Page 1 Page 2 Page 3

Be Careful

Do not plug the power cord into an electrical receptacle until system is installed and in place.

Operation of the system without being plumbed into the water lines will burn out the pump prema-

turely and void the warranty.void the warranty.

void the warranty.void the warranty.

void the warranty.

Pre-Installation Checklist

1.1.

1.1.

1. Check the package contentsCheck the package contents

Check the package contentsCheck the package contents

Check the package contents

Your Metlund SystemMetlund System

Metlund SystemMetlund System

Metlund System Includes:

• A pre-assembled Metlund Controller/Circulator Pump/Zone Valve Assembly

• S-46 models will not show zone valve. Zone Valve is inside the pump housing.

• Compression fit copper T’s (S-01PFR). (Homes with galvanized pipes will need

galvanized T’s).

• A plastic bag containing: one (1) push-button

• (If wireless remote option was purchased) one transmitter, one receiver, one 12V

battery, three gray wire nuts & three screws.

Check the components for visible damage and contact your supplier immediately if anyCheck the components for visible damage and contact your supplier immediately if any

Check the components for visible damage and contact your supplier immediately if anyCheck the components for visible damage and contact your supplier immediately if any

Check the components for visible damage and contact your supplier immediately if any

damage is found.damage is found.

damage is found.damage is found.

damage is found.

2.2.

2.2.

2. Make sure you have the tools to do the jobMake sure you have the tools to do the job

Make sure you have the tools to do the jobMake sure you have the tools to do the job

Make sure you have the tools to do the job

No special tools are required to install the Metlund SystemMetlund System

Metlund SystemMetlund System

Metlund System other than those tools usually

needed in any plumbing job. They include:

• Pipe wrench or crescent wrench

• Pliers

• Small Phillips head and medium flat head screwdriver

• Wire strippers

• Drill and 5/8" drill bit

• Soldering equipment (if applicable)

3.3.

3.3.

3. Determine where you will install The SystemDetermine where you will install The System

Determine where you will install The SystemDetermine where you will install The System

Determine where you will install The System

Typically, this should be at the fixture farthest away from the water heater. If your hot water

supplylineruns intwo separatedirections fromthewater heater,you mayneedmore thanone

Metlund SystemMetlund System

Metlund SystemMetlund System

Metlund System to satisfy all of your hot water requirements.

2. After installation adjustments2. After installation adjustments

2. After installation adjustments2. After installation adjustments

2. After installation adjustments

CHECK THE SYSTEM CAREFULLY TO MAKE SURE THE INSTALLATION IS FREE OFCHECK THE SYSTEM CAREFULLY TO MAKE SURE THE INSTALLATION IS FREE OF

CHECK THE SYSTEM CAREFULLY TO MAKE SURE THE INSTALLATION IS FREE OFCHECK THE SYSTEM CAREFULLY TO MAKE SURE THE INSTALLATION IS FREE OF

CHECK THE SYSTEM CAREFULLY TO MAKE SURE THE INSTALLATION IS FREE OF

WATER LEAKS.WATER LEAKS.

WATER LEAKS.WATER LEAKS.

WATER LEAKS.

All Electronic Sensitivity Adjustments are pre-set at the factory. If adjustments areIf adjustments are

If adjustments areIf adjustments are

If adjustments are

necessary please call 1-800-638-5863 for technical help prior to making anynecessary please call 1-800-638-5863 for technical help prior to making any

necessary please call 1-800-638-5863 for technical help prior to making anynecessary please call 1-800-638-5863 for technical help prior to making any

necessary please call 1-800-638-5863 for technical help prior to making any

adjustments.adjustments.

adjustments.adjustments.

adjustments. However, please make sure the off sensor (green tip wire), is firmly attached

and is touching the pipe. The sensor is designed to signal the controller to shut off

automatically when hot waterhot water

hot waterhot water

hot water has reached your fixture, and not to reactivate if hot waterhot water

hot waterhot water

hot water is

at the fixture. Review the troubleshooting page for additional information.

Wireless Remote Option - R0954

Wiring The Receiver

The remote receiver is the white rectangular box with the three protruding wires: black, white & green. ThisThis

ThisThis

This

does not need batteries.does not need batteries.

does not need batteries.does not need batteries.

does not need batteries. Wire the receiver directly to the corresponding wires on the controller by twisting each

same colored wire together with gray wirenuts provided. Receiver should be mounted toward front of cabinet.

(Range of transmitter is about 70’). If transmitter will activate system from short distance, but not from further away,

receiver may need to be relocated for better reception. Strapping receiver to front of drain trap facing outward will

optimize reception.

Installing Batteries to the Transmitter

Open transmitter with a small flat head screwdriver by inserting screwdriver into slot to release catch. Load

battery with negative side of battery toward spring. Carefully replace cover. When button is depressed, red indica-

tor light should turn on. Numbered jumper pins are inside the transmitter and receiver. The signal frequency can be

changed by removing the same numbered pins from both the receiver and transmitter. This should only be neces-This should only be neces-

This should only be neces-This should only be neces-

This should only be neces-

sary when two D’MANDsary when two D’MAND

sary when two D’MANDsary when two D’MAND

sary when two D’MAND

®®

®®

®

Systems are in same home or your neighbor has the system.Systems are in same home or your neighbor has the system.

Systems are in same home or your neighbor has the system.Systems are in same home or your neighbor has the system.

Systems are in same home or your neighbor has the system.

“Installations shall be in accordance with the manufacturer’s instructions“Installations shall be in accordance with the manufacturer’s instructions

“Installations shall be in accordance with the manufacturer’s instructions“Installations shall be in accordance with the manufacturer’s instructions

“Installations shall be in accordance with the manufacturer’s instructions

per the requirements of the Uniform Plumbing Code (UPC)”per the requirements of the Uniform Plumbing Code (UPC)”

per the requirements of the Uniform Plumbing Code (UPC)”per the requirements of the Uniform Plumbing Code (UPC)”

per the requirements of the Uniform Plumbing Code (UPC)”

Installing The Metlund

®

D’MAND

®

System for all S-Series Systems

This is for installation of the PF Accessory T’s only.This is for installation of the PF Accessory T’s only.

This is for installation of the PF Accessory T’s only.This is for installation of the PF Accessory T’s only.

This is for installation of the PF Accessory T’s only.

These do not replace the existing instructions includedThese do not replace the existing instructions included

These do not replace the existing instructions includedThese do not replace the existing instructions included

These do not replace the existing instructions included

with your system. Be sure you have read the instruc-with your system. Be sure you have read the instruc-

with your system. Be sure you have read the instruc-with your system. Be sure you have read the instruc-

with your system. Be sure you have read the instruc-

tions carefully before proceeding with your installation.tions carefully before proceeding with your installation.

tions carefully before proceeding with your installation.tions carefully before proceeding with your installation.

tions carefully before proceeding with your installation.

You have purchased a Metlund Hot Water Demand

System that is equipped with the PF accessory pack-

age.The1/2” male thread adapters have already been

pre-sweat to your Metlund System.

Enclosed with your system, are two T’s designed to sim-

plifyyourinstallationto1/2”copperhotandcoldsupplies.*

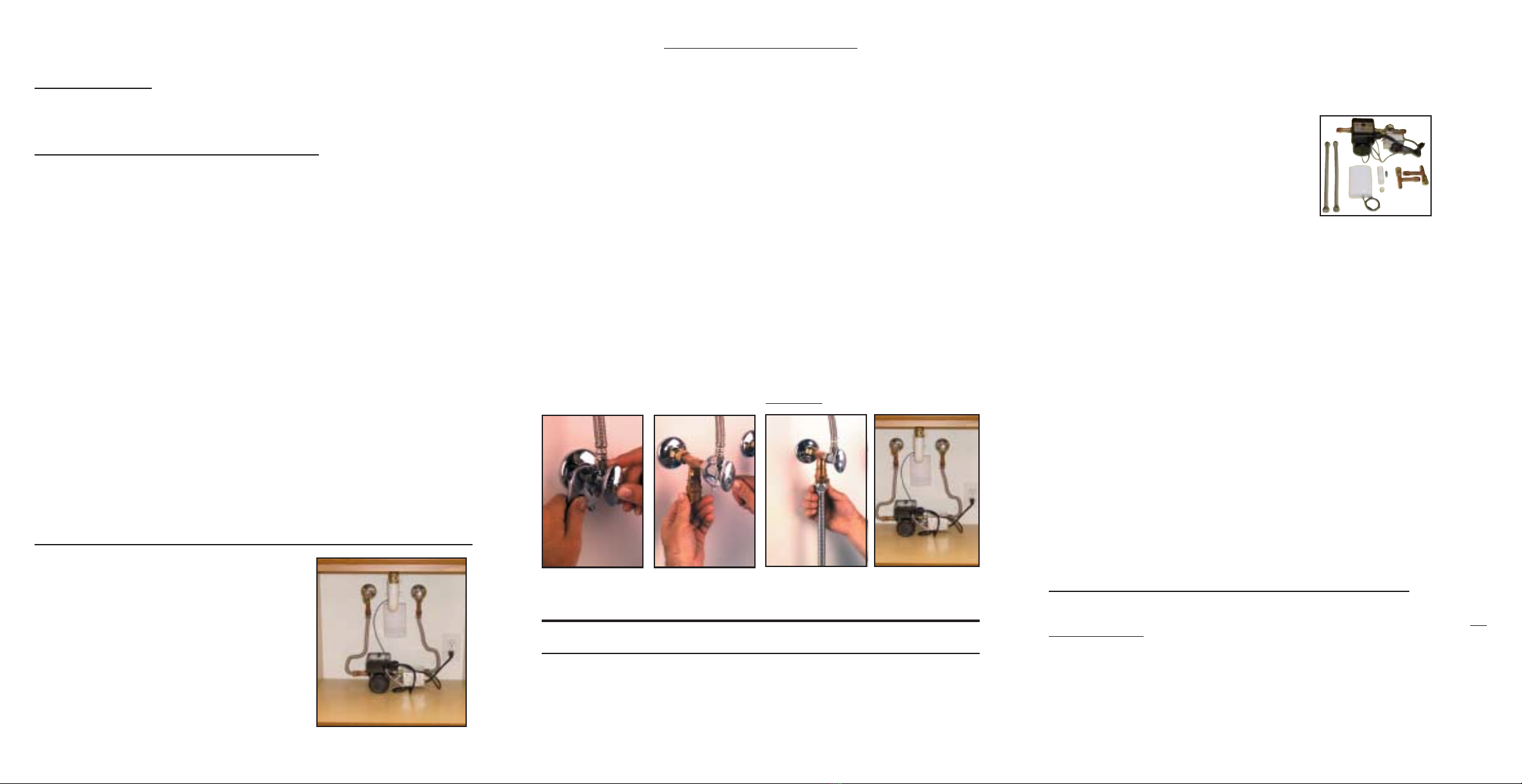

To Install Your “T” FittingsTo Install Your “T” Fittings

To Install Your “T” FittingsTo Install Your “T” Fittings

To Install Your “T” Fittings

1. Turn off the house water supply.

2. Open the hot and cold faucets at the fixture chosen for installation.This will relieve the water

pressure from the hot and cold water pipes.

3. Remove the shut-off valves that supply hot and cold water to the sink from the 1/2” copper

pipe. For ease of installation, leave the compression ring and nut from the angle stop on the

hot and cold water supplies.

4. Remove the compression ring and nut from the enclosed compression fitting on the PF-T’s,

and slide onto the other end. Attach the existing nut and ring to the end of the threaded T

and firmly tighten.

5. Install the remaining compression ring and nut to the shut-off valve,slide onto the 1/2” side of

the PF-T and firmly tighten.

6. Now you are ready to attach flex lines from the 1/2” male thread of the PF-T’s to your MetlundMetlund

MetlundMetlund

Metlund

D’MANDD’MAND

D’MANDD’MAND

D’MAND SystemSystem

SystemSystem

System. (Teflon tape is recommended for the 1/2” threaded fittings.)

7. Refer to Page 3 - “Installing the Demand Button(s)” and “Wireless Remote Option”.

1. Turn off water1. Turn off water

1. Turn off water1. Turn off water

1. Turn off water

supply andsupply and

supply andsupply and

supply and

remove angle stops.remove angle stops.

remove angle stops.remove angle stops.

remove angle stops.

2. Install & tighten2. Install & tighten

2. Install & tighten2. Install & tighten

2. Install & tighten

T’s (included),T’s (included),

T’s (included),T’s (included),

T’s (included),

attach angle stops.attach angle stops.

attach angle stops.attach angle stops.

attach angle stops.

3. Install copper flex lines3. Install copper flex lines

3. Install copper flex lines3. Install copper flex lines

3. Install copper flex lines

or any line withor any line with

or any line withor any line with

or any line with

1/2” inside diameter.1/2” inside diameter.

1/2” inside diameter.1/2” inside diameter.

1/2” inside diameter.

4. Connect Metlund4. Connect Metlund

4. Connect Metlund4. Connect Metlund

4. Connect Metlund

System, install pushSystem, install push

System, install pushSystem, install push

System, install push

button and plug in.button and plug in.

button and plug in.button and plug in.

button and plug in.

SYSTEM ADAPTS TO YOUR EXISTING PLUMBING!SYSTEM ADAPTS TO YOUR EXISTING PLUMBING!

SYSTEM ADAPTS TO YOUR EXISTING PLUMBING!SYSTEM ADAPTS TO YOUR EXISTING PLUMBING!

SYSTEM ADAPTS TO YOUR EXISTING PLUMBING!

FOLLOW THESEFOLLOW THESE

FOLLOW THESEFOLLOW THESE

FOLLOW THESE SIMPLESIMPLE

SIMPLESIMPLE

SIMPLE STEPS:STEPS:

STEPS:STEPS:

STEPS:

METLUND “NO SWEAT”

* Additional fittings may be required if your supply lines are galvanized or plastic pipe.* Additional fittings may be required if your supply lines are galvanized or plastic pipe.

* Additional fittings may be required if your supply lines are galvanized or plastic pipe.* Additional fittings may be required if your supply lines are galvanized or plastic pipe.

* Additional fittings may be required if your supply lines are galvanized or plastic pipe.

Installation must be as shown aboveInstallation must be as shown above

Installation must be as shown aboveInstallation must be as shown above

Installation must be as shown above

Installing The Metlund

®

D’MAND

®

System for all S-Series Systems

1.1.

1.1.

1. Installation ProceduresInstallation Procedures

Installation ProceduresInstallation Procedures

Installation Procedures

A. Turn off the house water supply.

B. Open the hot and cold faucets at the fixture chosen for installation. This will relieve the

water pressure from the hot and cold water pipes.

C. Remove the shut-off valves that supply the hot and cold water to the sink.

D. Install T-fittings to the pipe stubs from the hot and cold water supply.

This is the recommended position for installing the

Metlund SystemMetlund System

Metlund SystemMetlund System

Metlund System with the flow of the hot water into the

pump side of the system and the valve side into the cold

water line. The pump should lay on its side with the con-

troller on top. (Figure 1)

4.4.

4.4.

4. Installing the Demand Button(s)Installing the Demand Button(s)

Installing the Demand Button(s)Installing the Demand Button(s)

Installing the Demand Button(s)

To install the Demand Button, follow these steps:

A. Drill a 5/8" hole into the desired location.

B. Insert the 5 foot gray wire from the controller through the back side of the hole and

connect it to the push button switch. Then, firmly insert the push button back into the

hole. Additional push button switches can be spliced into the same wires. It is

important to use a button comparable in quality to the button provided.

3.3.

3.3.

3. Try the MetlundTry the Metlund

Try the MetlundTry the Metlund

Try the Metlund®®

®®

®System and check water temperatureSystem and check water temperature

System and check water temperatureSystem and check water temperature

System and check water temperature

Once installed, turn water supply on and plug in the system. (Pump will automatically turn

itself on when it is initially plugged in without pushing the demand button). The Metlund

System will continue to operate until the sensor signals that hot water has arrived, then it will

automatically shut off. To test the system again, wait until pipes cool down. You may then test

the system by pushing the demand button, or to pre-test your system after plugging the unit

into 110v outlet, place a hot rag over thermosensor located to the right of the ump housing.

The unit will shut off immediately. Remove rag from sensor and test remote switches.

To operate the Metlund System from another location in the home, place remote button in

desired location. Push remote button (red activation light will light up when pushed), wait a

few seconds for system to cycle. You may now turn on hot water. NOTE: The MetlundNOTE: The Metlund

NOTE: The MetlundNOTE: The Metlund

NOTE: The Metlund

Controller is designed with an automatic safety feature that will shut off the pump inController is designed with an automatic safety feature that will shut off the pump in

Controller is designed with an automatic safety feature that will shut off the pump inController is designed with an automatic safety feature that will shut off the pump in

Controller is designed with an automatic safety feature that will shut off the pump in

approximately three minutes.approximately three minutes.

approximately three minutes.approximately three minutes.

approximately three minutes.

1.1.

1.1.

1. Installation Procedures (continued)Installation Procedures (continued)

Installation Procedures (continued)Installation Procedures (continued)

Installation Procedures (continued)

NOTE: Using piping with less than 1/2" inside diameter will restrict the flow of theNOTE: Using piping with less than 1/2" inside diameter will restrict the flow of the

NOTE: Using piping with less than 1/2" inside diameter will restrict the flow of theNOTE: Using piping with less than 1/2" inside diameter will restrict the flow of the

NOTE: Using piping with less than 1/2" inside diameter will restrict the flow of the

water, causing it to take longer for hot water to arrive. Before sweating 1/2” pipewater, causing it to take longer for hot water to arrive. Before sweating 1/2” pipe

water, causing it to take longer for hot water to arrive. Before sweating 1/2” pipewater, causing it to take longer for hot water to arrive. Before sweating 1/2” pipe

water, causing it to take longer for hot water to arrive. Before sweating 1/2” pipe

to zone valve, be sure zone valve is in manual position.to zone valve, be sure zone valve is in manual position.

to zone valve, be sure zone valve is in manual position.to zone valve, be sure zone valve is in manual position.

to zone valve, be sure zone valve is in manual position.

E. Install the Metlund SystemMetlund System

Metlund SystemMetlund System

Metlund System between the hot and cold lines, but be sure that the arrows on

the pump and the valve point from the hot side to cold as shown in Figure 1.Figure 1.

Figure 1.Figure 1.

Figure 1.

F. Re-install the shut-off valves to the water

supply and sink.

Figure 1Figure 1

Figure 1Figure 1

Figure 1