7

housing (26). Pulling the seal

plate (16) off will also force

the lower seal (22) from shaft.

Remove lower seal (22) from

seal plate (16).

4. Remove snap ring (25) and

pull upper seal (27) from shaft.

It may be necessary to use

packing hooks to remove seal.

Use a screwdriver to break

the upper stationary ceramic

seal ring so that it can be

removed easily.

CAUTION: Do not use any old

seal parts. Replace all parts

with new pieces. Mixing old and

new parts will cause immediate

seal failure.

5. When cleaning all parts before

replacement, check to be sure

bearings or shaft is not worn.

Be sure all O-rings are in

excellent condition without

cuts or nicks, and replace them

if not in excellent condition.

Use O-ring lube to prevent

cutting at assembly.

6. After upper seal (27) is

replaced we recommend an air

test be made by inserting 5 lb.

of air pressure into the motor

housing and allow ample time

for air to escape. If pressure

remains steady for five minutes

continue by replacing the seal

plate (16), lower shaft seal (22)

and impeller (17). Repeat the

air test in the seal chamber.

Next the pump must be filled

with oil. Start by filling the seal

chamber. Do not fill completely.

Allow about 1⁄2inch air space

for expansion. Next fill the

motor housing just above the

motor winding.

7. Use only Hydromatic

submersible oil in motor

chamber and seal chamber. In

an emergency, a high grade

transformer oil can be used in

the motor chamber and #20

non-detergent automobile oil

can be used in the seal chamber.

Replacing Motor Stator:

1. If necessary to replace stator

(30), completely dismantle

pump as described above.

2. Drain all oil from upper

housing. Remove drain plug

(11) in bottom of bearing

housing, and remove connection

box assembly (34) by removing

capscrews (37). Motor leads

can be disconnected. The leads

are connected with connectors

and must be cut. DO NOT

TAPE LEADS WHEN

REPLACING STATOR AS

OIL WILL DETERIORATE

THE TAPE AND CAUSE

MOTOR FAILURE. USE

ONLY INSULATED BUTT

CONNECTORS.

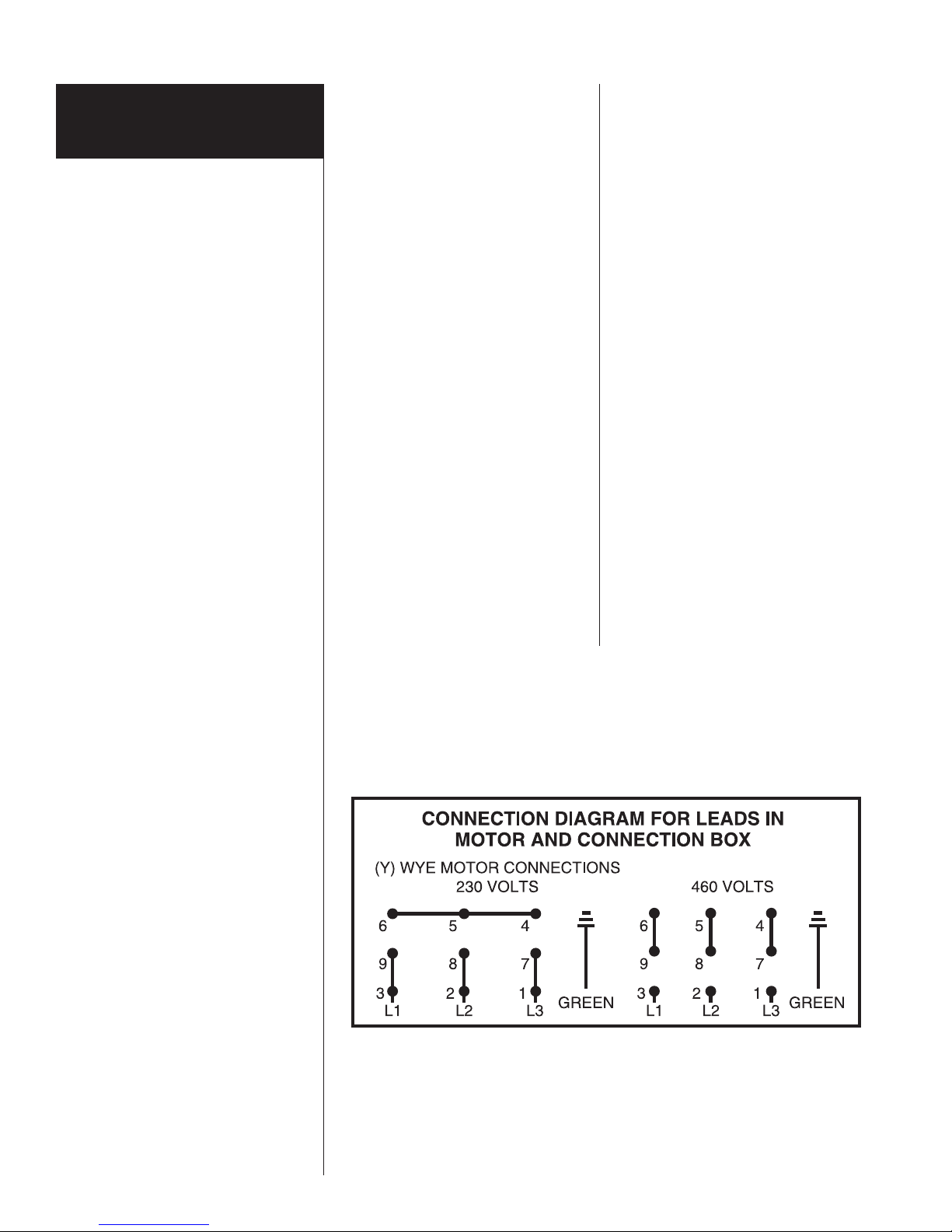

3. If cord leads are burned, it will

be necessary to replace power

cord and cord group assembly

(1). If any wires in the

connection box (34) are

burned, it will be necessary to

replace the connection box

assembly. Connect wires per

connection diagram.

4. Remove motor housing bolts

(28) and lift off motor housing

(32). Use care in lifting as the

seal failure connection wire

must be disconnected before

housing is completely removed.

5. Remove stator screws (29) and

set motor housing (32) on

hardwood blocks. Bump motor

housing (32) up and down on

hardwood block to loosen

stator which should drop out.

This should be reinstalled with

the new stator.

6. Thoroughly clean motor housing

(32) and other parts and install

new stator.

7. Connect leads through housing

bore and tuck leads back

behind the stator windings

to prevent rubbing on rotor.

USE ONLY INSULATED

BUTT CONNECTORS TO

CONNECT WIRES.

8. If the upper ball bearing (33)

is rusted or feels rough

when turned, it should be

replaced. Press the bearing off

the shaft. Install the new

bearing by pressing on inner

face only. PRESSING ON

THE OUTER FACE WILL

RUIN THE BEARING.

9. In reassembly, replace any

O-rings that are defective. Use

Parker O-Ring Lube on all

O-rings for easy assembly and

to prevent cutting.

10.Completely reassemble, making

sure seal failure wires are

connected.

11. Make a high voltage

ground test on each wire. The

only wires that should show

ground are the two green leads.

12.Air test the motor housing and

the seal housing by inserting

5 lb. of air pressure and allow

ample time for air to escape. If

pressure remains steady for

five minutes, you are ready to

fill the pump with oil.

13.Fill seal chamber with oil by

laying pump on side with oil

fill hole upright. Do not

completely fill; leave oil about

1⁄2" below plug hold. Use only

Hydromatic submersible oil.

Replace plug with Permatex on

threads.

14.Refill motor chamber with

oil through connection box

opening. Use high grade,

nonsynthetic transformer oil

or Hydromatic special

submersible oil. Fill housing

until oil covers top of windings.

Leave air space for expansion.