-5-

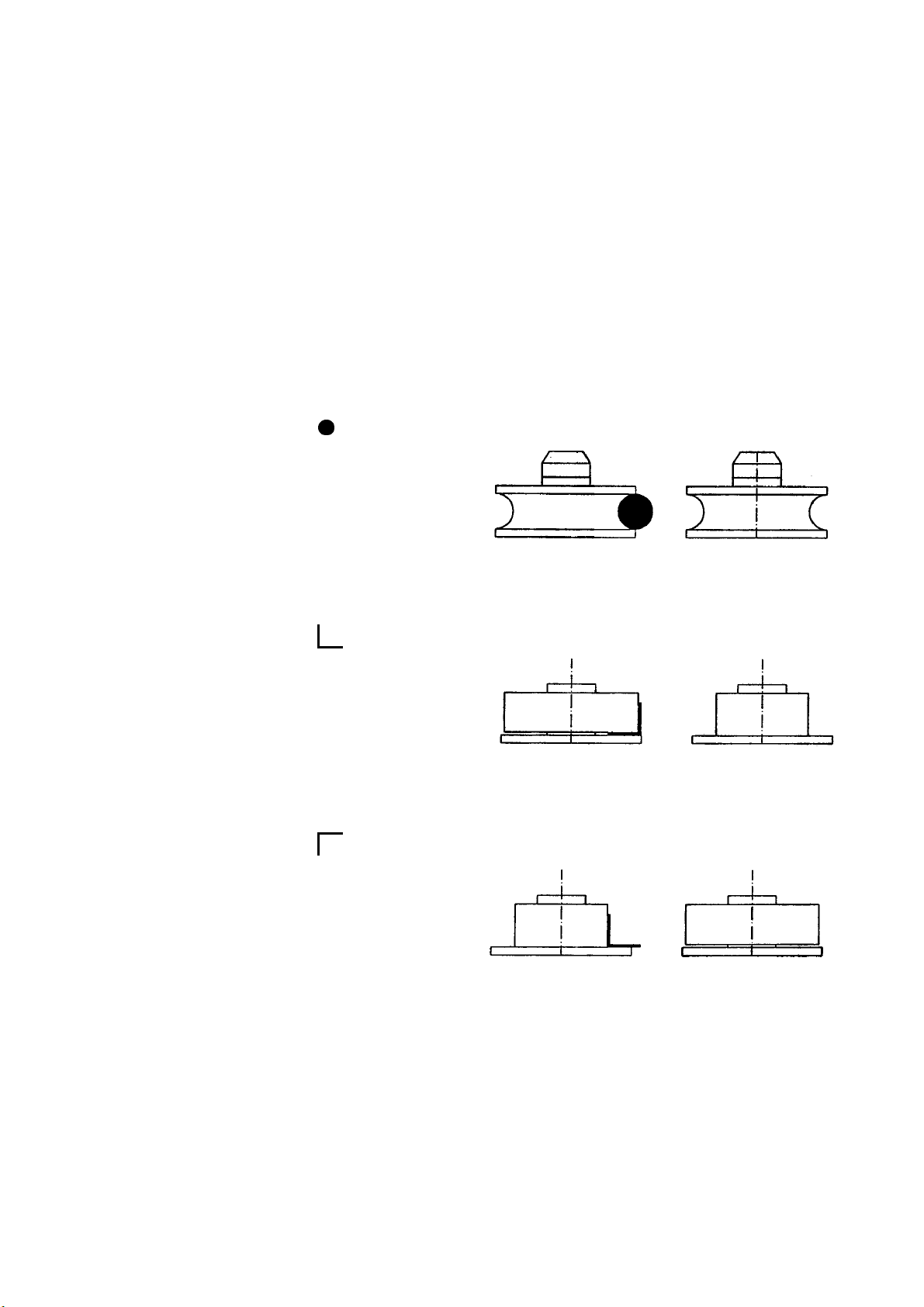

4. T-profile with clean inside MIP 30-15-7-0

Guide roll R6/R5 MIP 30-15-7-1 4

Guide roll R4/R3 MIP 30-15-7-2 4

Ring Ø58x5 MIP 30-15-5-1 2

Ring Ø58x4 MIP 30-15-5-2 2

Ring Ø58x3 MIP 30-15-5-3 2

Ring Ø58x2 MIP 30-15-5-4 2

Flange Ø148x13 MIP 30-15-3-2 2

Leading roll 50 MIP 30-15-1-8 1

Leading roll 45 MIP 30-15-1-9 1

Leading roll 40 MIP 30-15-1-10 1

Leading roll 35 MIP 30-15-1-11 1

Leading roll 30 MIP 30-15-1-12 1

Leading roll 25 MIP 30-15-1-13 1

5. T-profile with clean

outside

MIP 30-15-8-0

Leading roll R6/R5 MIP 30-15-8-1 2

Leading roll R4/R3 MIP 30-15-8-2 2

Ring Ø58x5 MIP 30-15-6-1 1

Ring Ø58x4 MIP 30-15-6-2 1

Ring Ø58x3 MIP 30-15-6-3 1

Ring Ø58x2 MIP 30-15-6-4 1

Flange Ø148x13 MIP 30-15-3-1 4

Guide roll 50 MIP 30-15-1-2 2

Guide roll 45 MIP 30-15-1-3 2

Guide roll 40 MIP 30-15-1-4 2

Guide roll 35 MIP 30-15-1-5 2

Guide roll 30 MIP 30-15-1-6 2

Guide roll 25 MIP 30-15-1-7 2

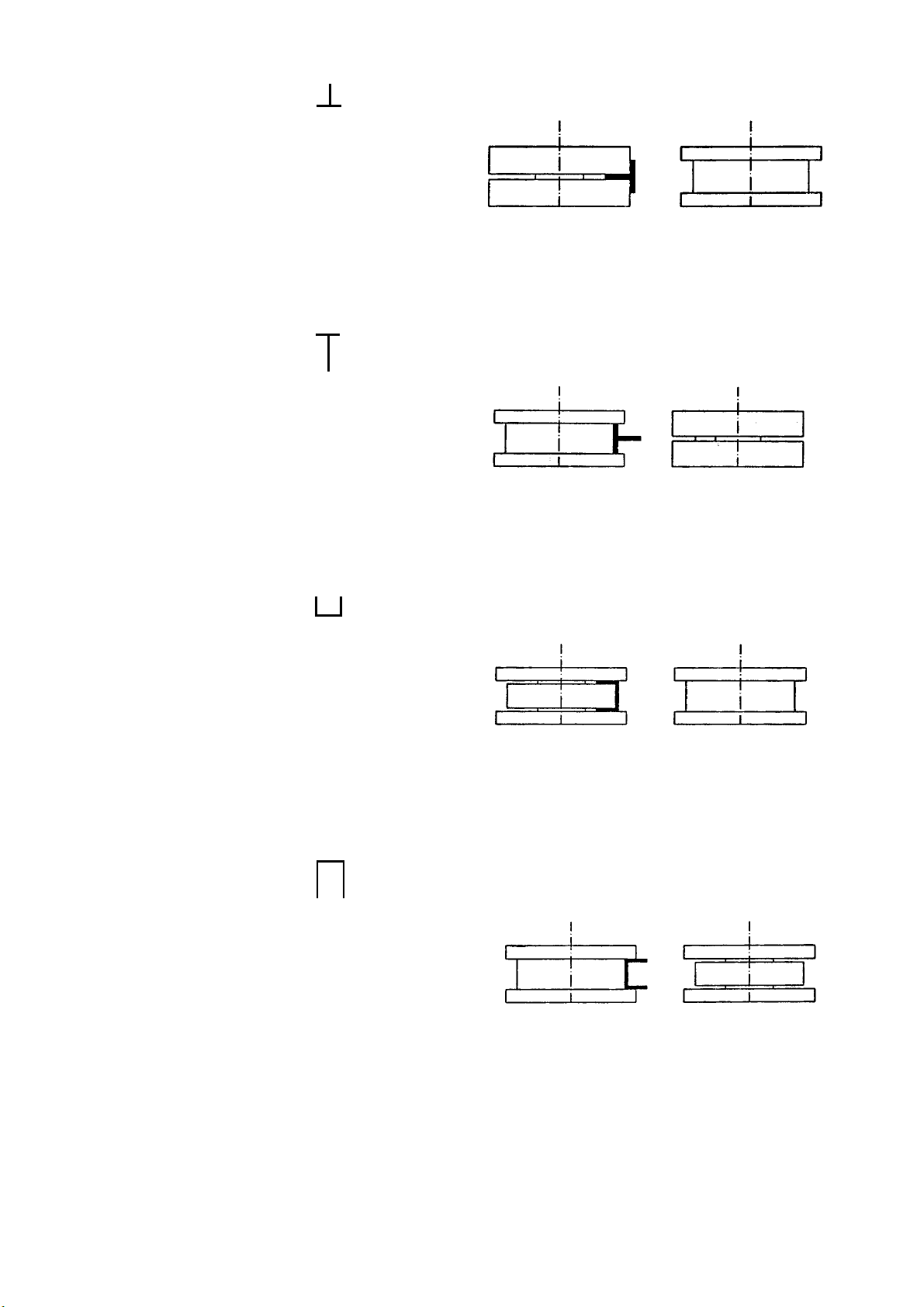

6. U-profile with clean inside MIP 30-15-9-0

Flange Ø148x13 MIP 30-15-3-1 4

Flange Ø148x13 MIP 30-15-3-2 2

Ring Ø58x5 MIP 30-15-5-1 4

Ring Ø58x4 MIP 30-15-5-2 4

Ring Ø58x3 MIP 30-15-5-3 4

Ring Ø58x2 MIP 30-15-5-4 4

Guide roll 50 MIP 30-15-9-1 4

Guide roll 40 MIP 30-15-9-2 4

Guide roll 30 MIP 30-15-9-3 4

Driving axle ring 4 MIP 30-15-9-4 2

Driving axle ring 2 MIP 30-15-9-5 2

Leading roll 50 MIP 30-15-1-8 1

Leading roll 40 MIP 30-15-1-10 1

Leading roll 30 MIP 30-15-1-11 1

7. U-profile with clean

outside MIP 30-15-10-0

Flange Ø148x13 MIP 30-15-3-1 4

Flange Ø148x13 MIP 30-15-3-2 2

Ring Ø58x5 MIP 30-15-6-1 4

Ring Ø58x4 MIP 30-15-6-2 4

Ring Ø58x3 MIP 30-15-6-3 4

Ring Ø58x2 MIP 30-15-6-4 4

Leading roll 50 MIP 30-15-10-1 1

Leading roll 40 MIP 30-15-10-2 1

Leading roll 30 MIP 30-15-10-3 1

Driving axle ring 4 MIP 30-15-10-4 1

Driving axle ring 2 MIP 30-15-10-5 1

Guide roll 50 MIP 30-15-1-2 2

Guide roll 40 MIP 30-15-1-4 2

Guide roll 30 MIP 30-15-1-6 2