4 | © Sonny’s CarWash Backroom by Hydra-Flex, Inc. 2022

SPECIFICATIONS

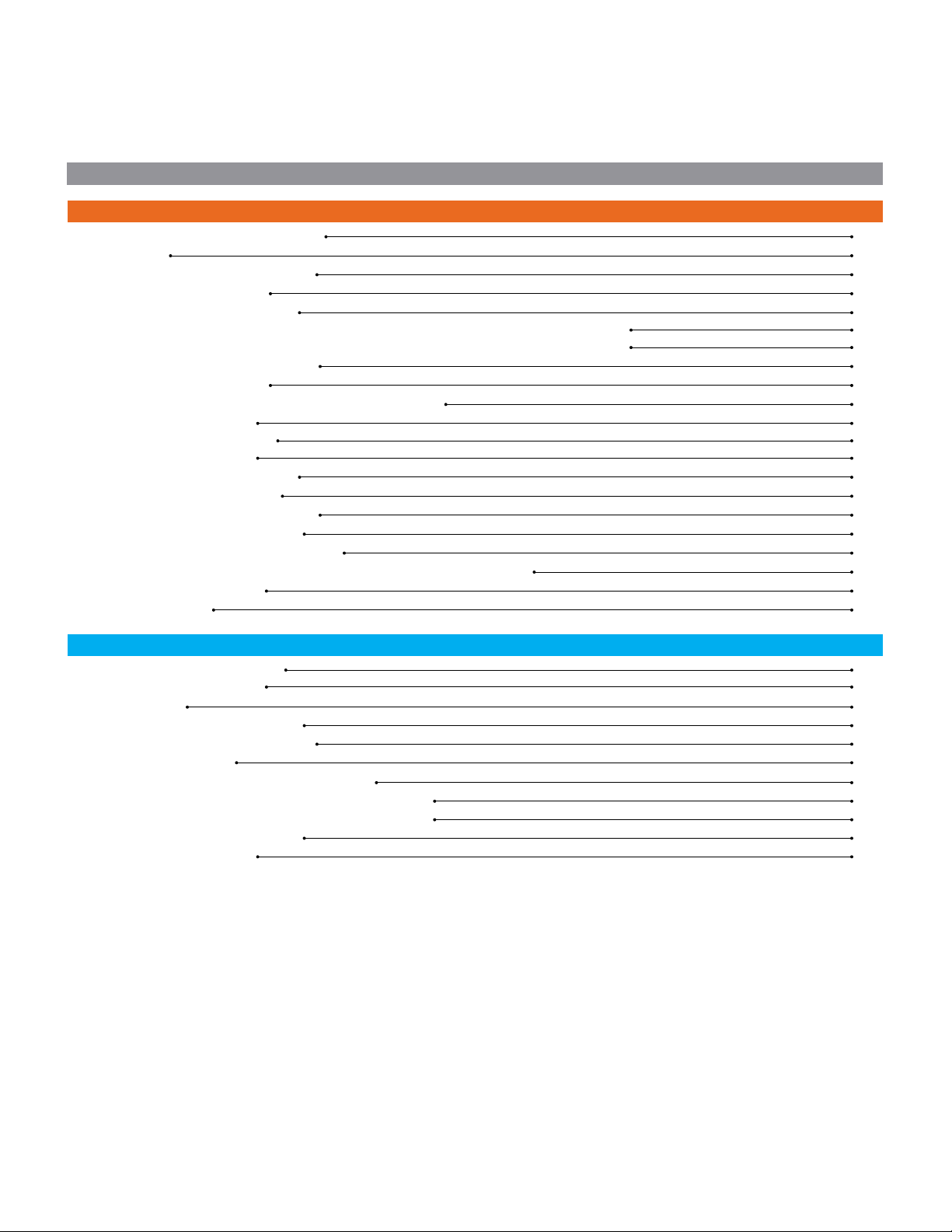

AQUALAB 3 SYSTEM SPECIFICATIONS

POWER REQUIREMENTS

20 GPM (75 LPM) 5 HP Grundfos pump 40 GPM (150 LPM) 7.5 HP Grundfos pump Air-actuated valves

230V / 3PH / 60Hz / 13.2A

460V / 3PH / 60Hz / 6.2A

230V / 3PH / 60Hz / 20A

460V / 3PH / 60Hz / 9.1A

24 VDC

Node converts all voltage signals, but only one

control voltage type can be used per node

230V: Recommended for use

with 20A breaker

460V: Recommended for use

with 15A breaker

230V: Recommended for use

with 30A breaker

460V: Recommended for use

with 30A breaker

WATER INLET LINES

20 GPM (75 LPM) Grundfos pump 40 GPM (150 LPM) Grundfos pump

1” ID 2” ID

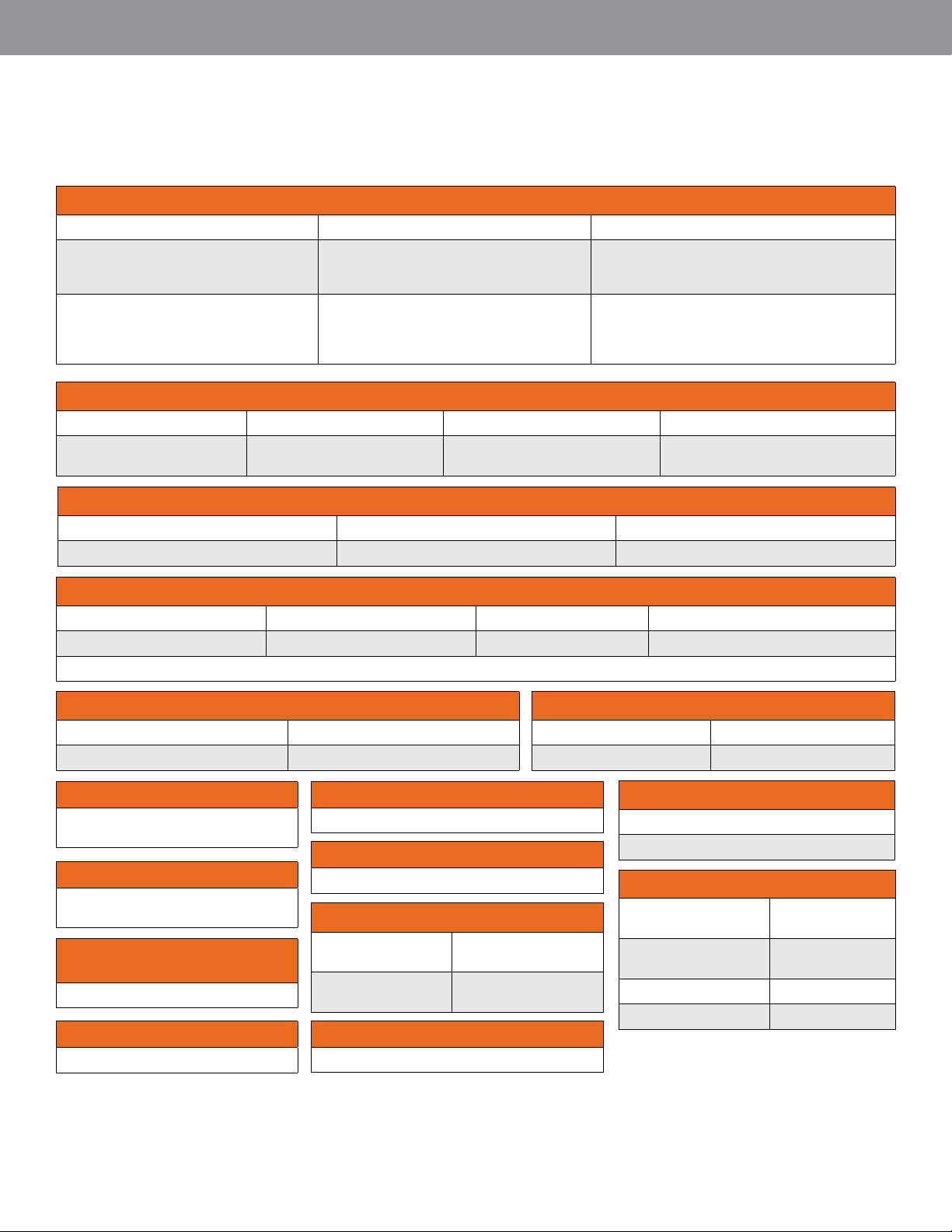

SPACE REQUIREMENTS (DEPTH X WIDTH X HEIGHT)

Main Disconnect Box Additional Small Disconnect Box Alfred Gateway

7.5” x 14” x 12” (19.1 x 35.6 x 30.5 cm) 4” x 5” x 8” (10.2 x 12.7 x 20.3 cm) 4” x 7” x 7” (10.2 x 17.8 x 17.8 cm)

SPACE REQUIREMENTS (DEPTH X WIDTH X HEIGHT)

40 GPM Grundfos pump 20 GPM Grundfos pump Aqua-Lab 3 panel (w/o VersaDial) Aqua-Lab 3 panel (w/ VersaDial)

26” x 18” x 39”

(66.0 x 45.7 x 99.1 cm)

14” x 24” x 48”

(35.6 x 60.9 x 121.9 cm)

8” x 32” x 24”

(20.3 x 81.3 x 60.9cm)

8” x 32” x 41.39”

(20.3 x 81.3 x 105.1cm)

OPERATING WATER PRESSURE

200 PSI (14 bar) factory set

(Assumes 40 PSI (2.8 bar) city feed)

MAX. WATER SOURCE TEMP.

Recommended 110°F (43°C)

(Max. water temp.) 180°F (82.2°C)

AIR INLET LINE

3/8” OD Poly Tube per panel

WATER FILTRATION

(SUGGESTED)

50 Micron

AIR OUTLET LINE

3/8” OD Poly Tube per application

AIR INLET PRESSURE

20 CFM @ 80-120 PSI (5.5-8.3 bar) Dry Air

BACK ROOM AMBIENT AIR TEMP

MAX: 130°F (54°C)

SOLUTION OUTLET LINES

Up to 2.25 GPM (8.5 LPM) 3.25 - 4.5 GPM (13.3 - 17 LPM) 5.5 GPM (20.8 LPM) 8.0 - 15.0 GPM (37.9 - 56.8 LPM)

3/8” ID (1/2” OD Poly Tube*) 1/2” ID* 5/8” ID* 3/4” ID

*Assuming line length is 50’ (15 m) or less. Refer to page 42 for recommended size chart for other lengths of tubing.

OUTLET CONNECTION FROM MANIFOLD

20 GPM pump 40 GPM Grundfos pump

1” FNPT 1” FNPT

WATER SUPPLYMAX FLOW PER PORT

Max flow per MAM

valve port 6 GPM

Max flow per BAM

valve port 15 GPM

FLANGE TORQUE

40 GPM Grundfos pump

40 ft-lbs (Min.)

PRESSURE TRANSDUCER (VFD)

Pressure range (20

GPM) 0-300 PSI

Pressure range (40

GPM) 0-363 PSI

Set point 200 PSI

Cord length 23 feet / 7 meters