MP25.999

18MAR2

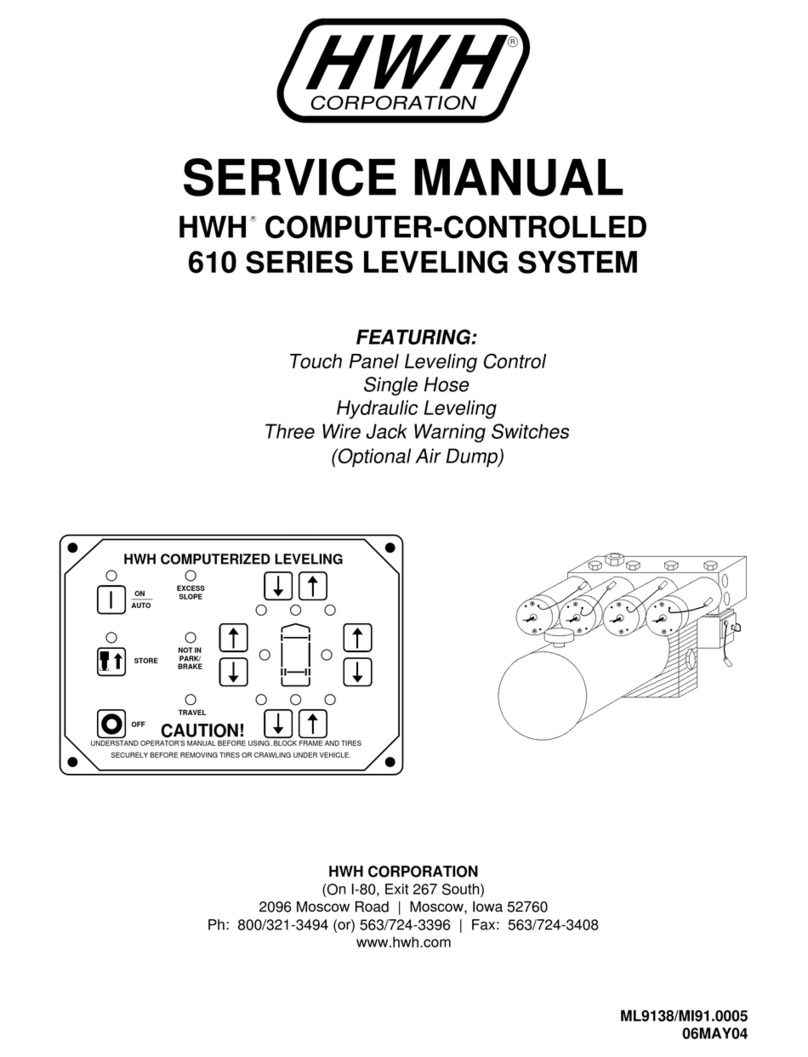

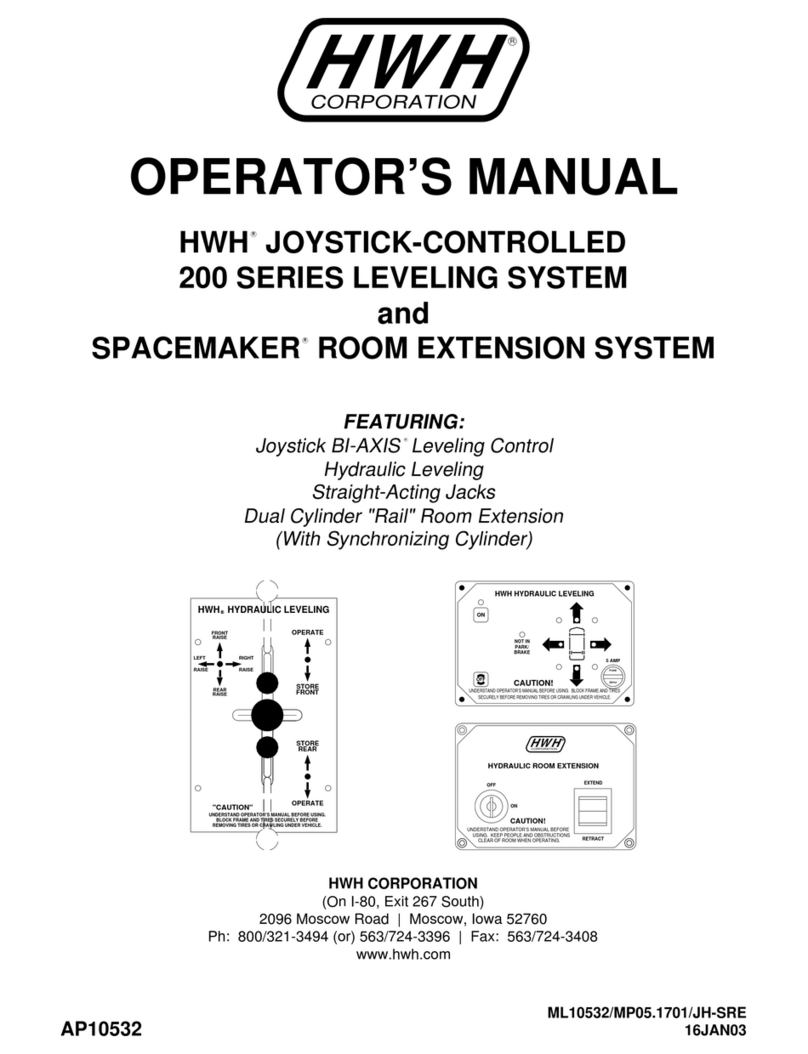

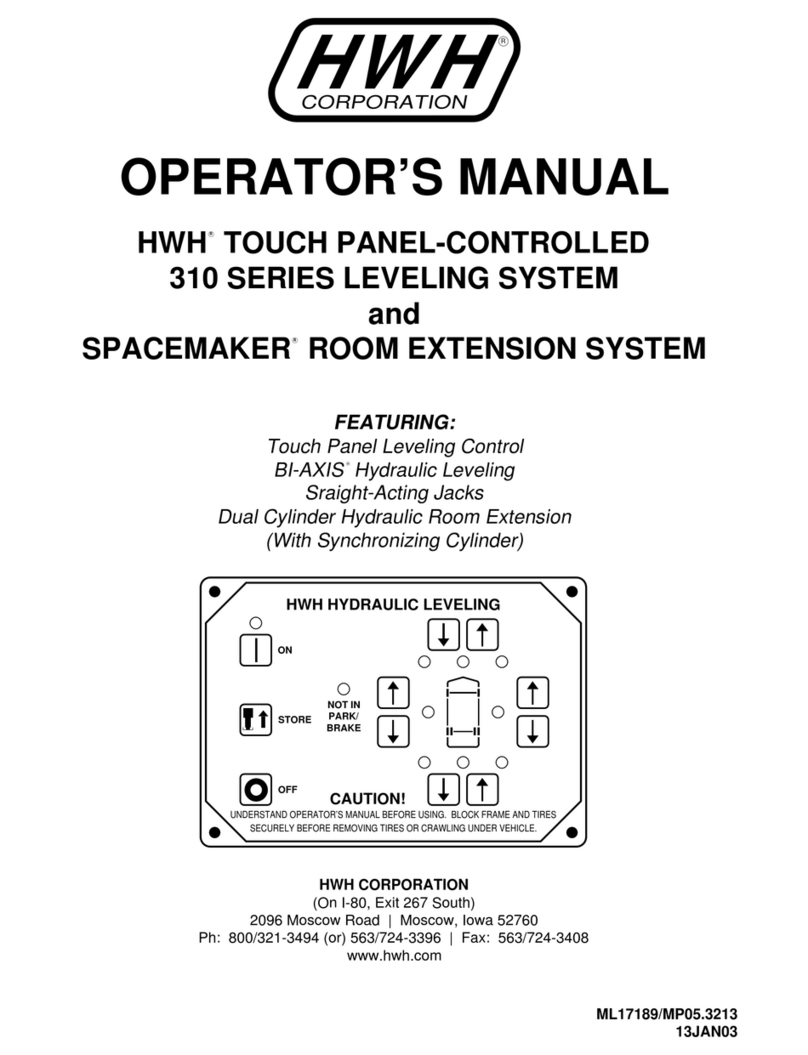

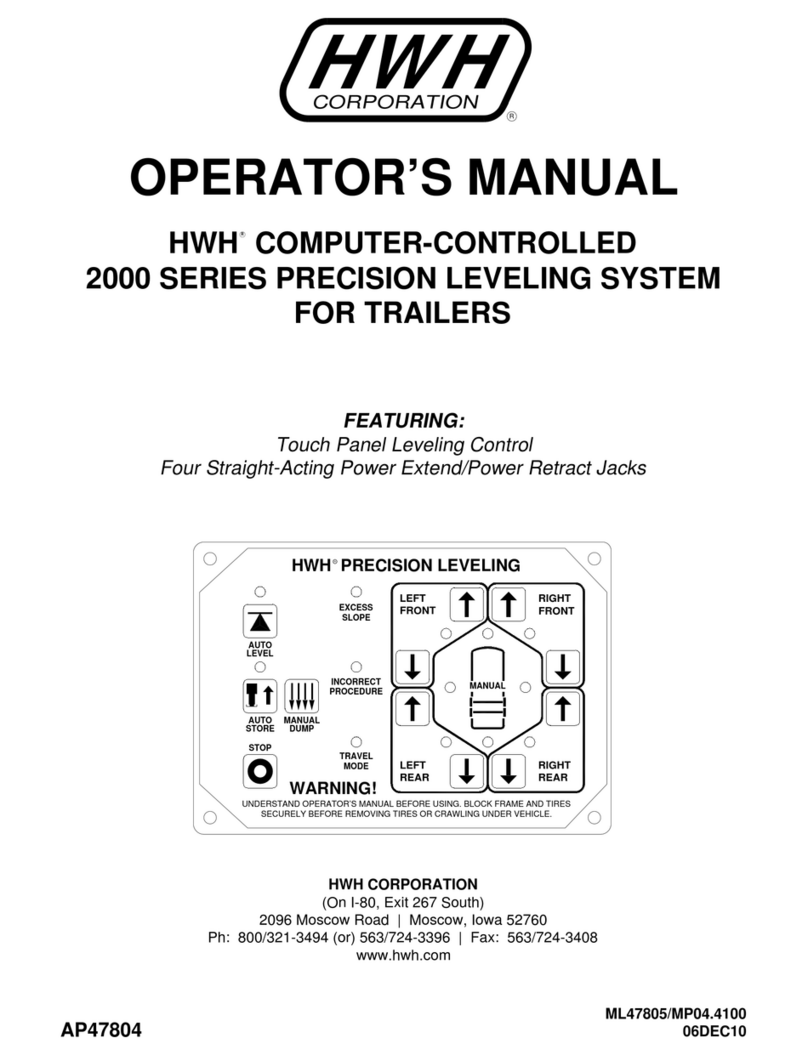

CONTROL IDENTIFICATION

PUMP RUN TIME

SYSTEM VARIATIONS FOR PUMP RUN TIME

Contact HWH corporation to get specific information about the system in this vehicle.

No matter what HWH system is on the vehicle, the pump should not be ran for more than three minutes

(3" motors) or six minutes (3.7" or 4.5" motors) without allowing the pump motor to cool for thirty minutes.

Continuous operation of the pump motor without allowing the motor to cool can damage the pump motor.

Some HWH systems are equipped with a lighted reset switch.

If the processor turns the pump off because the run time has

been exceeded, the light in the reset switch will turn on. The

With some systems, when the processor has turned the pump off because the run time has been exceeded, power

to the HWH system must be turned off and back on before the system will operate. With motorized vehicles, turn the

ignition off and back on. With non-motorized vehicles, turn the master power switch for the HWH system off and back

DO NOT continue without allowing the pump motor to cool for thirty minutes.

When operating some leveling systems manually or operating the room extensions, the pump will turn off and back

on while pushing the control button when the pump run time has been exceeded.

the pump motor to cool for thirty minutes.

Some systems can be turned back on immediately after the processor turns the pump off.

back on or run the pump without allowing the pump motor to cool for thirty minutes.

Some systems with rooms run the rooms separate from the system processor. These systems do not monitor pump

run time when operating the rooms.

pump motor to cool for thirty minutes.

The HWH systems with a computer processor monitor the pump run time and will turn the pump off if the run time exceeds a

specified time. This time can vary with different systems. Due to available electronics or system design, the pump run time

programs will also vary. Leveling systems and room extensions that are not controlled by a system processor have no pump

run time protection.

thirty minutes.

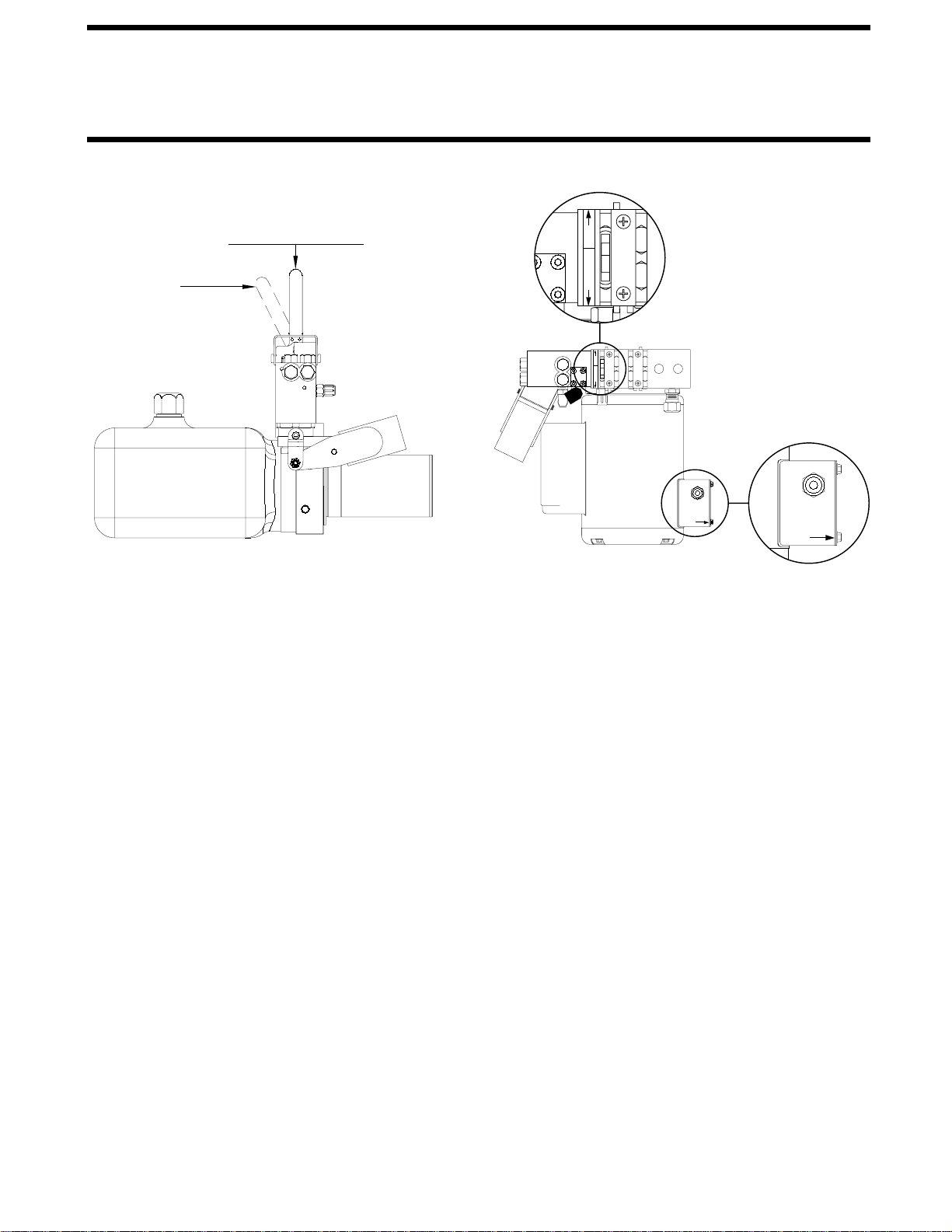

Pump motors used with HWH leveling systems and room extension systems come in 3 different diameters; 3", 3.7" and 4.5".

Contact the vehicle manufacturer or HWH for help with identifying the motor size.

runs for more than three minutes with a 3" motor; or six minutes with a 3.7" or 4.5" motor that the motor is allowed

to cool for thirty minutes before continuing. Continuous operation of the pump motor without allowing the motor

PUMP RUN TIME

It is important that any time the pump

to cool can damage the motor.

DO NOT run the pump more than three or six minutes without allowing the pump motor to cool for

DO NOT run the pump more than three or six minutes without allowing the

DO NOT turn the system

DO NOT continue without allowin

on.

system will not operate until the reset switch is pushed.

DO NOT continue without allowing the pump motor to

cool for thirty minutes. LIGHTED RESET SWITCH

For cold weather information see "COLD WEATHER OPERATIONS" below.

COLD WEATHER OPERATIONS

HWH leveling and room extension systems are designed to function in cold weather down to 0 degrees Fahrenheit. Below

freezing (32 degrees Fahrenheit) the jacks or rooms will operate slower than usual.

For operation in temperatures dropping below -20 degrees Fahrenheit, it is necessary that the system is equipped with oil

designed for extreme cold weather application such as a synthetic oil. (Contact HWH for recommendations.)

DO NOT run the pump motor continuously.

Continuous operation of the pump with slow moving jacks or rooms in cold weather, without allowing the pump motor to

cool will cause the pump motor to burn up and damage the pump assembly.

It is important that any time the pump runs for more than three minutes

continuing. Continuous operation of the pump motor without allowing the motor to cool can damage the motor.

with a 3" motor; or six minutes with a 3.7" or 4.5" motor that the motor is allowed to cool for thirty minutes before