9555 Dry Fork Rd., Harrison, OH 45030-1994 • 1-800-543-7374 • www.hubert.com

4

Hubert #53232

U.L. Listed

Operation

The wrapper is appropriate for fruit, vegetable, fish, meat, cold food, etc. First, insert the electrical plug into a standard

NEMA 5 -15 outlet and switch on. A red light will appear. Turn the thermostat to set the desired temperature. Before

starting the operation, let the machine preheat for 5 to 10 minutes. This can be done by leaving the temperature

setting on the desired temperature. Put the wrapping material in place. Next, open up the cover plate. The wrapping

material is then placed between the cover plate and bar. Adjust the tightness of the plastic wrap. Then put the food on

cover plate and pull out the wrapping material. After finished wrapping the food, cut-off the wrapping with the heated

cut-off rod equipped with the machine. Put the wrapped food on hot plate for a few seconds. If only using the heated

cut-off rod and not wrapping any food, please turn thermostat to Min. “LO”.

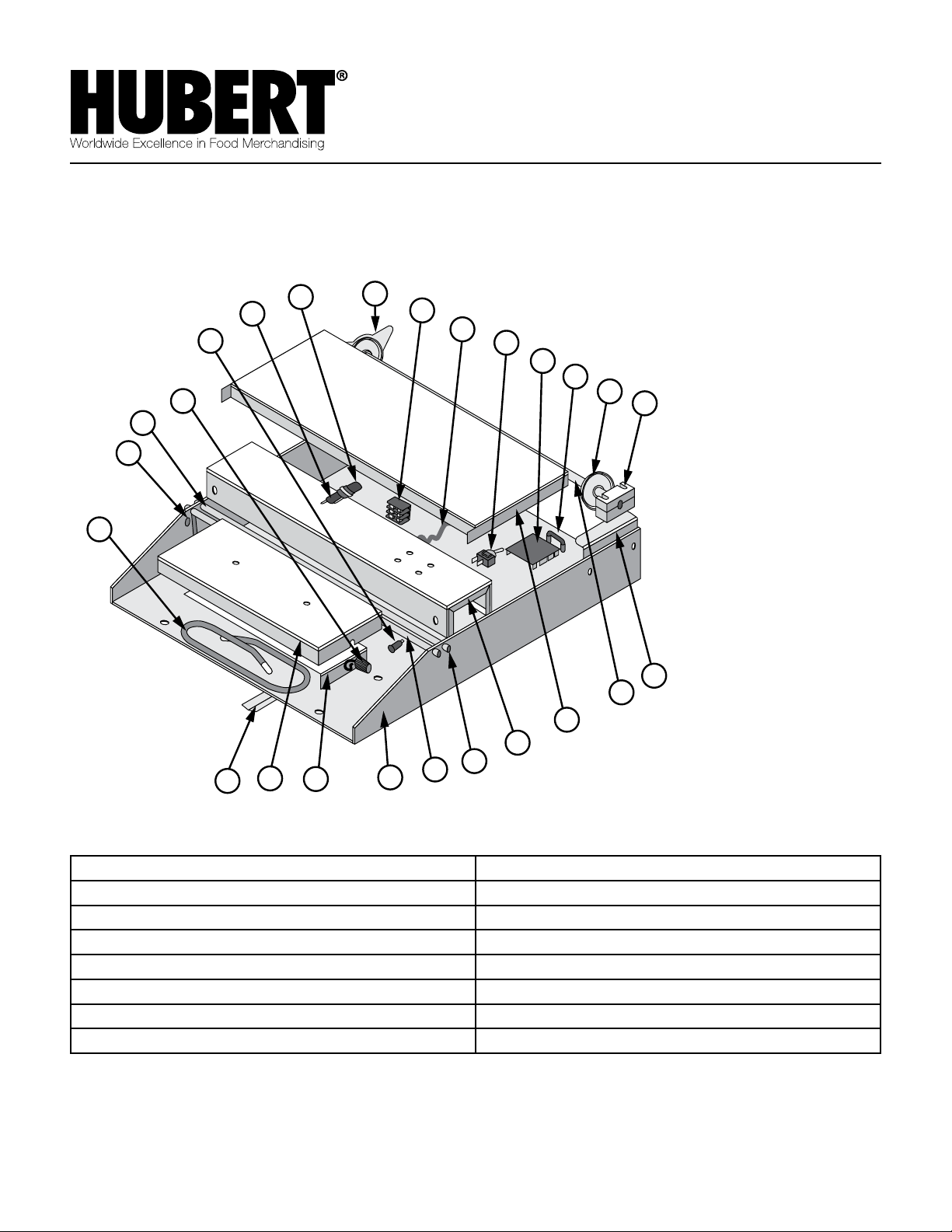

Dispensing Mechanism: Axle

The film dispensing mechanism is the axle. Model accepts film roll widths up to 18" W x 8" D. Contact your film supplier

for application information regarding film thickness and color.

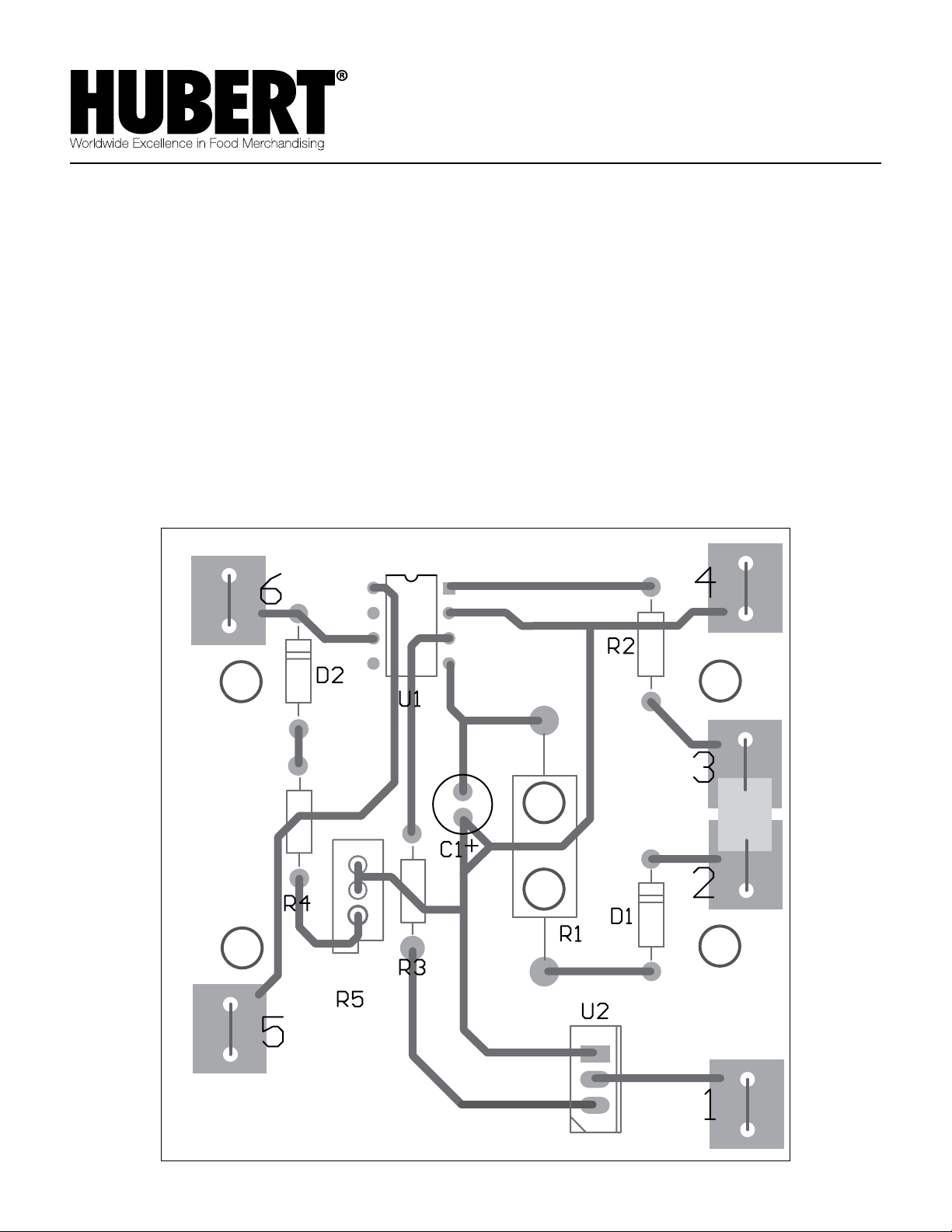

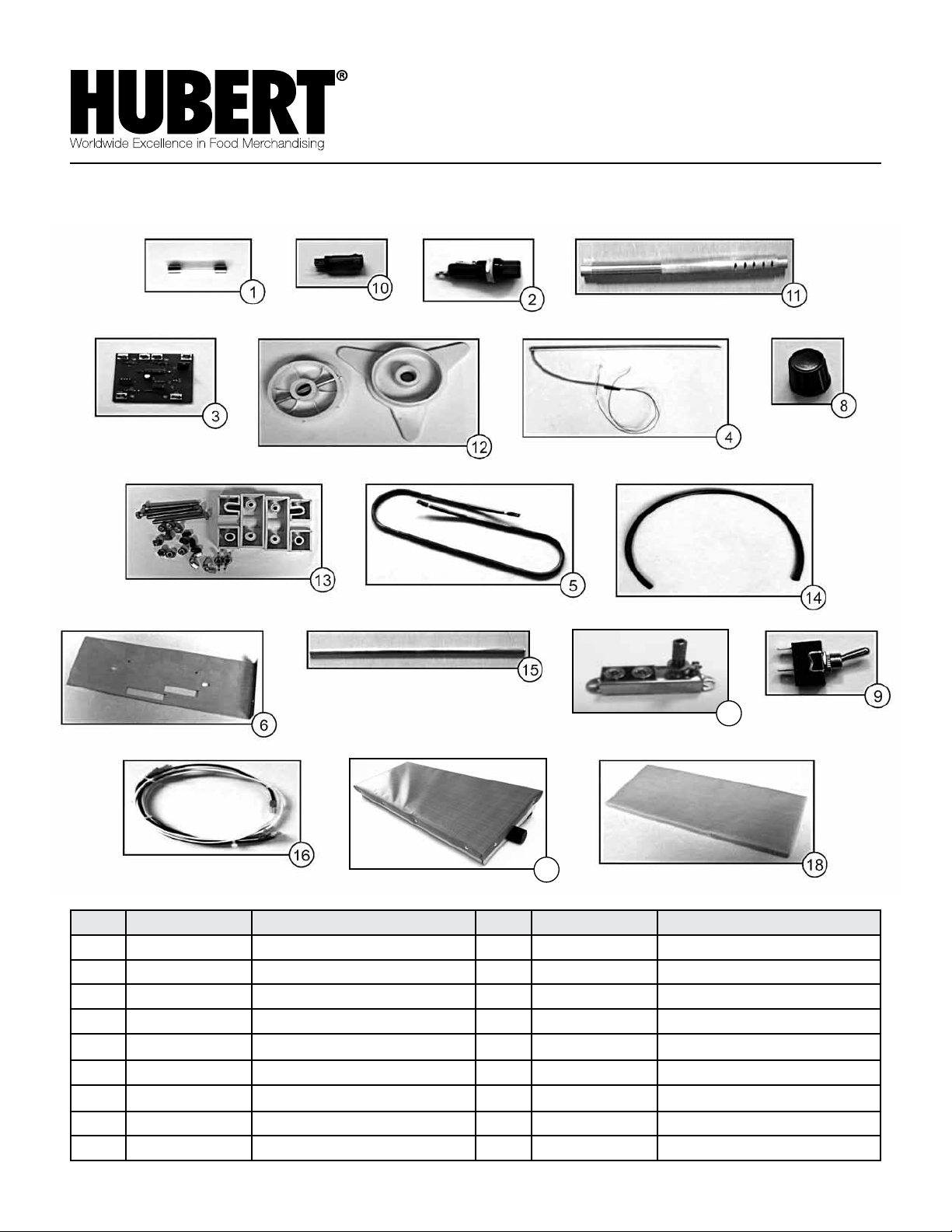

Heated Cut-off Rod

The heated cut-off Rod cuts the desired length of film. The temperature is factory preset at 266°F +/-50°F and monitored

and controlled electronically by a printed circuit board mounted inside the electronic box. It is field adjustable by an

electrical technician.

Hot Plate Sealing

The hot plate is a 15 3/16" x 6 1/2" aluminum casting with a built-in heating element. The operator seals the ends of the

film on the Hot Plate. The thermostat mounted under the hot plate is adjusted by a plastic knob mounted on the right

side of the hot plate. Adjustment ranges from “off” to 330°F. Temperature setting is determined by film thickness, air

temperature (kitchen or cooler) and operator’s speed.

FILM ROLE AXLE ASSEMBLY INSTRUCTIONS

1. Install Bearing Block Assembly (A) on the

left side of Base, line up holes and insert

Carriage Bolts (B) and tighten.

2. Repeat step (1) on right side of Base.

3. Loosen all Wing Nuts (C) on Bearing

Blocks on both sides to loosen top

of Bearing Blocks, and then rotate top

to expose Film Roll Axle Slots.

4. Install Film on Film Roll Axle (E),

tighten Core Adapter Wing Nut (F),

and insert in slots in the bottom of

the Bearing Blocks.

5. Rotate the top of Bearing Block to cover shaft

of Film Roll Axle, and tighten Wing Nuts (C) to the

required tension.

A

B

C

D

E

F