Micro – Instruction Manual

CONTENTS

1INTRODUCTION..............................................................................................................3

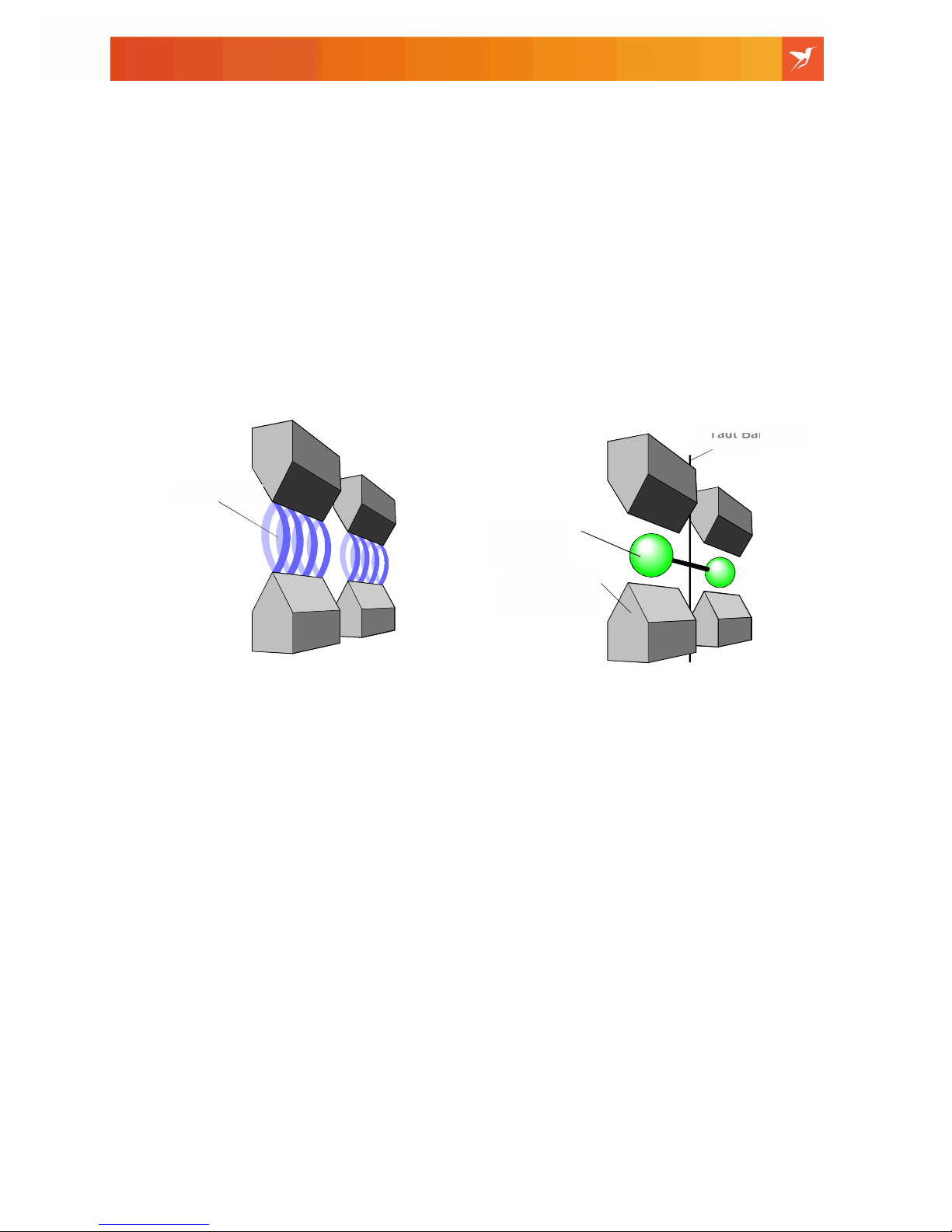

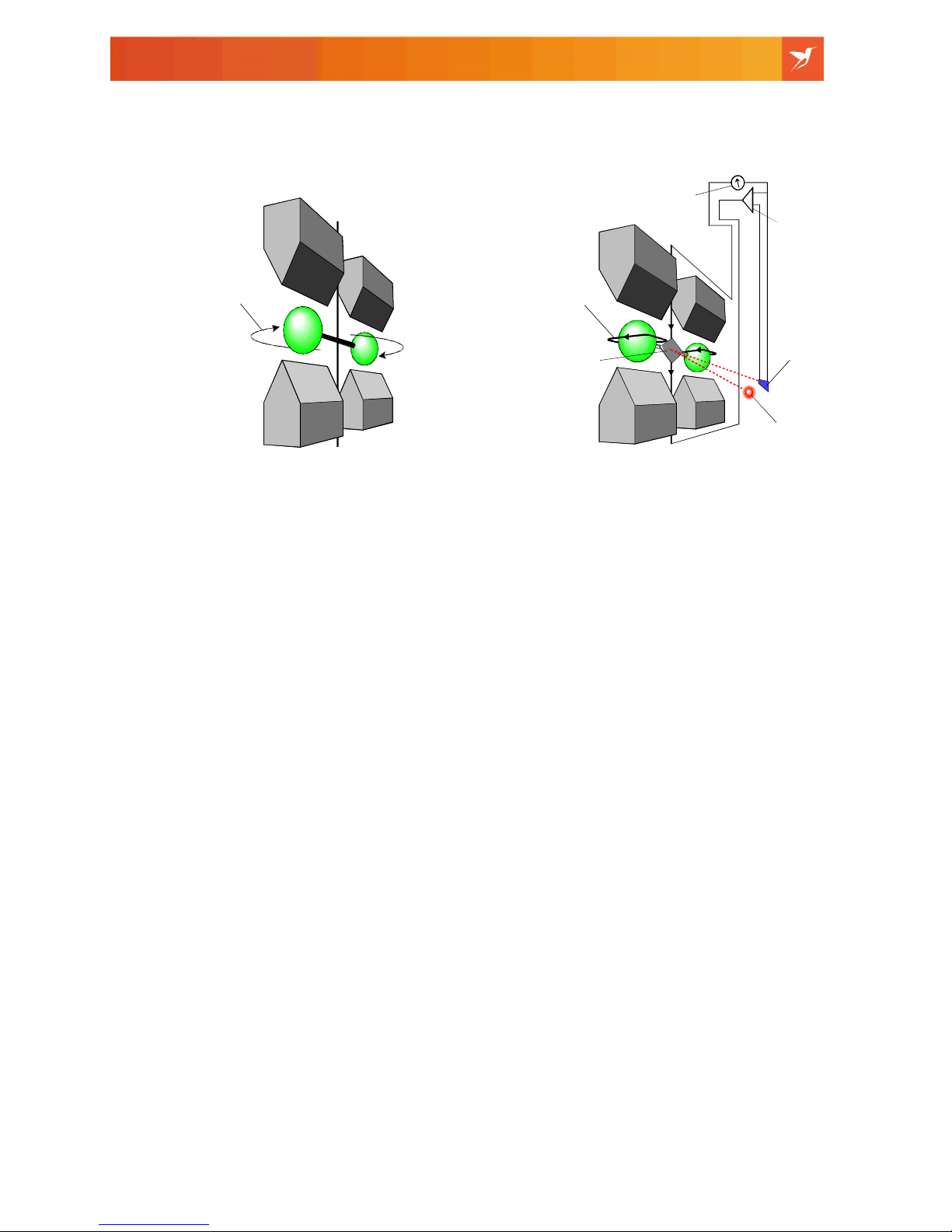

2HUMMINGBIRD PARAMAGNETIC MEASUREMENT PRINCIPLE..................................4

3PRODUCT SPECIFICATION ...........................................................................................6

3.1 PERFORMANCE SPECIFICATION (UNDER CONSTANT CONDITIONS) ........................................6

3.2 MECHANICAL SPECIFICATION ...........................................................................................7

3.3 EXTERNAL POWER SUPPLY SPECIFICATION.......................................................................8

3.4 ENVIRONMENTAL SPECIFICATION .....................................................................................8

4SENSOR INTEGRATION............................................................................................... 10

4.1 SENSOR MOUNTING......................................................................................................10

4.2 ELECTRICAL ARRANGEMENT .......................................................................................... 13

4.3 ANALOGUE OUTPUT......................................................................................................14

4.4 LOCATION OF SENSOR .................................................................................................. 15

4.5 HOW TO MINIMISE EXPOSURE OF PNEUMATIC SYSTEM TO CONTAMINANTS......................... 15

4.6 HOW TO HANDLE THE SENSOR ...................................................................................... 15

4.7 ORIENTATION OF SENSOR ............................................................................................. 16

4.8CONDITIONING OF THE SAMPLE...................................................................................... 16

4.9 PRESSURE EFFECTS.....................................................................................................16

4.10 USE OF SENSOR WITH FLAMMABLE /TOXIC SAMPLE GASES..............................................18

5OPERATION AND CALIBRATION ................................................................................18

5.1 CALIBRATION –INITIAL CONDITIONS ...............................................................................18

5.2 SINGLE POINT OFFSET CORRECTION (SPOC).................................................................18

5.3 ZERO DRIFT OFFSET CORRECTION IN THE HOST EQUIPMENT............................................22

5.4 LED SENSOR STATUS ...................................................................................................22

6VARIANTS, SPARES, PACKAGING AND WARRANTY ...............................................23

6.1 SENSOR VARIANTS OPTIONS –AS SHIPPED FROM HUMMINGBIRD ......................................23

6.2 PRODUCT SPARES........................................................................................................23

6.3 SPECIAL PACKAGING .................................................................................................... 23

6.4 PRODUCT FAILURE DURING WARRANTY..........................................................................24

6.5 PRODUCT FAILURE OUT OF WARRANTY ..........................................................................24

6.6 MAINTENANCE AND SERVICING ...................................................................................... 24

6.7 DECONTAMINATION.......................................................................................................24

6.8 ROHS AND WEEE DIRECTIVES .....................................................................................25

7APPENDICES................................................................................................................26

APPENDIX 7.1 OUTLINE DIMENSIONS,KK FRICTION LOCK CONNECTOR............................... 26

APPENDIX 7.2 OUTLINE DIMENSIONS,SMT LOW PROFILE CONNECTOR .............................. 27

APPENDIX 7.3 PROCEDURE FOR FIXING OF THE ADAPTOR PLATE........................................28

APPENDIX 7.4 MECHANICAL VIBRATION AND SHOCK RESISTANCE ....................................... 29

APPENDIX 7.5 SAMPLE GAS CROSS SENSITIVITY GUIDE .................................................... 30

APPENDIX 7.6 ROHS II DIRECTIVE 2011/65/EU DECLARATION ..........................................33