CAUTION: Do not use the rubber

caterpillar tracks in temperatures that are

higher than 70°C/158°F. If the temperature

is higher than 70°C/158°F, use steel tracks.

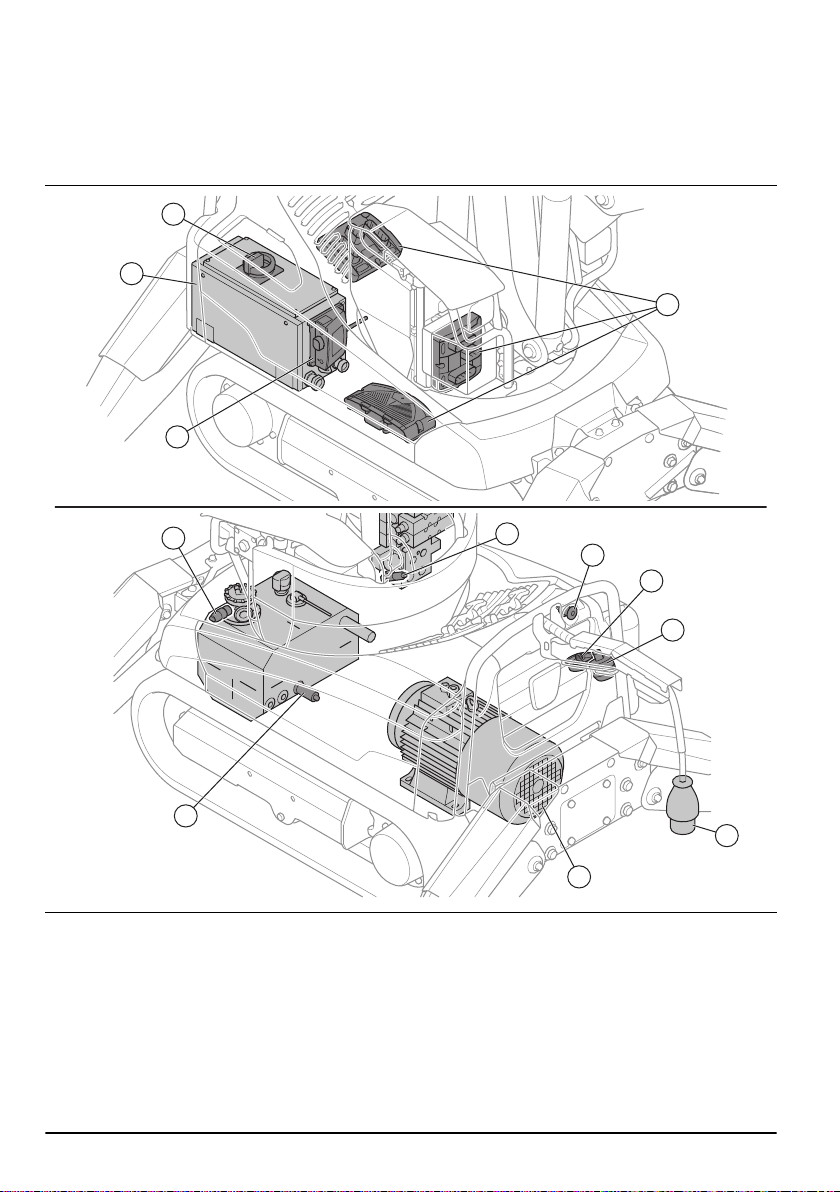

Outriggers

The product has 2 outriggers on each side of the

product. The outriggers make the product stable. When

the product is in operation, the outriggers must always

be extended.

Tools

WARNING: Please read the operator’s

manual carefully and make sure you

understand the instructions before using the

machine. You should also read and

understand the manual that accompanies

the tool.

CAUTION: Ensure that the tool’s and

the machine’s performance (weight,

hydraulic pressure, flow etc) are compatible.

The machine must be equipped with the tools and

accessories appropriate for the job and the machine.

The weight and performance requirements of the tools

are important in determining the suitability and

compatibility for installation on the machine. Read,

understand and follow the handling instructions in the

operator´s manual and the tool supplier´s

recommendations and instructions. Never use the

machine with a tool contrary to operator´s manual or tool

supplier´s recommendations. Contact the machine

manufacturer if you have any doubts. Always read

separate precautions and handling instructions from the

relevant tool supplier before using a new tool.

The machine is recommended to be used with the

following tools or accessories marketed by Husqvarna.

Refer to

Tools overview on page 111

.

The tools are installed on the tool holder on the arm

system. Only use tools that are correct for the operation

task.

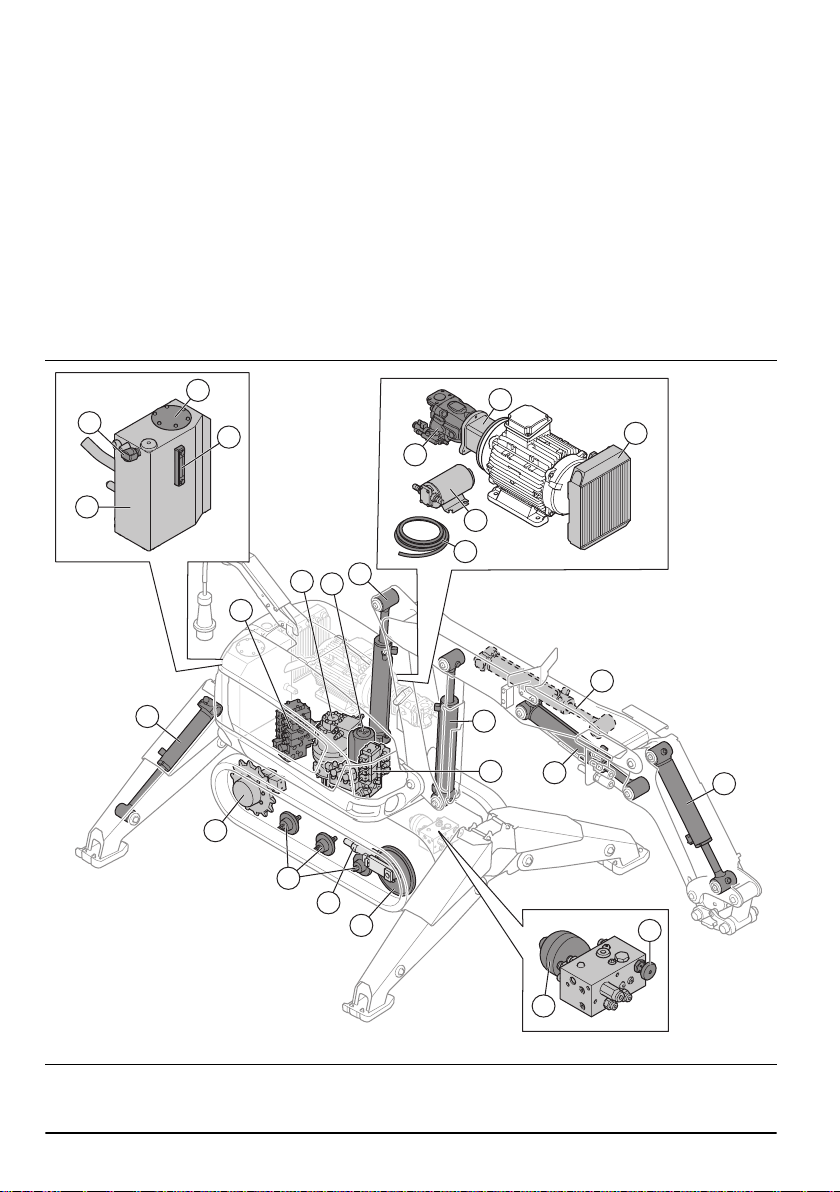

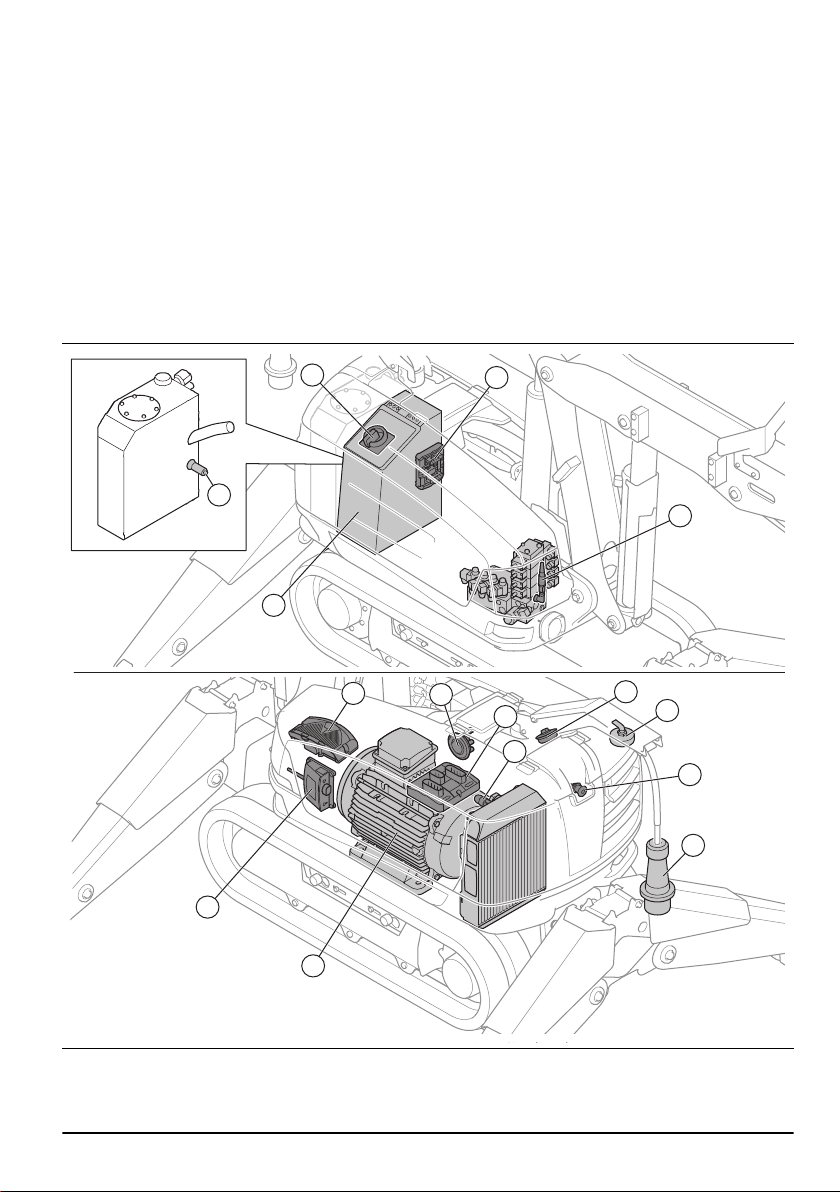

Hydraulic system

The hydraulic system operates the hydraulic pressure

and flow in the product. The hydraulic system has a

hydraulic oil tank with filters, a hydraulic pump, a

hydraulic oil cooler, hydraulic motors, hydraulic cylinders

and valves of different types. Hoses or pipes connect

the components.

The pressure control valves limit or decrease pressure

to the valves. The flow control valves control the flow of

the hydraulic oil and the speed of the functions of the

product. The directional control valves make sure that

the hydraulic oil goes to different functions of the

product.

The hydraulic system has different pressure levels.

Refer to

Technical data on page 107

. If many functions

are used at the same time, the pressure is set to the

lowest value. If the oil temperature is more than 80°C/

176°F, the pressure of the breaker is automatically

decreased. This increases the operation time before the

product becomes too hot.

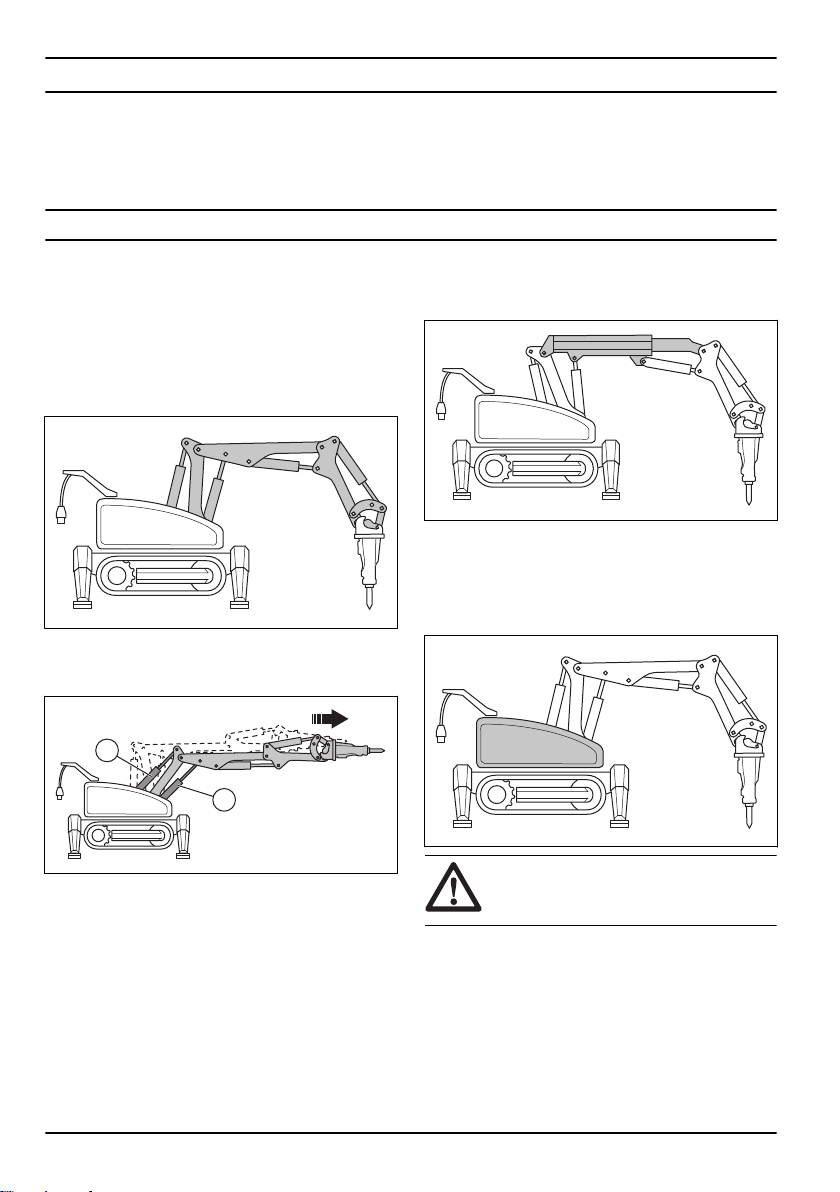

Intended use

The product is used for demolition in many different

environments and for different types of constructions.

The product can be used in risk areas, for example

where there is a risk that objects can fall down. The

product can be equipped for very high temperatures and

can also be used in environments with dangerous

materials and chemicals. The remote control lets the

operator control the product at a safe distance from the

risk area. The product can be used indoors and

outdoors. Do not use the product for other tasks.

1401 - 002 - 15.10.2021 3