Page 2of 25

Rodgard Runflat System Instruction and User Guide

Rev: 060520

TABLE OF CONTENTS

RODGARD RUNFLAT KIT CONTENTS ................................................................ 3

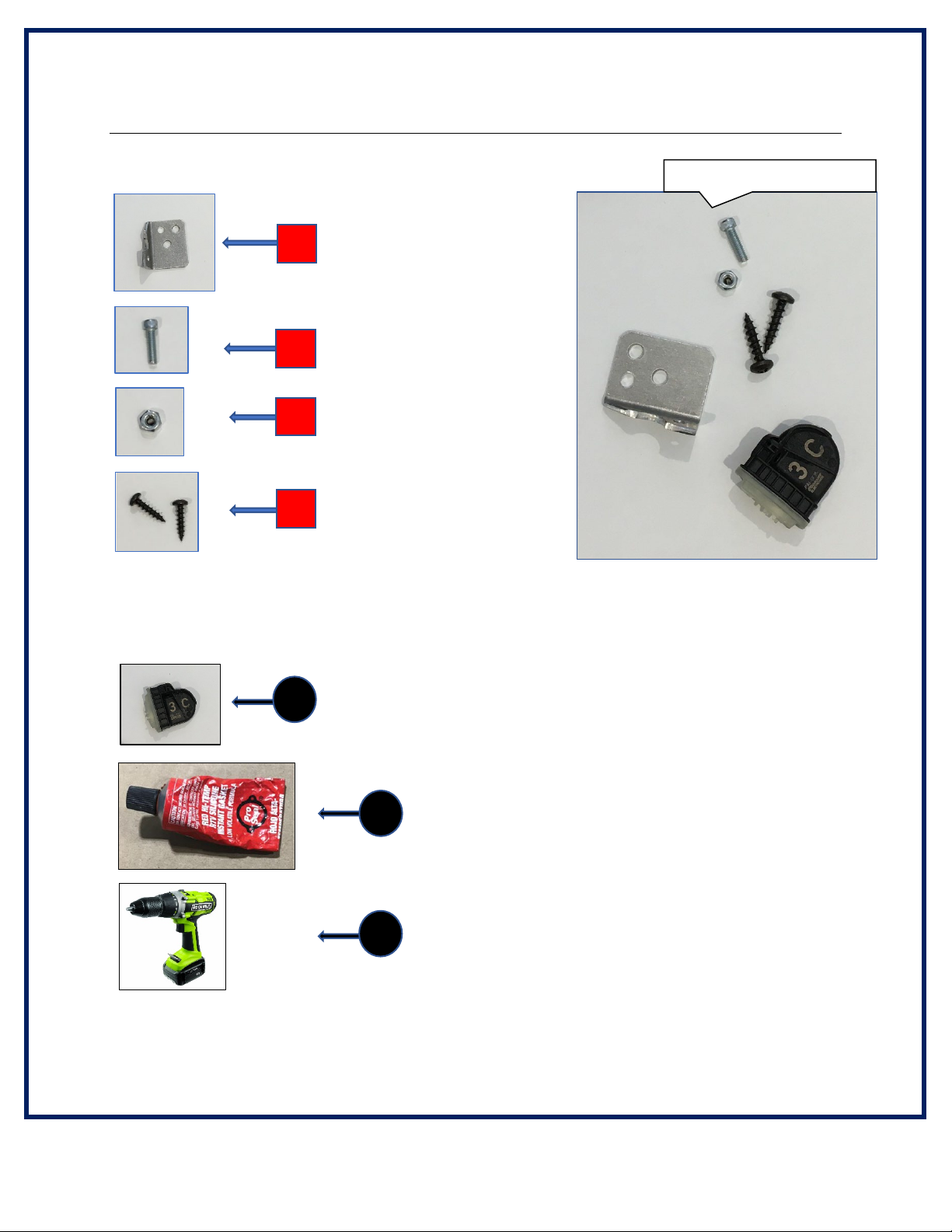

TPMS RELOCATION KIT CONTENTS.................................................................. 4

REQUIRED HAND TOOLS, EQUIPMENT AND HARDWARE (not included) ....... 5

SAFETY NOTES AND ASSEMBLY PREPARATION ............................................ 6

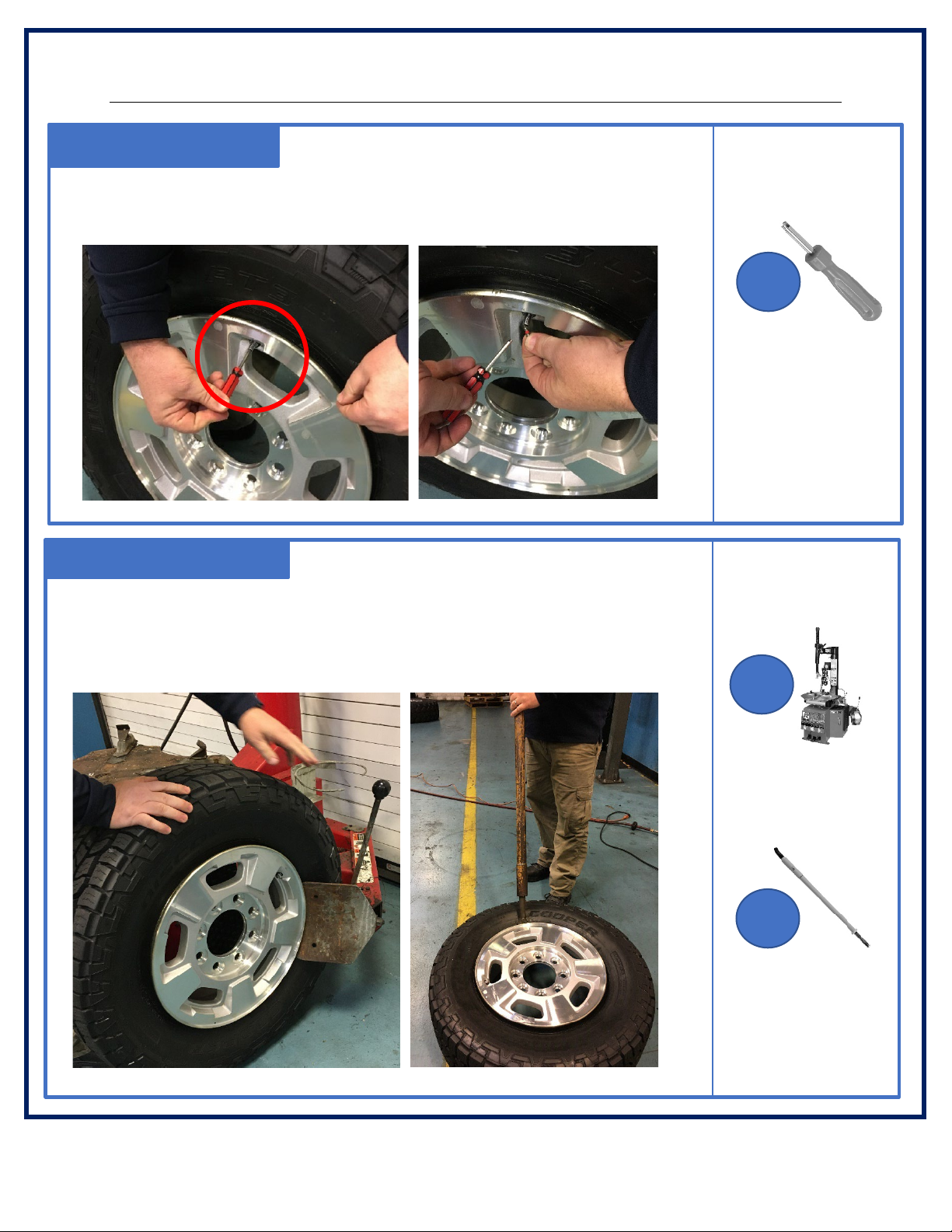

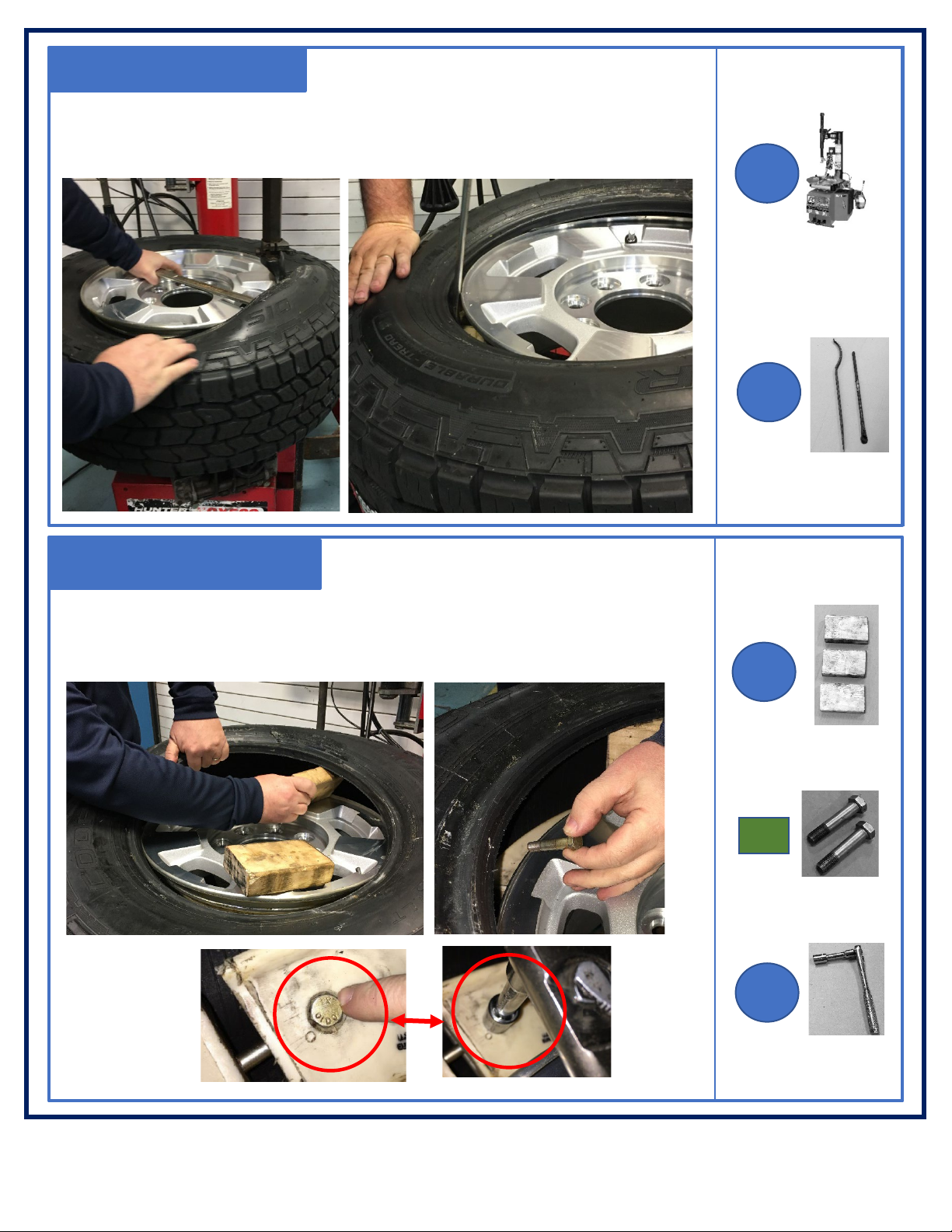

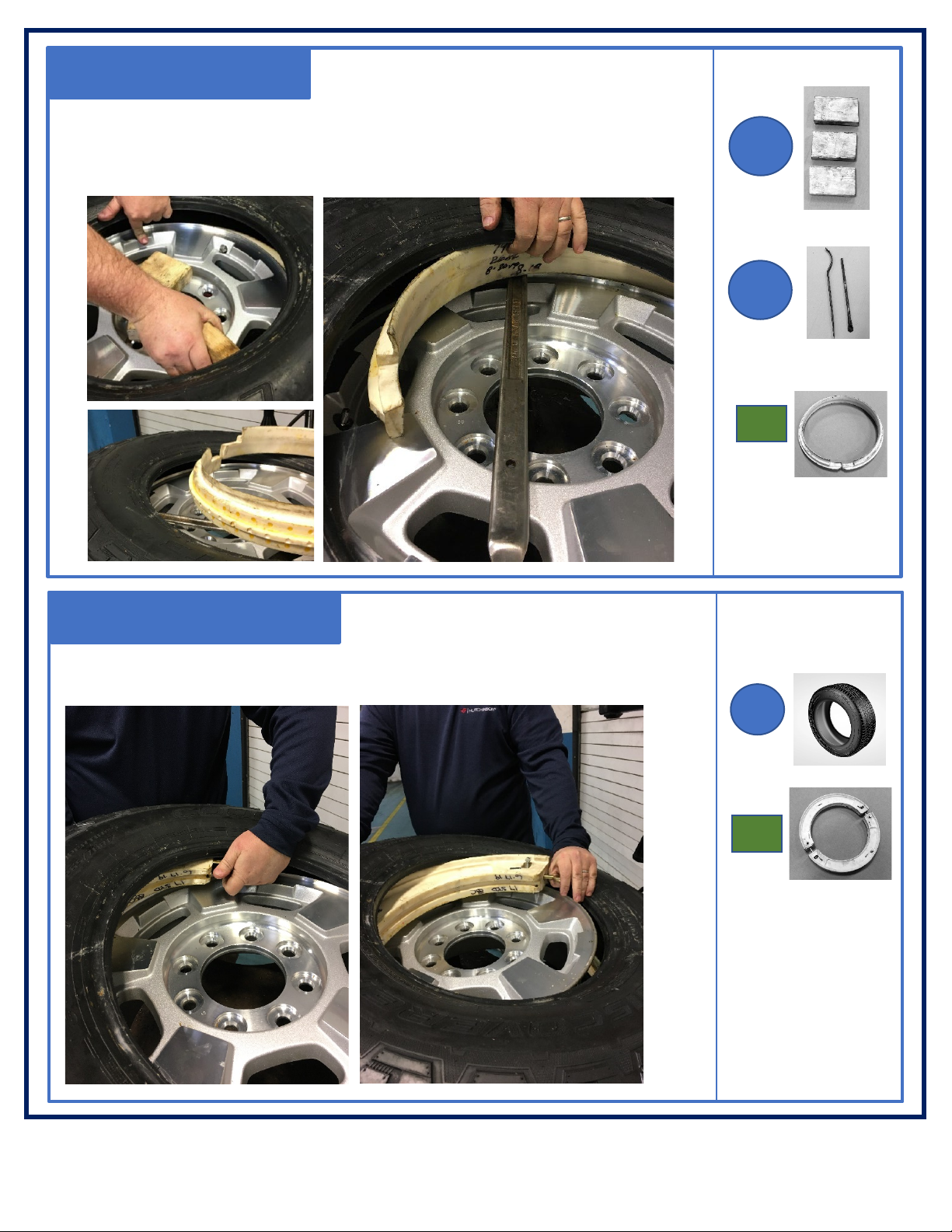

RODGARD RUNFLAT DISASSEMBLY INSTRUCTIONS .................................... 7-10

RODGARD RUNFLAT INSPECTION CRITERIA................................................... 11

HOW TO ORDER RODGARD RUNFLAT COMPONENTS .................................. 12

RODGARD RUNFLAT PART NUMBERS ............................................................. 13

RODGARD RUNFLAT INSTALLATION AND TPMS RELOCATION INSTRUCTIONS

................................................................................................................................14-25

Hutchinson Industries Defense & Mobility Systems

92 Monsignor Valente Drive, Buffalo, New York 14206

Phone: (716) 710-5175 Website: www.hutchinsoninc.com Email: runflats@hutchinsoninc.com

TO REORDER WHEELS, TIRES, RUNFLATS OR PARTS:

CALL (716) 710-5175

OR EMAIL: runflats@hutchinsoninc.com