English – 9

OPERATING

Protective equipment

General

Do not use the machine unless you are able to call for help in

the event of an accident.

Personal protective equipment

You must use approved personal protective equipment

whenever you use the machine. Personal protective

equipment cannot eliminate the risk of injury but it will reduce

the degree of injury if an accident does happen. Ask your

dealer for help in choosing the right equipment.

Always wear:

• Protective helmet

• Hearing protection

• Protective goggles or a visor

• Breathing mask

• Heavy-duty, firm grip gloves.

• Tight-fitting, heavy-duty and comfortable clothing that

permits full freedom of movement.

• Boots with steel toe-caps and non-slip sole

Be careful as clothing, long hair, and jewellery can get caught

in moving parts.

Other protective equipment

• Fire fighting equipment

• Always have a first aid kit nearby.

General safety precautions

This section describes basic safety directions for using the

machine. This information is never a substitute for

professional skills and experience.

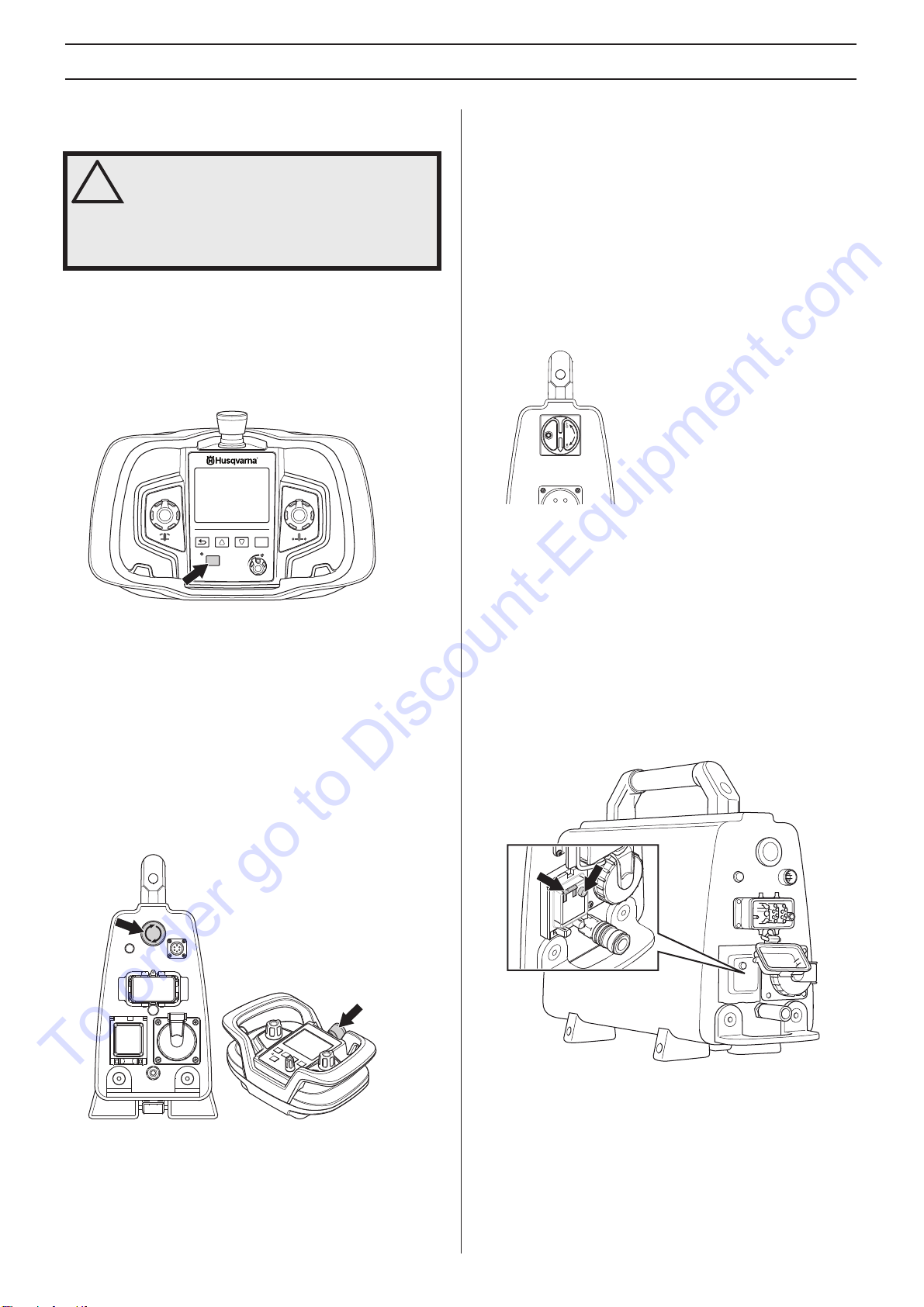

• Please read the operator’s manual carefully and make

sure you understand the instructions before using the

machine.

• Read through the manual supplied with the wall saw

before starting to use the hydraulic unit.

• Keep in mind that the operator is responsible for accidents

or hazards occuring to other people or their property.

• All operators shall be trained in the use of the machine.

The owner is responsible for ensuring that the operators

receive training.

• The machine must be kept clean. Signs and stickers must

be fully legible.

!

WARNING! The use of products such as

cutters, grinders, drills, that sand or form

material can generate dust and vapours

which may contain hazardous chemicals.

Check the nature of the material you intend

to process and use an appropriate breathing

mask.

!

WARNING! Long-term exposure to noise can

result in permanent hearing impairment. So

always use approved hearing protection.

Listen out for warning signals or shouts

when you are wearing hearing protection.

Always remove your hearing protection as

soon as the engine stops.

!

WARNING! There is always a risk of crush

injuries when working with products

containing moving parts. Wear protective

gloves to avoid body injuries.

!

WARNING! Sparks may appear and start a

fire when you work with the machine. Always

keep fire fighting equipment handy.

!

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings

and instructions may result in electrtic

shock, fire and/or serious injury.

!

WARNING! The machine can be a dangerous

tool if used incorrectly or carelessly, which

can cause serious or fatal injury to the

operator or others.

Never allow children or other persons not

trained in the use of the machine to use or

service it. Never allow anyone else to use the

machine without first ensuring that they

have understood the contents of the

operator’s manual.

Never use the machine if you are fatigued,

while under the influence of alcohol or

drugs, medication or anything that could

affect your vision, alertness, coordination or

judgement.

!

WARNING! Unauthorized modifications and/

or accessories may lead to serious injury or

death to the user or others.

Do not modify this product or use it if it

appears to have been modified by others.

Never use a machine that is faulty. Carry out

the checks, maintenance and service

instructions described in this manual. Some

maintenance and service measures must be

carried out by trained and qualified

specialists. See instructions under the

heading Maintenance.

Always use genuine accessories.

To order go to Discount-Equipment.com