SECTION 1

MINIFLEX LR PROGRAMMABLE LEVEL CONTROLLER

USER MANUAL

INTRODUCTION

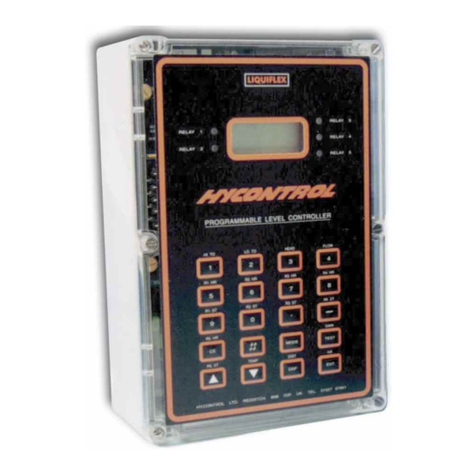

Miniflex LR is a programmable multi-purpose level measurement and flow control

instrument. It consists of two elements, a wall mounted transceiver, which has a display and

an integral keypad for programming, and a transducer, which must be mounted directly above

the surface to be monitored.

Ultrasonic pulses are transmitted by the transducer to the surface of the material to be

monitored and are reflected back to the transducer. The time period between transmission and

reception of the sound pulses is directly proportional to the distance between the transducer

and the material.

Since speed of sound through air is affected by changes in temperature, a separate or

integrated temperature sensor may be fitted to improve accuracy.

Miniflex LR is capable of the following functions:-

a) Distance Measurement (distance from a datum)

b) Level Measurement (height above datum)

c) Volume Measurement

d) Pump Control

e) Open Channel Flow Measurement (O.C.M.)

f) Differential Level Measurement

WARNING

DO NOT OPEN THE TRANSCEIVER

TERMINAL COVER WHEN THE POWER IS ON TO

THE SUPPLY OR RELAY TERMINALS.

IMPORTANT INSTALLATION REQUIREMENTS

1: A SWITCH OR CIRCUIT BREAKER SHALL BE INCLUDED IN

THE INSTALLATION

2: IT SHALL BE IN CLOSE PROXIMITY TO THE EQUIPMENT AND

WITHIN EASY REACH OF THE OPERATOR

3: IT SHALL BE MARKED AS THE DISCONNECTING DEVICE FOR

THE EQUIPMENT

Ref: MINIFLEX LR MANUAL Rev. 0 1