PAGE 1 OF 40 0321 IH-7208

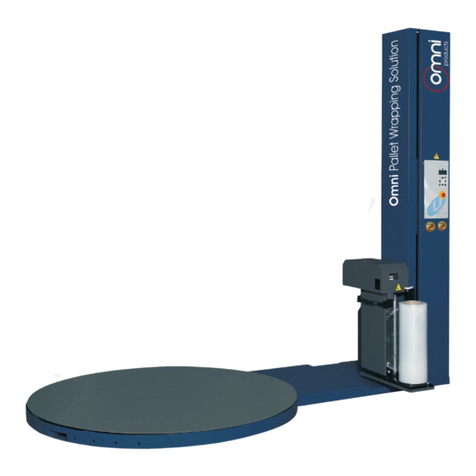

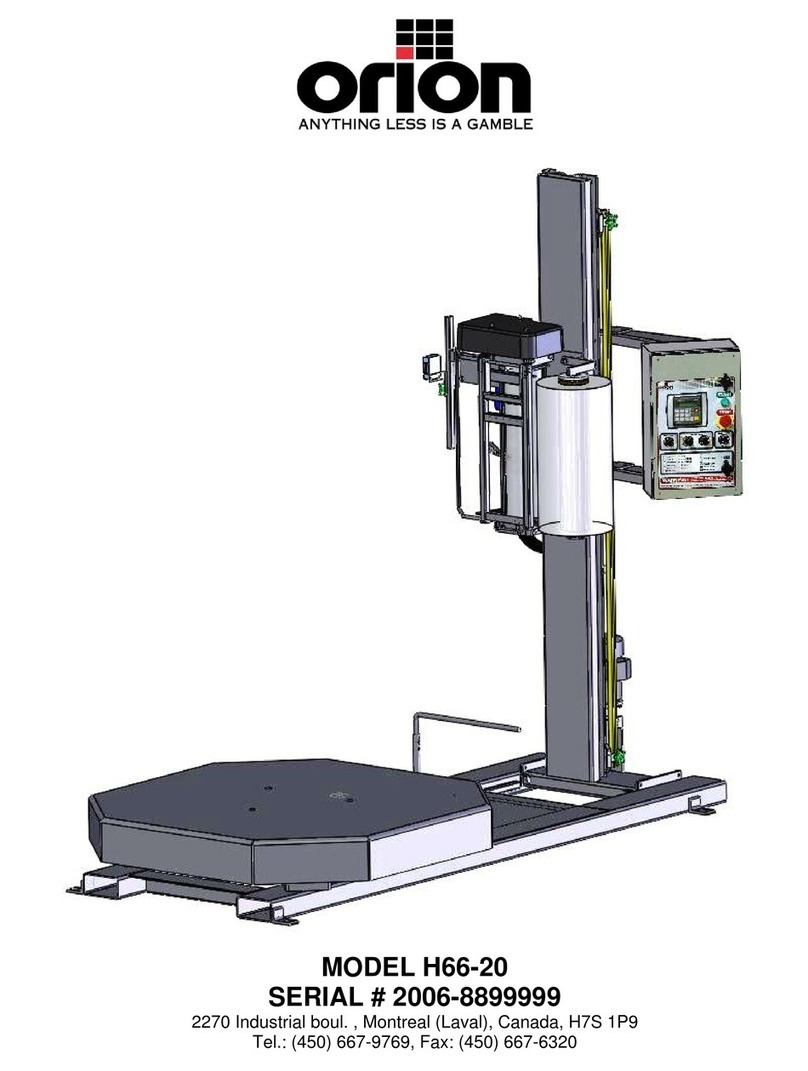

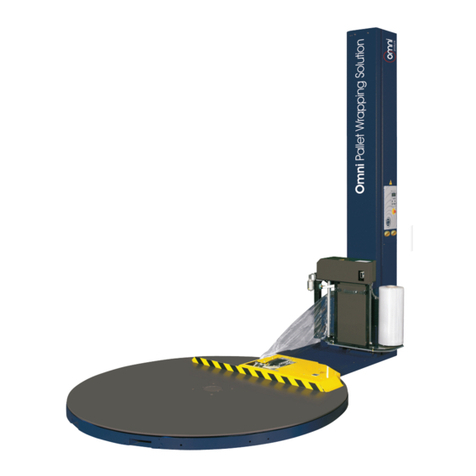

SEMI-AUTOMATIC

STRETCH WRAP

MACHINE WITH SCALE

1-800-295-5510

uline.com

H-7208

MACHINE DIMENSIONS

Length 98"

Width 60"

Height 132"

Turntable Diameter 60"

Turntable Height from Floor 4⁄"

Wrapping Height 110 "

Operation Space 98 x 60 x 132"

Maximum Load Size 52 x 52 x 110"

Approximate Shipping Weight 1,700 lbs.

ELECTRICAL SPECIFICATIONS

• 115 VAC, 60 Hz, Single-phase, 15 AMP

TURNTABLE SYSTEM

• 20 loads per hour (spiral)

• 12 RPM turntable maximum speed

• 4,000 lbs. turntable maximum load capacity

FILM CARRIAGE/ELEVATOR SYSTEM

• Adjustable raise and lower speeds

• Automatic height detection photoelectric sensor

SCALE

• RS232 Serial Port

FILM DELIVERY SYSTEM

• Infinite / Manual Stretch Adjustment

• 10" Diameter Roll Capacity

• 20" Roll Width Capacity

CAUTION! Motor control equipment and

electronic controllers are connected to

hazardous line voltages. When servicing

drive and controllers, there may be exposed

components with housings or protrusions at or

above line potential. Extreme care should be

taken to protect against shock.

The user is responsible for conforming to all

applicable code requirements with respect to

grounding requirements. Do NOT use extension

cords to operate the equipment.

Disconnect AC input power before checking

components, performing maintenance,

cleaning up, and when the machine is not in

use. Do NOT connect or disconnect wires and

connectors while power is applied to circuit.

Wiring work should be performed only by

qualified personnel. There is a danger of

electric shock or fire.

WARNING! Loose clothing must NOT be worn

while the machine is in operation. Stay clear

of moving parts while the machine is running.

Para Español, vea páginas 14-26.

Pour le français, consulter les pages 27-40.

SYSTEM SPECIFICATIONS

Two Person Assembly

Recommended