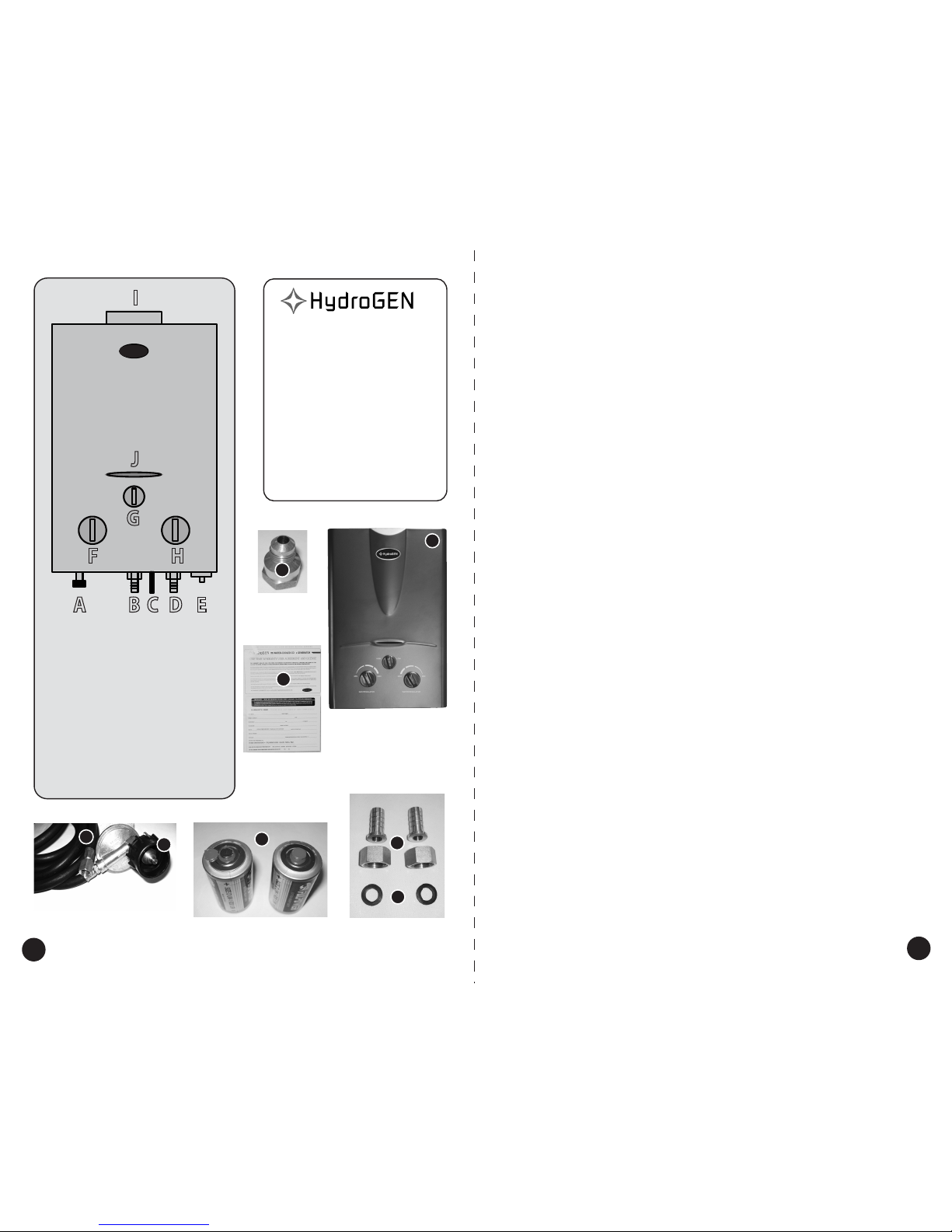

A B C D E

2

A - Gas Inlet

B - Water Outlet

C - High Water Pressure Relief

D - Water Inlet

E - Battery Compartment

F- CO2 Output Adjustment

G - High/Low Burner Setting

H - Water Cooling Adjustment

I - CO2 Exhaust

J - Flame Sight Glass

F H

G

J

I

3

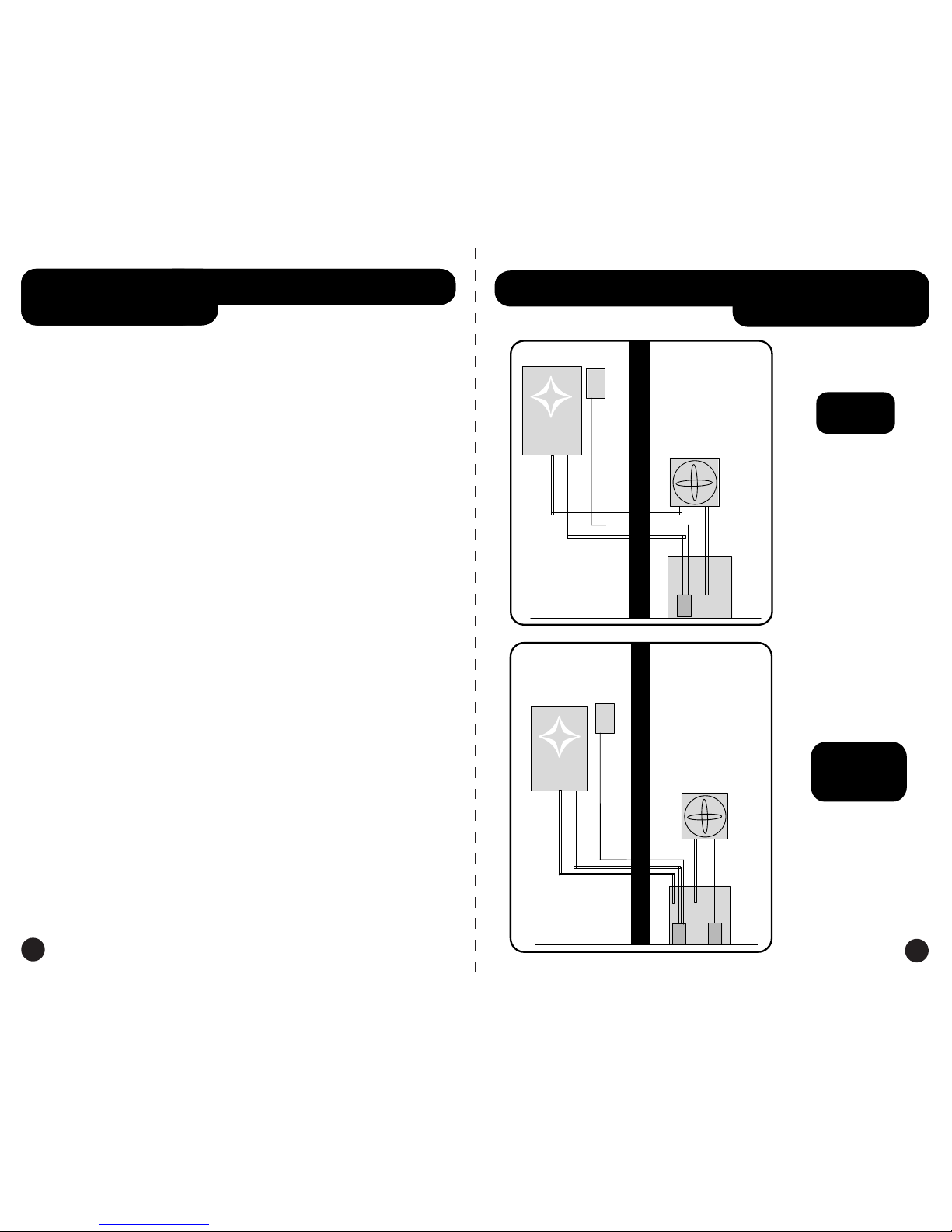

• HydroGEN Unit

• (1) 12’ Propane Hose

• Propane regulator

• (2) ½” Hose

Barb Adapters

• (2) Rubber Gaskets

• (2) ‘ D’ Size Batteries

• (1)GasAdapter Fitting

• (1) Warranty Card

• HydroGEN Unit

• (1) 12’ Propane Hose

• (2) Rubber Gaskets

• (2) 2 ½” Hose

Barb Adapters

• (2) ‘ D’ Size Batteries

• (1)GasAdapter

Fitting

Packing List:

2

1

34

5

6

7

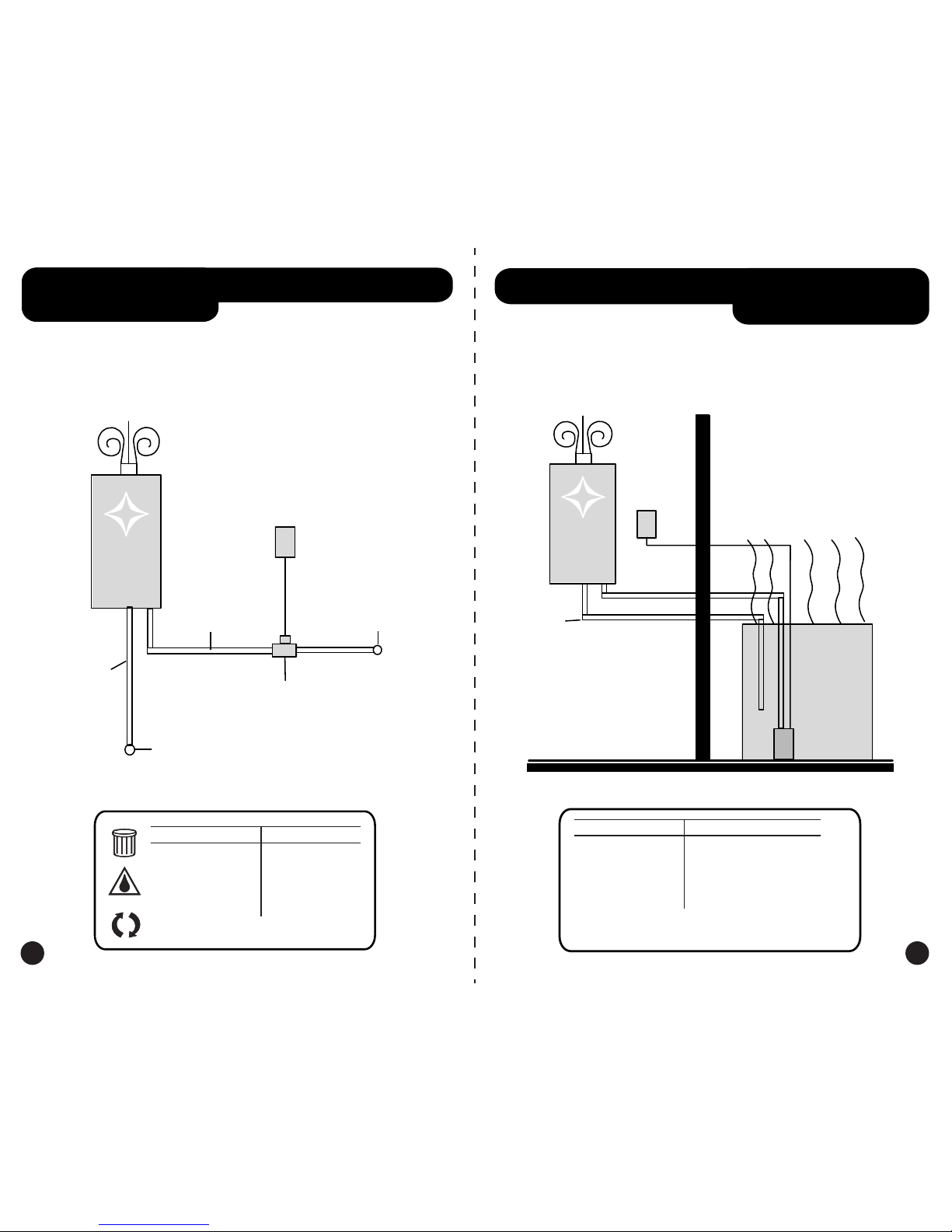

Hanging Method: The HydroGEN can be suspended

from the ceiling using chains and “S” hooks. First

securely fasten two chains 14” apart to a rafter,

brace, beam, etc (not just into the sheetrock). Keep in

mind that there is a flame inside and when we say

securely fasten we mean it. Notice there are ¼” holes

at the top center of the sides. These holes are there to

allow for installations of “S” hooks that can then be

attached to the chains at least 2’ from the ceiling or

any other obstruction.

Wall Mount Method: The HydroGEN can be screwed

into a wall brace, stud, or beam using the brackets

located at the top and bottom of the unit. Remember

2’ from the top of the HydroGEN to the ceiling or any

other obstruction.

Ducting CO2: When mounting the unit inside the

grow room, no ducting is required. If you choose to

mount your HydroGEN outside your grow room, a

3"double-wall ducting from your local hardware

store is recommended. Note that this is NOT

aluminum dryer vent, it's double-walled, insulated

steel of the same type used in hot water heater

applications. The vent piping should travel at an

upward pitch to ensure that CO2 will travel into the

grow room. When installed at an upward pitch CO2

will travel up to 5 feet. We do not recommend using

a booster fan as they can affect flame efficiency, but

a very low cfm fan can be used if forced to duct CO2

further than 5 feet from the unit. DO NOT use a fan

more powerful than 20 cfm. Also, when using the

CO2 generator outside the grow room, we

recommend mounting a carbon monoxide detector

in the room with the generator. This can be

purchased at your local discount store for about $10.

We recommend this because even though the

majority of CO2 is being ducted into the grow room,

some will still be released into the room in which

the generator is housed, and gas levels should be

monitored to ensure safety. The odds of CO levels

rising to dangerous levels is very, very slim but it's

much better to be safe than sorry.

Propane Hose: The propane hose should be in good

condition free from cracks or kinks. The hoses

fittings and regulator should also be in good

condition and should not be used if any damage has

occurred. Attach the supplied propane hose to the

HydroGEN using a properly sized wrench WITH A

BACKUP WRENCH on the unit itself. Make it snug,

but don’t break it. Over tightening can cause a gas

leak. Attach the other end of the hose to a 20 lb

propane bottle that is in good condition. Do not use

propane bottle that has a damaged, old, or leaky

valve. After installing open gas valve and check for

leaks. Applying soapy water over the joints will tell

you right away if there is a leak.

Attaching Water Hoses: Snugly screw both supplied

hose barb adapters onto the water inlet and outlet.

MAKE SURE THE RUBBER GASKET IS INSTALLED!

Attach ½” ID HEAVY DUTY REINFORCED TUBING to

the hose barbs and install hose clamps. Cold water

inlet should be clearly marked along with the hot

water outlet.

Installing Batteries: The battery compartment is

grey and is located on the bottom of the

HydroGEN. The unit is supplied with two “D” size

batteries and they must be installed properly. The

+ and – are marked on the inside of the battery

compartment.

Starting Unit:

The HydroGEN's burner is activated

by 1.5 gpm of water flow and also requires at least

3 P.S.I. of pressure to operate. You must either

connect the unit to a submersible or inline pump

with at least 15' of lift that is powered on by the

co2 monitor, or the unit can be hooked directly to a

pressurized water source like a municipal water

supply. In this manner an on/off valve can be

controlled by the co2 monitor. For more water

supply ideas go to www.hydroinnovations.com. If

your water supply is ready it’s time to fire it up.

Turn on the water supply to the HydroGEN and you

should hear clicks which is the automatic ignition

lighting the burner. If the unit does not light right

away this is most likely caused by air in the

propane hose. Turn off the water

supply and then

on again , this is normal and it may take several

attempts to remove all the air from a new unit.

Acceptable Water Sources: Clean water of course,

used nutrient water, RO waste water, well water,

municipal water supply, swimming pool or hot

tub, collected rain water, etc. You can store your

old nutrient water and/or RO waste and run it

through the unit prior to discarding down the

drain. If using sources other than tap, we

recommend using a simple sediment filter of some

kind that can be located at any hardware store.

There is also a protective screen at the water

intake on the unit to keep large debris from

running through the unit. We recommend

checking and/or cleaning this intake screen and

your water filter (if using) at least monthly to

ensure continued adequate water flow. If water

flow diminishes, a dirty filter or clogged screen is

the most likely culprit.

Acceptable reservoirs: In-ground pools, above-

ground pools, kiddie pools, bath tubs, hydroponics

reservoirs, hot tub/jacuzzi, barrels, trash cans, or

any other water-tight container. An above-ground

pool, which can be purchased at your local

discount store for less than $100, functions as a

great reservoir when placed outside. Night air is

also a very effective cooling method.

Adjusting CO2 output and water flow valve:

There are two knobs that ultimately control the

CO2 output. At the lowest setting for both knobs

the unit generates 15 cubic feet of C02 an hour and

45 cu/ft/hr at the highest settings for both knobs.

For more cooling turn the water flow up and when

less is needed, in the winter for example, you can

turn the water flow down to retain some of the

heat. The most efficient setting for removing the

most heat is the minimum setting for the gas and

the maximum output for the water.

Installation Instructions

1

2

3

4

5

6

7

8

• (1) Warranty Card

8