Huvema HU 300 HAC-4 Topline User manual

Other Huvema Saw manuals

Huvema

Huvema HU 270 DHG-4 User manual

Huvema

Huvema HU 440 DGH User manual

Huvema

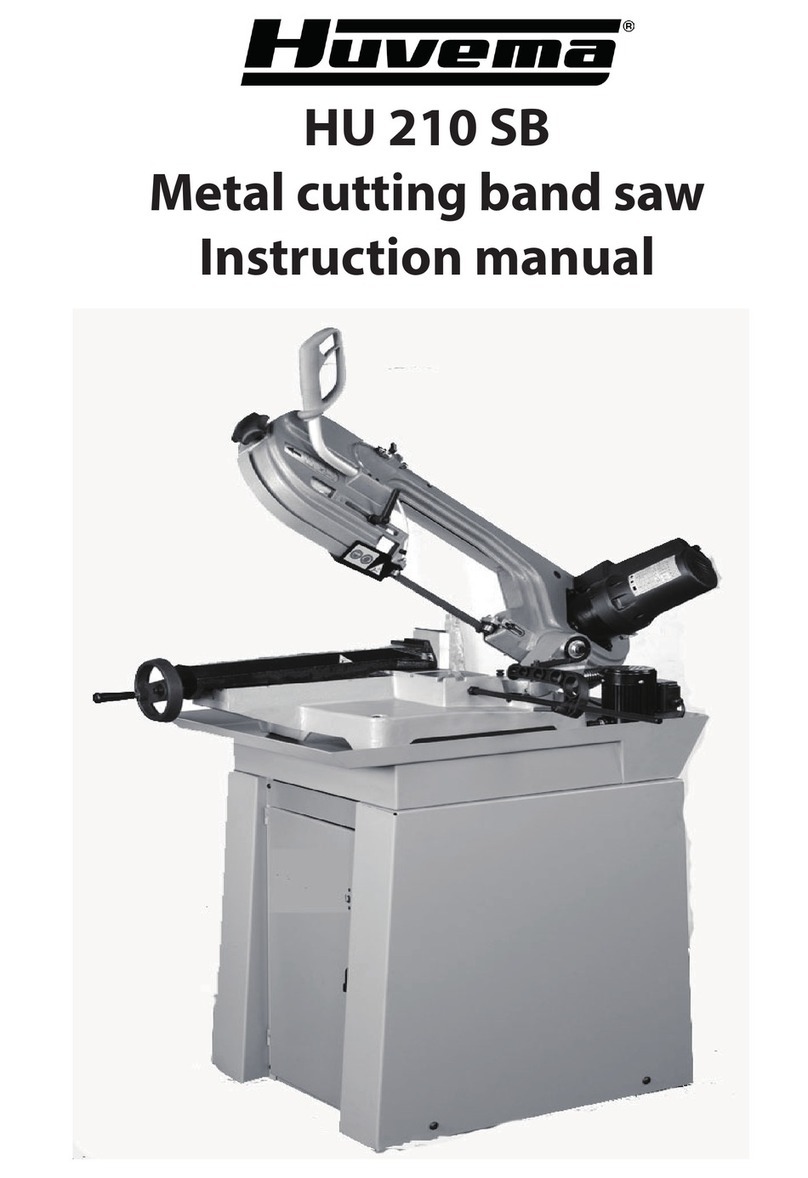

Huvema HU 210 SB User manual

Huvema

Huvema HU 150 PB User manual

Huvema

Huvema HU 370 ASK User manual

Huvema

Huvema HU 285 AC-4 TOPLINE User manual

Huvema

Huvema HU 250 CS-4 User manual

Huvema

Huvema HU 250 CS User manual

Huvema

Huvema HU 315 ASK User manual

Huvema

Huvema HU 300 Automatic User manual

Huvema

Huvema TL-400-A User manual

Huvema

Huvema HU 100 BM User manual

Huvema

Huvema HU 1610 VBS SUPER User manual

Huvema

Huvema HU 2613 VBS Super User manual

Huvema

Huvema HU 315 SK User manual

Huvema

Huvema HU 250 CS User manual

Huvema

Huvema TL-500-AA User manual

Huvema

Huvema HU 350 DC User manual

Huvema

Huvema HU 355 DRYCUTTER-2 User manual

Huvema

Huvema HU 331 DGH User manual