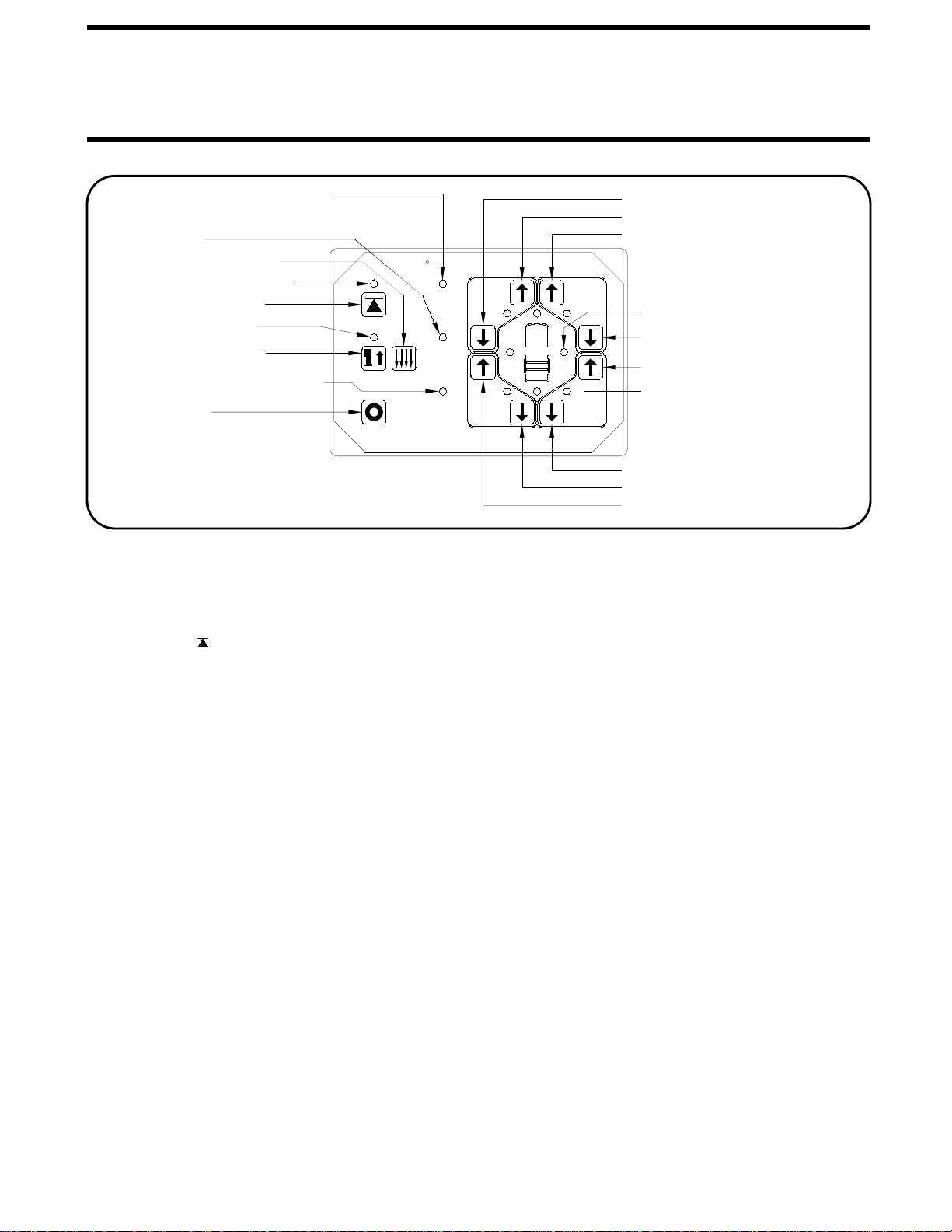

OPERATING PROCEDURES

SET UP AND AUTOMATIC LEVELING PROCEDURE

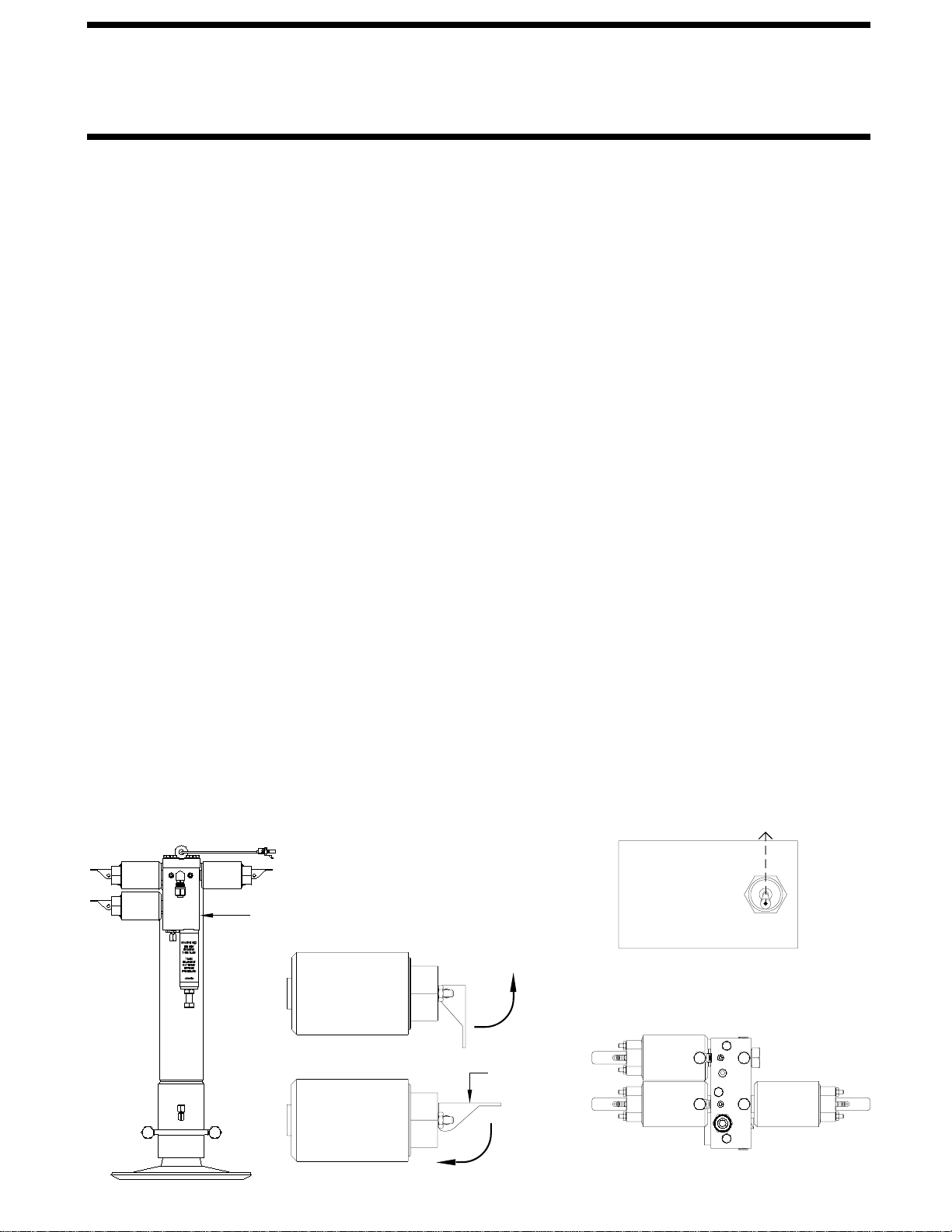

Trailer must be unhitched from the tow vehicle before

leveling. The HWH front jacks may be used to lift the trailer for

unhitching. If auxiliary jacks are used to unhitch the trailer,

If parking on soft ground or asphalt paving, a wood block or

for unhitching.

pad should be placed under each jack.

will result if raise arrows are operated for an extended

period of time.

NOTE: Refer to the trailer manufacturer owner’s manual

IMPORTANT: Overheating and excessive current drain

09MAY13

MP34.2780

extend the HWH front jacks to the ground and retract the

auxiliary jacks before the leveling system is used for leveling.

the vehicle and then extend any remaining jacks for stabilizing.

The system will first automatically extend the jacks to level

1. Turn the master power switch on.

2. Use the front UP arrow manual buttons to extend the

front jacks to unhitch the trailer. - OR - The trailer may be

The system will level the trailer front to rear (if needed)

before leveling side to side. If the rear yellow level indicator

is on, the system will lower the front of the trailer to level the

trailer. After the system has finished leveling and stabilizing,

it will begin the precision leveling sequence. The precision

NOTE: The system will only lower the front of the trailer

if the rear level light is on when the "AUTO LEVEL"

button is pushed. If the rear light is not on or goes

out while lowering the trailer, no lowering procedure

is used after that no matter what level light may come

on.

If either front red warning light goes out while the front

is lowering, the system stop lowering and begin raising

the rear of the trailer to level the trailer.

NOTE: Before unhitching the trailer, the operator may

want to check the jacks and place pads under the jacks

if the ground will not support the vehicle.

IMPORTANT: The "AUTO LEVEL" button will not

function unless both front jacks are firmly on the

ground, supporting the weight of the trailer.

If the rear yellow level indicator is on, the "AUTO LEVEL"

button will not function unless both front jacks are firmly

on the ground supporting the trailer and both front

red warning lights are on.

If either of the above situations are encountered, the

"INCORRECT PROCEDURE" light will come on steady

for 10 seconds. Both front warning lights will flash

while the "INCORRECT PROCEDURE" light is on.

After 10 seconds, the "INCORRECT PROCEDURE"

light will shut off and the front warning lights will

stop flashing. When the situation has been corrected,

the "AUTO LEVEL" button will function. The manual

UP and DOWN arrow buttons will function while the

"INCORRECT PROCEDURE" light is on.

3. Push the "AUTO LEVEL" button. The AUTO LEVEL light

will flash and the auto leveling procedure will begin. The

4. Make sure the master power switch is off any time the

touch panel is not active whether the jacks are extended

or retracted.

In the event the jacks"EXCESS SLOPE" SITUATIONS:

equipped with a (2) toggle switch panel that is used to

extend or retract the front jacks only. This panel should

be located at the front of the trailer and can be used to

extend the front jacks to unhitch the trailer.

leveling procedure is two stages; a basic leveling and

stabilizing procedure, then a precision leveling procedure.

Both procedures are done automatically after pushing the

"AUTO LEVEL" button one time.

leveling procedure may take a few minutes to accomplish

the desired level position. During precision leveling, the

pump will cycle between loading up and freewheeling. One

or two jacks will extend a very small amount during each

cycle. Each cycle will be about 10 seconds. When the level

sensor tolerances are satisfied, the system will shut off.

are unable to level the coach during the "basic" leveling

procedure, the "EXCESS SLOPE" light will come on.

Excess slope is one or two jacks fully extended without

turning the yellow level light out. The system will not

stabilize the vehicle if the "EXCESS SLOPE" light comes

on. One or more jacks may NOT be extended. The system

will shut off leaving the "EXCESS SLOPE" light on.

The "EXCESS SLOPE" light will remain on if there is power

to the control box, until the jacks have been fully retracted

using the touch panel manual DOWN ARROW buttons,

turning the red warning lights out. Refer to the HITCHING

AND STORING JACKS section. Move the trailer to a more

level position or level the trailer as close as possible

according to the MANUAL LEVELING section. Cycling

power to the system will also turn the "EXCESS SLOPE"

light off.

The manual UP and DOWN ARROW buttons will

function when the "EXCESS SLOPE" light is on.