September 2019

CONTENT

PREFACE.............................................................................................................................................................. 1

1 EC DECLARATION OF CONFORMITY .......................................................................................... 2

2 INFORMATION CONTENT AND RIGHTS...................................................................................... 3

3 GENERAL .............................................................................................................................................. 4

3.1

MANUFACTURER

'

S INSTRUCTIONS

.............................................................................................................. 4

3.2

C

ONTACT FOR MACHINE SUPPORT

............................................................................................................. 4

3.3

T

ECHNICAL

DATA.................................................................................................................................... 4

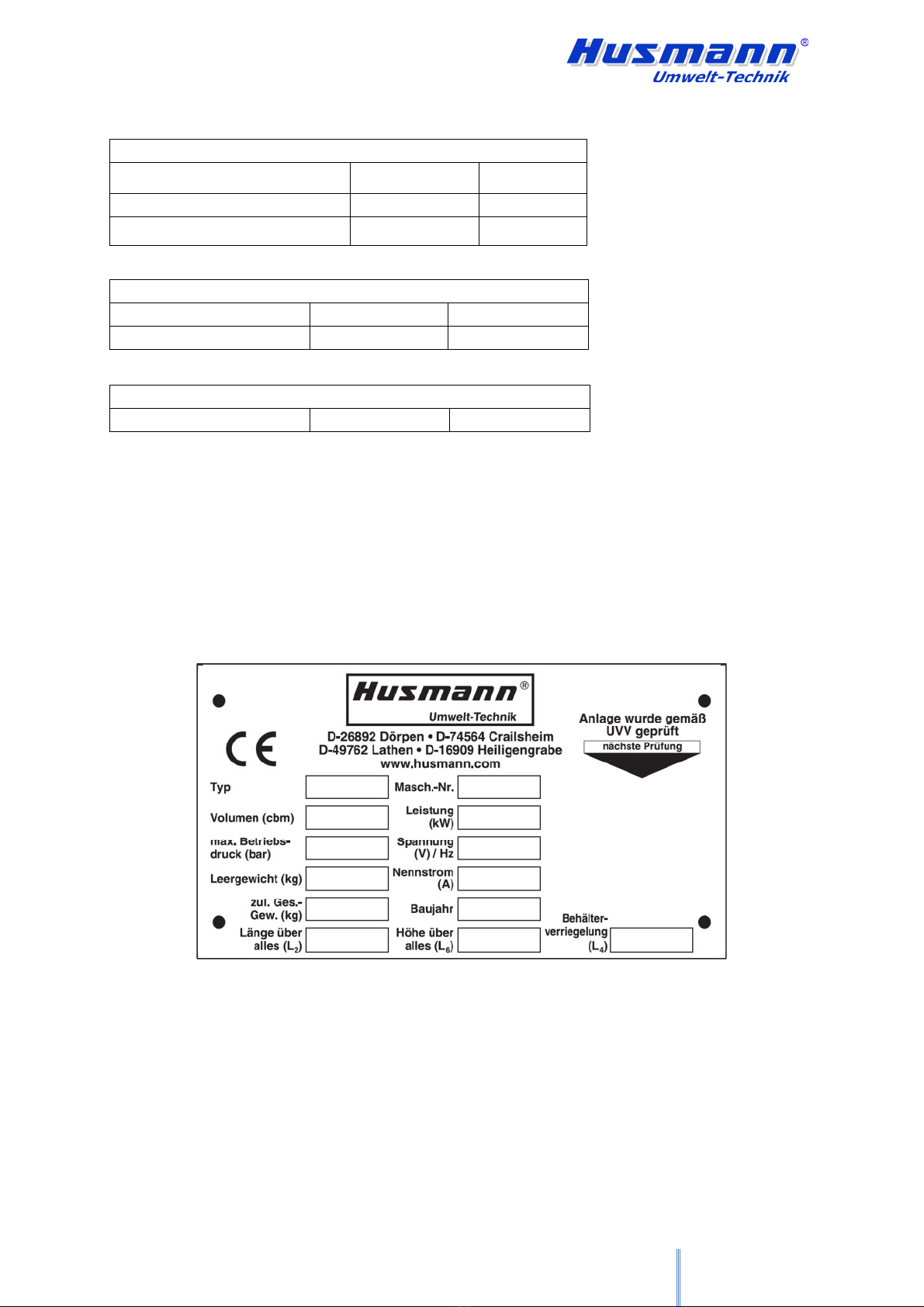

3.3.1

Rating plate

............................................................................................................................................. 5

3.3.2

Sound pressure level

.............................................................................................................................. 6

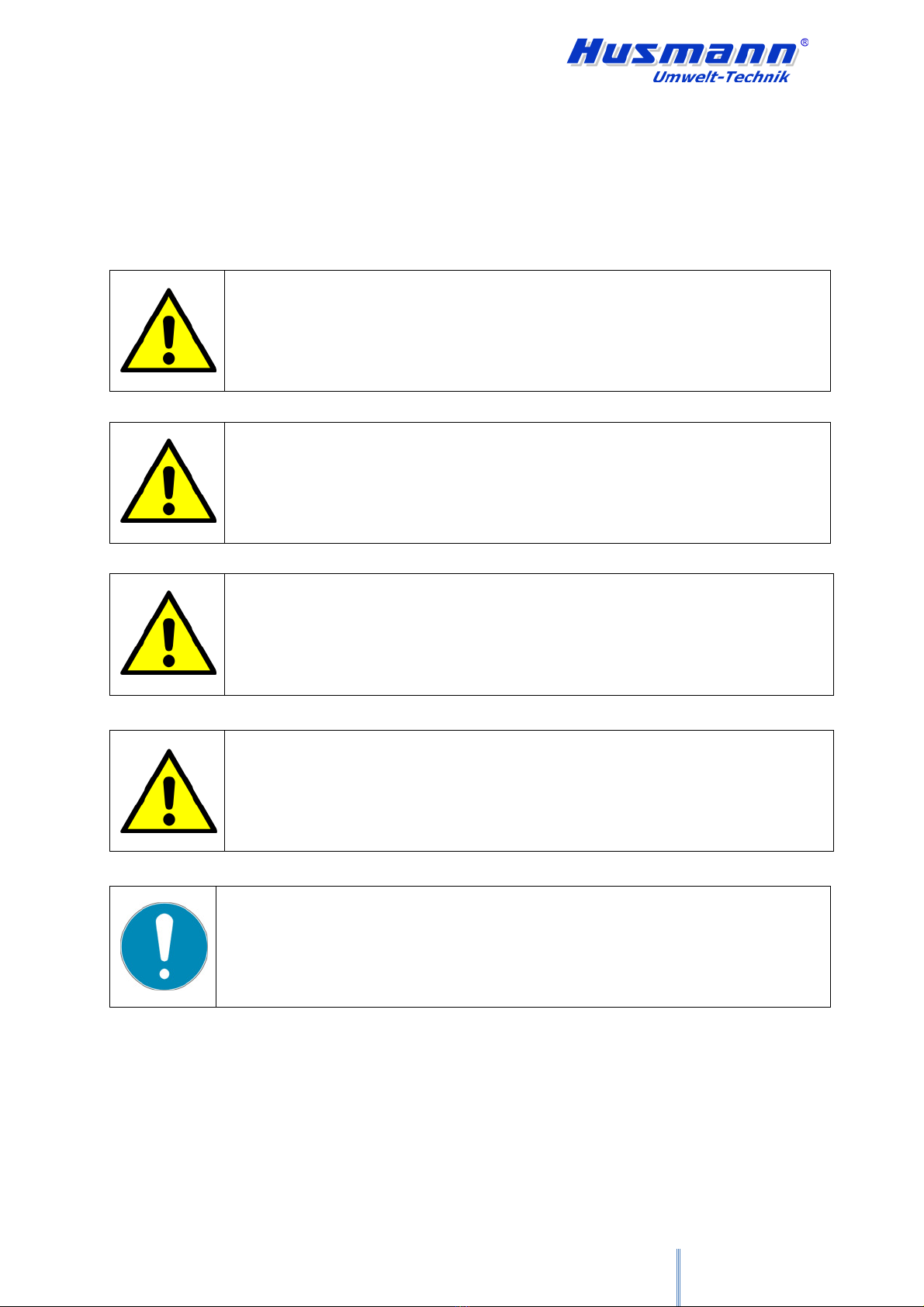

4 SAFETY .................................................................................................................................................. 7

4.1

M

EANING OF THE

SAFETY

SIGNAL WORDS

.............................................................................................. 7

4.2

SAFETY

...................................................................................................................................................... 8

4.2.1

Basic safety instructions............................................................................................................................ 8

4.2.2

Machine-specific safety regulations........................................................................................................ 10

4.2.3

Tipping device

...................................................................................................................................... 11

4.3

R

ESPONSIBILITIES OF THE OPERATOR

...................................................................................................... 12

4.4

W

ARNING AND INFORMATION SIGNS

....................................................................................................... 13

4.5

DANGER ZONES

........................................................................................................................................ 16

4.6

RESIDUAL RISKS

....................................................................................................................................... 18

4.7

P

ERSONAL PROTECTIVE EQUIPMENT

........................................................................................................ 20

4.8

F

IRE PROTECTION

.................................................................................................................................... 20

5 SAFETY AND PROTECTIVE EQUIPMENT .................................................................................. 21

6

INTENDED USE .................................................................................................................................. 25

6.1

FORESEEABLE

MISUSE

................................................................................................................. 26

7

DIMENSIONED DRAWINGS OF PORTABLE COMPACTORS ................................................. 27

8

INSTALLATION.................................................................................................................................. 34

8.1

I

NSTALLATION

S

ITE

................................................................................................................................. 34

8.2

I

NSTALLATION ON RAMPS

,

PEDESTALS AND WORKING PATFORMS

........................................................... 35

8.3

I

NSTALLATION IN GENERALLY ACCESSIBLE AREAS

.................................................................................. 36

9

INITIAL START-UP............................................................................................................................ 37

9.1

E

LECTRICAL CONNECTION

....................................................................................................................... 40

9.2

I

NSTALLATION

......................................................................................................................................... 41

9.2.1

SERVICE................................................................................................................................................ 42

9.3

O

PTIONAL CONTROLS

.............................................................................................................................. 44

9.4

O

PTIONAL ADDITIONAL EQUIPMENT

....................................................................................................... 45

9.5

O

PTIONAL SPECIAL ACCESSORY

.............................................................................................................. 47

10

LID ABOVE

THE FILLING OPENING......................................................................................... 49

10.1 O

NE

-

PIECE LID

(

WITH

GAS

STRUTS)..................................................................................................... 50

10.2 H

YDRAULIC

LID ..................................................................................................................................... 51

10.3

L

ID WITH

L

INAK

MOTOR ....................................................................................................................... 53

10.4

CENTRALLY

DIVIDED

LID................................................................................................................ 54

10.4.1

RAMP OPERATION WITH A CENTRALLY DIVIDED LID

with fall protection (optional)............. 56

11

LID AND TIPPING DEVICE (OPTIONAL)..................................................................................... 58

12

TIPPING DEVICE (OPTIONAL) ...................................................................................................... 59

12.1

L

ID AND

TIPPING

DEVICE

VARIATIONS .......................................................................................... 60