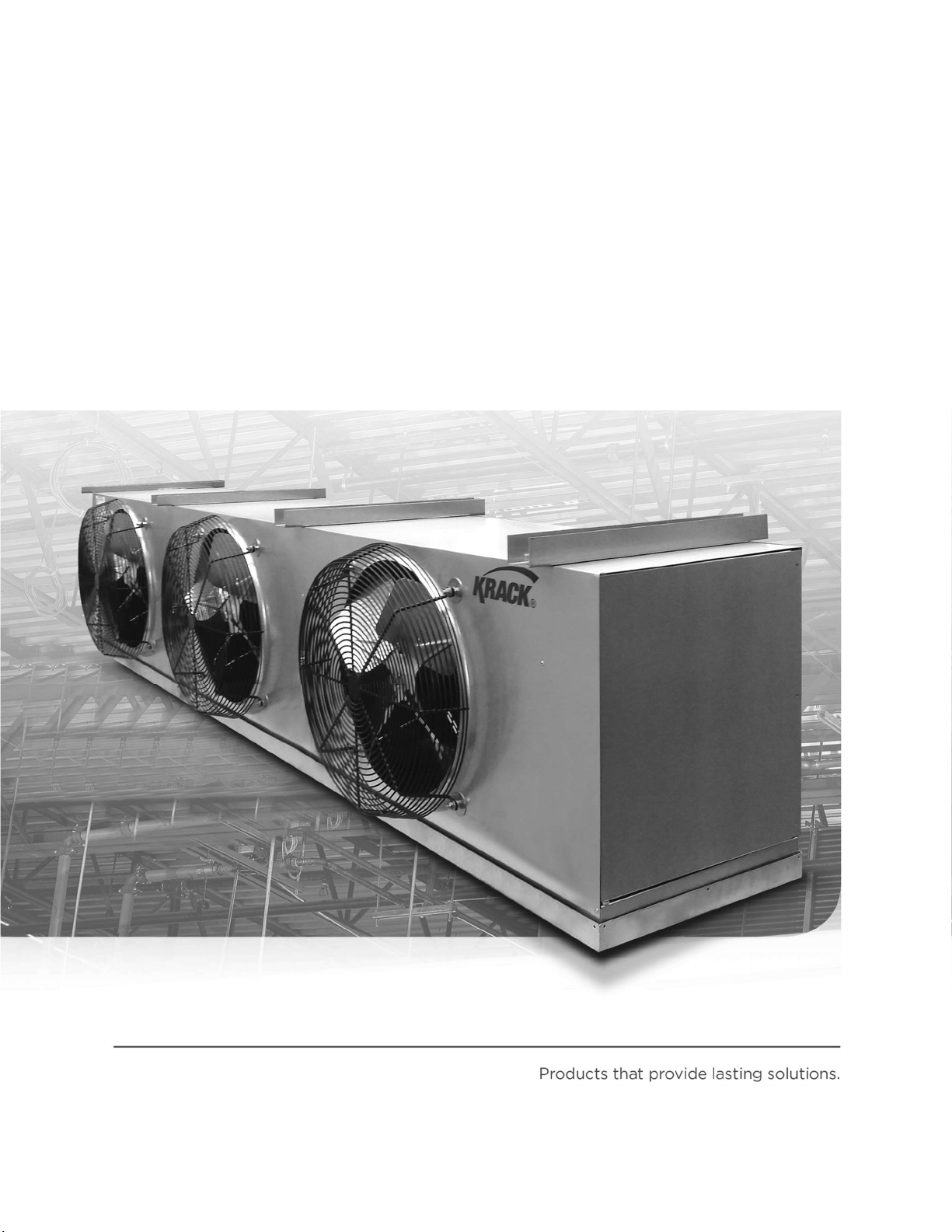

MS Series Medium Profile Unit Coolers (E270190_H) 3

TABLE OF CONTENTS

1 UNIT INFORMATION AND DIMESIONS ............................................................................................................ 5

1.1 MODELS COVERED ____________________________________________________________________ 5

1.2 UNIT DIMESION _______________________________________________________________________ 6

2 RECEIPT OF EQUIPMENT..................................................................................................................................... 7

2.1 INSPECTION __________________________________________________________________________ 7

2.2 LOSS OF GAS HOLDING CHARGE ________________________________________________________ 7

3 ASSEMBLY OF COMPONENTS ............................................................................................................................. 7

3.1 SHIPPED LOOSE PARTS - LONG THROW ADAPTERS _______________________________________ 7

3.2 REFRIGERANT DISTRIBUTOR NOZZLES _________________________________________________ 7

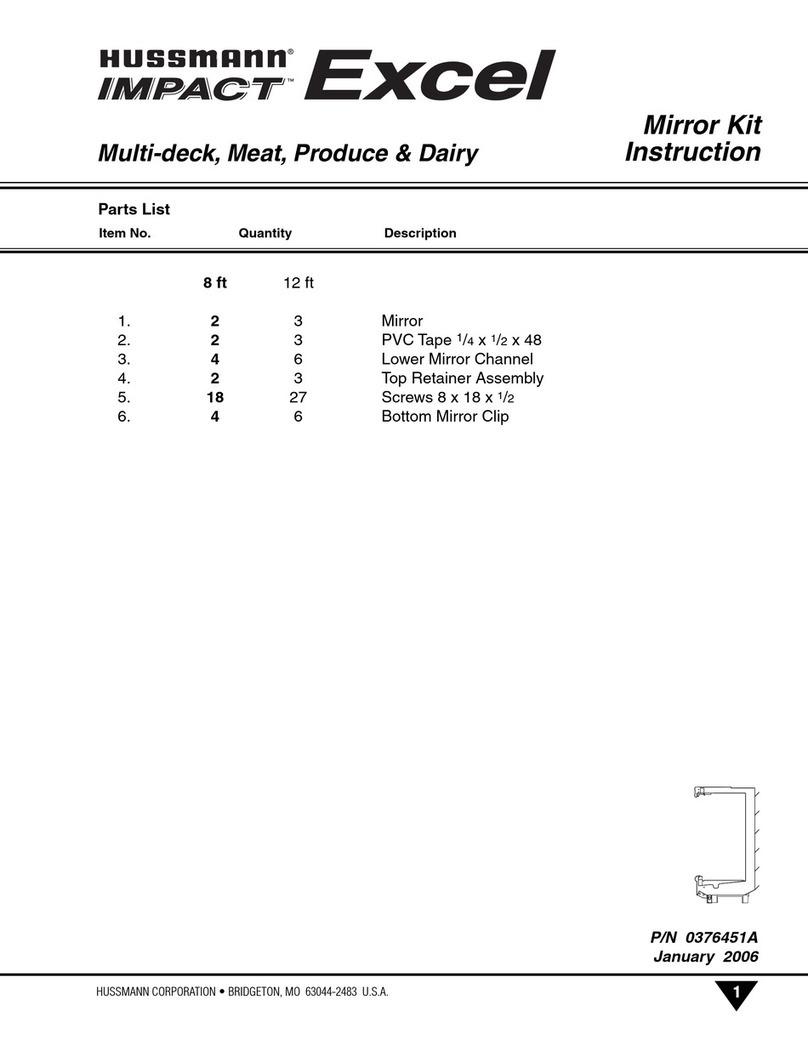

3.3 EXPANSION VALVE____________________________________________________________________ 7

3.4 CHECK VALVE ________________________________________________________________________ 8

4 RIGGING INSTRUCTIONS ..................................................................................................................................... 8

4.1 RIGGING INSTRUCTIONS _______________________________________________________________ 8

5 UNIT LOCATION AND MOUNTING .................................................................................................................... 8

5.1 UNIT LOCATION _______________________________________________________________________ 8

5.2 MOUNTING ___________________________________________________________________________ 8

6 PIPING INSTALLATION ......................................................................................................................................... 9

6.1 DRAIN LINE ___________________________________________________________________________ 9

6.2 REFRIGERATION PIPING _______________________________________________________________ 9

6.3 EVACUATION AND LEAK TEST ________________________________________________________ 11

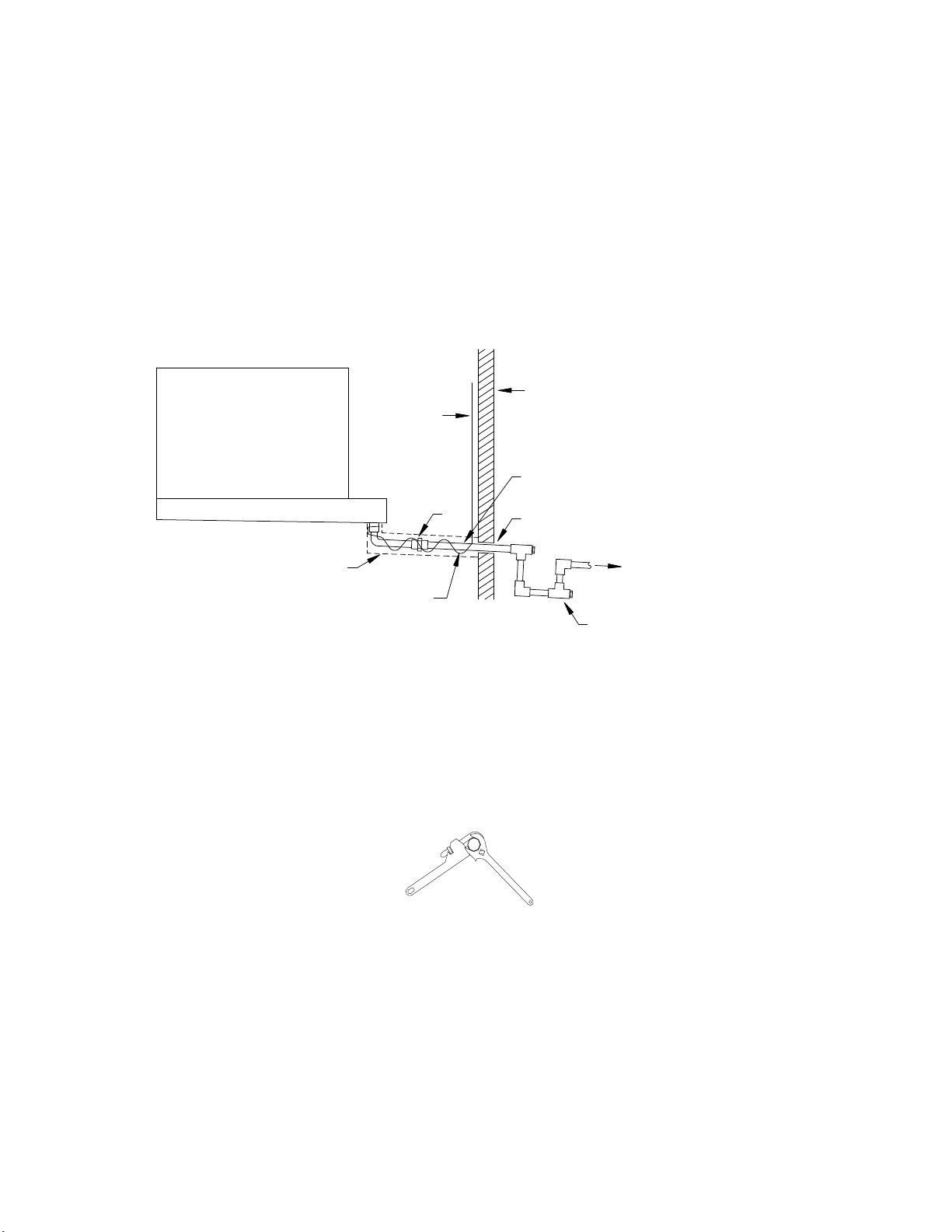

6.4 MS GAS DEFROST PIPING _____________________________________________________________ 111

6.5 REFRIGERANT DISTRIBUTOR NOZZLES _______________________________________________ 111

6.6 EXPANSION VALVE___________________________________________________________________ 13

7 ELECTRICAL ........................................................................................................................................................ 133

7.1 FIELD WIRING ______________________________________________________________________ 133

7.2 ELECTRICAL DATA __________________________________________________________________ 133

7.3 AIR DEFROST SEQUENCE OF OPERATION ______________________________________________ 144

7.4 ELECTRIC DEFROST SEQUENCE OF OPERATION ________________________________________ 166

7.5 HOT GAS DEFROST SEQUENCE OF OPERATION _________________________________________ 188

7.6 DUAL SPEED MOTOR – SEQUENCE OF OPERATION ______________________________________ 20

7.7 VARIABLE SPEED MOTOR – SEQUENCE OF OPERATION _________________________________ 21

7.8 VARIABLE SPEED MOTOR WITH SYSTEM 450 – SEQUENCE OF OPERATION ________________ 21

7.9 INTERLOCKING SINGLE COMPRESSOR UNIT WITH KRACK COILS _________________________ 22

8 START UP ............................................................................................................................................................... 233

8.1 PRE-STARTUP _______________________________________________________________________ 233

8.2 OPERATION CHECKOUT _____________________________________________________________ 233

9 PREVENTATIVE MAINTENANCE ................................................................................................................... 244

9.1 DRAIN PAN _________________________________________________________________________ 244

9.2 COIL AND CABINET __________________________________________________________________ 244

9.3 FAN GUARD OR LONG THROW ADAPTER REPLACEMENT _______________________________ 255

9.4 FAN REPLACEMENT _________________________________________________________________ 255

9.5 UNIT MOTOR REPLACEMENT _________________________________________________________ 255

9.6 ELECTRIC DEFROST HEATERS ________________________________________________________ 255

10 TROUBLESHOOTING CHART .......................................................................................................................... 266

11 REPLACEMENT PARTS LIST ........................................................................................................................... 266