CONTENTS

4

–

English

Contents

KEY

TO SYMBOLS

Symbols on the machine

...................................... 2

Explanation of warning levels ............................... 3

Note the following before starting: ........................ 3

CONTENTS

Contents

............................................................... 4

INTR

ODUCTION

Dear customer!

..................................................... 5

Good service ........................................................ 5

Serial Number ....................................................... 5

Applications .......................................................... 5

User responsibility ................................................ 5

The manufacturer’s reservation ............................ 5

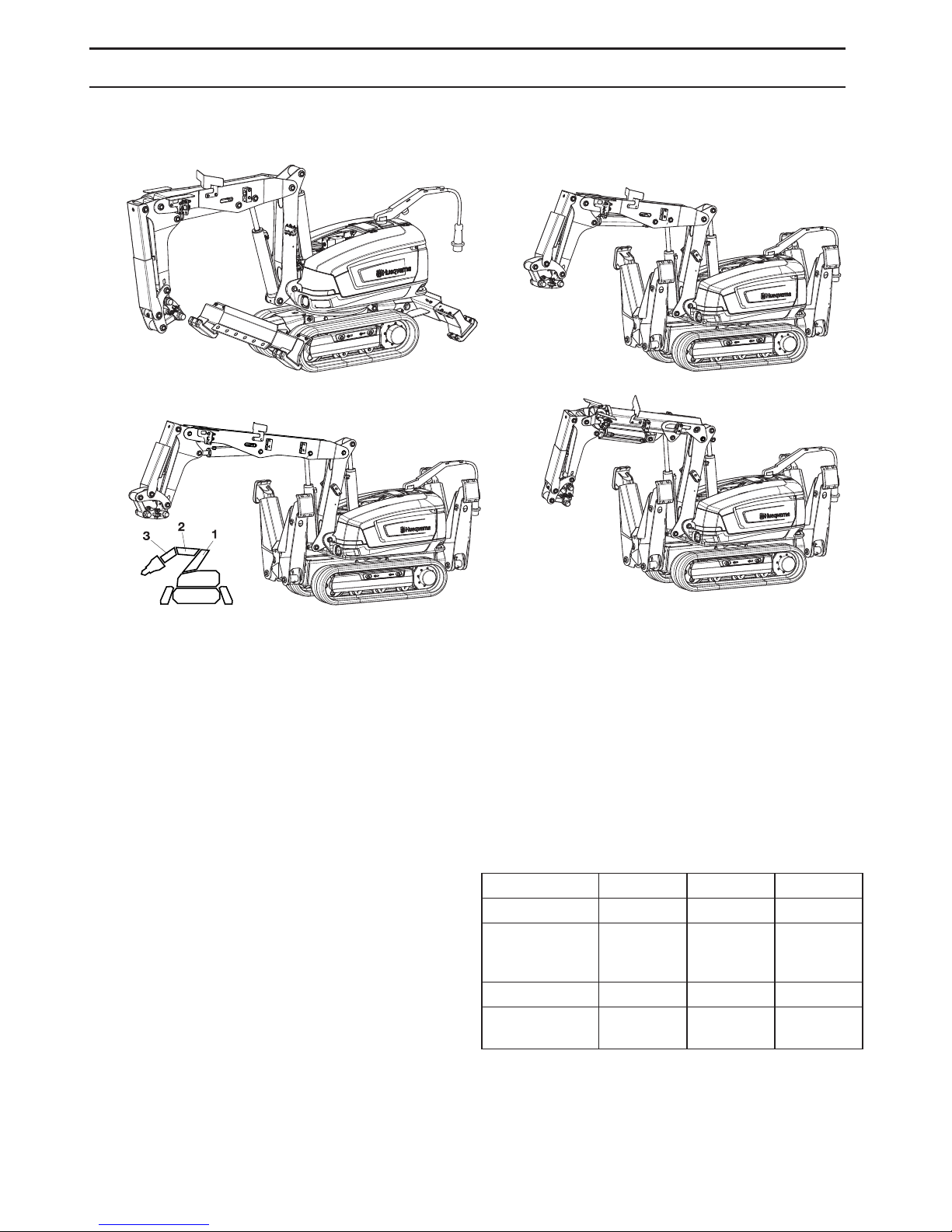

Machine equipment .............................................. 6

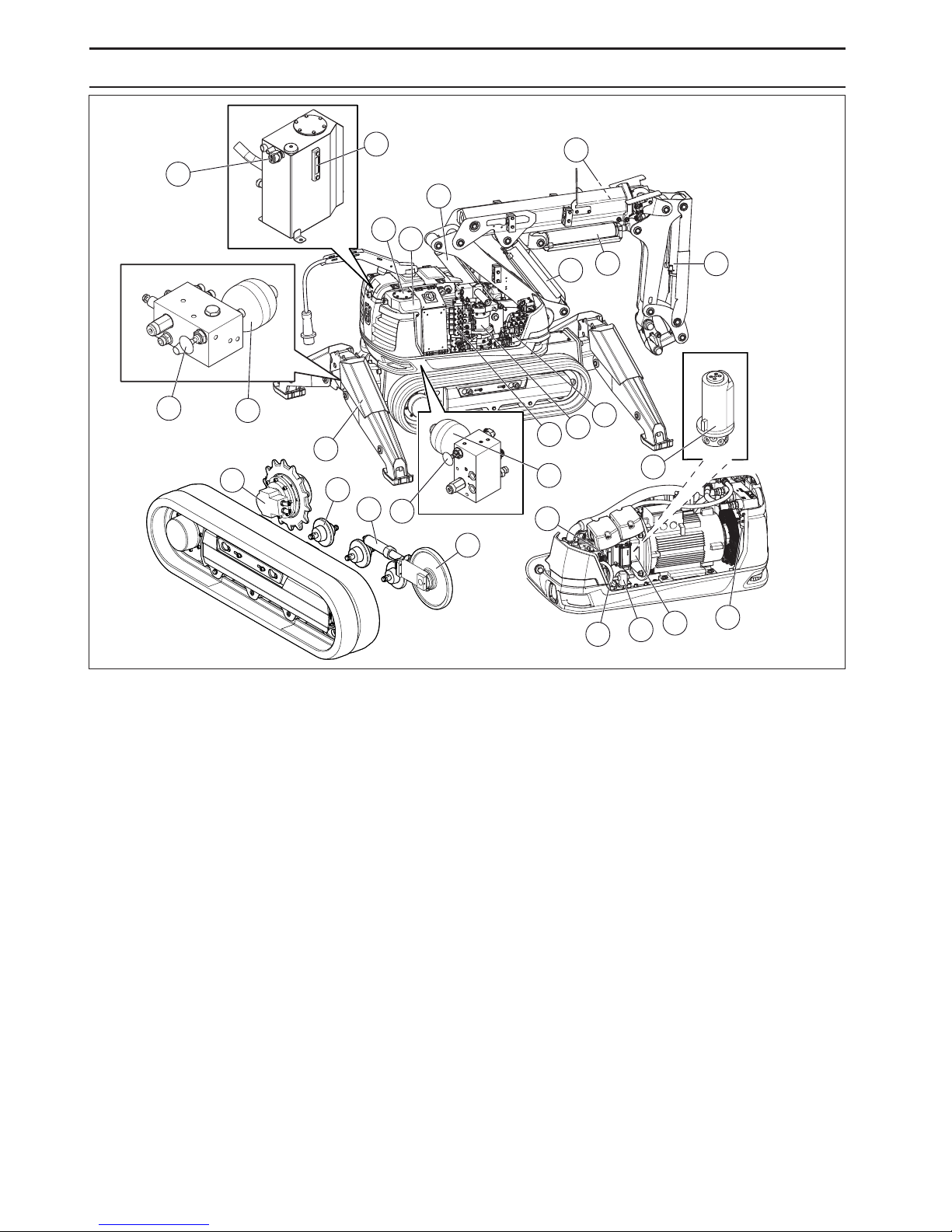

What is what on the machine? .............................. 7

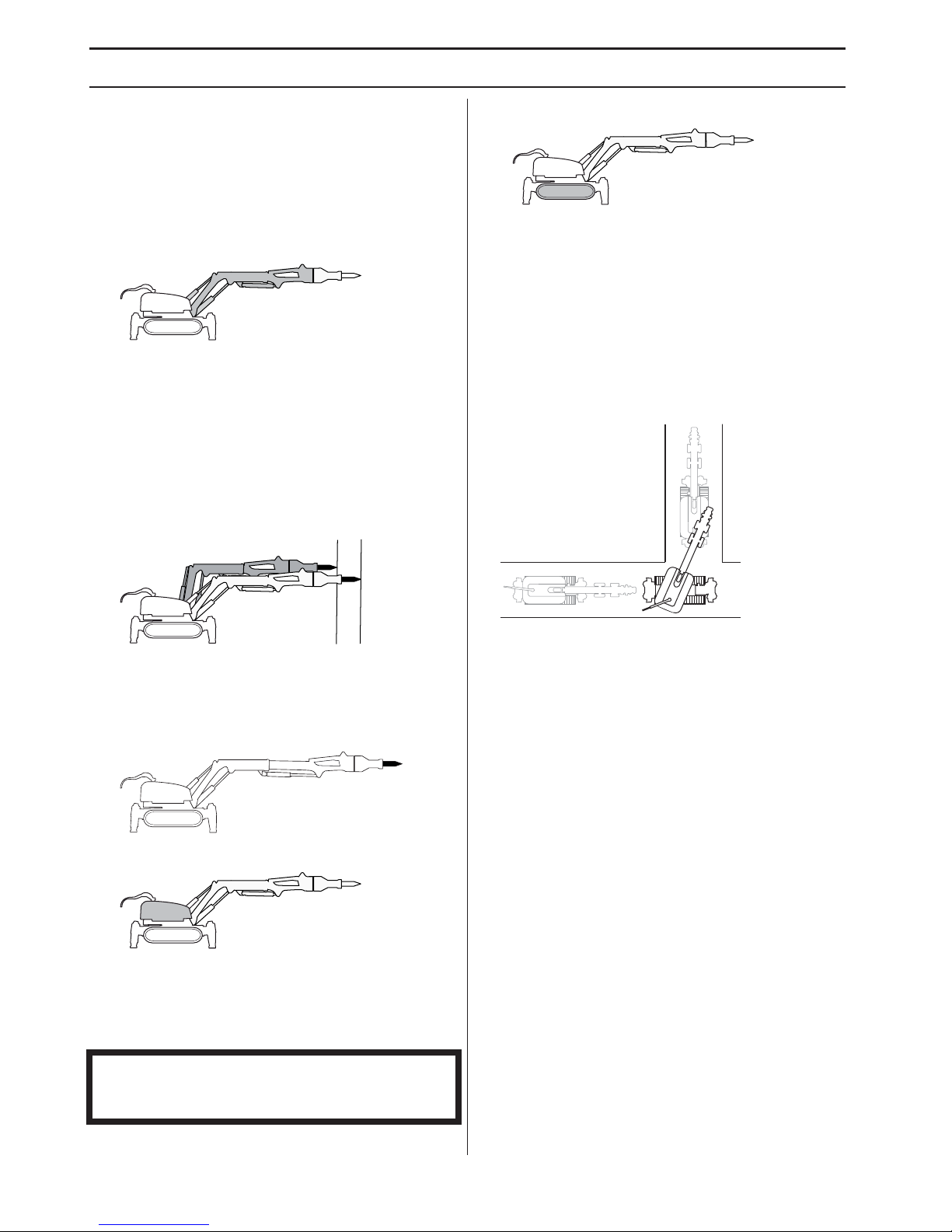

The machine’s functions ....................................... 8

HYDRA

ULIC SYSTEM

The machine’

s hydraulic system ........................... 10

General ................................................................. 11

Main pressure ....................................................... 11

Cooler ................................................................... 11

ELECTRICAL SYSTEM

The machine’

s electric system .............................. 12

General ................................................................. 13

High-voltage circuit ............................................... 13

Low-voltage circuit ................................................ 13

CONTR

OL SYSTEM

What is what on the remote control?

.................... 14

General ................................................................. 15

Remote control ..................................................... 15

Signal transmission ............................................... 15

Battery .................................................................. 15

The machine’s software ........................................ 15

MA

CHINE´S SAFETY EQUIPMENT

Gener

al ................................................................. 16

SAFETY INSTR

UCTIONS

Protectiv

e equipment ............................................ 18

General safety warnings ....................................... 18

General working instructions ................................ 19

External environmental factors ............................. 24

ST

ARTING AND STOPPING

Bef

ore starting ...................................................... 26

Starting ................................................................. 26

Stopping ................................................................ 26

Inspection after work ............................................. 26

OPERA

TION

Oper

ating modes .................................................. 27

Key to commands ................................................. 27

Designation of the machine’s parts ...................... 27

Work mode ........................................................... 28

Extra function ....................................................... 28

Transport mode - Two hand .................................. 29

Transport mode - One hand ................................. 30

Transport mode - Crawl ........................................ 30

T

OOLS

Gener

al ................................................................ 31

Work mode ........................................................... 32

Changing tools ..................................................... 32

Storage ................................................................. 33

A

CCESSORIES

Accessor

y kits ...................................................... 34

Service check ....................................................... 36

What is what on the control unit? ......................... 36

SETTINGS

Track widener ...................................................... 37

Menu overview ..................................................... 38

Operational settings ............................................. 38

Work ..................................................................... 38

Service ................................................................. 40

Joystick pattern .................................................... 43

MAINTENANCE AND SER

VICE

Gener

al ................................................................ 48

Measures to take in advance of maintenance,

service and trouble shooting ................................ 48

After Maintenance and Service ............................ 48

Cleaning ............................................................... 49

Service schedule .................................................. 50

MAINTENANCE AND SER

VICE

Ser

vice review ...................................................... 59

MAINTENANCE AND SER

VICE

Mountings

............................................................. 60

TR

OUBLESHOOTING

Error messages

.................................................... 66

Troubleshooting schedule .................................... 70

TECHNICAL D

ATA

Guide v

alues for mains connection ...................... 72

The hydraulic system pressure ............................ 72

Hydraulic fluid and lubricant ................................. 73

Preset limit values ................................................ 73

Technical data ...................................................... 74

Range and transport diagram .............................. 75

US WARRANTY STATEMENT

WARRANTY POLICY ........................................... 83

EQUIPMENT ........................................................ 83