OPERATING PROCEDURES

MP35.485

20AUG96

AUTOMATIC HYDRAULIC LEVELING

the vehicle suspension. After approximately 45 seconds, the

light will start to flash. The system will begin to dump air from

4. Press the "HYD" button a second time. The "HYD" indicator

place pads under the jacks if the ground will not support the

3. At this time the operator may want to check the jacks and

mode. The "HYD" indicator light will glow steady.

2. Press the "HYD" button to enter the hydraulic operation

erratic operation and inhibit proper leveling of the vehicle.

Turn the ignition to the "ACCESSORY" position.

vehicle and set parking brake. Turn the coach engine off.

1.Place transmission in the recommended position for parking

vehicle.

5. Turn the ignition switch to the "OFF" position.

the MANUAL HYDRAULIC OPERATION section.

ition or level the vehicle as close as possible according to

RETRACTION section. Move the vehicle to a more level pos-

SLOPE" light comes on. Store the jacks according to the JACK

off. The system will NOT stabilize the vehicle if the "EXCESS

continue to blink for 2 minutes, then the system will shut

indicator lights will remain on. The "HYD" indicator light will

come on. The pump will shut off. One or two yellow leveling

to level the coach the "EXCESS SLOPE" indicator light will

EXCESS SLOPE SITUATION: In the event the jacks are unable

completed the air dump cycle it will automatically shut off.

After the system has finished leveling and stabilizing, and has

and then extend any remaining jacks until they touch the ground.

system will automatically extend the jacks to level the vehicle

OFF

ON

EXTEND

RETRACT

EXTEND

RETRACT

OFF

ON

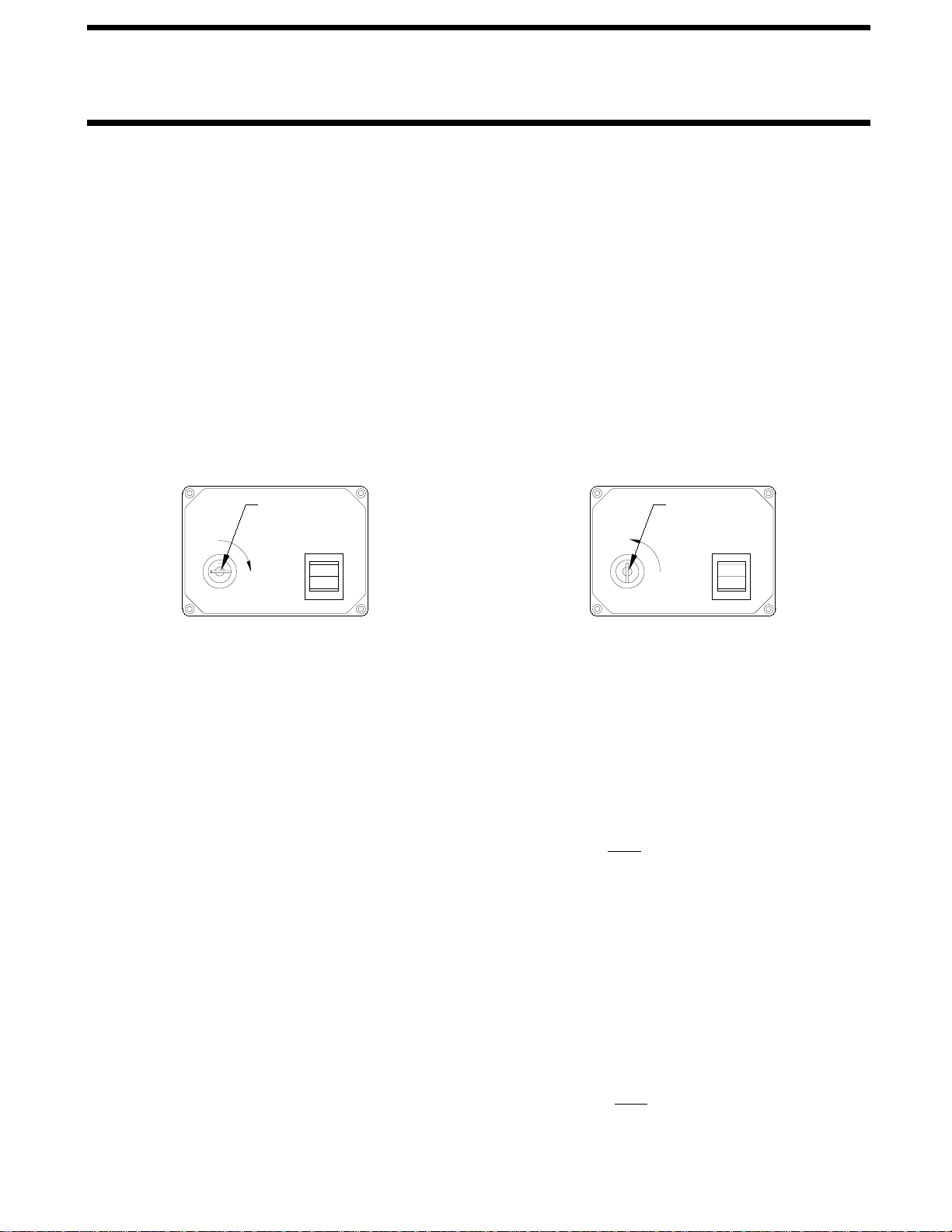

KEY SWITCH

ON POSITION KEY SWITCH

ON POSITION

ROOM EXTEND PROCEDURE

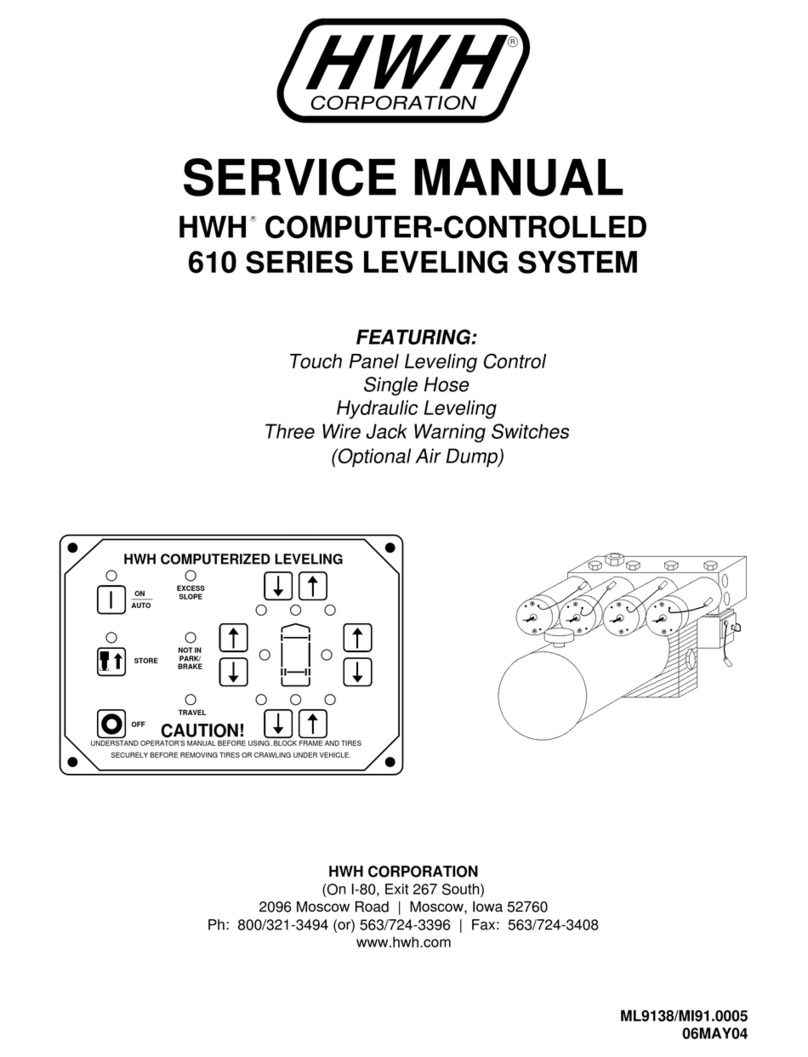

FIGURE 1 FIGURE 2

CAUTION:

OPERATING THE ROOM WITH ANY

ROOM -LOCKING DEVICES LOCKED OR THE MANUAL-

RETRACT WINCH ATTACHED CAN CAUSE PERSONAL

INJURY AND VEHICLE DAMAGE. IT IS THE OPERATOR’S

RESPONSIBILITY TO ENSURE THAT ALL ROOM-LOCKING

DEVICES AND THE MANUAL-RETRACT WINCH ARE DIS-

ENGAGED BEFORE OPERATING THE ROOM.

1. Follow the LEVELING AND STABILIZING PROCEDURE.

2. Unlock all room-locking devices.

room, remove it before extending the room.

CAUTION:

KEEP PEOPLE AND OBSTRUCTIONS

CLEAR OF ROOM WHEN OPERATING.

the room.

3. Turn the ignition switch to ACCESSORY.

4. Press the "HYD" button if the HYDRAULIC OPERATION

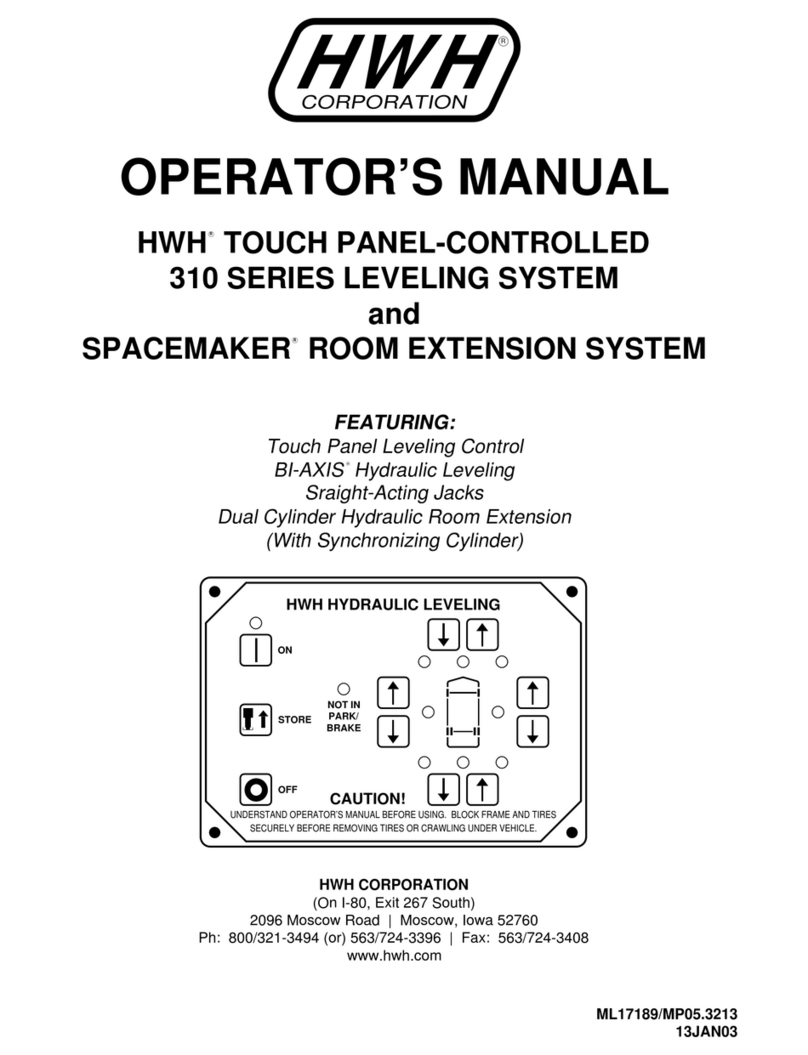

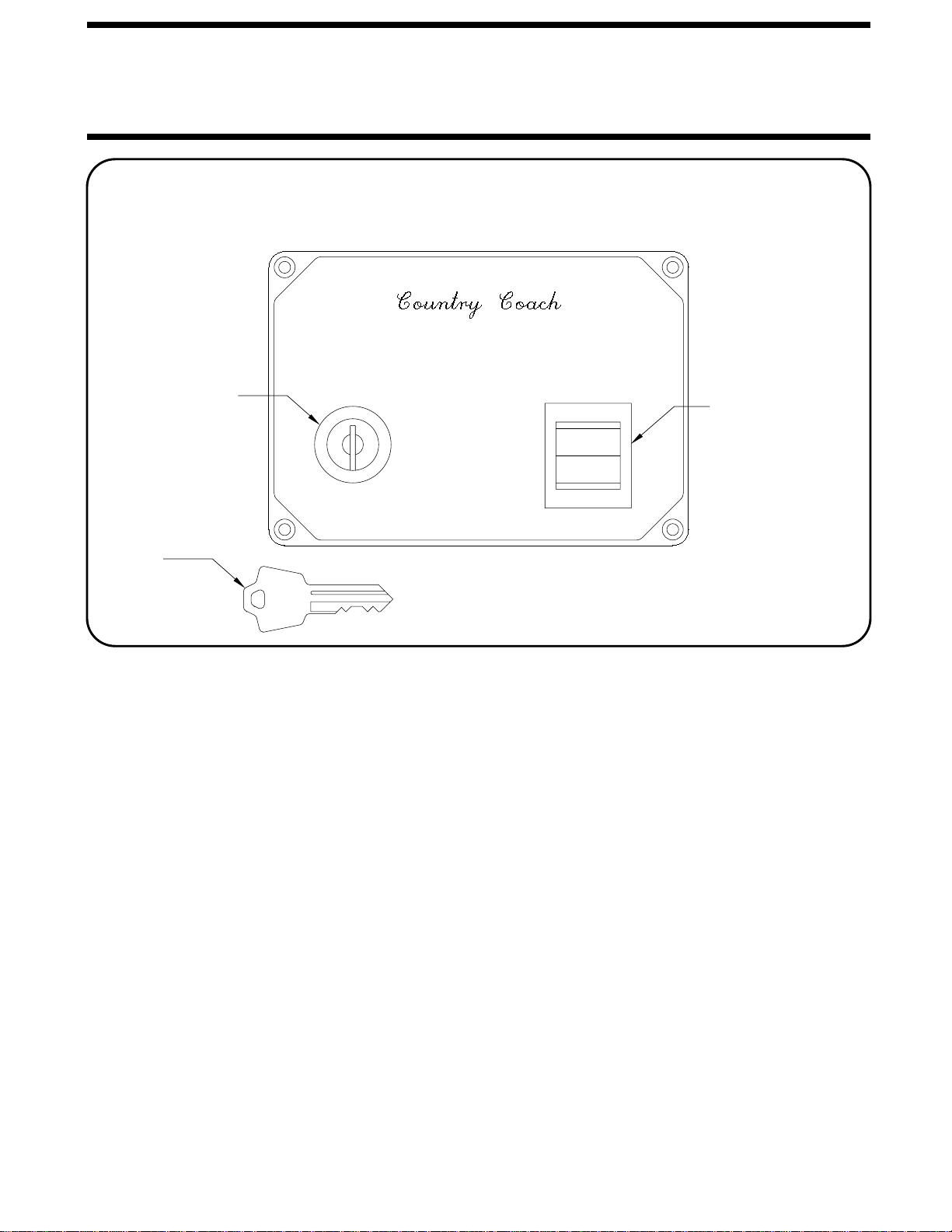

5. Turn the KEY SWITCH on the room extension operator’s

panel to the "ON" position. (Figure 1)

light and a WARNING light must be illuminated. The room will

not extend if the system is in automatic leveling or retract.

6. To EXTEND the room, press and hold the ROOM CONTROL

switch in the EXTEND position. When the room is fully ex-

tended, release the ROOM CONTROL switch.

IMPORTANT:

Do NOT hold the ROOM CONTROL switch in

the EXTEND position for more than ten seconds after the room

is fully extended. If either side of the room stops moving, re-

lease the ROOM CONTROL SWITCH immediately.

operation of the room.

7. Press the "OFF" button.

8. Turn the KEY SWITCH to the "OFF" position and remove

the key. (See Figure 2)

9. Turn off the ignition switch.

IMPORTANT:

Do NOT use the room extension support

when the vehicle is supported by the leveling system.

IMPORTANT:

The park brake must be set and the vehicle

must be leveled using the hydraulic leveling system before

the room can be extended or retracted. If the leveling sys-

tem stopped with the excess slope light on, see "EXCESS

SLOPE SITUATION" under "AUTOMATIC HYDRAULIC

LEVELING". DO NOT EXTEND the room.

NOTE:

Running the vehicle engine during leveling can cause

NOTE:

NOTE:

NOTE:

If the MANUAL RETRACT WINCH is attached to the

Make sure there is adequate clearance to fully extend

Releasing the ROOM CONTROL switch will halt the

NOTE:

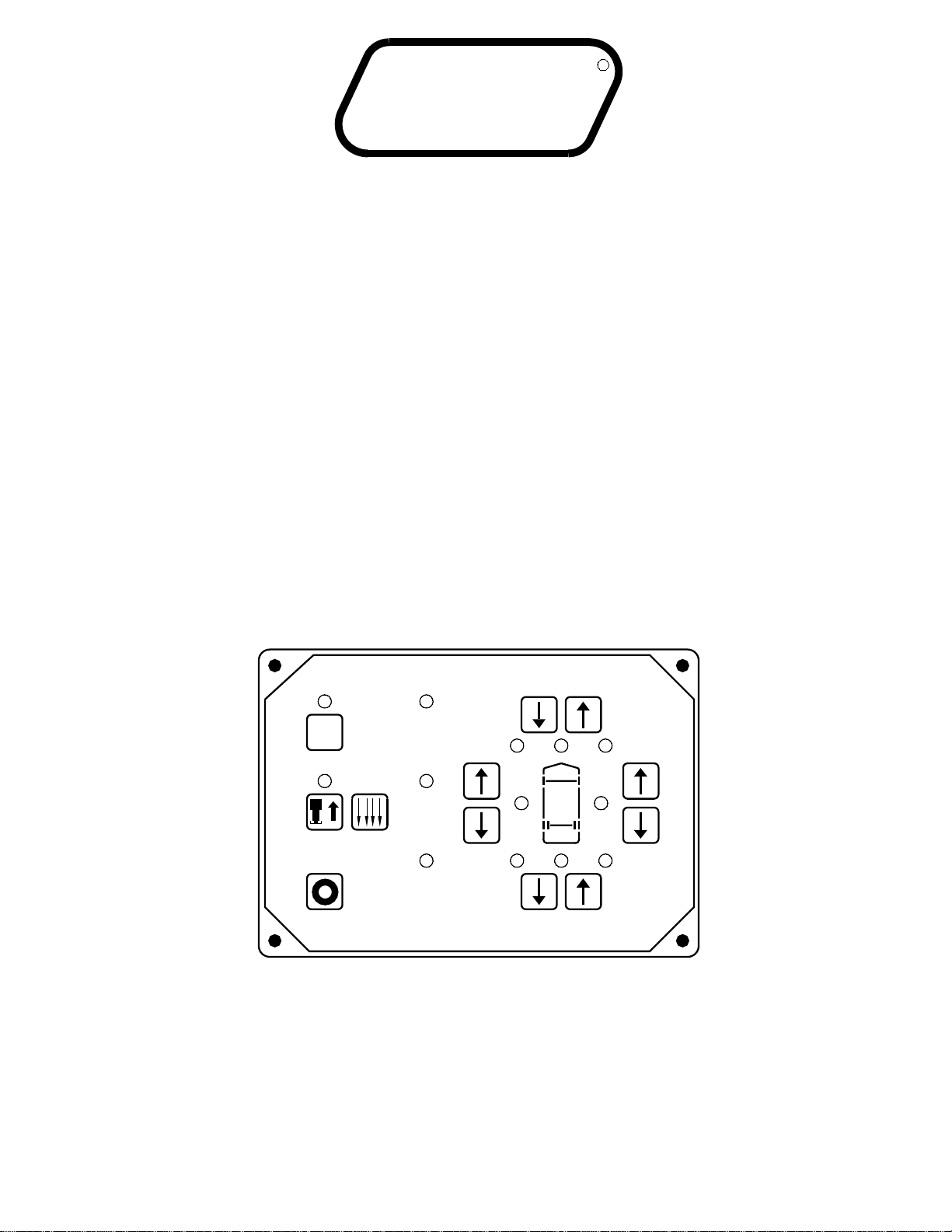

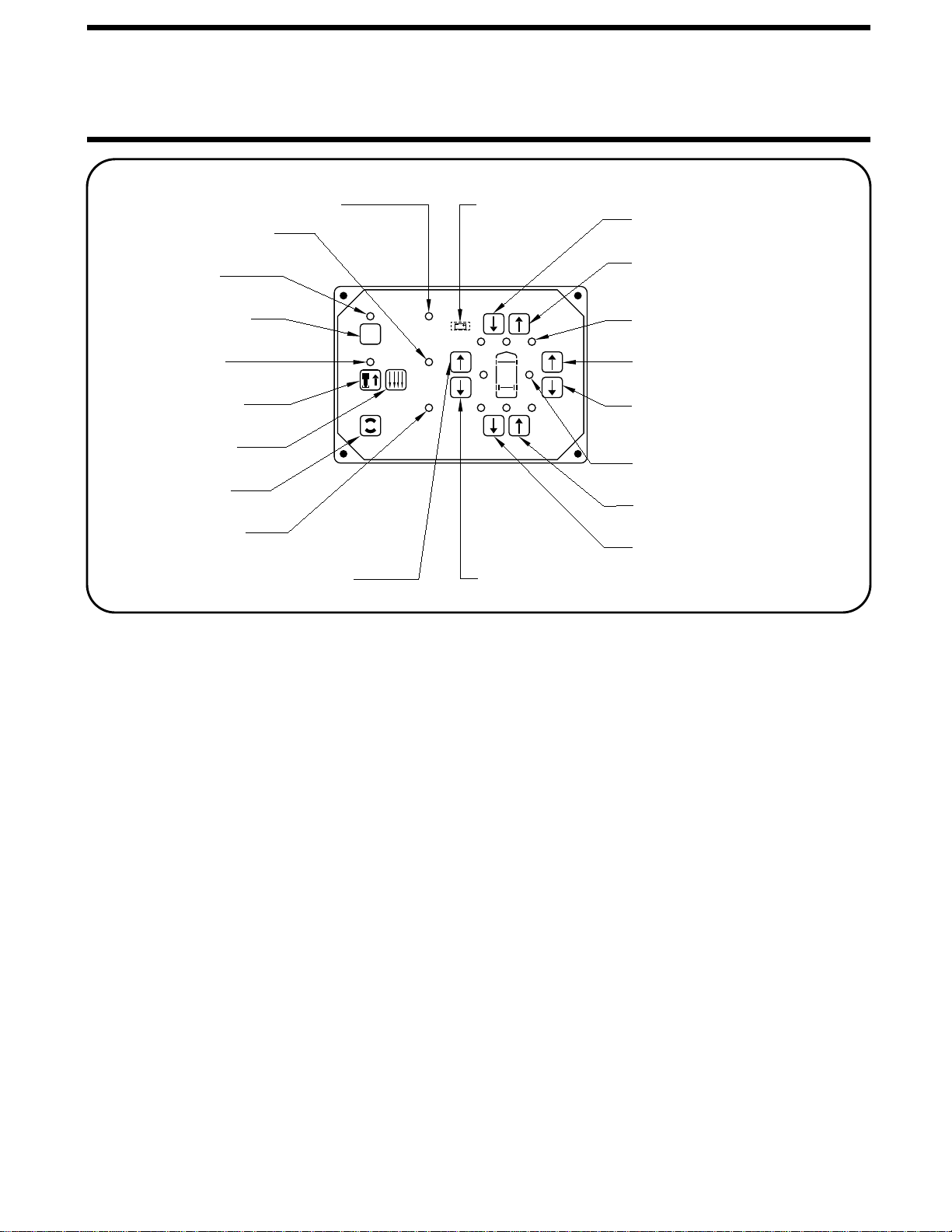

To operate the room, the HYDRAULIC OPERATION

LIGHT is not illuminated. Refer to the CONTROL IDENTI-

FICATION page.