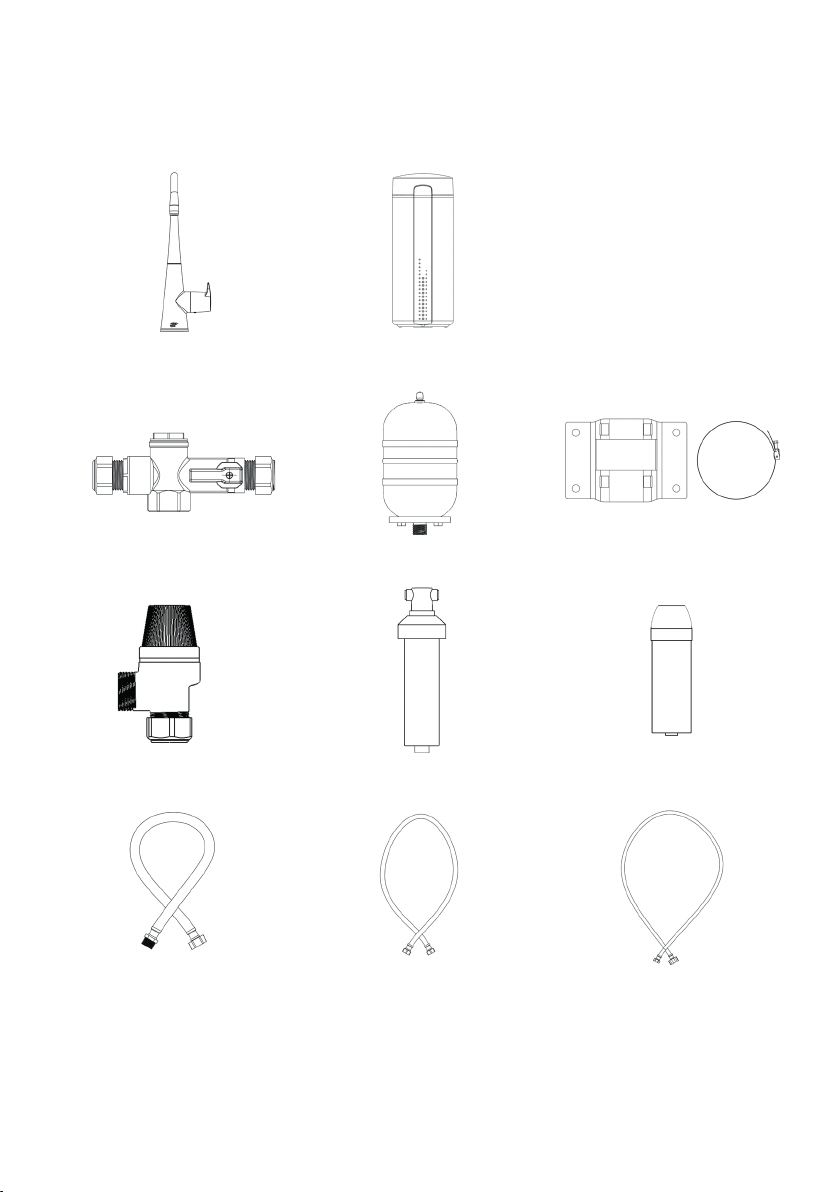

Overview

Thank you for purchasing a Zen Spa 2 in 1 Boiling and Chilled Tap. The Zen Spa is a hot and

cold drinks station that provides boiling water and ltered cold (ambient) drinking water. If

desired an undersink chiller can be purchased to provide ltered chilled drinking water.

In the home it replaces the need for a kettle and provides high quality cold drinking water.

In the oce it replaces the need for a wall mounted boiling water unit and separate oor

standing chiller.

Key Features

• Energy ecient boiling water tank.

• Safety lock on the boiling side and a cool touch spout.

• 360° swivel spout.

• Pattern recognition technology to learn and predict boiling water usage.

• Supplied with initial high quality scale lter for the inlet to the boiling tank and a cold

drinking water lter.

• Two temperature settings 100°C and 98°C.

• Can be installed over a sink or with a stylish Zen Font.

• Designed and assembled in the UK.

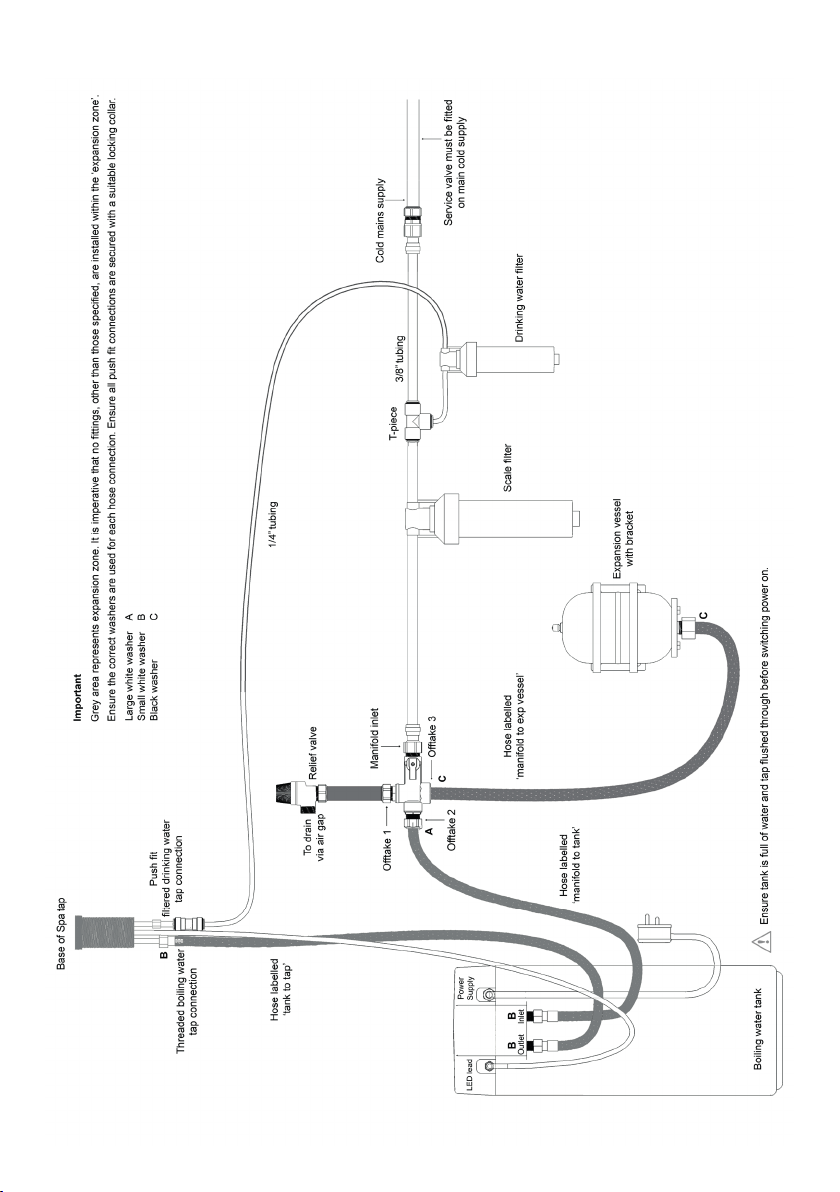

Always switch o the mains electricity before commencing installation.

Only connect the unit to a single-phase supply as specied on the rating plate.

Ensure tank is full of water and tap ushed through before switching power on.

The supply cord cannot be replaced by the user. If the cord is damaged the

appliance should be returned to the manufacturer or an authorised service agent

for replacement.

The hoses and pipes supplying this heater must not come into contact with any

xed wiring or the supply cord.

Do not carry the appliance by the supply cord.

An RCD circuit breaker is strongly recommended.

This unit dispenses boiling water.

1. Important Safety Points

2