TABLE OF CONTENTS

Important Notice................................................................................................................................................... 2

Owner’s Responsibility.........................................................................................................................................2

Before You Begin...................................................................................................................................................2

Installer Operator/ Protective Equipment......................................................................................................... 4

Introduction/ Safety Warning Instructions......................................................................................................... 5

Tools Required.......................................................................................................................................................6

Step 1 / Selecting Site.........................................................................................................................................6

Step 2 / Floor Requirements / Concrete Specifications.................................................................................... 6

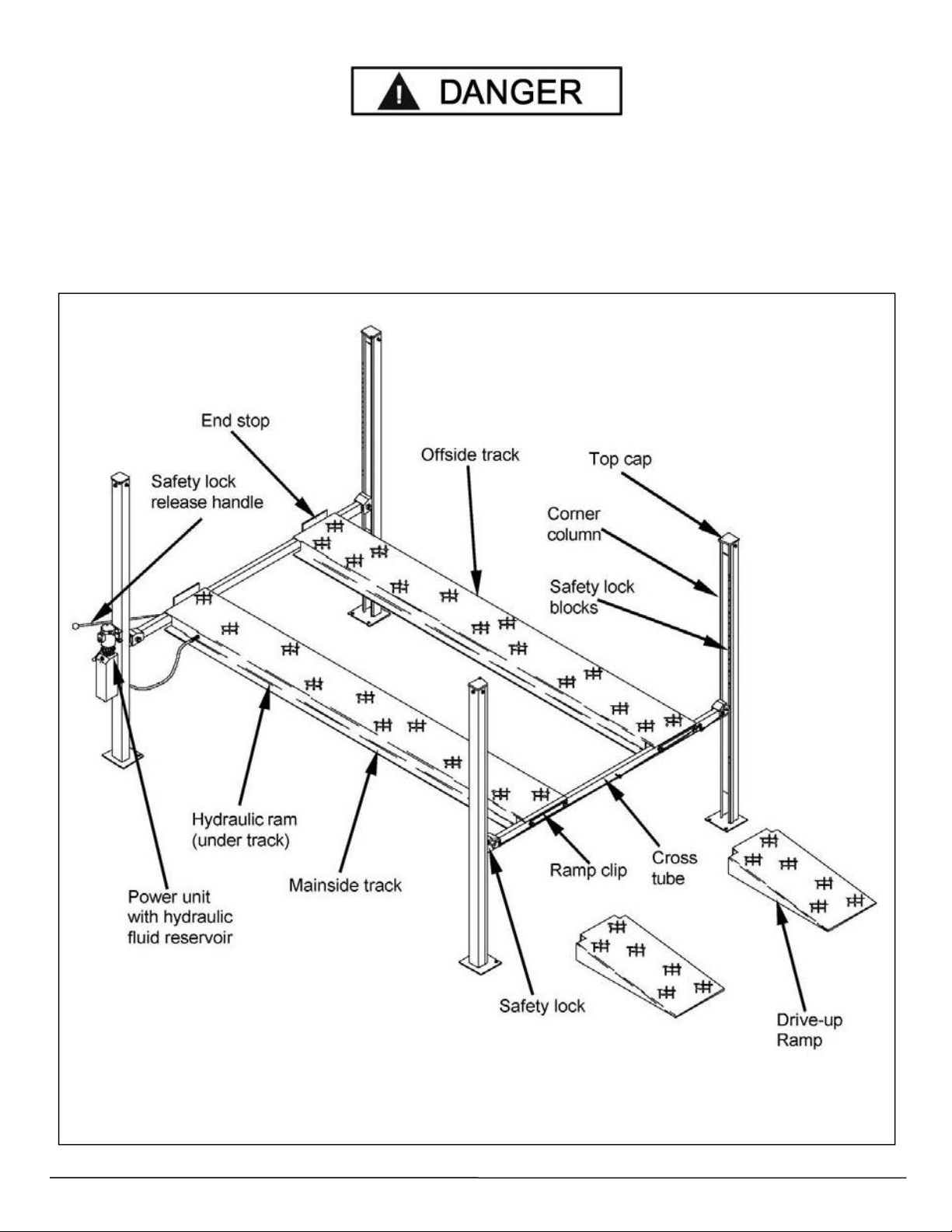

Assembly View / Description of Parts................................................................................................................7

Floor Plan / Specifications.................................................................................................................................. 8

Clearances............................................................................................................................................................. 9

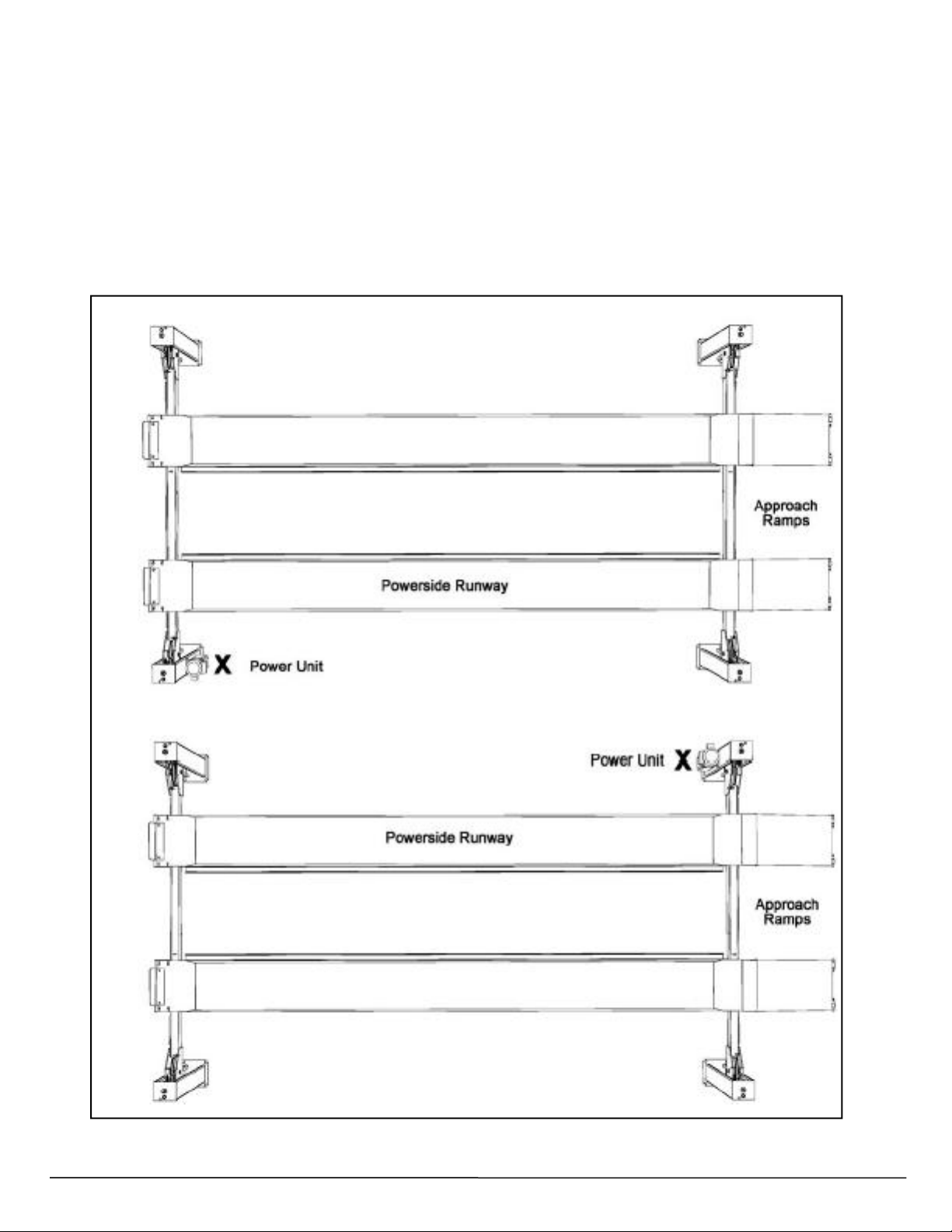

Power Unit Location........................................................................................................................................... 10

Step 3 / Column and Crosstube Installation....................................................................................................11

Step 4 / Raising the Crosstubes.......................................................................................................................11

Step 5 / PowersideRunway Installation.......................................................................................................... 12

Step 6 / OffsideRunway Installation................................................................................................................ 13

Step 7 / Safety Lock Release Installation.......................................................................................................13

Cable Routing..................................................................................................................................................... 14

Step 8 /Cable Sheave Installation....................................................................................................................15

Step 9 / Cable Installation................................................................................................................................. 15

Step 10 / Power Unit Installation......................................................................................................................16

Step 11 / Routing Hydraulic Hoses.................................................................................................................. 17

Step 12 / Power Unit Hook Up..........................................................................................................................19

Step 13 / Lift Start Up/Final Adjustments...................................................................................................... 19

Step 14 / Anchoring The Columns....................................................................................................................20

Step 15 / Attaching Approach Ramps/Tire stops.......................................................................................... 21

Step 16 / Leveling/Synchronizing....................................................................................................................21

Step 17 / Bleeding.............................................................................................................................................. 22

Step18 / Lift Operation Safety......................................................................................................................... 22

Maintenance........................................................................................................................................................ 22

Troubleshooting Guide...................................................................................................................................... 27

Parts Drawings ..................................................................................................................................................31

WW W . T MG I N D US T R IA L . C OM P 03 / 33 To l l F r ee : 1 - 87 7 - 76 1 - 28 1 9