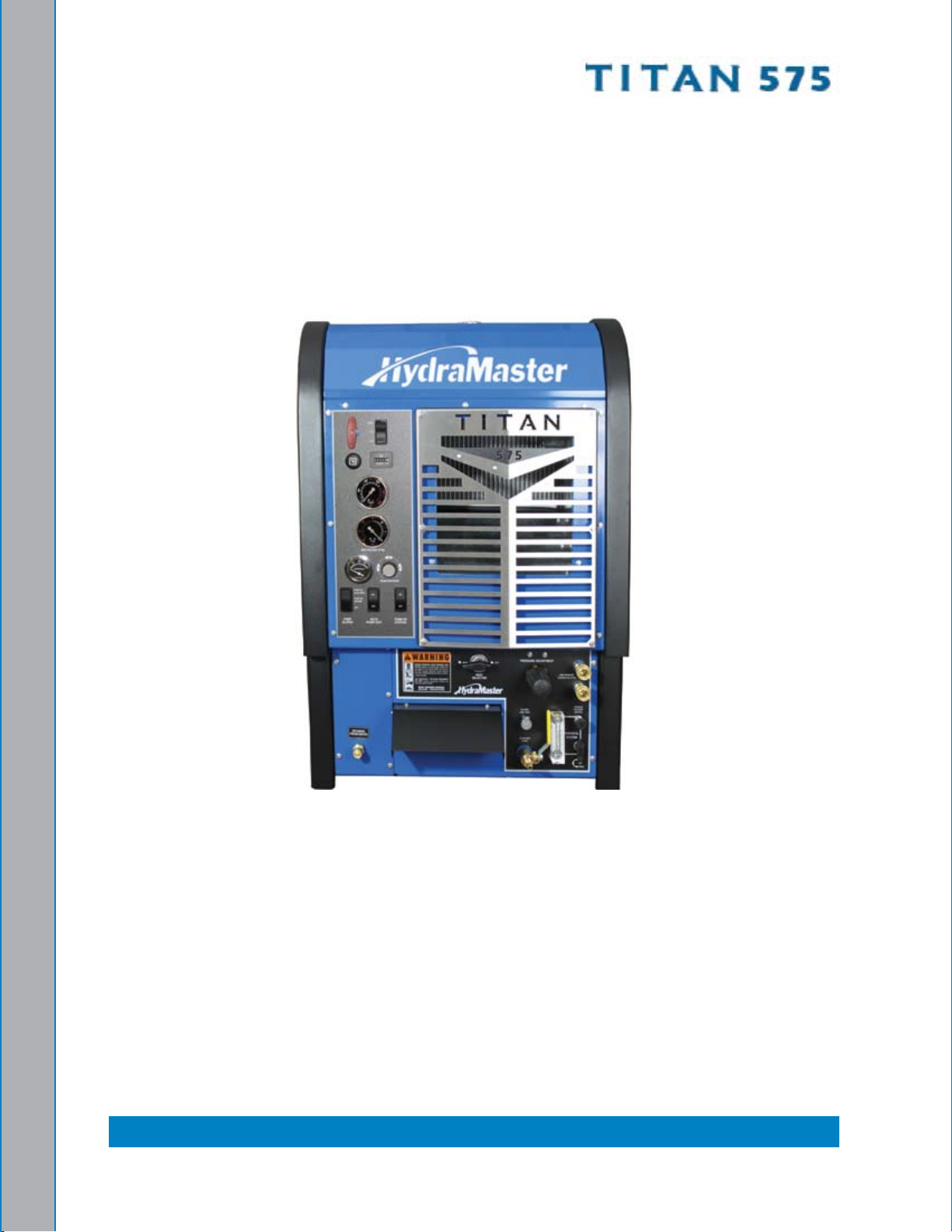

v - Titan 575 Owner’s Manual

Figure 6-1. Annotated Water, Chemical and Solution Flow Diagram - View 1 of 3 ......6-3

Figure 6-2. Annotated Water, Chemical and Solution Flow Diagram - View 2 of 3 ......6-4

Figure 6-3. Annotated Water, Chemical and Solution Flow Diagram - View 3 of 3 ......6-5

Figure 6-4. Water, Chemical and Solution Flow Diagram - Larger View ......................6-6

Figure 6-5. Chemical Flow Diagram - Larger View.......................................................6-7

Figure 6-6. Exhaust Flow Diagram...............................................................................6-8

Figure 7-1. Electrical Schematic...................................................................................7-2

Figure 7-2. Wiring Diagram - View 1 of 3 .....................................................................7-3

Figure 7-3. Wiring Diagram - View 2 of 3 .....................................................................7-4

Figure 7-4. Wiring Diagram - View 3 of 3 .....................................................................7-5

Figure 9-1. Machine Assembly - View 1 of 4................................................................9-2

Figure 9-2. Machine Assembly - View 2 of 4................................................................9-3

Figure 9-3. Machine Assembly - View 3 of 4................................................................9-4

Figure 9-4. Machine Assembly - View 4 of 4................................................................9-5

Figure 9-5. Frame Assembly - View 1 of 5 ...................................................................9-6

Figure 9-6. Frame Assembly - View 2 of 5 ...................................................................9-7

Figure 9-7. Frame Assembly - View 3 of 5 ...................................................................9-8

Figure 9-8. Frame Assembly - View 4 of 5 ...................................................................9-9

Figure 9-9. Frame Assembly - View 5 of 5 .................................................................9-10

Figure 9-10. Engine Assembly - View 1 of 3...............................................................9-12

Figure 9-11. Engine Assembly - View 2 of 3...............................................................9-13

Figure 9-12. Engine Assembly - View 3 of 3...............................................................9-14

Figure 9-13. Exhaust Assembly..................................................................................9-16

Figure 9-14. Top CoverAssembly ..............................................................................9-17

Figure 9-15. Flywheel Plate Assembly .......................................................................9-18

Figure 9-16. Upper Dash Assembly............................................................................9-20

Figure 9-17. Electrical Panel Assembly - View 1 of 2.................................................9-22

Figure 9-18. Electrical Panel Assembly - View 2 of 2.................................................9-23

Figure 9-19. Blower Assembly....................................................................................9-25

Figure 9-20. Pump and Silencer Assembly ................................................................9-27

Figure 9-21. Pump Assembly - View 1 of 2 ................................................................9-28

Figure 9-22. Pump Assembly - View 2 of 2 ................................................................9-29

Figure 9-23. Water Box Assembly..............................................................................9-31

Figure 9-24. Lower Dash Assembly - View 1 of 2.......................................................9-33

Figure 9-25. Lower Dash Assembly - View 2 of 2.......................................................9-34

Figure 9-26. Side Cover - Machine Assembly............................................................9-36

Figure 9-27. Grill Assembly ........................................................................................9-37

Figure 9-28. Blower Heat Exchanger Assembly - View 1 of 2 ...................................9-38

Figure 9-29. Blower Heat Exchanger Assembly - View 2 of 2 ...................................9-39