Maintenace

Case cleaning

•

•

power at the source.

USE WATER AND MILD DETERGENT FOR EXTERIOR USE ONLY

Wipe interior with damp non abrasive cloth. Soap and hot water are not

enough to kill bacteria; a sanitizing solution must be included with each

cleaning process to eliminate bacteria.

•

•

•

the deck pans).

DO NOT USE A CHLORINATED CLEANER ON ANY SURFACE.

DO NOT USE ABRAISIVES OR STEEL WOOL SCOURING PADS (these will

marthefinish)

DO NOT USE A CLEANING OR SANITIZING SOLUTION THAT HAS AN OIL

BASE (these will dissolve the butyl sealants) or an AMMONIA BASE (this

will corrode the coppercomponents ofthe case)

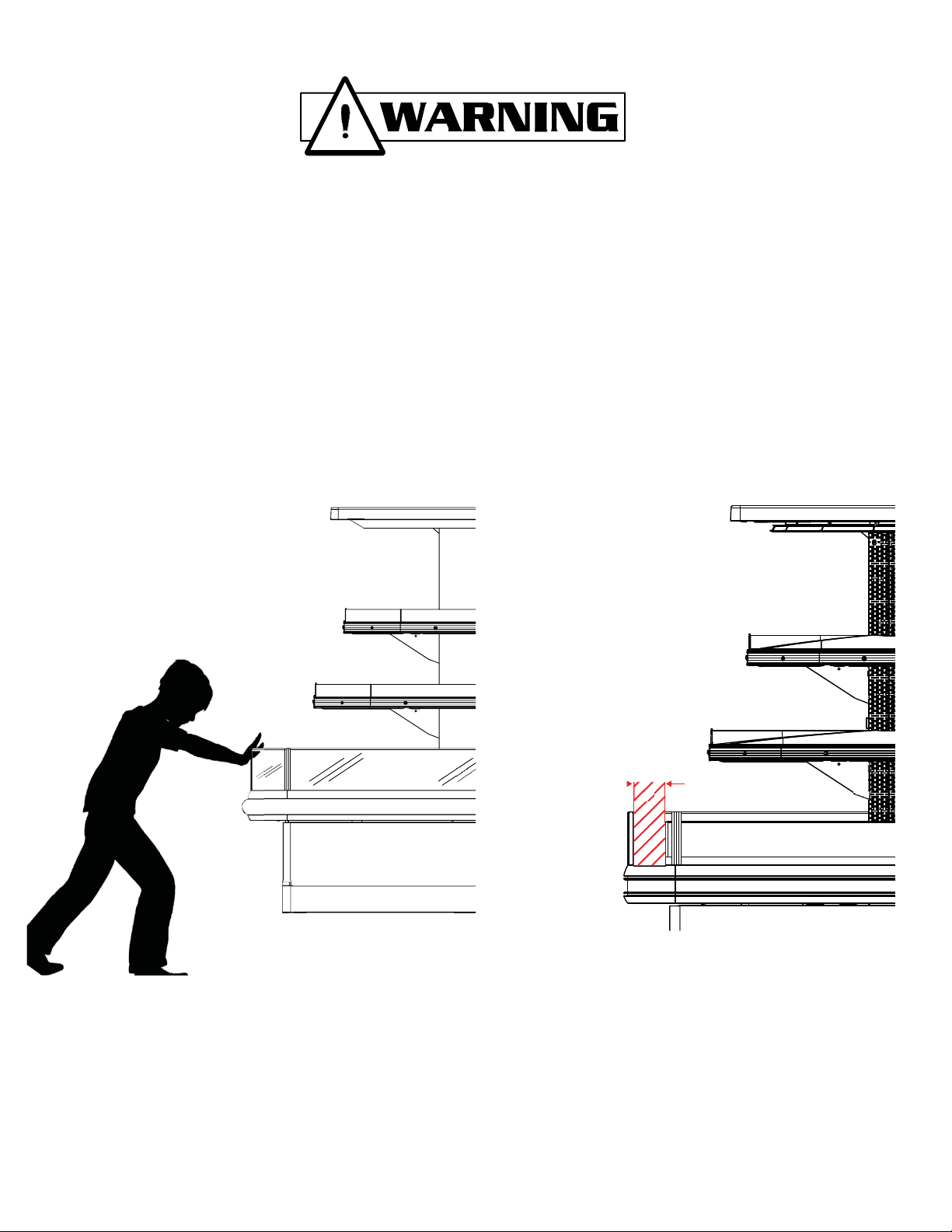

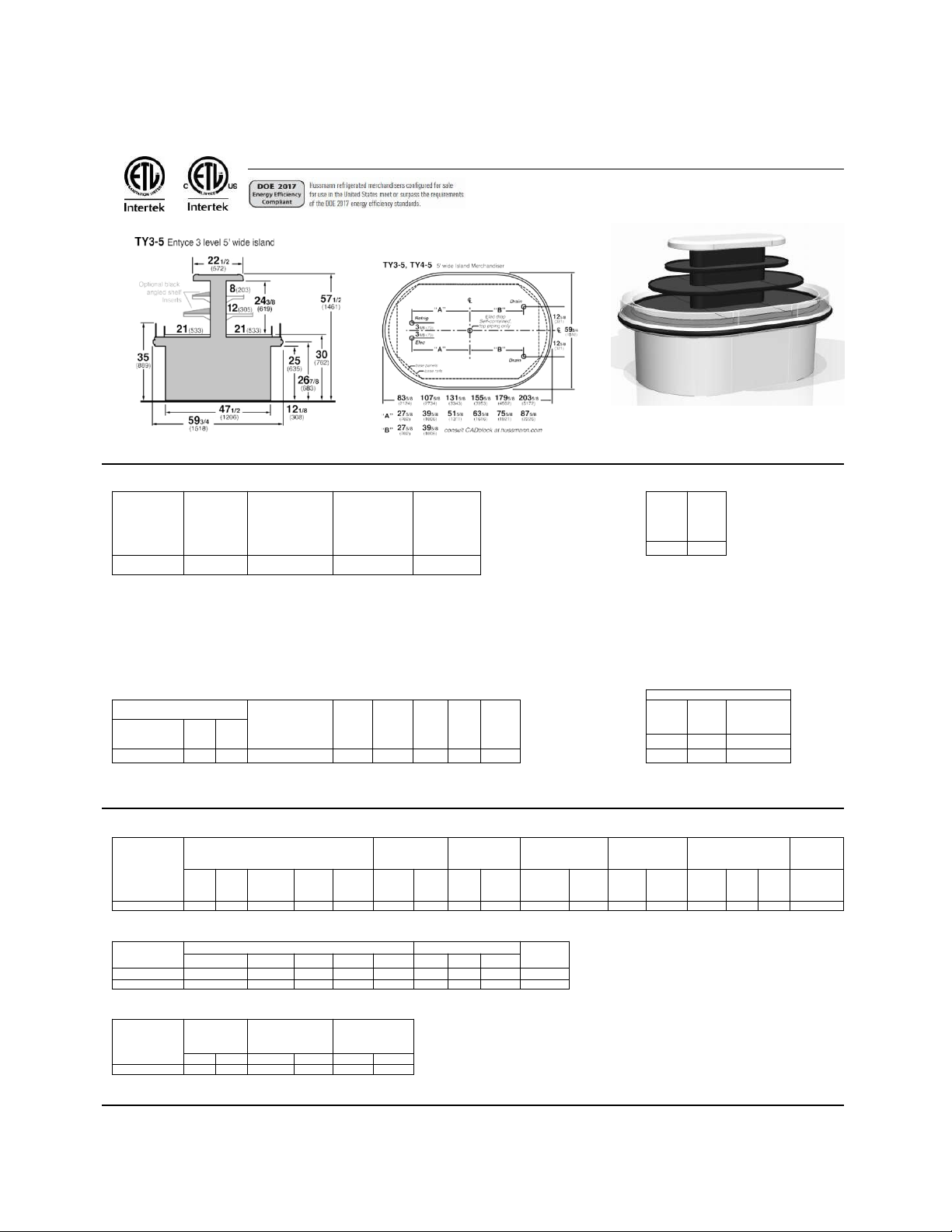

WARNING! DO NOT USE WATER HOSES! A self contained case empties

into an evaporator pan thatWILL OVERFLOW IFTOO MUCHWATER IS

INTRODUCED during cleaning.

To insure long life, proper sanitation and minimum maintenace costs, the•

case should be thoroughly cleaned frequently. SHUT OFF FAN BEFORE

CLEANING: turncontrollerdialto fullcounter‐clockwise, or shut off case

•

•

•

Filter Replacements

• REPLACE FILTER EVERY 6 MONTHS, or as needed. A dirty/clogged air

filter restrictsthe airflow. thiswill resultin warmer temperatures in the

case, and premature compressor failure.

Service

• SCHEDULE SERVICE EVERY 6 MONTHS. To maintain good refrigerator

performance, a refrigeration service technician should regularly clean

the discharge Honeycomb and remove any accumilated dirt from the

condenser coil and condensate evaporator pan.

POOR AIR CIRCULATION THROUGH THE CONDENSER WILL RESULT IN

POOR REFRIGERATION PERFORMANCE, IN INCREASED PRODUCT TEM‐

PERATURES, AND PERMANENT COMPRESSOR FAILURE

Dirt accumilation inside the condensate evaporator pan will reduce the

pan’s capacity and reduce the efficiency of the heater causing a burned

out heater an an overflow of defrost water onto the store floor.

•

Tips and Troubleshooting

Clean any visible debris on‐or near the case drain (drain is located under Before calling for service:

•Checkpower.Ensure reliable electrical power supply to the

equipment.

Check shelf loading. Overstocking will adversely affect case

performance.

If Frost is collecting on fixture or product, verify that store Hu‐

midity Control is working properly, and that no outside doors or

windows allow moisture into store.

•

•

Installation

Store Conditions

•

•

•

•mum

Case is designed to operate attemperatures 80°Fat55%rela‐

tive humidity.Case must be kept in that environmentto ensure

case performance and product safety.

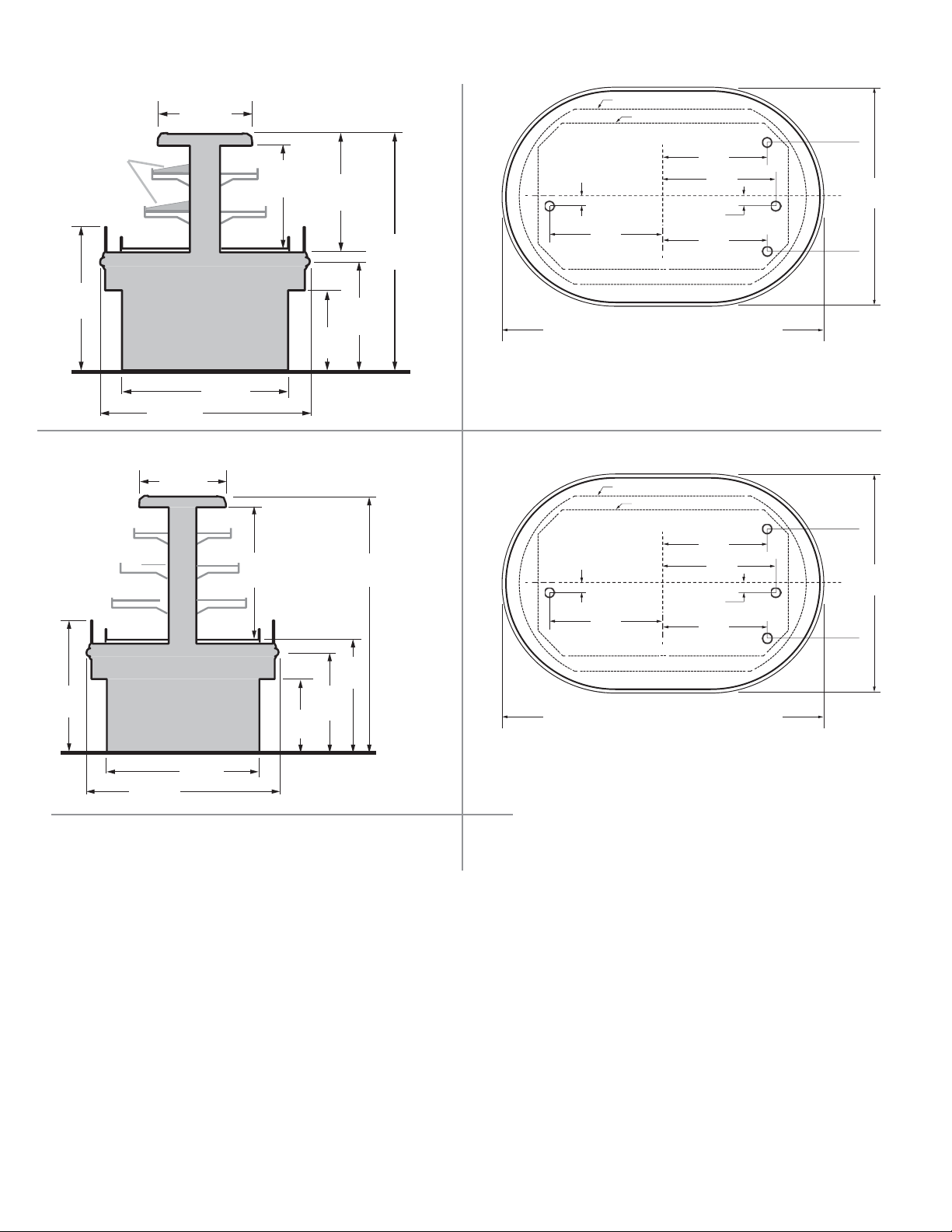

DO NOT position the case near HVAC vent. a minimum of 15’

clearance is required.

DO NOT position the case near an entrance door. Outside

Ambient conditions have adverse affect on refrigeration per‐

formance.

DO NOT position case against ceiling or soffit.amini

clearnace of 8” above the unit is required for proper compres‐

sor discharge airflow.

DO NOT block case front panel vent (supplies critical intake

airflow to the compressor). INTAKE AIR temperature should

not exceed 80°F.

•

For prompt service when contacting the factory regarding

problems, be sure to have the Case Model and Serial Number

handy. Thisimformation isonaplatelocated onitself.

www.hussmann.com (909) 590‐4910 (800) 395‐9229

1H62575650