Hussmann SPECIALITY VR3/HV Series User manual

Other Hussmann Merchandiser manuals

Hussmann

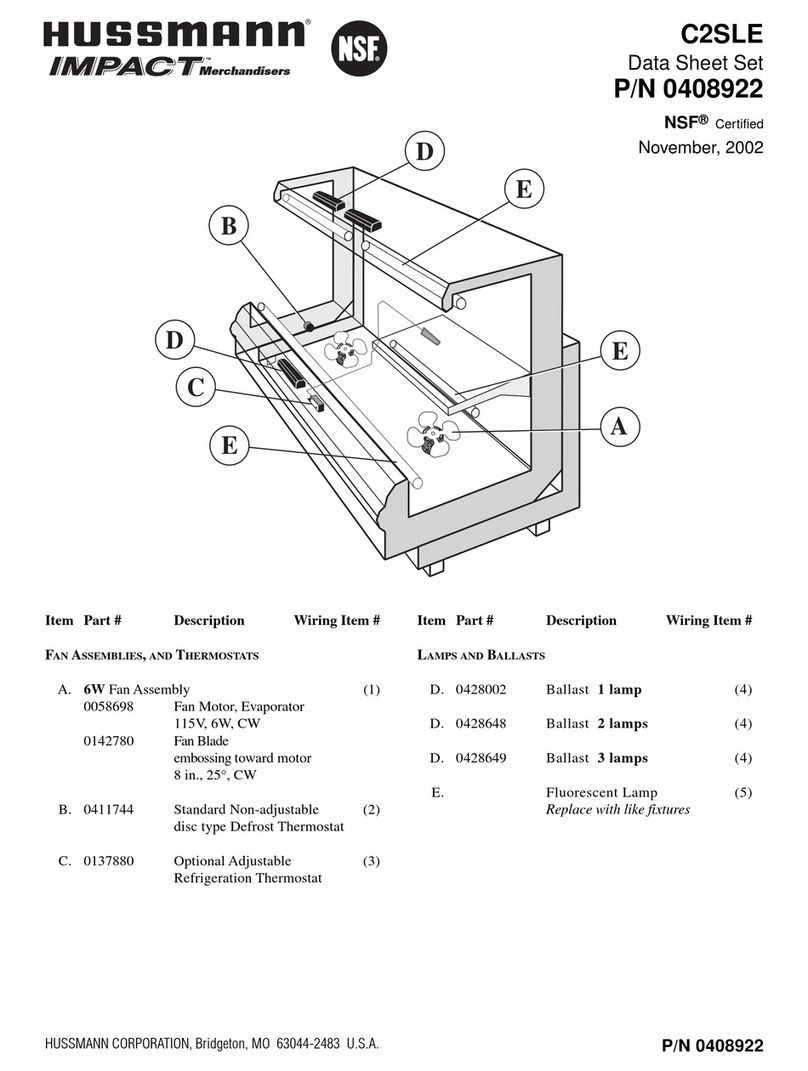

Hussmann Impact C2SLE User manual

Hussmann

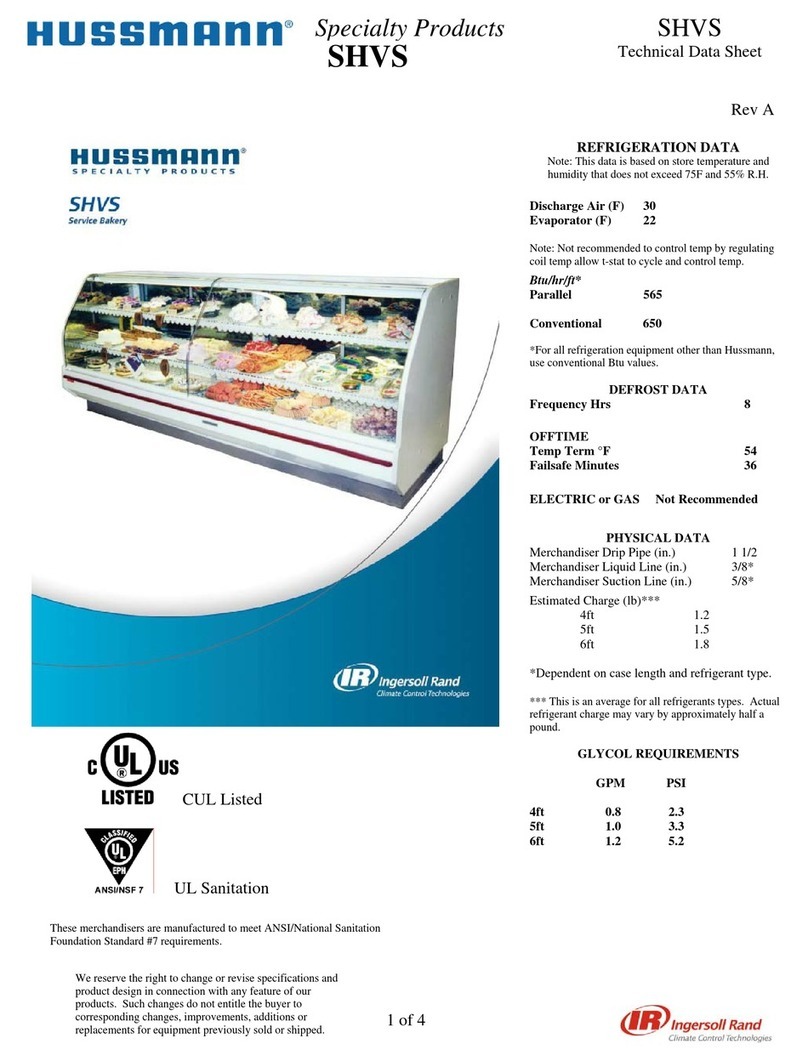

Hussmann SHVS Instruction Manual

Hussmann

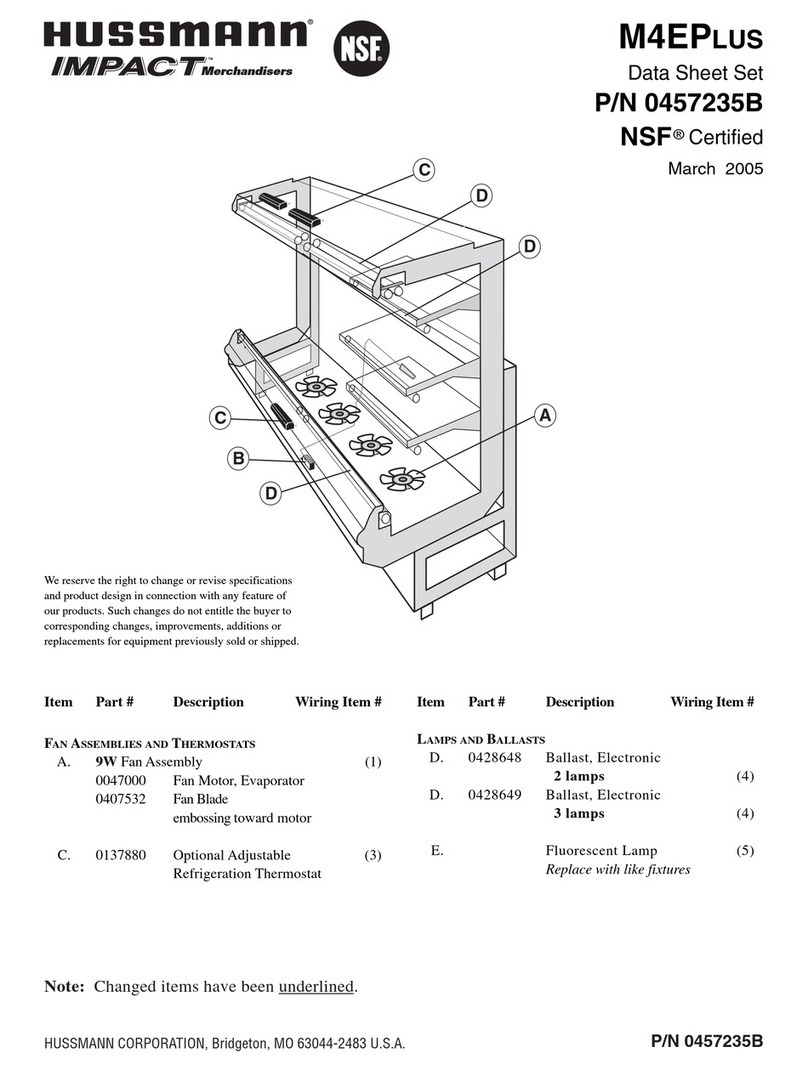

Hussmann M4EP User manual

Hussmann

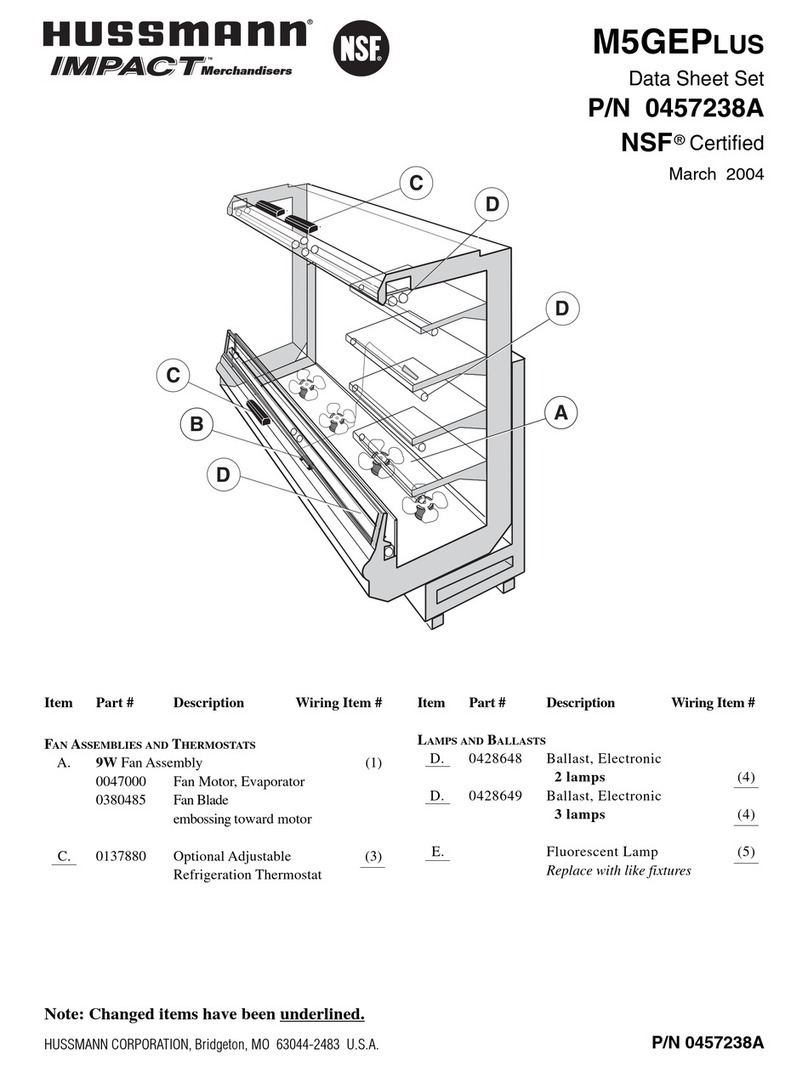

Hussmann M5GEP User manual

Hussmann

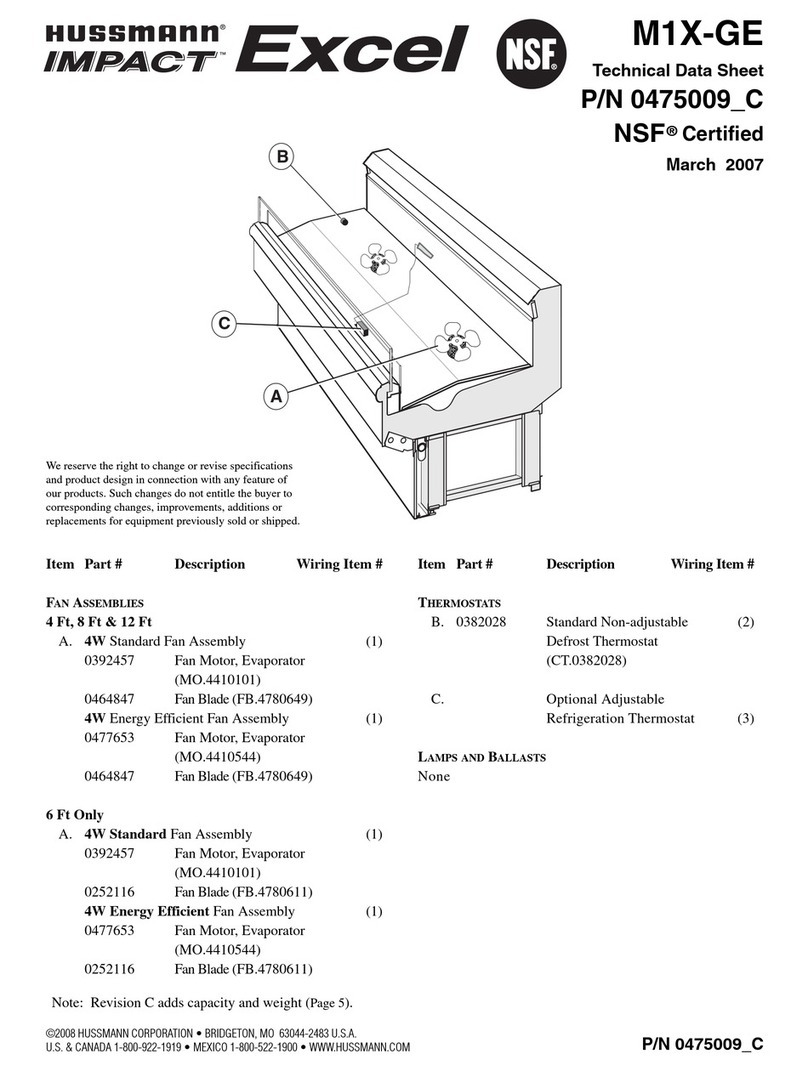

Hussmann Impact Excel M1X-GE Instruction Manual

Hussmann

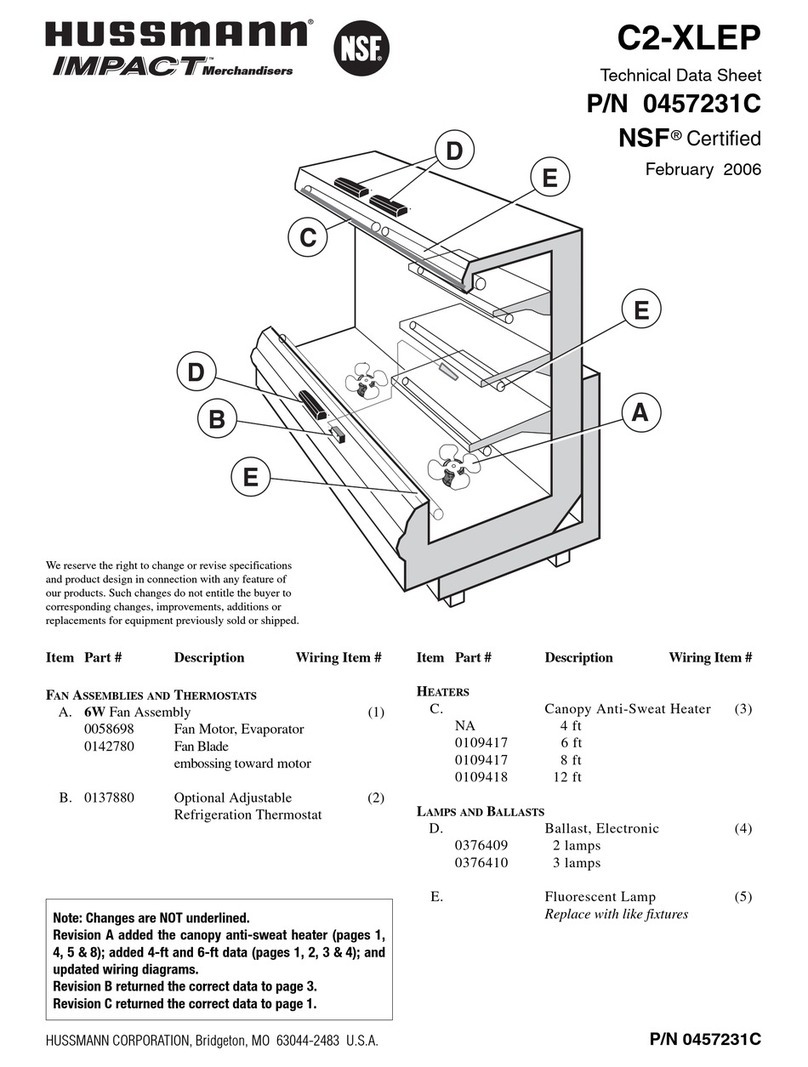

Hussmann impact Excel C2X-LEP Instruction Manual

Hussmann

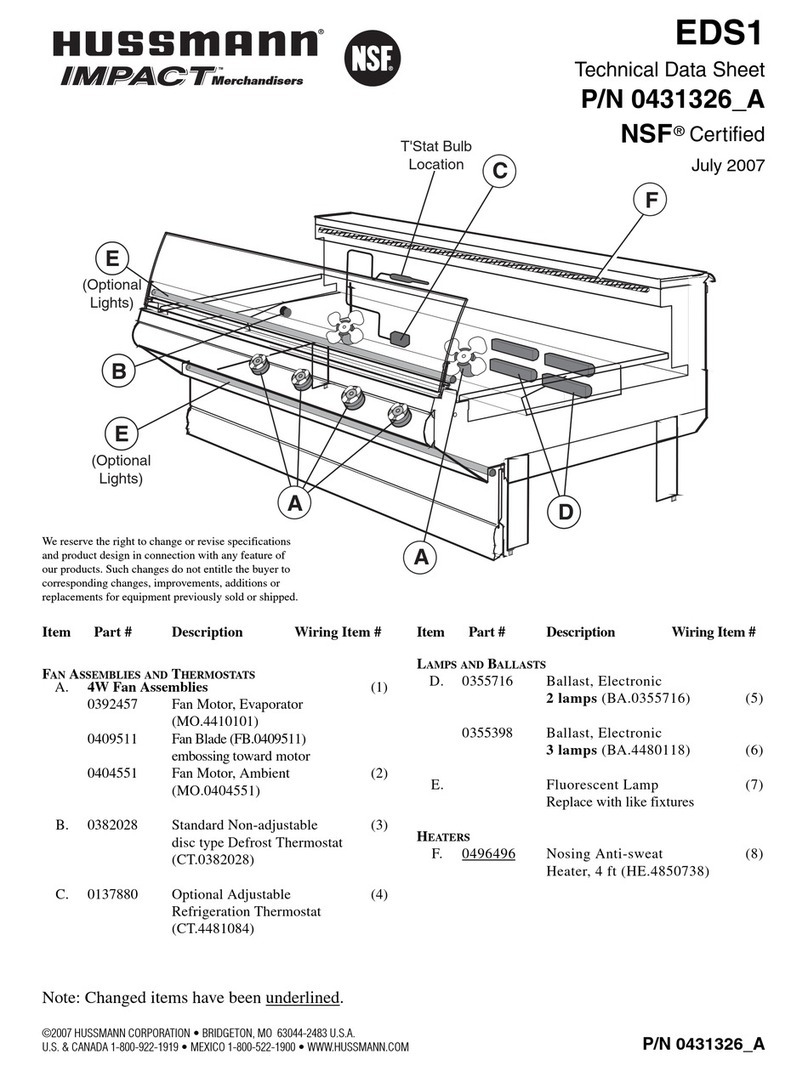

Hussmann IMPACT EDS1 Instruction Manual

Hussmann

Hussmann XR75CX User manual

Hussmann

Hussmann RHR-HEX Operating instructions

Hussmann

Hussmann GGSM Quick guide

Hussmann

Hussmann MBC Quick guide

Hussmann

Hussmann R3HV-ND-B User manual

Hussmann

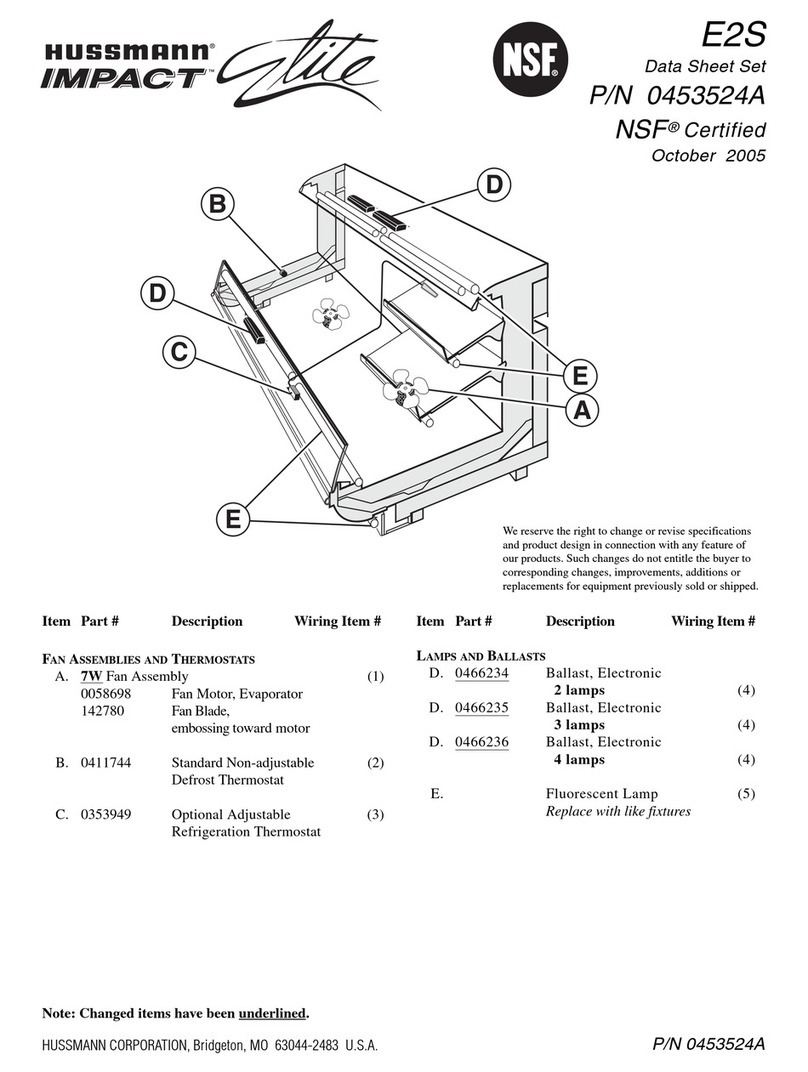

Hussmann IMPACT Elite E2S User manual

Hussmann

Hussmann NAV-4 User manual

Hussmann

Hussmann DDS User manual

Hussmann

Hussmann Q1-DC Wedge Operating instructions

Hussmann

Hussmann GSVM4060F User manual

Hussmann

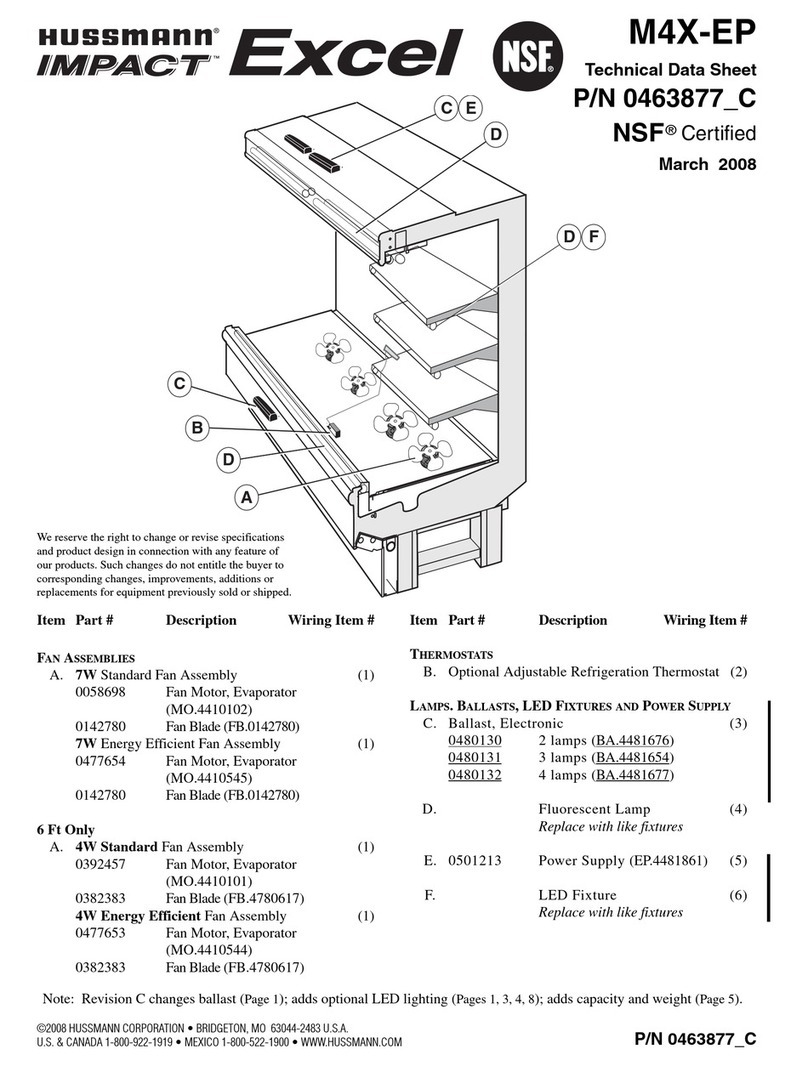

Hussmann Impact Excel M4X-EP Instruction Manual

Hussmann

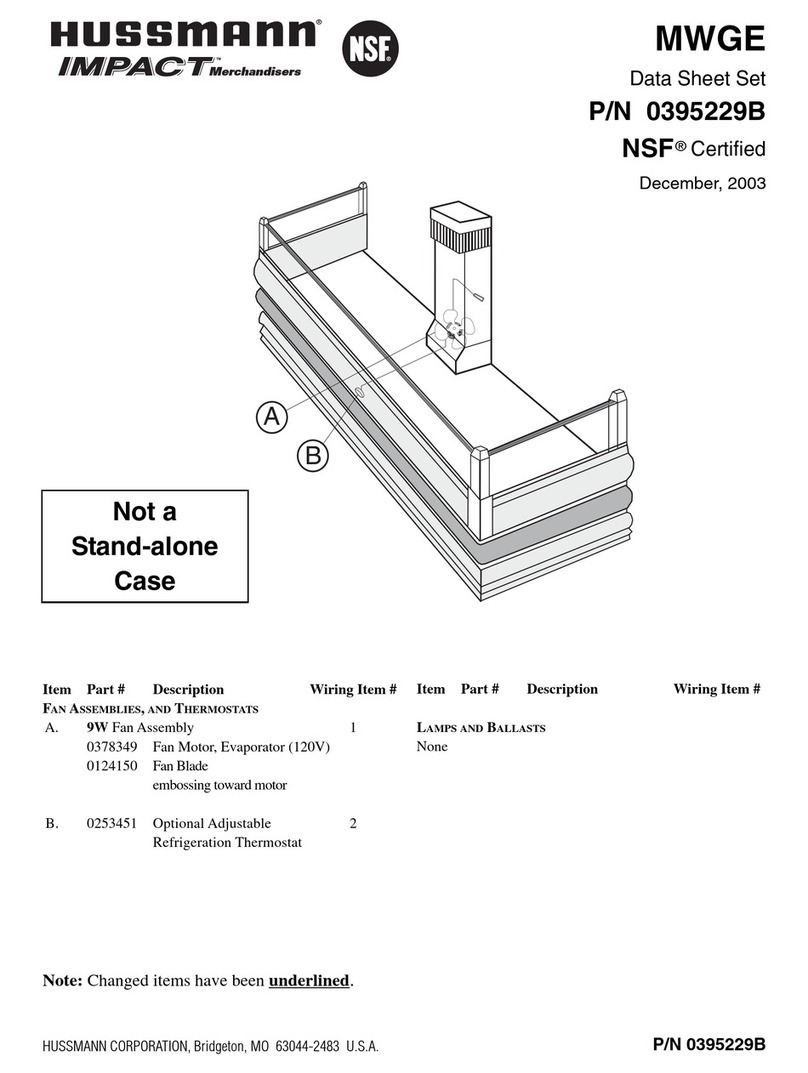

Hussmann MWGE User manual

Hussmann

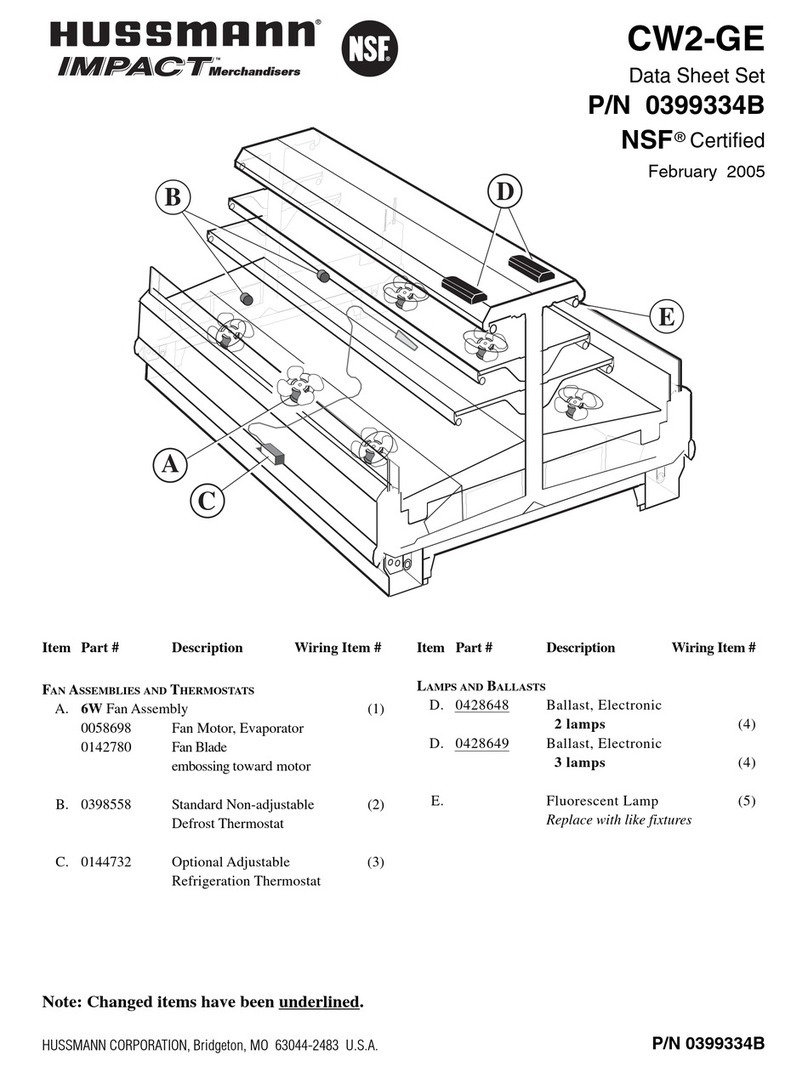

Hussmann IMPACT CW2-GE User manual

Popular Merchandiser manuals by other brands

FRIGOGLASS

FRIGOGLASS Flex 20 HC user manual

EPTA

EPTA COSTAN RHINO MULTI User instructions

CASCO

CASCO Nano Cube owner's manual

True

True GDIM-26 installation manual

Structural Concepts

Structural Concepts Oasis Mobile Series Installation & operating manual

Haussmann

Haussmann RL Installation & operation manual

Howard McCray

Howard McCray R-CDS32E-4 Specifications

EPTA

EPTA iarp Cool Emotions Delight Lite User instructions

VALERA

VALERA BC 85 datasheet

HL Display

HL Display 3eBin Assembly instructions

Dixie Narco

Dixie Narco DNCB 501E Technical manual

APW Wyott

APW Wyott Racer DMXD-30H Installation and operating instructions

Hoshizaki

Hoshizaki KD-90C Service manual

Summit

Summit SCR1006 instruction manual

Delfield

Delfield Shelleyspeed SPM-28E Specifications

EPTA

EPTA iarp Cool Emotions GLEE 40 User instructions

Kysor/Warren

Kysor/Warren GranBering KW TECHNICAL MANUAL & USER INSTRUCTIONS

Crane

Crane BevMAX Refresh 6 Media Operation guide