your smart ENERGY investment™

Page 3 of 87

K500 Auto Hydroheater –3.5 Rev: 8-2016

© Hydro-Thermal Corp., 2014. All rights reserved

Hydroheater, Solaris, Jetcooker, EZ Heater and K5 Autopilot are trademarks of Hydro-Thermal Corp, and are protected under

U.S. and Canadian patents.

TABLE OF CONTENTS

1.0 K500 Automatic Hydroheater –General Information ....................................... 5

1.1 your smart ENERGY investment™ ............................................................. 5

1.2 Purpose of the Manual ............................................................................. 5

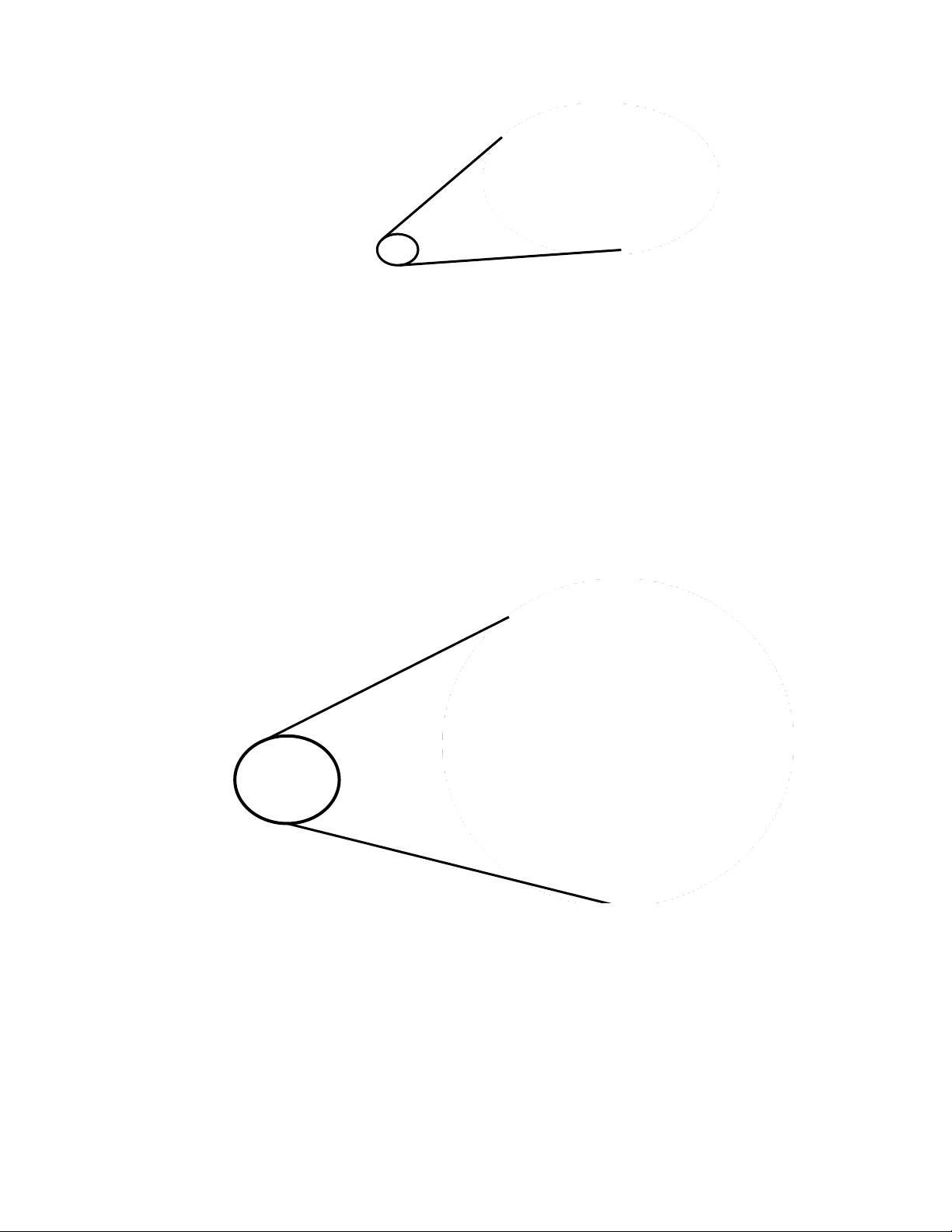

1.3 Principles of Direct Steam Injection (DSI) .................................................. 5

1.4 How the K500 Works...............................................................................6

1.5 Model Number Designation, Dimensions and Capacities............................... 7

1.5.1 Explanation of Model Numbers ........................................................... 7

1.5.2 Location of Markings on Body ............................................................. 7

1.6 Application Criteria.................................................................................. 9

1.6.1 Industries and Products .....................................................................9

1.6.2 Sizing Considerations ...................................................................... 10

1.7 Process and Steam Pressure Requirements............................................... 11

1.7.1 Maximum Process Pressure (Heater Discharge) ................................... 11

1.7.2 Minimum Process Pressure............................................................... 12

1.7.3 Superheated Steam ......................................................................... 12

1.7.4 Model Capacities and Heater Sizes.................................................... 13

2.0 Safety Precautions.................................................................................... 14

2.1 General Safety ...................................................................................... 14

2.2 Specific Safety...................................................................................... 15

3.0 Installation .............................................................................................. 16

3.1 General Installation ............................................................................... 16

3.2 Hardware Requirements ......................................................................... 17

3.2.1 Support and mounting ..................................................................... 17

3.3 Recommended Installation ..................................................................... 17

3.3.1 Steam Line Requirements ................................................................ 20

3.3.2 Strainer Sizing Table ....................................................................... 21

3.3.3 Condensate and Blow Down.............................................................. 21

3.3.4 Discharge Line Requirements ........................................................... 22

3.3.5 Insulation....................................................................................... 23

3.3.6 Utilities and Environmental Requirements.......................................... 23

3.4 Instrumentation and Control ................................................................... 24

3.4.1 General overview ............................................................................. 24

3.4.2 Components and Functions .............................................................. 24

3.4.3 Typical Control Logic ....................................................................... 26

3.4.4 K500 Control Characteristics............................................................ 26

3.4.5 Over Temperature Protection ............................................................ 27

4.0 Operation ................................................................................................ 28

4.1 Pre-Start .............................................................................................. 28

4.2 Initial Startup ....................................................................................... 29

4.3 Shutdown sequence (clean processes or short term with dirty fluids ............ 30

4.4 Shut Down sequence (long term with dirty fluids)...................................... 30

4.5 Applications with intermittent heat requirement ........................................ 31

5.0 Troubleshooting........................................................................................ 31

5.1 Insufficient Heating Capacity.................................................................. 31