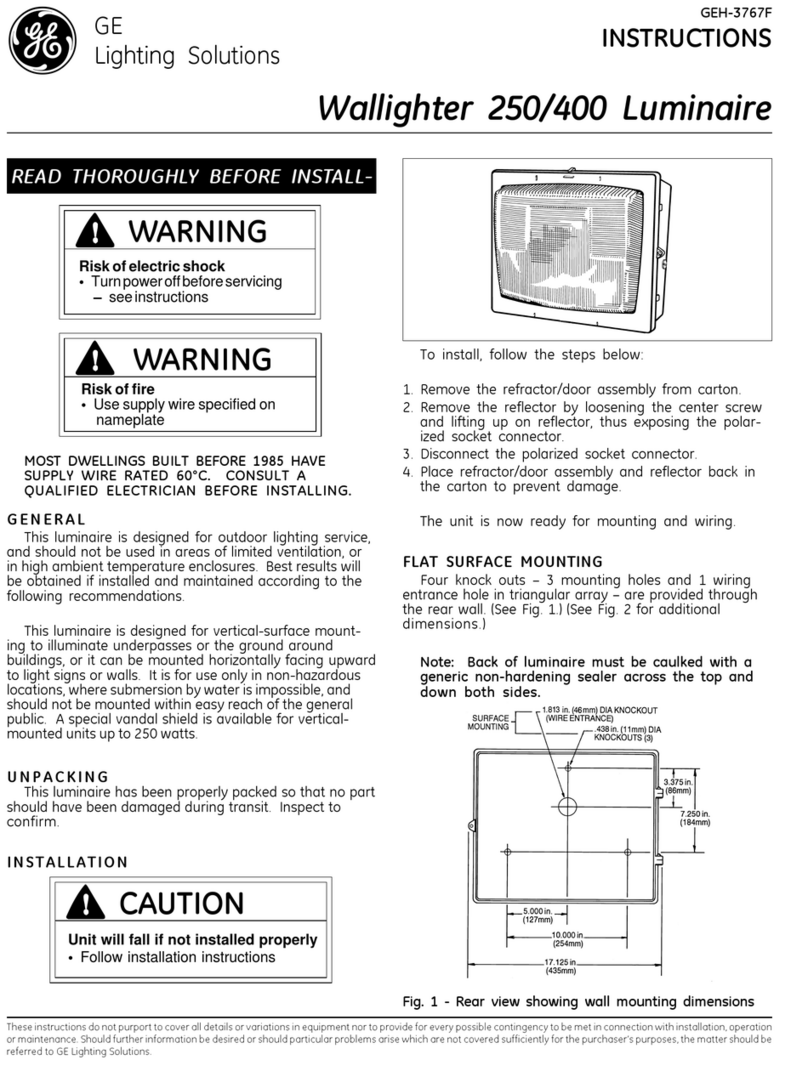

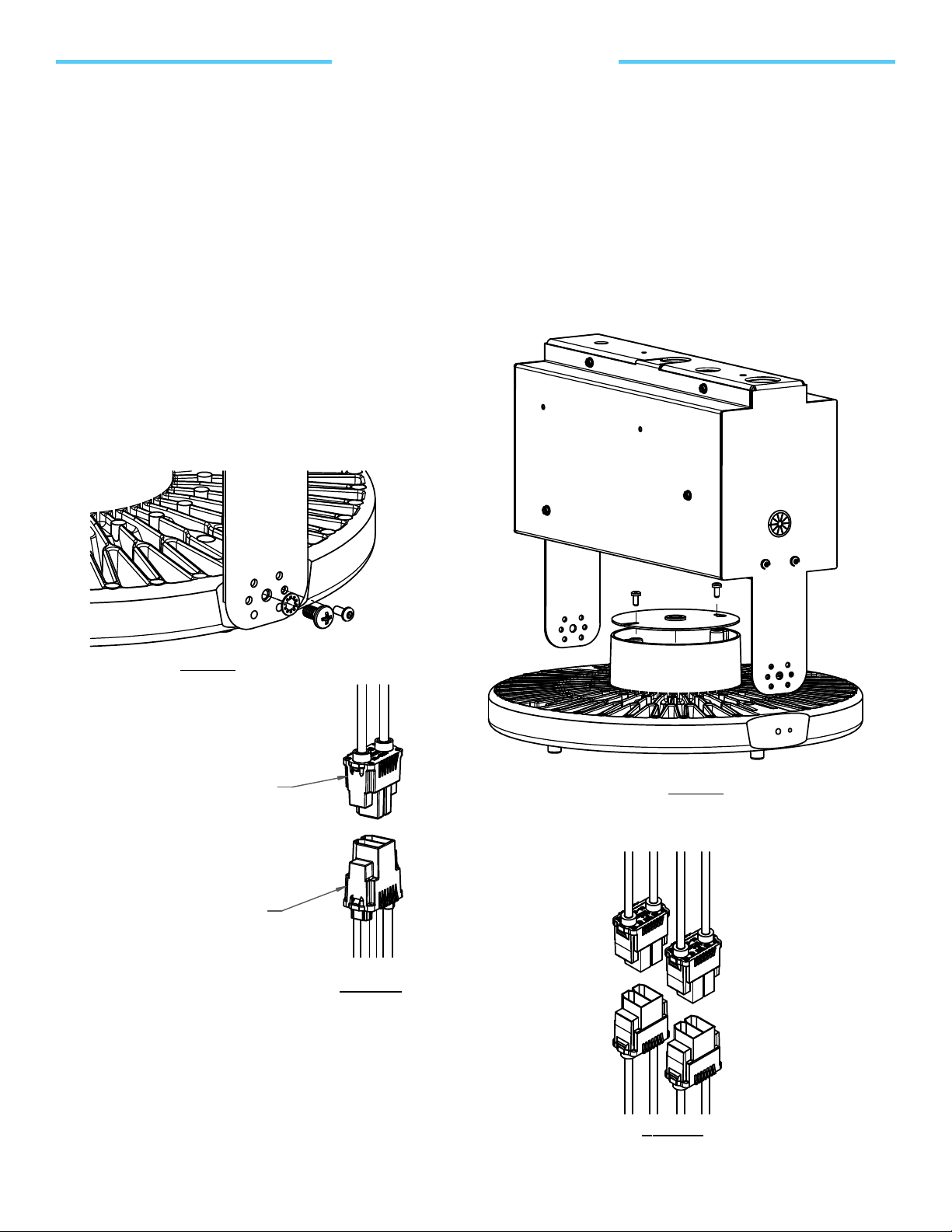

HOOK LOOP ASSEMBLY

FIGURE 5B

HOOK LOOP ASSEMBLY

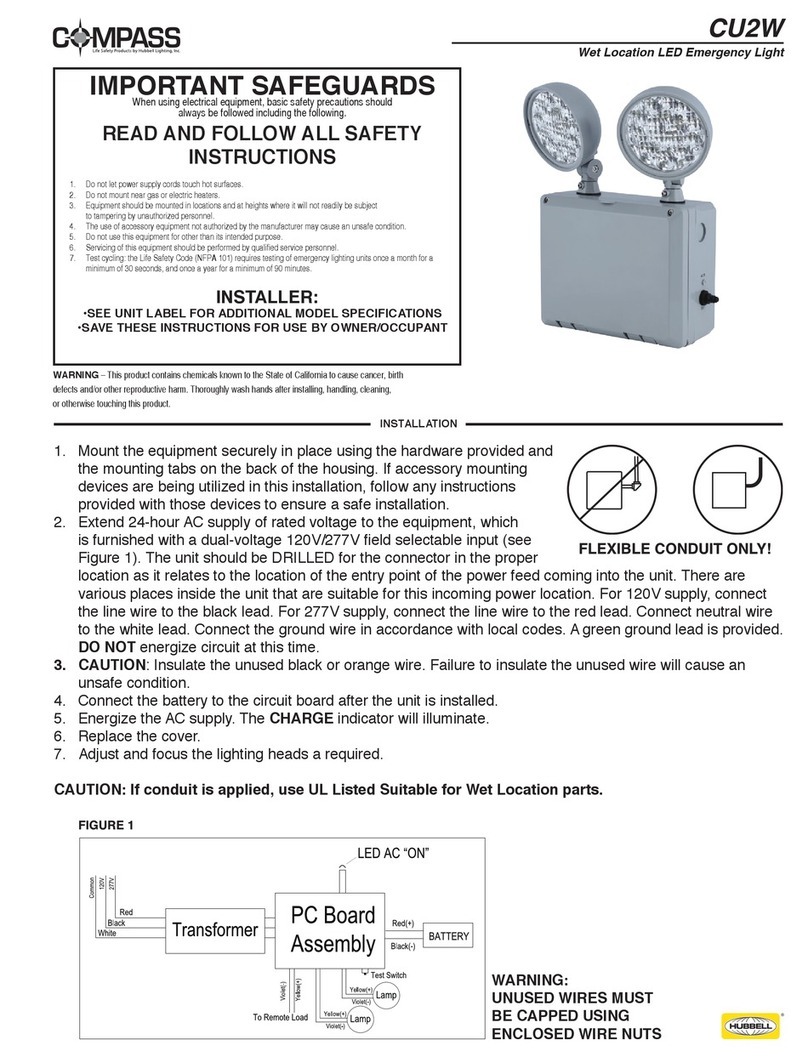

GENERALINFORMATION:

All12”(304.8mm)minimumsupplywireoutsideofconduit.

Fixturemountinghookloopthreadsare3/4‐14NPS.

HOOK/LOOPMOUNTING:(Figures5A,5B&5C)

Cord&Hook/LooporderedasCxHLPx(Plugoptional)

1. Ifnotalreadydone,assemblethehooklooppiecesaccordingtothefollowingsteps.

2. Threadtheupperlocknut(withflatsurfacedown)ontothehooklooptoapproximately1/8”

fromthetopofthethreads.(Figure5A)

3. Positionthesafetyclaspasshownandjuststartthefastener,butleaveloose.(Figure5A)

4. Insertthepowercord,mustberatedminimum90°C16/3SEOW‐Aorequivalent,throughthe

holeinthehookandinsertgotcharing,topwasher,gasket,lowerwasherandcast

bushing/nutontocord.Fullytightencastbushingagainstbottomofhook.(Figure5A)

5. Slidetheassemblyintotheslotonthefixtureyoke,sothattheupperlocknutisontopand

thetightenedcastbushingisonthebottomandhandtightentheupperlocknut.(Figure5B)

6. Afterthewiringisconnectedontheinsideofthefixture,closethehousingdoorsuchthat

thetabonthecoverfitsunderthetopexposedlocknutonthehookloop.(Figure5C)

7. Oncefixtureisfastenedclosed,tightentheupperlocknutwithapairofpliers.

CAUTION:DONOTTIGHTENTHEHOOKBYUSINGASCREWDRIVERBLADE‐TOOMUCH

FORCECOULDBREAKTHEHOOK.(Figure5C)

HOOK

LOOP

UPPER

LOCKNUT

WASHER

SAFETY

CLASP

FASTENER

SAFETY

CLASP

FIGURE 5C

HOOK LOOP ASSEMBLY

OPTIONAL

PLUG SHOWN

WASHER

CAST NUT

UTB2

INSTALLATION INSTRUCTIONS

Hubbell Lighting, Inc. Doc. No. 93097040

A subsidiary of Hubbell Incorporated Revision P0

701 Millennium Drive • Greenville, SC 29607 Page 5 Phone (864) 678-1000

FIGURE 5A

HOOK LOOP ASSEMBLY

FIGURE 5B

HOOK LOOP ASSEMBLY

GENERALINFORMATION:

All12”(304.8mm)minimumsupplywireoutsideofconduit.

Fixturemountinghookloopthreadsare3/4‐14NPS.

HOOK/LOOPMOUNTING:(Figures5A,5B&5C)

Cord&Hook/LooporderedasCxHLPx(Plugoptional)

1. Ifnotalreadydone,assemblethehooklooppiecesaccordingtothefollowingsteps.

2. Threadtheupperlocknut(withflatsurfacedown)ontothehooklooptoapproximately1/8”

fromthetopofthethreads.(Figure5A)

3. Positionthesafetyclaspasshownandjuststartthefastener,butleaveloose.(Figure5A)

4. Insertthepowercord,mustberatedminimum90°C16/3SEOW‐Aorequivalent,throughthe

holeinthehookandinsertgotcharing,topwasher,gasket,lowerwasherandcast

bushing/nutontocord.Fullytightencastbushingagainstbottomofhook.(Figure5A)

5. Slidetheassemblyintotheslotonthefixtureyoke,sothattheupperlocknutisontopand

thetightenedcastbushingisonthebottomandhandtightentheupperlocknut.(Figure5B)

6. Afterthewiringisconnectedontheinsideofthefixture,closethehousingdoorsuchthat

thetabonthecoverfitsunderthetopexposedlocknutonthehookloop.(Figure5C)

7. Oncefixtureisfastenedclosed,tightentheupperlocknutwithapairofpliers.

CAUTION:DONOTTIGHTENTHEHOOKBYUSINGASCREWDRIVERBLADE‐TOOMUCH

FORCECOULDBREAKTHEHOOK.(Figure5C)

HOOK

LOOP

UPPER

LOCKNUT

WASHER

SAFETY

CLASP

FASTENER

SAFETY

CLASP

FIGURE 5C

HOOK LOOP ASSEMBLY

GOTCHA

RING

GASKET

WASHER

CAST NUT

UTB2

INSTALLATION INSTRUCTIONS

Hubbell Lighting, Inc. Doc. No. 93097040

A subsidiary of Hubbell Incorporated Revision P0

701 Millennium Drive • Greenville, SC 29607 Page 5 Phone (864) 678-1000

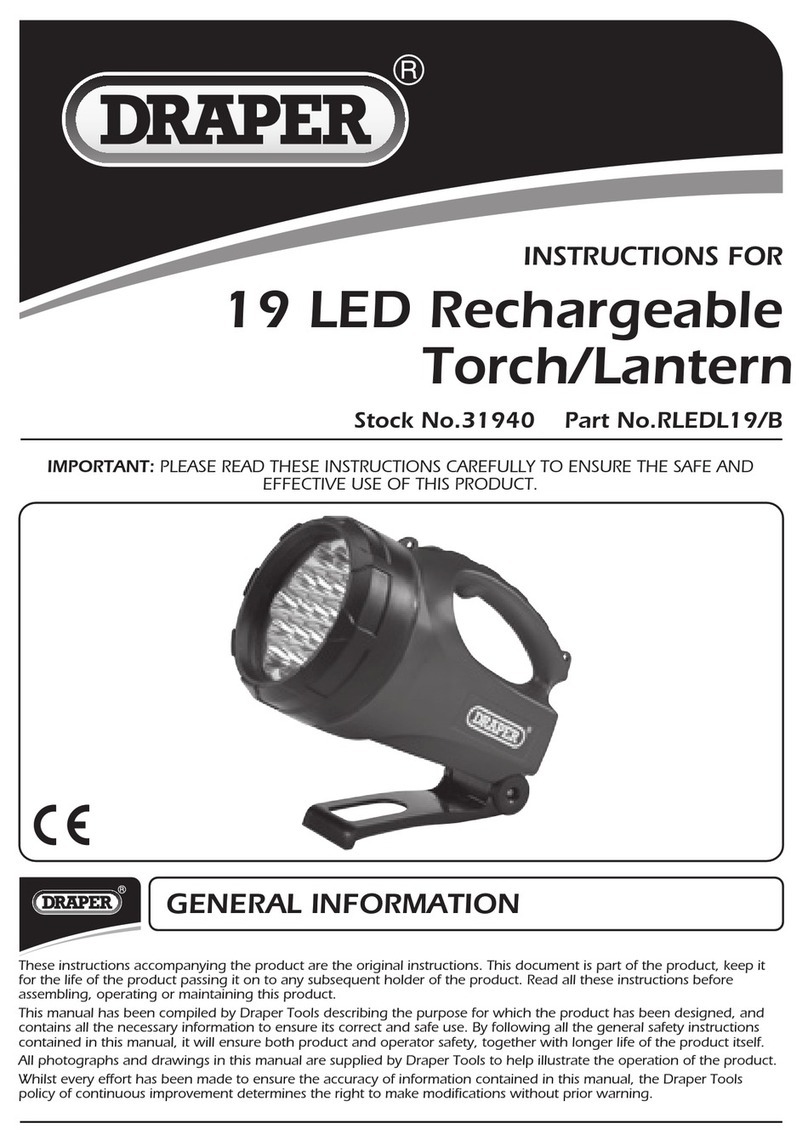

FIGURE 5A

HOOK LOOP ASSEMBLY

FIGURE 5B

HOOK LOOP ASSEMBLY

GENERALINFORMATION:

All12”(304.8mm)minimumsupplywireoutsideofconduit.

Fixturemountinghookloopthreadsare3/4‐14NPS.

HOOK/LOOPMOUNTING:(Figures5A,5B&5C)

Cord&Hook/LooporderedasCxHLPx(Plugoptional)

1. Ifnotalreadydone,assemblethehooklooppiecesaccordingtothefollowingsteps.

2. Threadtheupperlocknut(withflatsurfacedown)ontothehooklooptoapproximately1/8”

fromthetopofthethreads.(Figure5A)

3. Positionthesafetyclaspasshownandjuststartthefastener,butleaveloose.(Figure5A)

4. Insertthepowercord,mustberatedminimum90°C16/3SEOW‐Aorequivalent,throughthe

holeinthehookandinsertgotcharing,topwasher,gasket,lowerwasherandcast

bushing/nutontocord.Fullytightencastbushingagainstbottomofhook.(Figure5A)

5. Slidetheassemblyintotheslotonthefixtureyoke,sothattheupperlocknutisontopand

thetightenedcastbushingisonthebottomandhandtightentheupperlocknut.(Figure5B)

6. Afterthewiringisconnectedontheinsideofthefixture,closethehousingdoorsuchthat

thetabonthecoverfitsunderthetopexposedlocknutonthehookloop.(Figure5C)

7. Oncefixtureisfastenedclosed,tightentheupperlocknutwithapairofpliers.

CAUTION:DONOTTIGHTENTHEHOOKBYUSINGASCREWDRIVERBLADE‐TOOMUCH

FORCECOULDBREAKTHEHOOK.(Figure5C)

HOOK

LOOP

UPPER

LOCKNUT

WASHER

SAFETY

CLASP

FASTENER

SAFETY

CLASP

FIGURE 5C

HOOK LOOP ASSEMBLY

GOTCHA

RING

OPTIONAL

PLUG SHOWN

GASKET

WASHER

CAST NUT

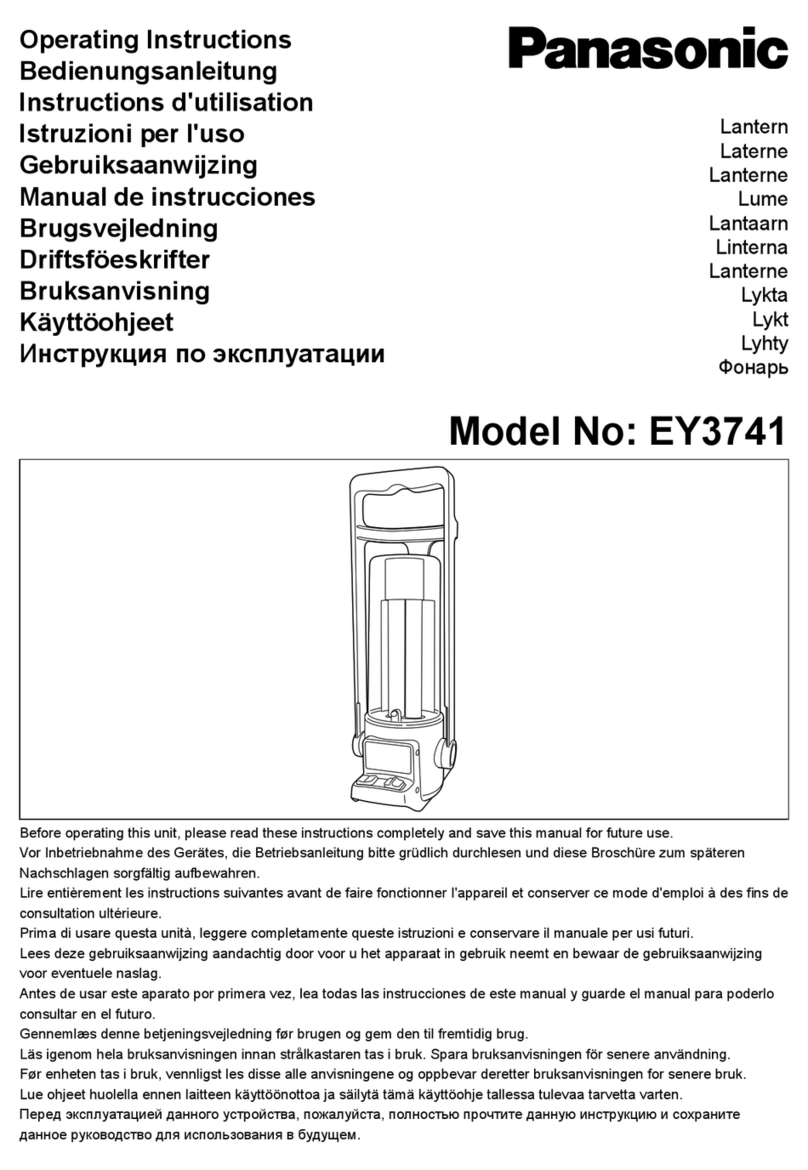

6. After the wiring is connected on the inside of the fixture, close

the housing door such that the tab on the cover fits under the top

exposed locknut on the hook loop. (Figure 5C)

7. Once fixture is fastened closed, tighten the upper locknut with a

pair of pliers.

CAUTION: DO NOT TIGHTEN THE HOOK BY USING A SCREWDRIVER

BLADE; TOO MUCH FORCE COULD BREAK THE HOOK. (Figure 5C)

UTB2

INSTALLATION INSTRUCTIONS

Hubbell Lighting, Inc. Doc. No. 93097040

A subsidiary of Hubbell Incorporated Revision P0

701 Millennium Drive • Greenville, SC 29607 Page 5 Phone (864) 678-1000

FIGURE 5A

HOOK LOOP ASSEMBLY

FIGURE 5B

HOOK LOOP ASSEMBLY

GENERALINFORMATION:

All12”(304.8mm)minimumsupplywireoutsideofconduit.

Fixturemountinghookloopthreadsare3/4‐14NPS.

HOOK/LOOPMOUNTING:(Figures5A,5B&5C)

Cord&Hook/LooporderedasCxHLPx(Plugoptional)

1. Ifnotalreadydone,assemblethehooklooppiecesaccordingtothefollowingsteps.

2. Threadtheupperlocknut(withflatsurfacedown)ontothehooklooptoapproximately1/8”

fromthetopofthethreads.(Figure5A)

3. Positionthesafetyclaspasshownandjuststartthefastener,butleaveloose.(Figure5A)

4. Insertthepowercord,mustberatedminimum90°C16/3SEOW‐Aorequivalent,throughthe

holeinthehookandinsertgotcharing,topwasher,gasket,lowerwasherandcast

bushing/nutontocord.Fullytightencastbushingagainstbottomofhook.(Figure5A)

5. Slidetheassemblyintotheslotonthefixtureyoke,sothattheupperlocknutisontopand

thetightenedcastbushingisonthebottomandhandtightentheupperlocknut.(Figure5B)

6. Afterthewiringisconnectedontheinsideofthefixture,closethehousingdoorsuchthat

thetabonthecoverfitsunderthetopexposedlocknutonthehookloop.(Figure5C)

7. Oncefixtureisfastenedclosed,tightentheupperlocknutwithapairofpliers.

CAUTION:DONOTTIGHTENTHEHOOKBYUSINGASCREWDRIVERBLADE‐TOOMUCH

FORCECOULDBREAKTHEHOOK.(Figure5C)

HOOK

LOOP

UPPER

LOCKNUT

SAFETY

CLASP

FASTENER

SAFETY

CLASP

FIGURE 5C

HOOK LOOP ASSEMBLY

GOTCHA

RING

OPTIONAL

PLUG SHOWN

GASKET

WASHER

CAST NUT

OPTICS WIRE GUARD INSTALLATION (If Optioned):

1. With mounting screws removed from heatsink, install full wire guard (WG-16) onto Reflector.

2. Install Reflector onto fixture heatsink using screws (4x) provided.