IGSV-DSF, DSFM-0303

6

case,and flushingwitha hose.

**IMPORTANT INFORMATION**

TheASCS is capable of maintaining superb product qual-

ity with the installation of the proper controlling devices.

These devices should be set according to the Hussmann’s

specifications.The humidity system should be properly

maintained.Incorrect settings and failure to maintain the

humidity system will result in short product life. Below

are a few guidelines for optimum performance and prod-

uct life:

•Setthermostat to cut inatthe discharge tempera-

turedesignated in thecase specifications section

oftheappropriate installation guide orspec.sheet.

Maintainthe recommendedproducttemperature

forDeli,Meat,and Fish.DO NOTsettemperature

toocold,asthis causes productdehydration.

•Temperaturesshould be achievedby means of aT-

Statand Suction Solenoid ateachcase.DO NOT

useEPR valves,Liquid LineSolenoids,orelectronic

controldevicesof anykind.Thesecontrols allow

temperatureswingsthat cause dehydrationand

excessive energy consumption.

•Setdefrostcycles as listedinthe Case Specifica-

tionsData foryourparticular case.Thenumberof

defrosts per day shouldnever change.Thedura-

tionof the defrostcycle maybeadjusted to meet

conditionspresentat your location.

•Cleanhumidity system a minimumof every 90

daysforproper system operation.

•Workand rotateproduct-not to exceed afour

(4)hour period.

•Atnight,turnoff case lights,and coverunwrapped

product withmoistenedcheesecloth or fabric

towels.

•Keepmeat holding boxat 32°F.

•Keepmeat preproom refrigeratedat55°F.

•MeatBloom Box(ifapplicable)shouldbe at 36°F.

•Meatmustenter the caseat40°For below.

Productdeteriorates rapidlyabove 40°F.

•Clean,sanitaryconditions arerequiredthrough-

outthe meat holding,prep,andworkareas.

•Donot display productdirectlywithintheair

discharge

•Turn and rotate meat.Theblood worksdown

through the meatover time,which causes thetop

surfaceto discolor and dehydrate.Turn meat 3-4

timesper day.

•Itis not required to removeproductfromcase

overnight.Turn off caselights,andcover product

withmoistened cheesecloth or fabrictowel.This

helpsslowdownproductdehydration,bytaking

moisturefromthe clothandnot the product.This

isan old method usedbymeatshops formany

years,asit extends productlife.

•Coldcoils removeheat and moisturefromthe case

anddeposit this as frost onto the coil.Thusa defrost

isrequired to remove this frost.Our humidity

systeminduces moistureinto thecase,and helps

slowdown the dehydrationprocess.The only other

moisture in thecaseisthat which is in theproduct.

Asingle level of meatwill dry out fasterthan a fully

loadedcase with 3-4 levelsofmeat.

•Thecolder the case,the faster the product loses its

moistureand shelf life.Itis very important to

maintaina constant,even,correct,producttempera-

ture.

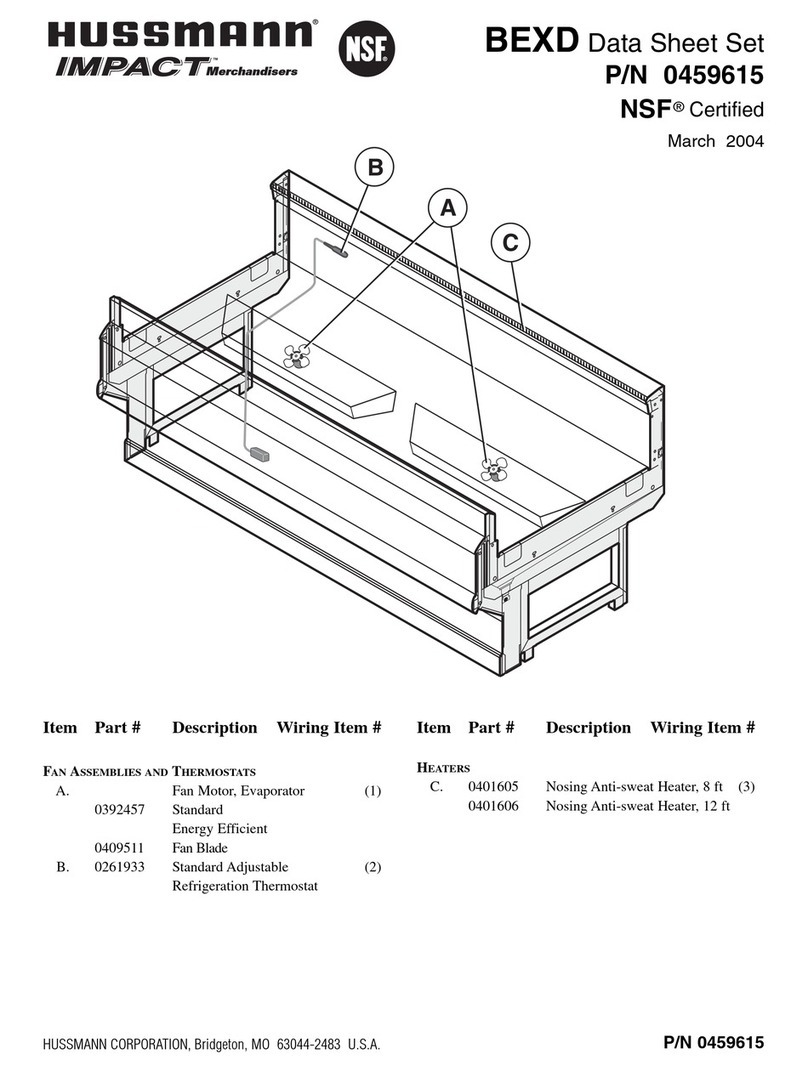

HUMIDIFICATION SYSTEM HOOKUPS

Remove the raceway panel on the lower back of the case.

The pre-piped water shut-off valve and the water filter

are located on the left hand side of the case.The water

line (which is a 1/4" OD copper fitting) can be connected

to the ball shut-off valve, by means of a compression fit-

ting (supplied).The line should be one size larger than the

supply line.The line can then be run from one case to

another from within the raceway(s) usingTee connectors.

Before connecting the water to the humidity system,it is

best to purge the line to flush any debris that may clog the

water filter. If the water line requires purging after the

cases are hooked together, it is not necessary to check

each one.Simply shut ball valves to each humidity system,

remove the water line from the last case in the flow,and

purge.By doing this as a precautionary measure,you may

avoid problems and repeat servicing.

START-UP

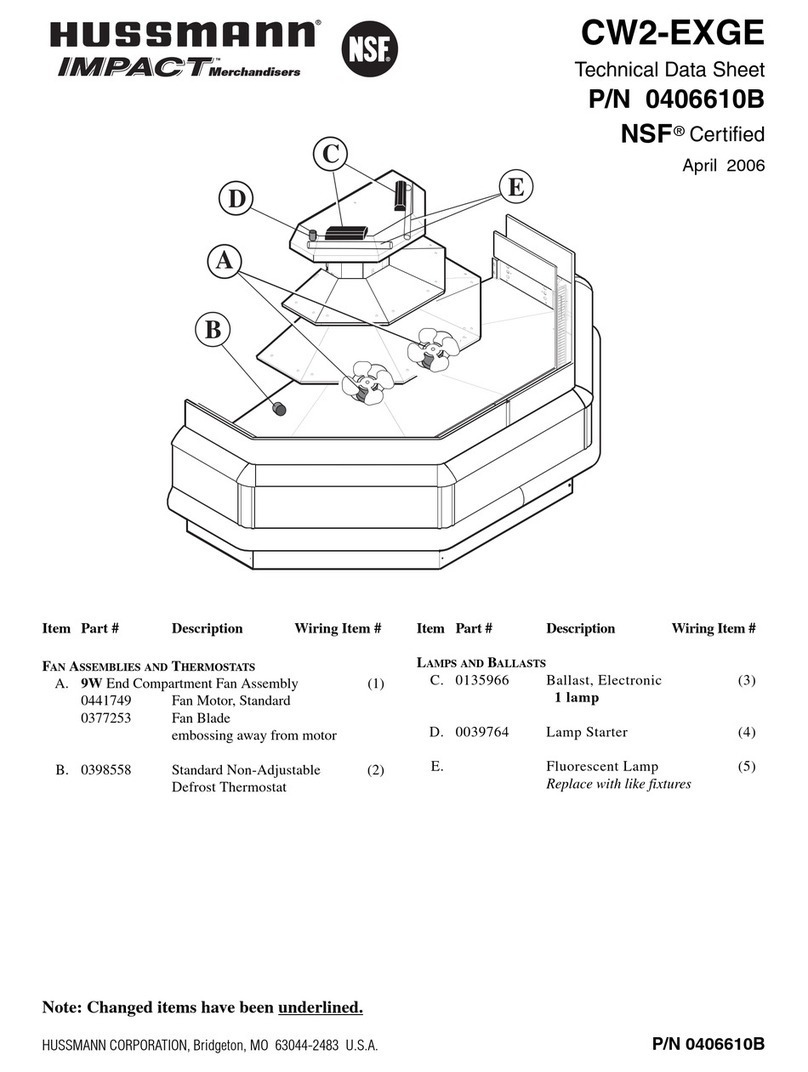

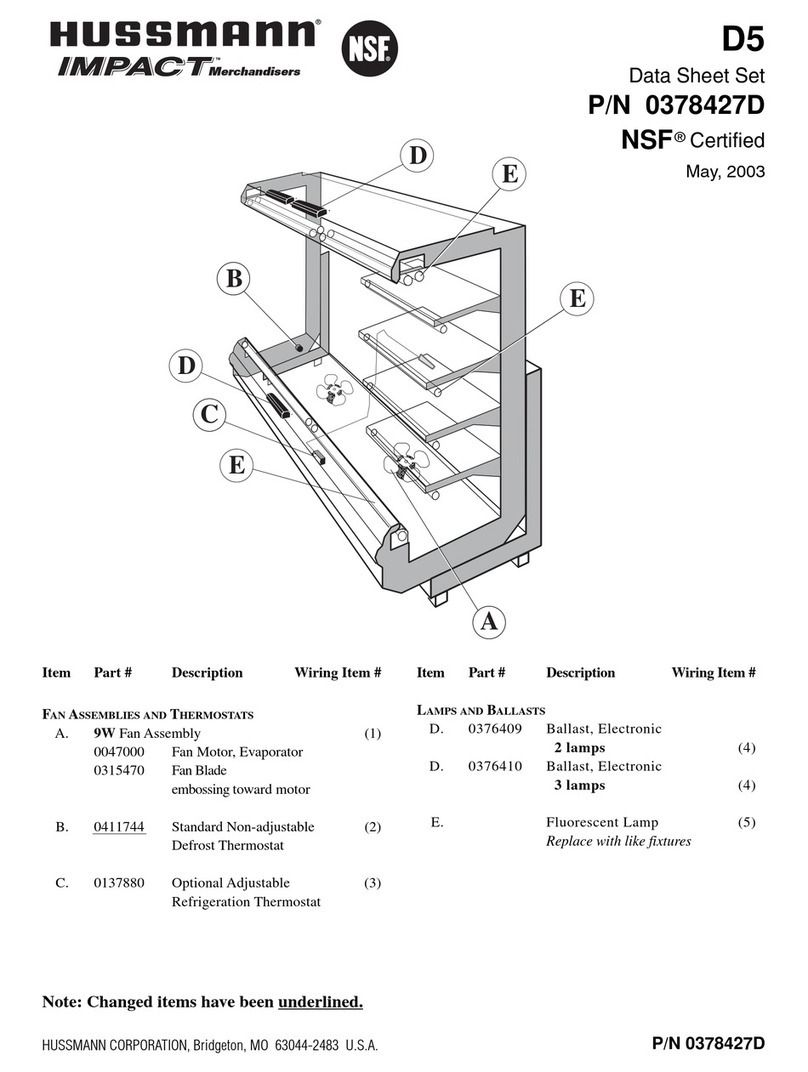

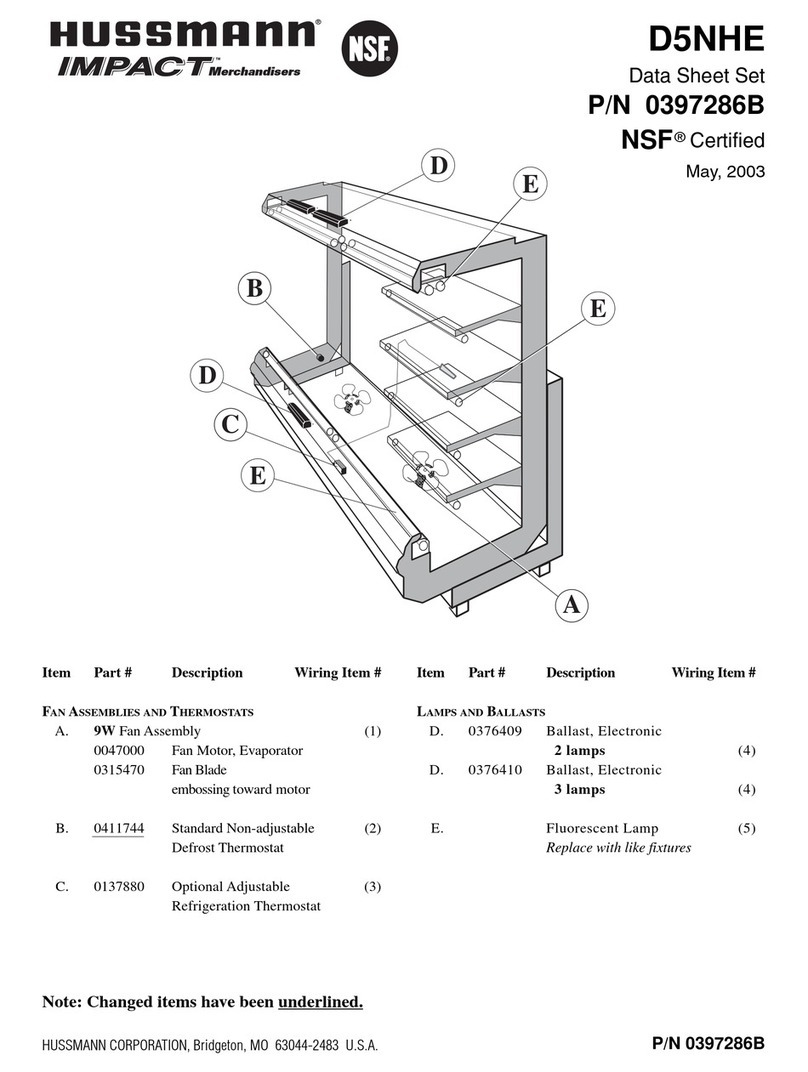

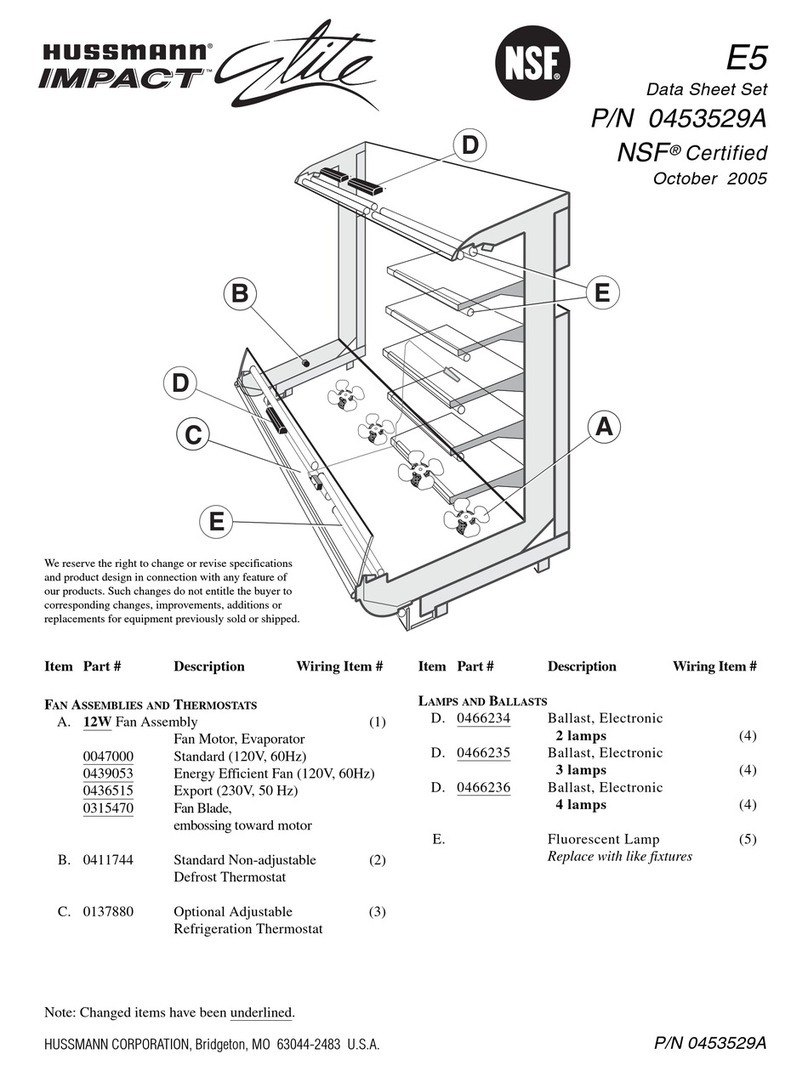

Turn on the fan circuit. Check to see if the fan for the

humidity system is running. Remove the right hand bot-

tom pan (when facing the front of the case),then theTXV

cover.The fan is located up against the right hand side of

the case,as viewed from the front,under the fan plenum

(see diagram).View the blade,and make sure the fan rota-

tion agrees with the air flow arrows.Turn on the water,by

turning the ball valve in the direction of the flow (OFF is

at 90° to the direction of flow).

After a few minutes,check the spray header by sliding the

honeycomb to the left to expose the discharge tube lo-

cated on the right hand side of the case (when viewed

from the rear),by lifting the 4'-0" section of honeycomb

with both ends, until the bottom clears. Pull up and set

aside.The spray header will be exposed.Grasp the header