General Information

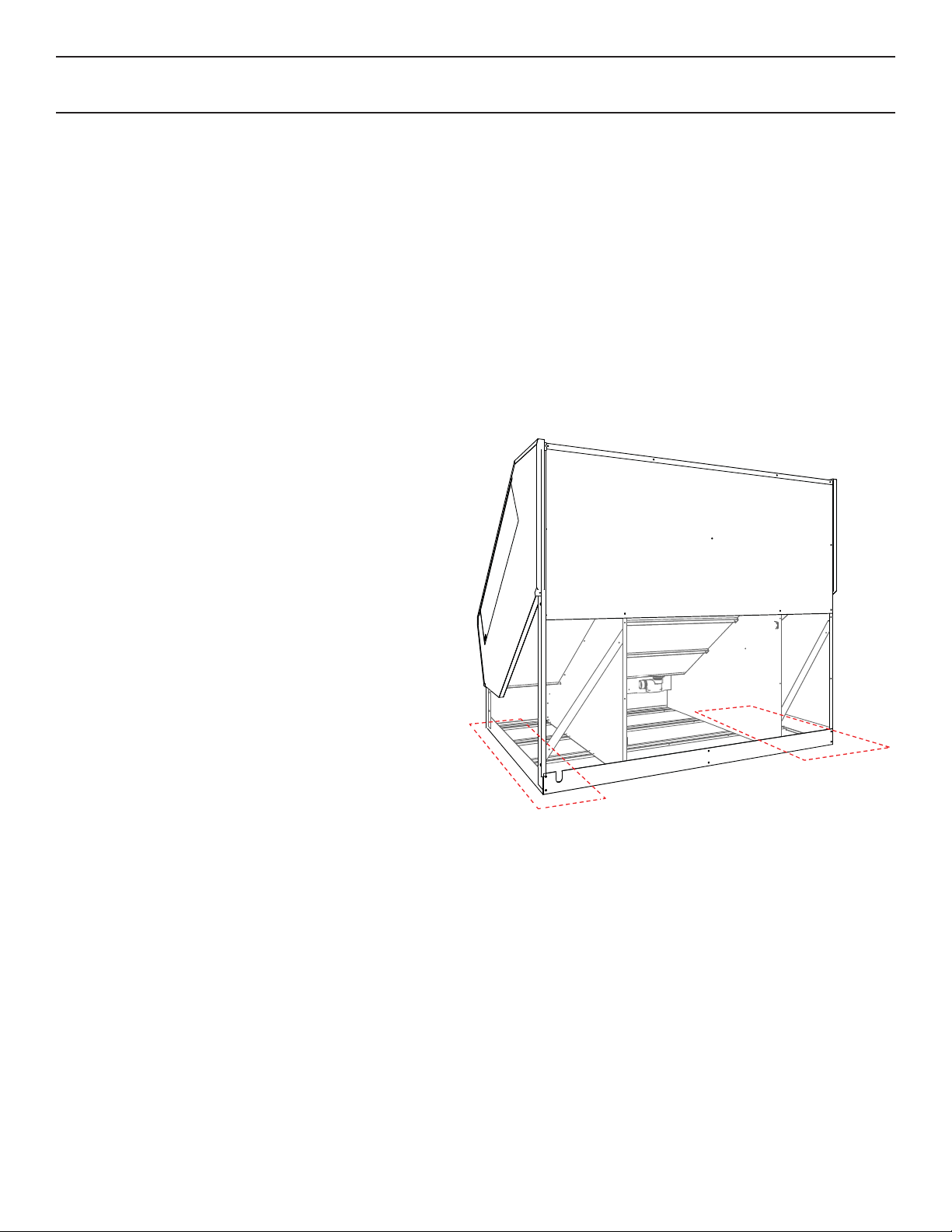

Description: Mobile Produce Case model series are Multi‐deck, spot merchandisers designed for non‐critical temperature

applications such as: Non Hazardous Produce. They are available in remote as well as self‐contained models. Each self‐

contained model will have it’s own condensing unit, factory installed beneath the display area of the case ready for

operationwhen electrical service is connected.

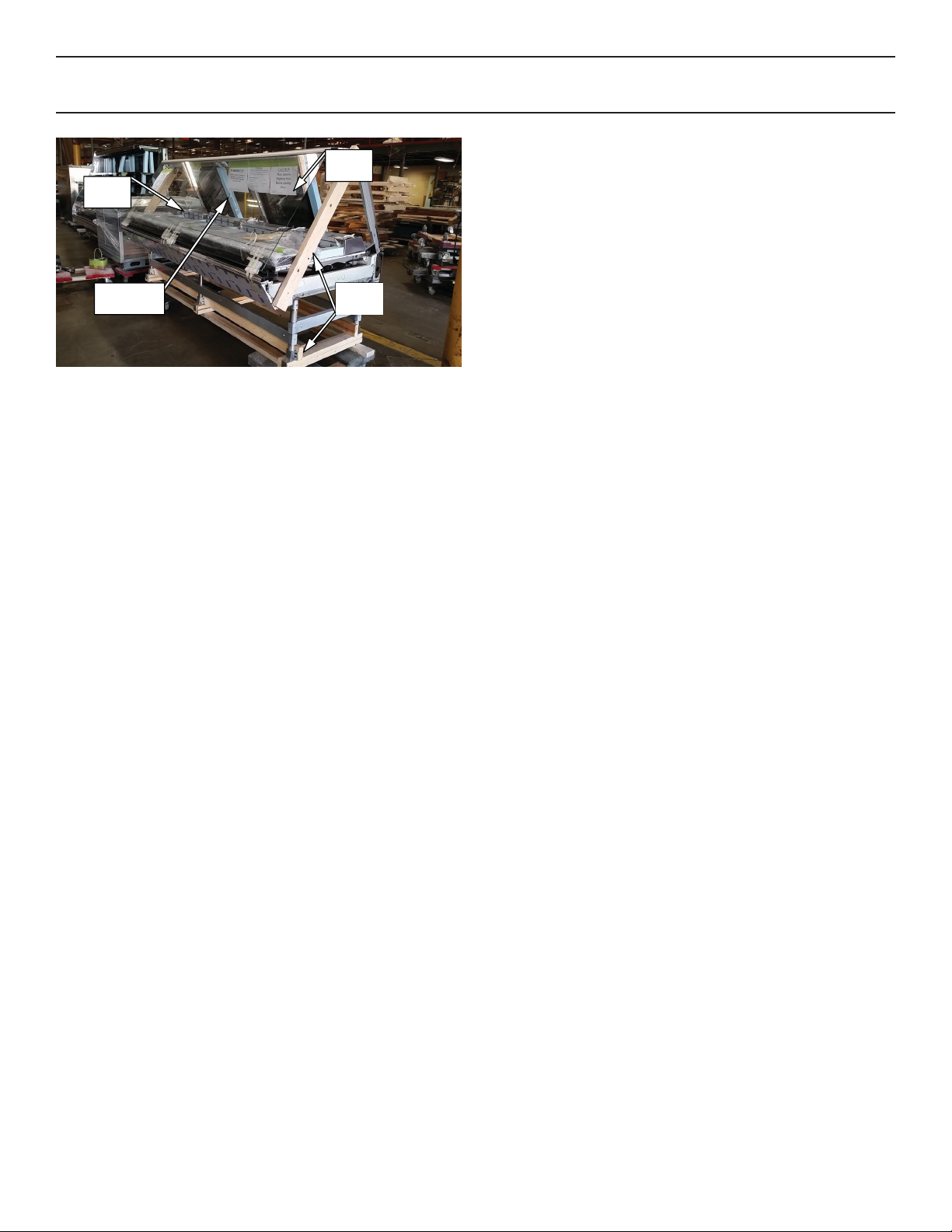

Shipping Damage: All equipment should be thoroughly examined for shipping damage before and during unloading.

This equipment has been carefully inspected at our factory and the carrier has assumed responsibility for safe arrival. If

damaged, either apparent or concealed, claim must be made to the carrier.

Apparent Loss or Damage: If there is an obvious loss or damage, it must be noted on the freight bill or express receipt

and signed by the carrier’s agent; otherwise, carrier may refuse claim. The carrier will supply necessary claim forms.

Concealed Loss or Damage: When loss or damage is not apparent until after all equipment is uncrated, a claim for

concealed damage is made. Make request in writing to carrier for inspection within 15 days, and retain all packaging. The

carrier will supply inspection report and required claim forms.

Location/Store Conditions: The refrigerated merchandisers have been designed for use only in air conditioned stores

where temperature and humidity are maintained either 75°F ambient and 55% RH . DO NOT allow air conditioning,

electric fans, ovens, open doors or windows (etc.) to create air currents around the merchandiser, as this will impair its

correct operation.

Shortages: Check your shipment for any possible shortages of material. If a shortage should exist and is found to be

the responsibility of Hussmann Chino, notify Hussmann Chino. If such a shortage involves the carrier, notify the carrier

immediately, and request an inspection. Hussmann Chino will acknowledge shortages within ten days from receipt of

equipment.

Hussmann Chino Product Control: The serial number and shipping date of all equipment has been recorded in

Hussmann’s files for warranty and replacement part purposes. All correspondence pertaining to warranty or parts

ordering must include the serial number of each piece of equipment involved, in order to provide the customer with the

correct parts.

This equipment is to be installed

to comply with the applicable

NEC, Federal, State ,and Local

Plumbing and Construction

Code ha ving jurisdiction.

ATTENTION

INSTALLER

Keep this booklet with the case at all times for future reference.

/CHINO

A publication of HUSSMANN®Chino

13770 Ramona Avenue • Chino, California 91710

(909) 628-8942 FAX

(909) 590-4910

(800) 395-9229

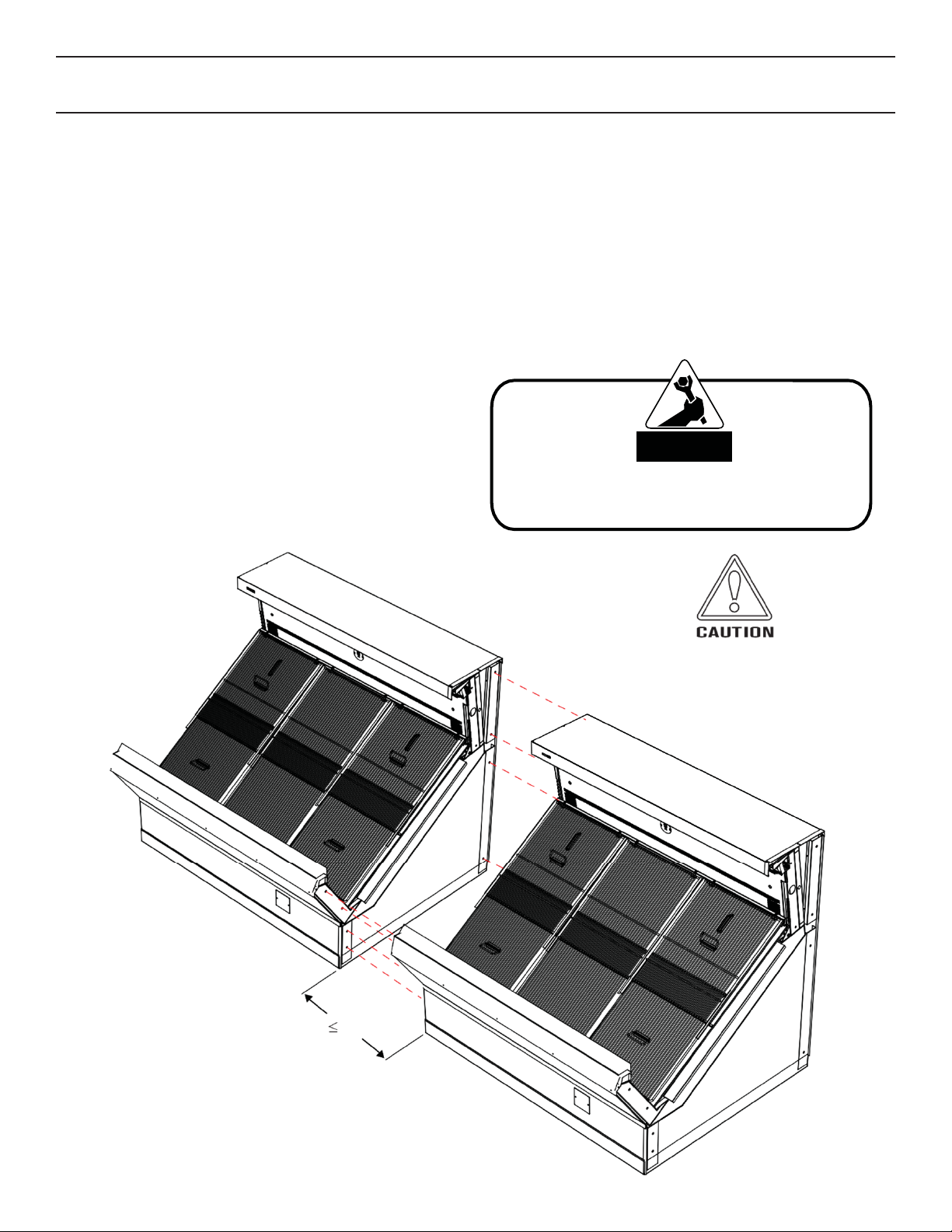

Case Description:

This Booklet specifically covers the

Following models:

Mobile Produce MPC‐ET(N)

3