CHANGES AND TYPING ERRORS RESERVED CHANGES AND TYPING ERRORS RESERVED

A quick removal of the cut material and a correct depth and rounding of the tooth cavity are of the utmost

importance. The tooth cavity must be large enough for the removed chips to be bend as long as the tooth is

cutting. When the cutting tooth leaves the saw cut, the chip drops out of the tooth cavity.

The alternate saw (alternately bevelled edge) is often used for small pitches, especially up to 4 mm.

The precutting and finishing teeth are used for larger, solid material, usually from pitch 4 mm onwards. These

teeth ensure that the chips are not all of the same length.

If a chip were to be cut out the normal way, it would get hot, expand and become wider than the width of the cut.

This would caus e it to get stuck, as a result of which the chip could not be removed from the cut. The finishing

tooth must be positioned 0.2 to 0.4 mm higher than the precutting tooth. The larger the pitch, the higher the

precutting tooth must be placed as compared to t he finishing tooth.

Consequently, only special machines are suitable for regrinding these teeth. When the blade has lost its cutting

power, do not strain it. As a result the teeth may break off, which doubles the regrinding costs.

5.3.

For the maximum capacity in mm see the schedule for the profile figure/cross -cut in relationship with the mitre

angle.

5.4.

insTalling and replacing THe saw blade

• Set the main switch in the off position.

• Put the saw head in the upper position.

• Open the guards (fig. 5.03A).

• Release the socket head screw M8 of the saw spindle (fig. 5.03B) and

remove the saw flange.

• Remove the saw blade.

• Carefully clean the saw spindle and the saw flange.

• Installing is done in reverse order. Pay attention to the direction of

rotation of the sawblade. Make sure the saw blade is placed flush

against the flange of the saw spindle. Check the setting of the sawing

depth (see chapter 4.2). Do not forget to close the safety guard.

5.5.

Manual saw feed The saw feed is determined by hand. The saw is lowered

onto the material by means of the handle. Press the saw blade firmly onto

the material, without using unnecessary force. When the saw pressure is

too high this can cause the saw to break; when the saw pressure is too low,

te saw will rapidly go blunt.

cavity are of the utmost importance. The tooth cavity must be large enough for the

removed chips to be bend as long as the tooth is cutting. When the cutting tooth

leaves the saw cut, the chip drops out of the tooth cavity.

The alternate saw (alternately bevelled edge) is often used for small pitches,

especially up to 4 mm.

The precutting and finishing teeth are used for larger, solid material, usually from

pitch 4 mm onwards. These teeth ensure that the chips are not all of the same length.

If a chip were to be cut out the normal way, it would get hot, expand and become

wider than the width of the cut. This would caus e it to get stuck, as a result of which

the chip could not be removed from the cut. The finishing tooth must be positioned

0.2 to 0.4 mm higher than the precutting tooth. The larger the pitch, the higher the

precutting tooth must be placed as compared to t he finishing tooth.

Consequently, only special machines are suitable for regrinding these teeth. When

the blade has lost its cutting power, do not strain it. As a result the teeth may break

off, which doubles the regrinding costs.

5.3 Sawing Capacity

For the maximum capacity in mm see the schedule for the profile figure/cross -cut in

relationship with the mitre angle. Write 90º we mean straight sawing.

HU250

CS

90º 80 70x70 70x70 70x70 90x50 35 35x35

60º 80 60x60 60x60 60x60 80x50 30 30x30

45º 80 60x60 60x60 60x60 60x60 25 25x25

5.4 Installing and replacing the saw blade

•Set the main switch in the off position.

•Put the saw head in the upper position.

•Open the guards (fig. 5.03A).

•Release the socket head screw M8 of the saw spindle

(fig. 5.03B) and remove the saw flange.

•Remove the saw blade.

•Carefully clean the saw spindle and the saw flange.

•Installing is done in reverse order. Pay attention to the

direction of rotation of the sawblade. Make sure the saw blade is

placed flush against the flange of the saw spindle. Check the

setting of the sawing depth (see chapter 4.2). Do not forget to close the safety guard.

cavity are of the utmost importance. The tooth cavity must be large enough for the

removed chips to be bend as long as the tooth is cutting. When the cutting tooth

leaves the saw cut, the chip drops out of the tooth cavity.

The alternate saw (alternately bevelled edge) is often used for small pitches,

especially up to 4 mm.

The precutting and finishing teeth are used for larger, solid material, usually from

pitch 4 mm onwards. These teeth ensure that the chips are not all of the same length.

If a chip were to be cut out the normal way, it would get hot, expand and become

wider than the width of the cut. This would caus e it to get stuck, as a result of which

the chip could not be removed from the cut. The finishing tooth must be positioned

0.2 to 0.4 mm higher than the precutting tooth. The larger the pitch, the higher the

precutting tooth must be placed as compared to t he finishing tooth.

Consequently, only special machines are suitable for regrinding these teeth. When

the blade has lost its cutting power, do not strain it. As a result the teeth may break

off, which doubles the regrinding costs.

5.3 Sawing Capacity

For the maximum capacity in mm see the schedule for the profile figure/cross -cut in

relationship with the mitre angle. Write 90º we mean straight sawing.

5.4 Installing and replacing the saw blade

•Set the main switch in the off position.

•Put the saw head in the upper position.

•Open the guards (fig. 5.03A).

•Release the socket head screw M8 of the saw spindle

(fig. 5.03B) and remove the saw flange.

•Remove the saw blade.

•Carefully clean the saw spindle and the saw flange.

•Installing is done in reverse order. Pay attention to the

direction of rotation of the sawblade. Make sure the saw blade is

placed flush against the flange of the saw spindle. Check the

setting of the sawing depth (see chapter 4.2). Do not forget to close the safety guard.

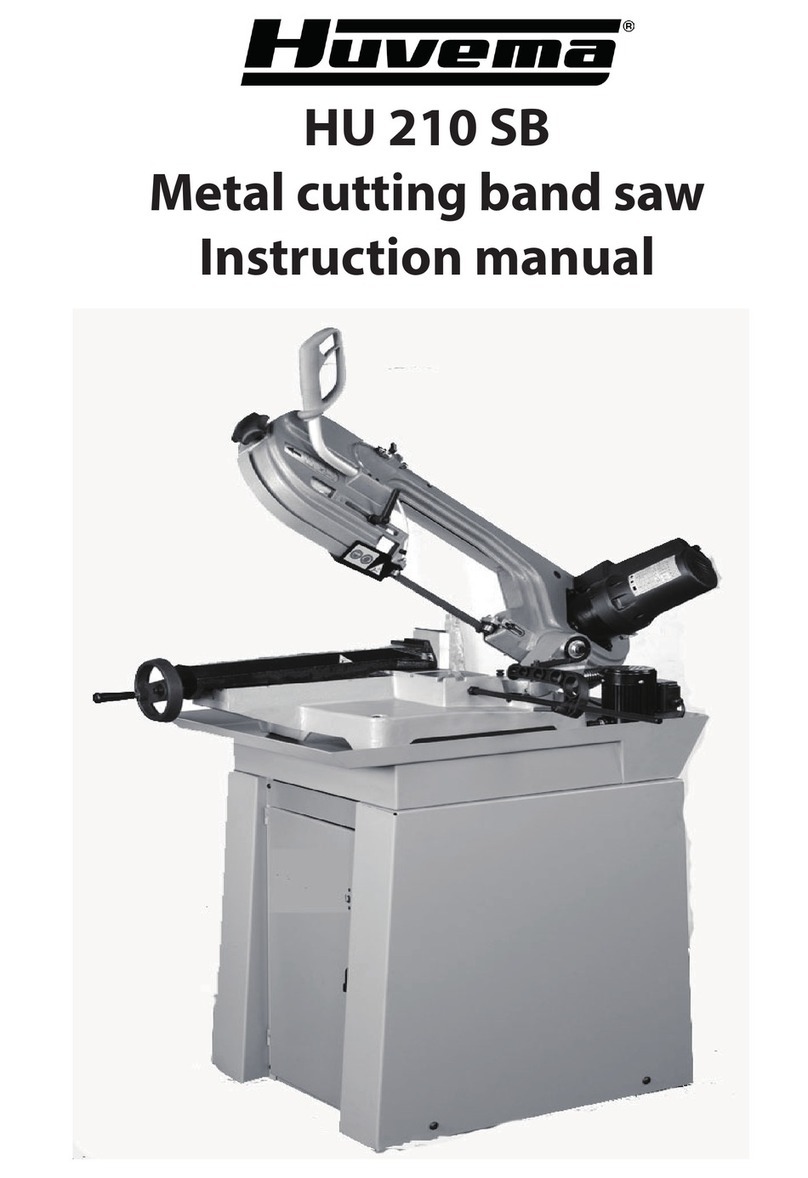

5.5 Saw feed

Manual saw feed The saw feed is determined by

hand. The saw is lowered onto the material by means

of the handle. Press the saw b lade firmly onto the

material, without using unnecessary force. When the

saw pressure is too high this can cause the saw to

break; when the saw pressure is too low, te saw will

rapidly go blunt.

5.6 Sawing speed

The following cutting speeds are po ssible:

HU 250 CS > speed in position 1: 40 m/min.

in position 2: 80m/min

Every material has it’s own cutting speed. Below advice for some materials:

20 m/min > For steel alloy e.g. stainless steel

40 m/min > For normal steel

80 m/min > For non-ferrous materials

5.7 Clamping the material

It is of the utmost importance that the material is safely clamped in the double material

vice, so that it cannot tilt over or even move during sawing. In ord er to work efficiently,

the material must always be clamped in such a way that the contact surface of the saw

and the material is as small as possible. For instance, saw flat material on its thinnest

side; this will considerable shorten sawing times. When very short pieces have to be

sawn, and consequently only half of the material vice

will be used, in order to prevent it from pulling out of

alingment, a piece of material of equal thickness must

be clamped in the other half of the vice. In this way the

material is clamped tightly and evenly. Application of

special vice jaws is recommendable for

repetitive work

The sawing depth can be limited by means of an

adjustable ring, see chapter 4.2

Mitre-sawing

Pull the clamping rod (fig. 5.06B) to the right and turn the sawing unit in the required mitre

position. The position can be read out on the scale division (fig 5.06A). Then fasten the

clamping rod again. Do not use unnecessary force, a slight pull will su ffice. Before clamping

the material, check whether the saw is running completely clear between the jaws of the

material vice. Place the steel vice jaws as closely as possible to the saw.

Material Clearance angle Rake angle

Steel 822°

Stainless steel 615°

Non-ferrous 12 25°